Sensor for use in a plastics processing machine and method for operating such a sensor

A sensor and processing machine technology, applied in the field of sensors, can solve problems such as high cost of algorithms, heavy computing workload of control devices, and hindering computing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

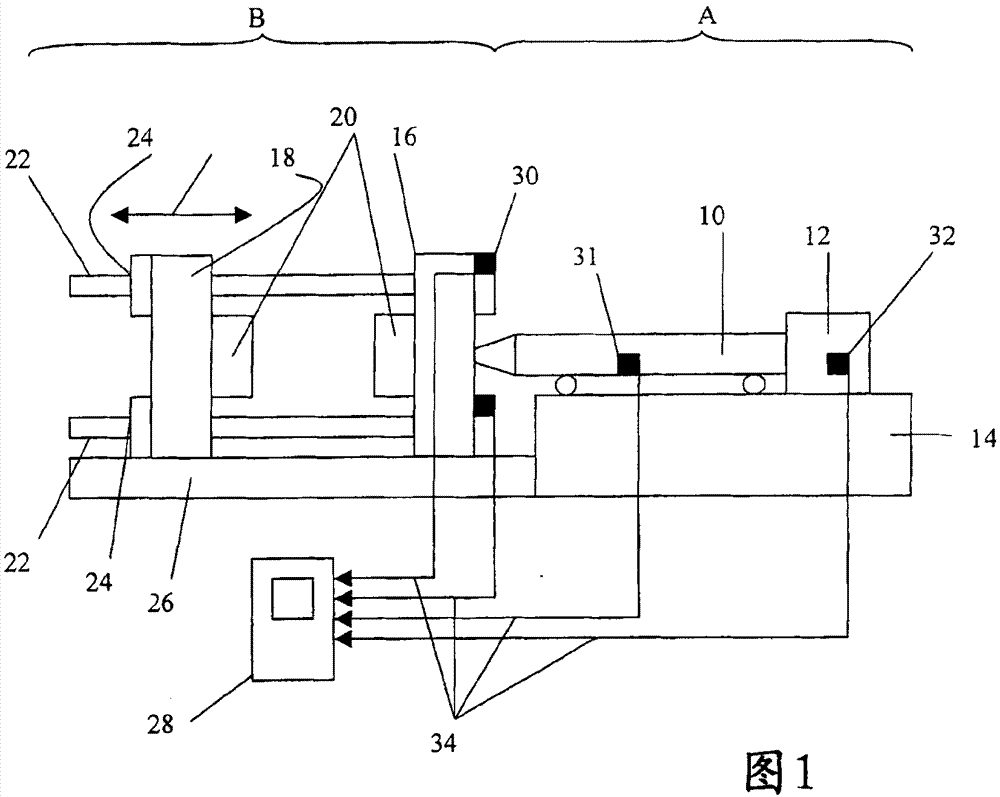

[0024] figure 1 Shows a schematic diagram of an injection molding machine with a plasticizing unit and a clamping unit, which are set in areas A (plasticizing unit) and B (clamping unit). The plasticizing unit in the area A includes a plasticizing cylinder 10 reciprocally supported on a bed 14 and includes an electric drive device 12 at its end. The mold clamping unit in the area B has two mold plates in a known manner, namely, a fixed mold plate 16 and a moving mold plate 18, on which a half mold 20 is respectively fixed. The template 18 is penetrated by four beams 22, among which figure 1 Only two can be seen in it. The moving template 18 can be fixed with respect to the beam 22 by the locking element 24, so that in the closed state of the clamping unit, a hydraulic pressure pad installed on the fixed template can be used to apply a clamping pressure. The sensors 30, 31 and 32 are respectively fixed on the two pressure pads and on the plasticizing cylinder 10 and the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com