Air cooling device used for textile printing and dyeing industry

A technology of textile printing and dyeing and air cooling, which is used in textile and papermaking, textile processing machine accessories, and textile material processing, etc. effect, reduce production costs and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

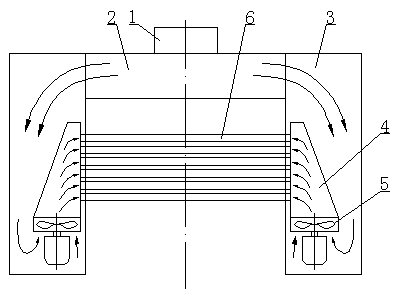

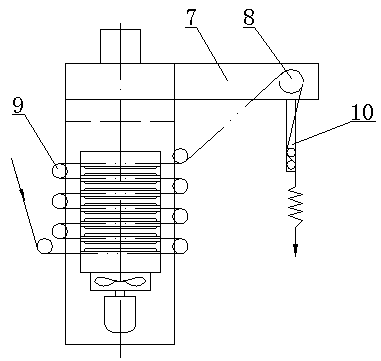

[0016] An air cooling device for the textile printing and dyeing industry, comprising a refrigeration air conditioner 1, a cold air box 2, a box body 3, a tapered air duct 4, an axial flow fan 5, a blowing air box 6, a cloth output frame 7, and a cloth output traction roller 8 , cloth guide roller 9, swinging cloth outlet device 10, a box body 3 is arranged on both sides of the cold air box 2 equipped with a refrigeration air conditioner 1, the inner cavity of the cold air box 2 communicates with the inner cavity of the box body 3, and an axial flow fan 5 is installed at the lower end The tapered air duct 4 is installed in the box body 3, and several blowing air boxes 6 are arranged up and down through the inner panel of the box body 3 to connect with the tapered air duct 4, and a fabric channel is formed between two adjacent blowing air boxes 6 A number of cloth guide rollers 9 are installed alternately on the front and rear sides of the box body 3 and can make the fabric live...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com