Novel laser cladding smoke collecting device

A technology of laser cladding and dust collection, applied in the direction of dust removal, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of device damage, inconvenient movement, inconvenient adjustment, etc., to increase the cooling effect and increase the cooling effect speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

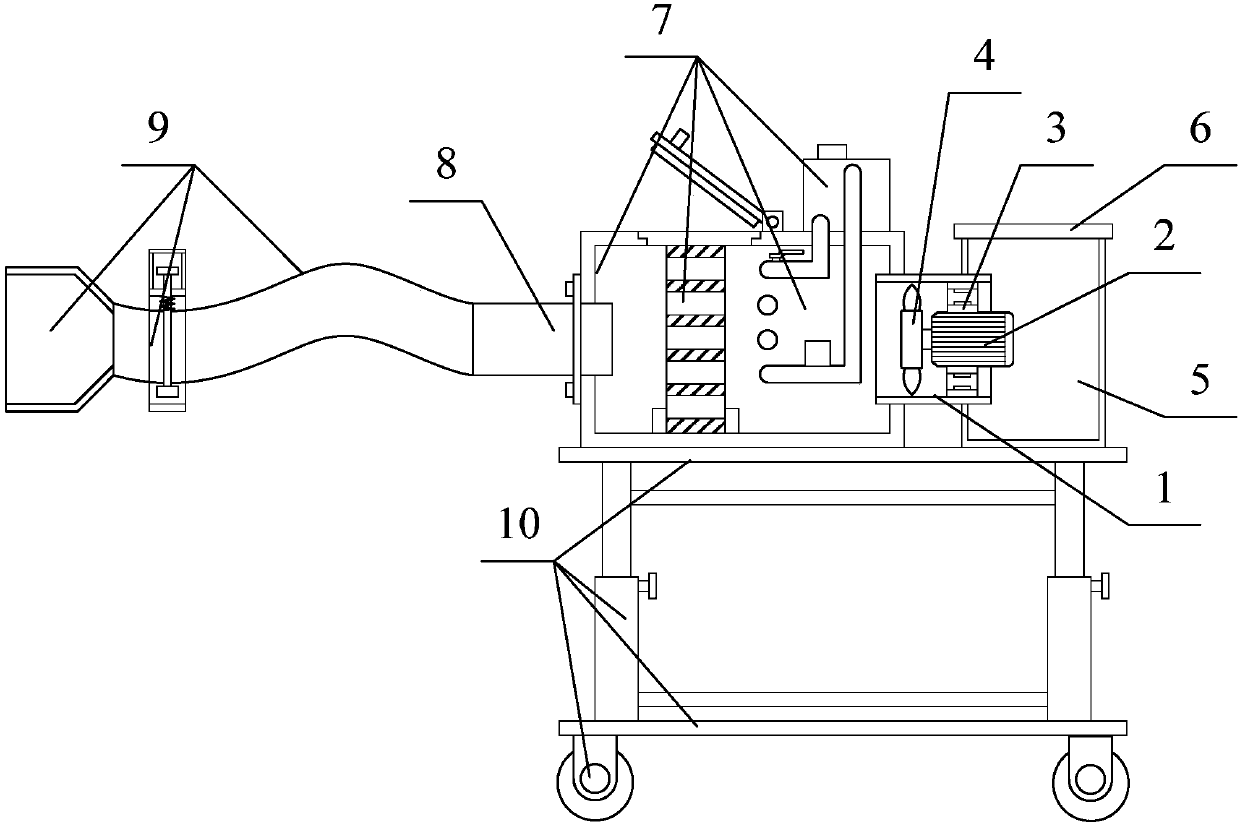

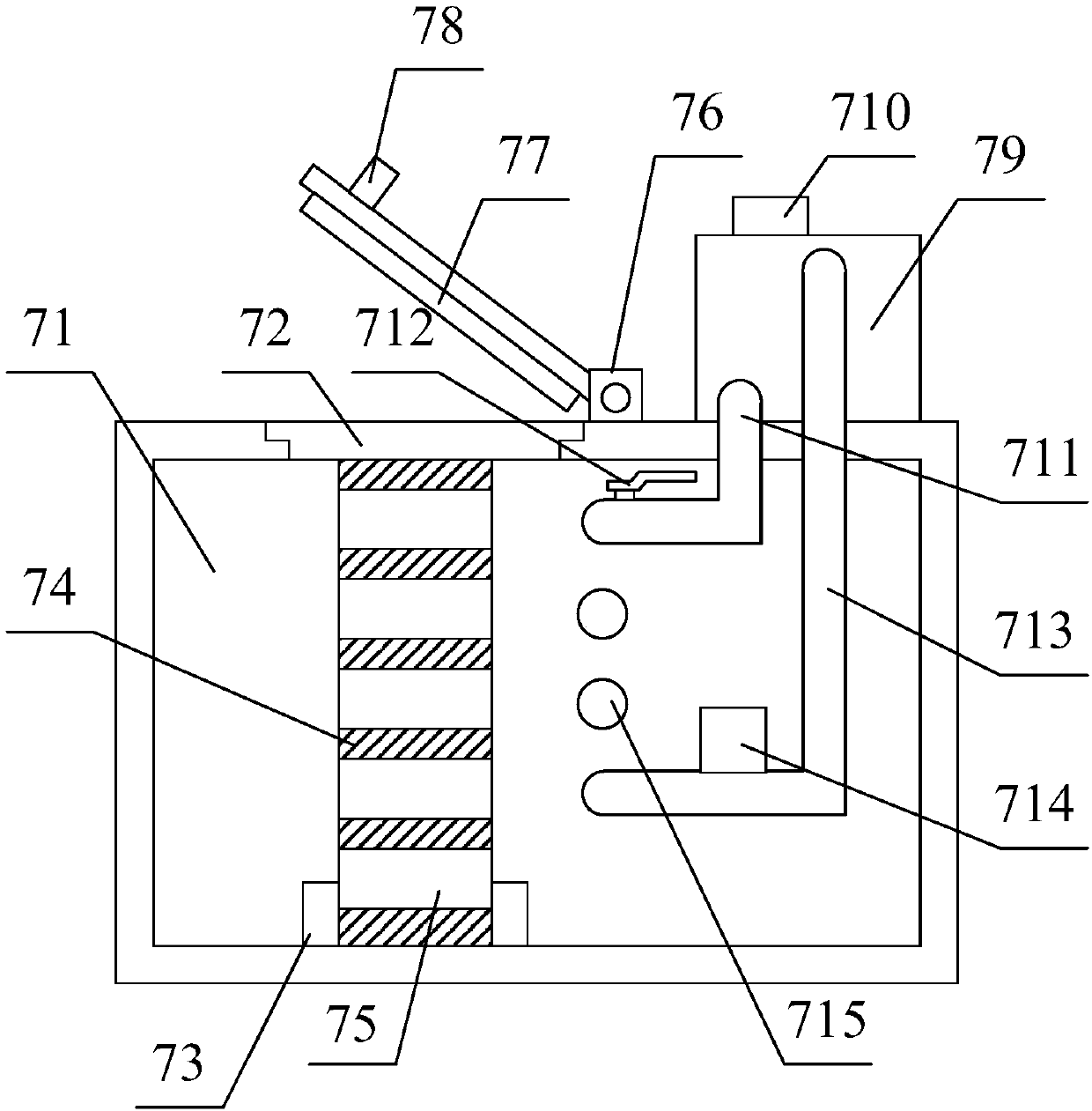

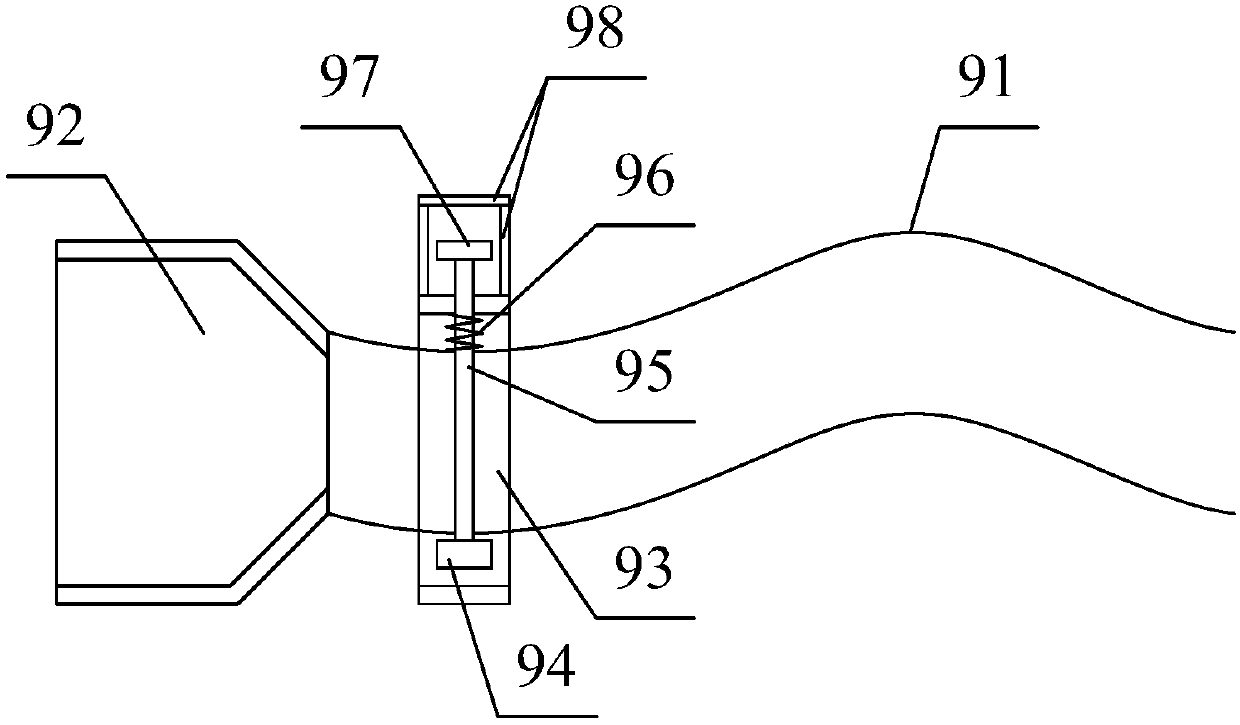

[0029] as attached figure 1 to attach Figure 4 shown

[0030] The invention provides a new type of laser cladding dust collection device, which includes a connecting installation pipe 1, a suction motor 2, a mounting frame 3, fan blades 4, a storage cylinder 5, a sealing cover 6, a protective box structure 7, a connecting pipe 8, Adjusting the pipe structure 9 and the protective mobile frame structure 10, the suction motor 2 is installed on the inner wall of the connecting installation pipe 1 through the mounting bracket 3 bolts; the fan blade 4 is installed on the output shaft of the suction motor 2; The storage tube 5 is welded on the upper right part of the protective mobile frame structure 10; the sealing cover 6 is screwed on the top of the storage tube 5; the protective box structure 7 is welded on the upper left part of the protective mobile frame structure 10; The regulating pipe structure 9 is installed on the left end of the protective box structure 7 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com