Novel full-automatic punching device with pipe visual inspection function

A technology of visual inspection and punching device, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of surface grinding, low applicability, waste of labor and cost, etc., to avoid scratches and damage, The effect of providing processing efficiency and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

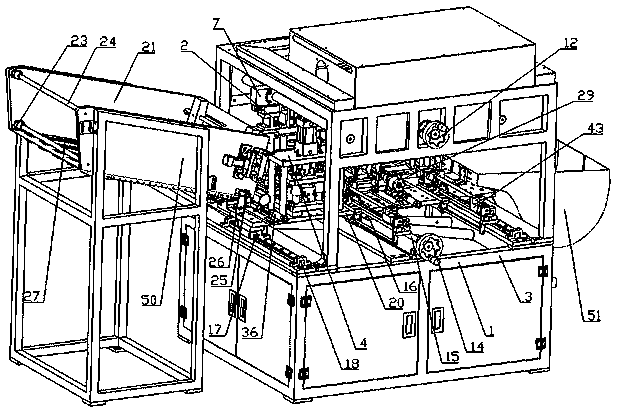

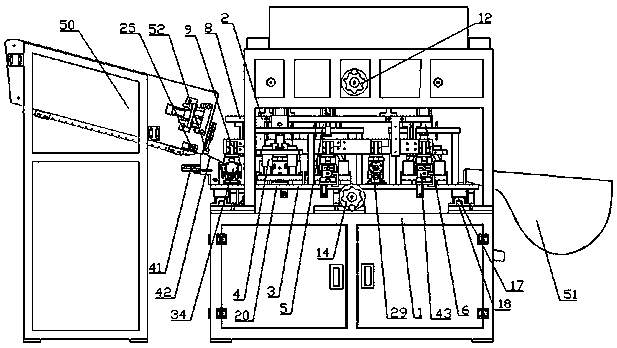

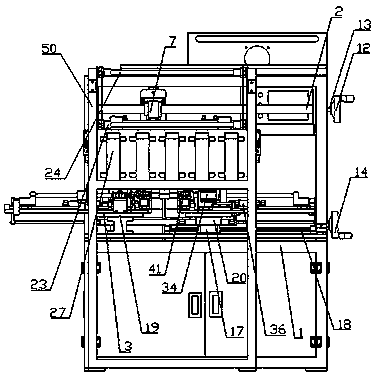

[0029] Such as Figure 1 to Figure 8 As shown, a new type of automatic punching device with pipe visual inspection, including a body 1, a feed funnel 50, an upper frame 2, a lower frame 3 and a discharge funnel 51; the feed funnel 50, the upper frame 2 , the lower frame 3 and the discharge funnel 51 are all arranged on the body 1; The end is connected with the feed station, the discharge station is provided with a discharge funnel 51, the upper frame 2 is located above the lower frame 3, and the upper frame 2 is provided with a transport assembly and a first adjustment assembly; the punching station is provided with There is a punching die, and the punching station includes a first punching station, a second punching station, a third punching station, the first punching station is provided with a first punching die 4, and the second punching stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com