Low-loss environmental-friendly preprinted sheet upward production line and production process thereof

A face-up, production line technology, applied in layered products, mechanical processing/deformation, lamination devices, etc., can solve the problem of affecting the drying efficiency of paste and the quality of cardboard, poor adhesion of pre-printed paper and pit paper, Problems such as poor drawing and scratching on the surface of the carton can be achieved to improve the bonding quality, avoid crushing the cardboard, and achieve the effect of beautiful printing texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

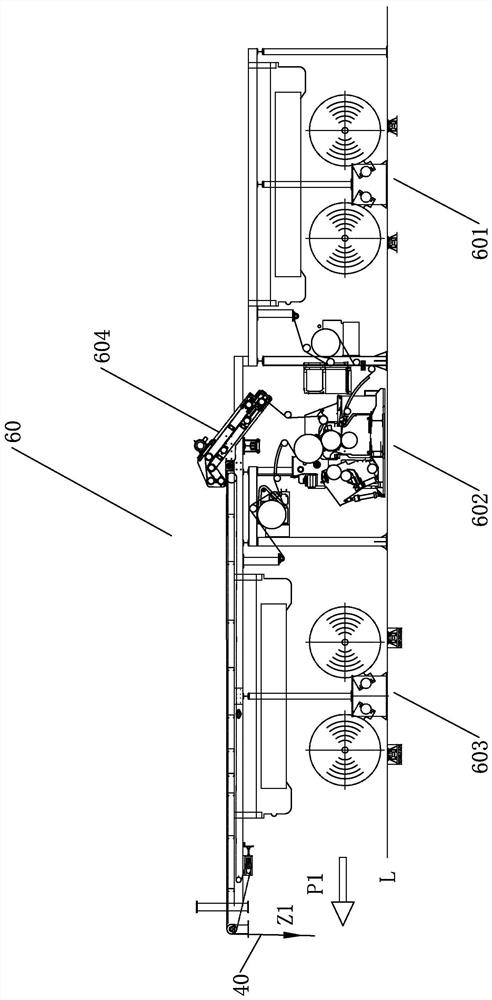

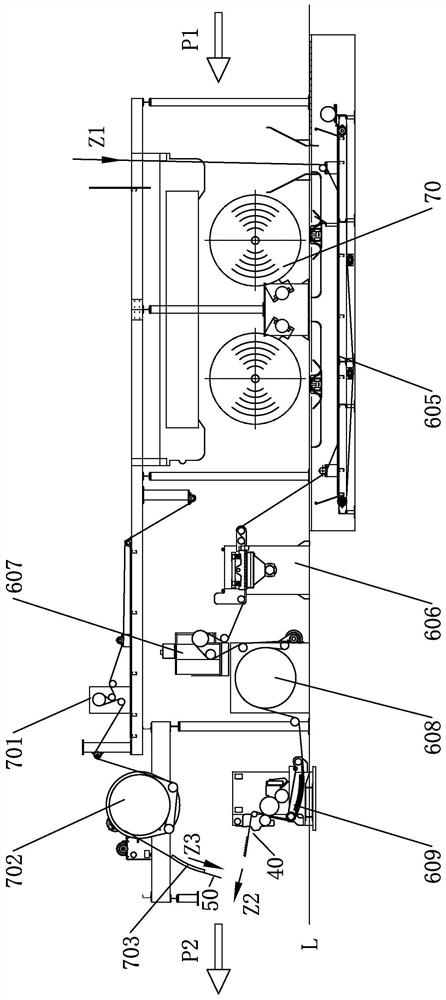

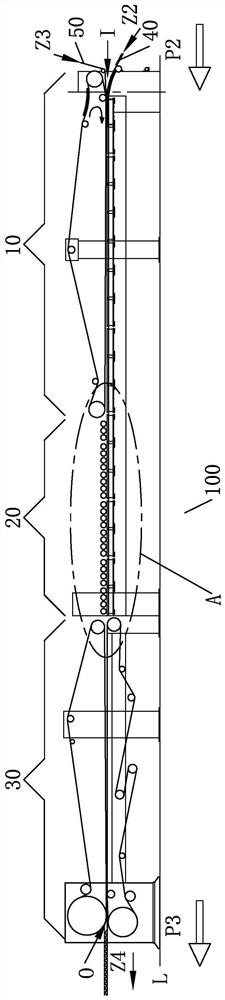

[0066] see Figure 1 to Figure 4 As shown, a face-up production line for low-loss and environmentally friendly pre-printed cardboard, including a pit paper forming section 60, a conveying section for pre-printed paper and pit paper, and a double-sided machine for bonding pre-printed paper 50 and pit paper 40 100, the double-sided machine 100 includes a front hot plate transfer part 10 and a rear transfer part 30, a ventilated heating transition section 20 is provided between the front hot plate transfer part 10 and the rear transfer part 30, and the ventilated heating transition section 20 is provided with a ventilated heating transition section 100. The heating channel 201, the upper side and the lower side of the air-permeable heating channel 201 are provided with a heat source, and the upper side of the air-permeable heating channel 201 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com