Spherical ternary composite positive electrode material of lithium ion battery and preparation method thereof

A lithium-ion battery, ternary composite technology, applied in battery electrodes, positive electrodes, electrical components, etc., can solve problems such as poor ionic conductivity and electronic conductivity, inability to withstand high current charge and discharge, and unsatisfactory rate performance. Achieve the effect of improving rate performance, slowing down the irreversible reduction of capacity, and improving lithium ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

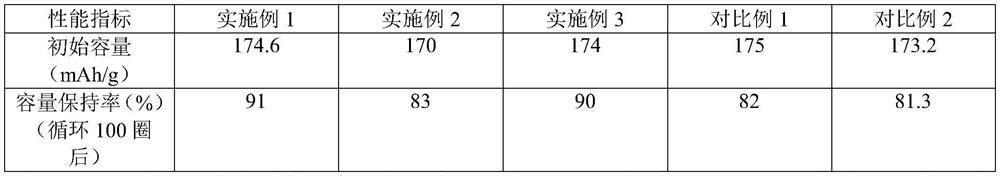

Examples

Embodiment 1

[0032] (1) After ball milling the commercial nickel cobalt lithium manganese oxide precursor material and lithium hydroxide, sintering at high temperature to obtain NCM powder balls with an average particle size of 10 μm; the commercial nickel cobalt lithium manganese oxide precursor material includes Components in the following molar percentages: Ni content is 80 mol%, Co content is 12 mol%, Mn content is 8 mol%;

[0033] (2) Lithium hydroxide, lanthanum chloride, and zirconium nitrate are added to deionized water to prepare a LLZO precursor solution with a concentration of 15mol / ml;

[0034] (3) Add the NCM powder balls obtained in step (1) to the LLZO precursor solution obtained in step (2), stir evenly at 48r / min, control the temperature at 58°C during the stirring process, dry to obtain solid powder, 700°C Calcined at high temperature to obtain mixed powder of NCM@LLZO;

[0035] (4) Add graphene to the mixed powder of NCM@LLZO obtained in step (3), and mix evenly to obta...

Embodiment 2

[0037] (1) After the commercial nickel cobalt lithium manganese oxide precursor and lithium carbonate are ball milled, they are sintered at high temperature to obtain NCM powder balls with an average particle size of 8 μm; the commercial nickel cobalt lithium manganese oxide precursor material includes the following molar Components by percentage: Ni content is 85mol%, Co content is 7mol%, Mn content is 8mol%;

[0038] (2) Lithium carbonate, lanthanum chloride, and zirconium nitrate are added in ethanol, and the preparation concentration is the LLZO precursor solution of 30mol / ml;

[0039] (3) Add the NCM powder balls obtained in step (1) to the LLZO precursor solution obtained in step (2), stir evenly at 45r / min, control the temperature at 55°C during the stirring process, dry to obtain solid powder, 55°C Calcined at high temperature to obtain mixed powder of NCM@LLZO;

[0040] (4) Add graphene to the mixed powder of NCM@LLZO obtained in step (3), and mix evenly to obtain a ...

Embodiment 3

[0042] (1) After ball milling the commercialized nickel-cobalt lithium manganese oxide precursor and anhydrous lithium acetate, sintering at high temperature to obtain NCM powder balls with an average particle size of 3 μm; the commercial nickel-cobalt lithium manganese oxide precursor material includes Components in the following molar percentages: Ni content is 83mol%, Co content is 10mol%, Mn content is 5mol%;

[0043] (2) adding anhydrous lithium acetate, lanthanum chloride, and zirconium sulfate into a mixed solvent of deionized water and ethanol (volume ratio 1:1) to prepare a LLZO precursor solution with a concentration of 5mol / ml;

[0044] (3) Add the NCM powder ball obtained in step (1) to the LLZO precursor solution obtained in step (2), stir evenly at 50r / min, control the temperature at 60°C during the stirring process, dry to obtain a solid powder, 800°C Calcined at high temperature to obtain mixed powder of NCM@LLZO;

[0045](4) Add graphene to the mixed powder o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com