Method for recovering aluminum salt coagulant from aluminum-containing sludge

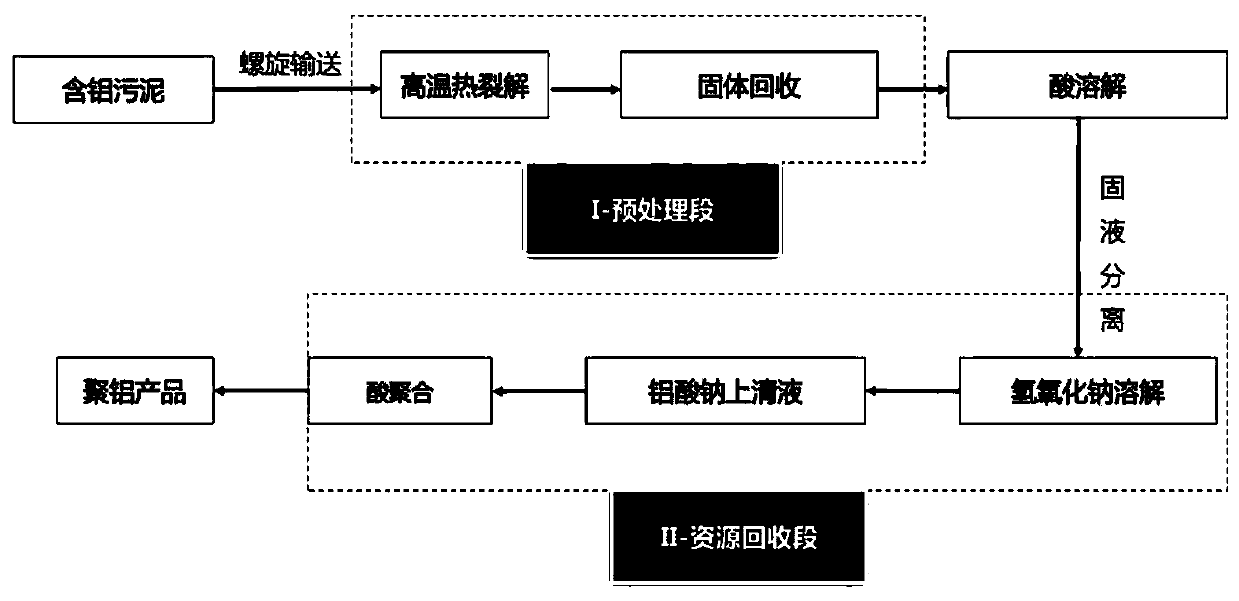

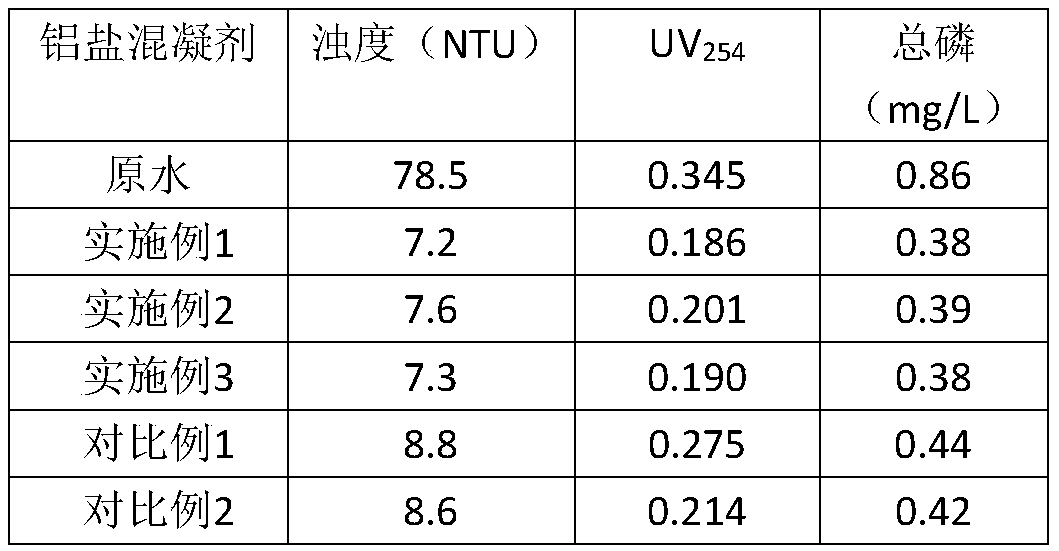

A technology of aluminum sludge and coagulant, which is applied in the direction of sludge treatment, pyrolysis treatment of sludge, chemical instruments and methods, etc. Low coagulant recovery rate and other problems, to achieve the effect of wide application range, good coagulation effect, and better quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for recovering aluminum salt coagulant from aluminum-containing sludge, the steps are:

[0028] (1) the alumina content is 34wt.%, the Fe content is 60mg / kg aluminum-containing sludge (aluminum-containing sludge is taken from the air flotation sludge of the sewage treatment station of an APG manufacturer in Shanghai) from the hopper through the screw conveying pipe Enter the high-temperature anaerobic pyrolysis system in the middle, and then heat up to 850°C at a rate of 75°C / h in an oxygen-free environment, and then pyrolyze for 30 minutes;

[0029] (2) The hot gas produced by the thermal cracking reaction is condensed by the condensing device and then burned, wherein the heat released during the condensation process of the hot gas and the heat released during the combustion process are reused for the high-temperature thermal cracking reaction; The alumina-containing solid particles are acidified and dissolved with hydrochloric acid, and the acidified solution...

Embodiment 2

[0033] A method for recovering aluminum salt coagulant from aluminum-containing sludge, the steps are:

[0034] (1) The aluminum-containing sludge with an alumina content of 28wt.% and a Fe content of 100mg / kg (aluminum-containing sludge is obtained from a certain river water purification plant in Shanghai) enters the high-temperature sludge from the hopper through a spiral conveying pipe. Anaerobic pyrolysis system, and then heat up to 750°C at a rate of 50°C / h in an oxygen-free environment, and then a pyrolysis reaction occurs, and the reaction time is 60 minutes;

[0035] (2) The hot gas produced by the thermal cracking reaction is condensed by the condensing device and then burned, wherein the heat released during the condensation process of the hot gas and the heat released during the combustion process are reused for the high-temperature thermal cracking reaction; The alumina-containing solid particles are acidified and dissolved with hydrochloric acid, and the acidified...

Embodiment 3

[0039] A method for recovering aluminum salt coagulant from aluminum-containing sludge, the steps are:

[0040] (1) The aluminum-containing sludge with an alumina content of 32wt.% and a Fe content of 60mg / kg (aluminum-containing sludge from a thermal power plant in Shanghai) enters the high-temperature anaerobic heat sink from the hopper through a spiral conveying pipe. Cracking system, and then heat up to 1350°C at a rate of 100°C / h in an oxygen-free environment, and then a thermal cracking reaction occurs, and the reaction time is 20 minutes;

[0041] (2) The hot gas produced by the thermal cracking reaction is condensed by the condensing device and then burned, wherein the heat released during the condensation process of the hot gas and the heat released during the combustion process are reused for the high-temperature thermal cracking reaction; The alumina-containing solid particles are acidified and dissolved with hydrochloric acid, and the acidified solution is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com