Preparation method of ultrafine platinum nano-wire

A platinum nanowire and chloroplatinic acid technology, applied in the field of nanomaterials, can solve the problems of complex process, hindering the application of ultra-fine platinum nanowires, low aspect ratio of platinum nanowires, etc., achieving simple process, simple production control method, Ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 1mg of bovine insulin powder, dissolve it in 0.87mL of 25mM hydrochloric acid solution, and prepare a 0.2mM insulin hydrochloric acid solution, put the solution into a container, vortex and mix well, let it stand at room temperature until the bubbles dissipate, and seal it with a parafilm , the solution was heated in a constant temperature metal bath at 70°C for about 5 hours to form an insulin fiber suspension.

[0023] Take 40 μL of 5 mM chloroplatinic acid solution (pH = 1.6) and add it to 200 μL of the above insulin fiber suspension, mix well, and incubate at 4°C for 10 h on a shaker at 50 r / min. Then 60 μL of sodium borohydride reducing agent solution with a concentration of 10 mM was added dropwise, and then shaken at 4° C. and 50 r / min for 8 h to complete the reaction, and ultrafine platinum nanowires were obtained.

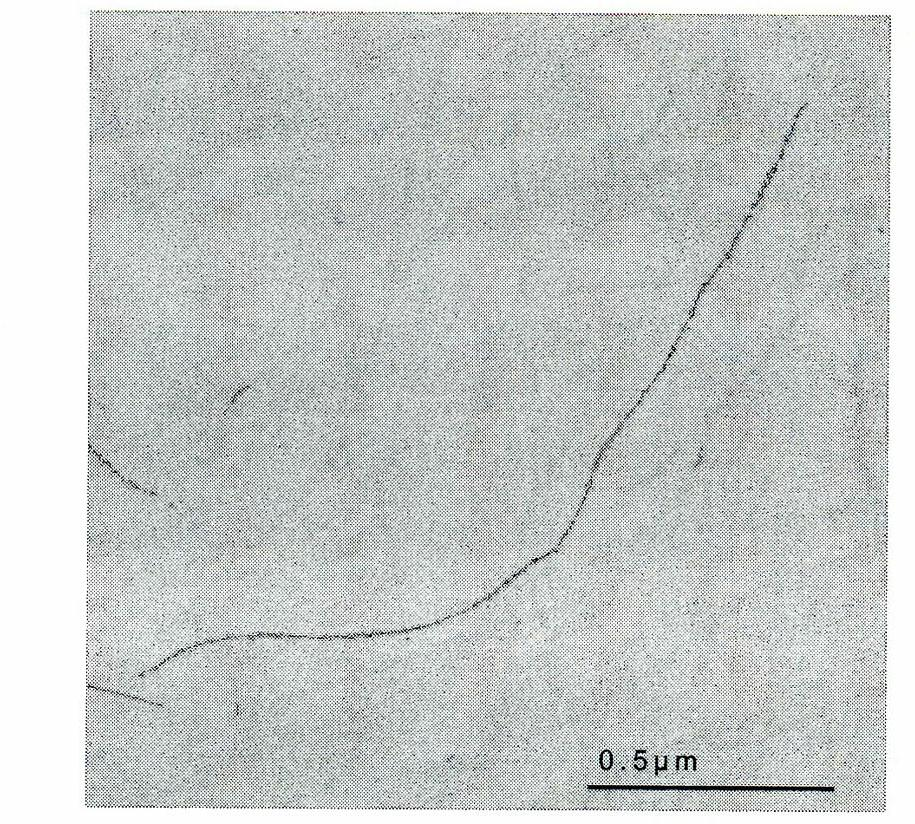

[0024] Such as figure 1 As shown, the obtained single ultrafine platinum nanowire has a diameter of 2.5 nm and a length of 1.8 μm.

Embodiment 2

[0026] Take 1 mg of bovine insulin powder, dissolve it in 0.17 mL of 18 mM hydrochloric acid solution, and prepare 1 mM insulin hydrochloric acid solution, put the solution into a container, vortex and mix it, and let it stand at room temperature until the bubbles dissipate, then seal it with a parafilm. The solution was heated in a constant temperature metal bath at 67°C for about 12 hours to form an insulin fiber suspension.

[0027] Take 100 μL of 3.5 mM chloroplatinic acid solution (pH=1.8) and add it to 150 μL of the above insulin fiber suspension, mix well, and incubate at 6°C, 80 r / min on a shaker for 15 h. Then 90 μL of sodium borohydride reducing agent solution with a concentration of 7.5 mM was added dropwise, and then shaken at 6° C. and 80 r / min for 20 h to complete the reaction, and ultrafine platinum nanowires were obtained.

Embodiment 3

[0029] Take 1mg of bovine insulin powder, dissolve it in 0.087mL of newly prepared 10mM hydrochloric acid solution, and prepare a 2mM insulin hydrochloric acid solution, put the solution into a container, vortex and mix it, let it stand at room temperature until the bubbles dissipate, and seal it with a parafilm , the solution was heated in a constant temperature metal bath at 65°C for about 20h to form an insulin fiber suspension.

[0030] Take 130 μL of 2.5 mM chloroplatinic acid solution (pH=2) and add it to 100 μL of the above insulin fiber suspension, mix well, and incubate at 10°C and 100 r / min on a shaking table for 20 h. Then 120 μL of sodium borohydride reducing agent solution with a concentration of 5 mM was added dropwise, and then shaken at 10° C. and 100 r / min for 24 hours to complete the reaction, and ultrafine platinum nanowires were obtained.

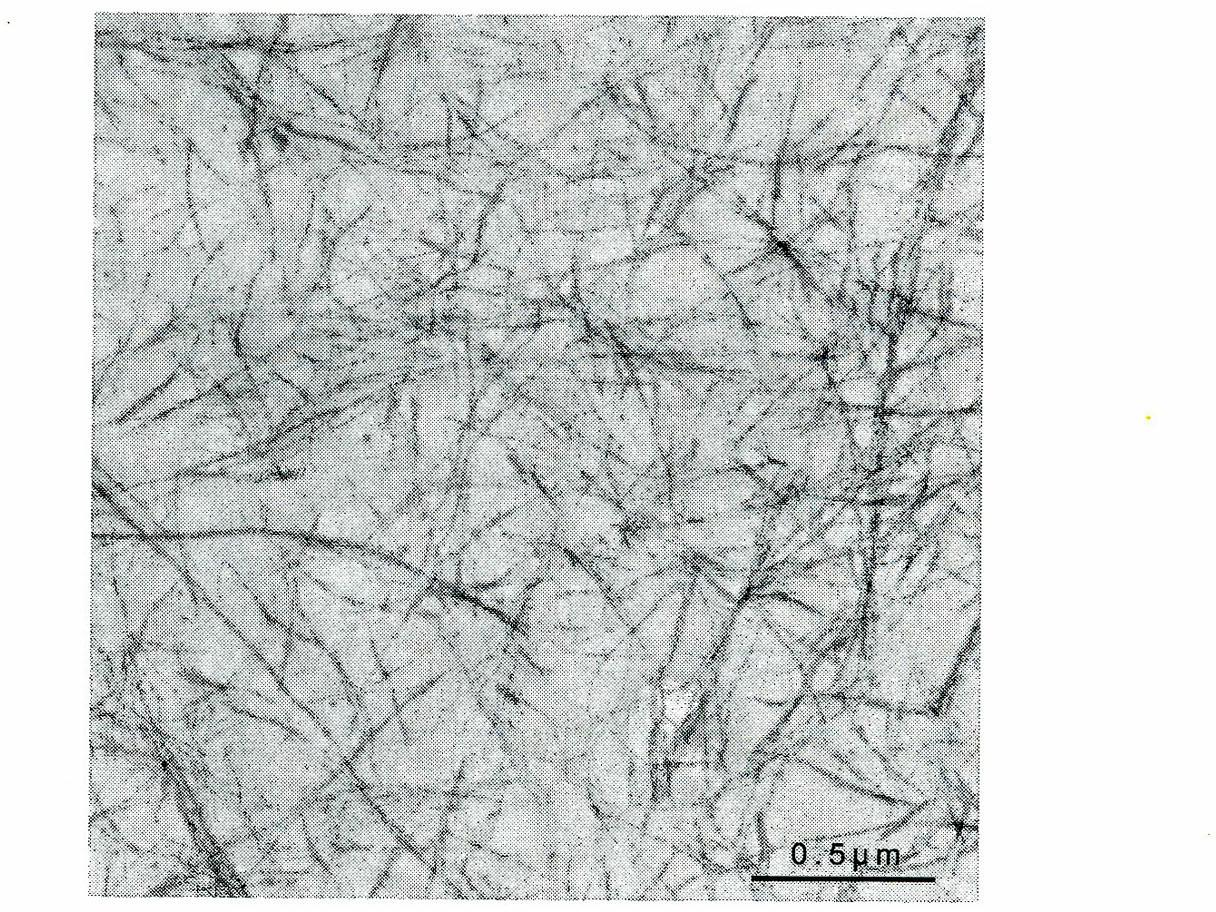

[0031] Such as figure 2 As shown, the yield of the prepared ultra-fine platinum nanowires is significantly increased...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com