Toughening polylactic acid resin composition

A technology of polylactic acid resin and composition, applied in the field of toughening polylactic acid resin composition, can solve problems such as reducing tensile strength, and achieve the effects of improving elongation at break, simple equipment and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Add 1500mL of water, 2.5g of sodium pyrophosphate, 3.5g of glucose, 0.08g of ferrous sulfate, 0.7g of potassium hydroxide, 17mL of rosin soap, and 360g of polybutadiene latex into a three-necked flask in sequence, and blow in nitrogen. The temperature was raised to 70°C, and after stirring for 10 minutes, a polybutadiene mixed liquid was obtained, and then 228 g of methyl methacrylate, 12 g of glycidyl methacrylate, and 2.6 mL of cumene hydroperoxide were mixed and continuously added dropwise to the above In the polybutadiene mixed solution, continue to react for 1 h after the dropwise addition, and then add 1.5 grams of the mixture of antioxidant 1010 and antioxidant 168 with a mass ratio of 1:1, obtain a coagulated emulsion after half an hour, and place it in Dry at 60°C for 24 hours to obtain a toughening agent, which is denoted as MB-g-GMA-1. Wherein, the mass fraction of butadiene-styrene copolymer is 60%, and the mass fraction of butadiene and styrene is 70:30; Th...

Embodiment 2

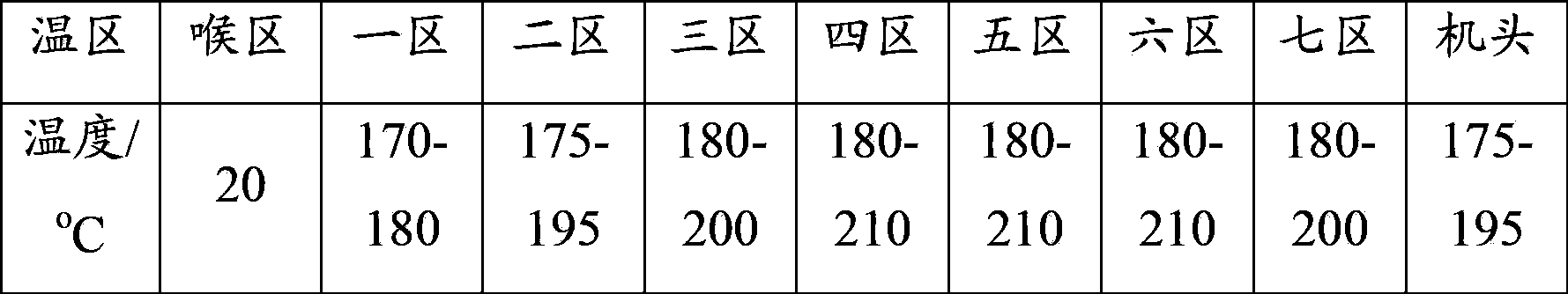

[0050] 100g of polylactic acid with a number average molecular weight of 80,000 Daltons, 5g of the toughening agent MB-g-GMA-1 prepared in Example 1, and 0.5g of antioxidant 1010 and antioxidant with a mass ratio of 1:2 The mixture of 168 was mechanically blended to obtain a premix, and then the SHJ-20 twin-screw extruder was used to mix and prepare the polylactic acid resin composition. The rotation speed was set at 100 rpm for 5 minutes. The temperature of each section was set as As shown in Table 1, Table 1 shows the temperature setting of each section of the twin-screw extruder in the embodiment of the present invention.

[0051] The obtained toughened polylactic acid resin was tested for mechanical properties, and the results are shown in Table 2. Table 2 shows the performance test results of the toughened polylactic acid resin composition prepared in the embodiment of the present invention.

Embodiment 3

[0053] Combine 100g of polylactic acid with a number average molecular weight of 80,000 Daltons, 10g of toughening agent MB-g-GMA-1 prepared in Example 1, and 0.3g of antioxidant 1010 and antioxidant with a mass ratio of 1:2 The mixture of 168 was mechanically blended to obtain a premix, and then the SHJ-20 twin-screw extruder was used to mix and prepare the polylactic acid resin composition. The rotation speed was set at 100 rpm for 5 minutes. The temperature of each section was set as As shown in Table 1, Table 1 shows the temperature setting of each section of the twin-screw extruder in the embodiment of the present invention.

[0054] The obtained toughened polylactic acid resin was tested for mechanical properties, and the results are shown in Table 2. Table 2 shows the performance test results of the toughened polylactic acid resin composition prepared in the embodiment of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com