Battery anode material and preparation method thereof

A technology of a battery negative electrode and a manufacturing method, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of difficult control, residual metal impurities, complicated preparation process, etc., so as to achieve the effect of unaffected capacity and improved liquid permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

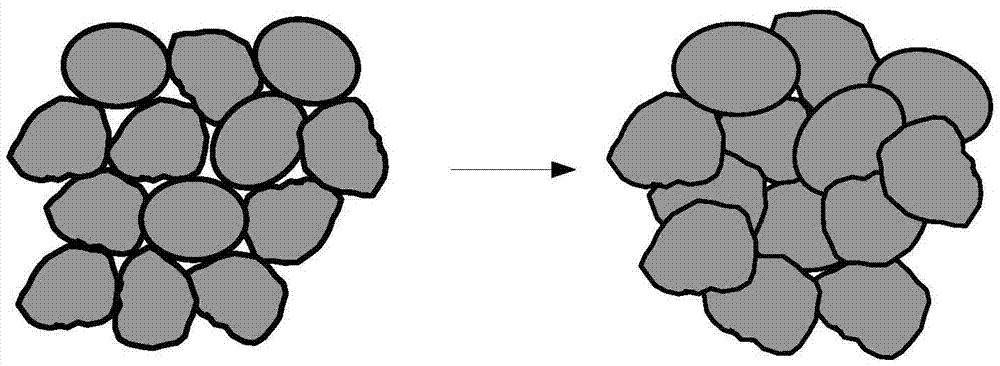

Problems solved by technology

Method used

Image

Examples

preparation example Construction

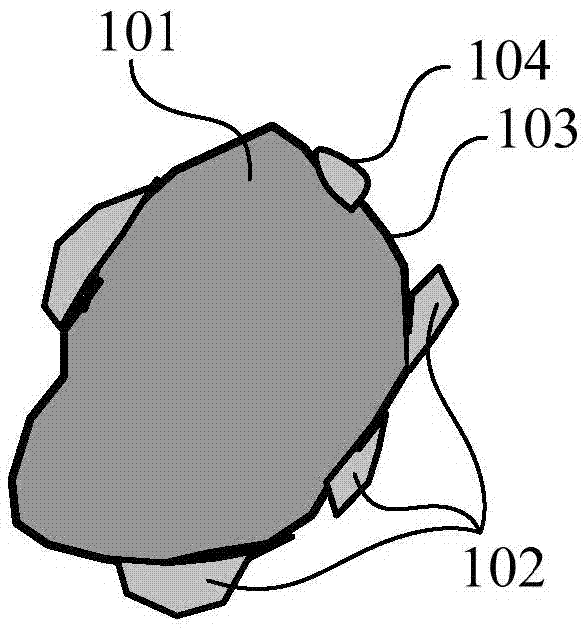

[0028] The preparation method of battery negative electrode material provided by the invention comprises the following steps:

[0029] 1. Raw material preparation:

[0030] Raw material 1, natural graphite and / or artificial graphite and / or coke, with an average particle size D50 of 12-25 μm;

[0031] Raw material 2, natural graphite and / or artificial graphite and / or coke, with an average particle size D50 of 2-6 μm;

[0032] Raw material 3, asphalt: average particle size 0.5-3μm. The asphalt can be one or more of petroleum-based and / or coal-based high-temperature asphalt, medium-temperature asphalt, and low-temperature asphalt.

[0033] 2. Premix:

[0034] 1) The above-mentioned raw material 1 and raw material 3 are uniformly mixed according to the mass ratio of 100:1-100:15 to obtain intermediate 1; the mixed raw material 1 and raw material 3 can also be added into 0-10% (mass percentage) graphitization catalyst at the same time , such as silicon carbide and / or iron oxide...

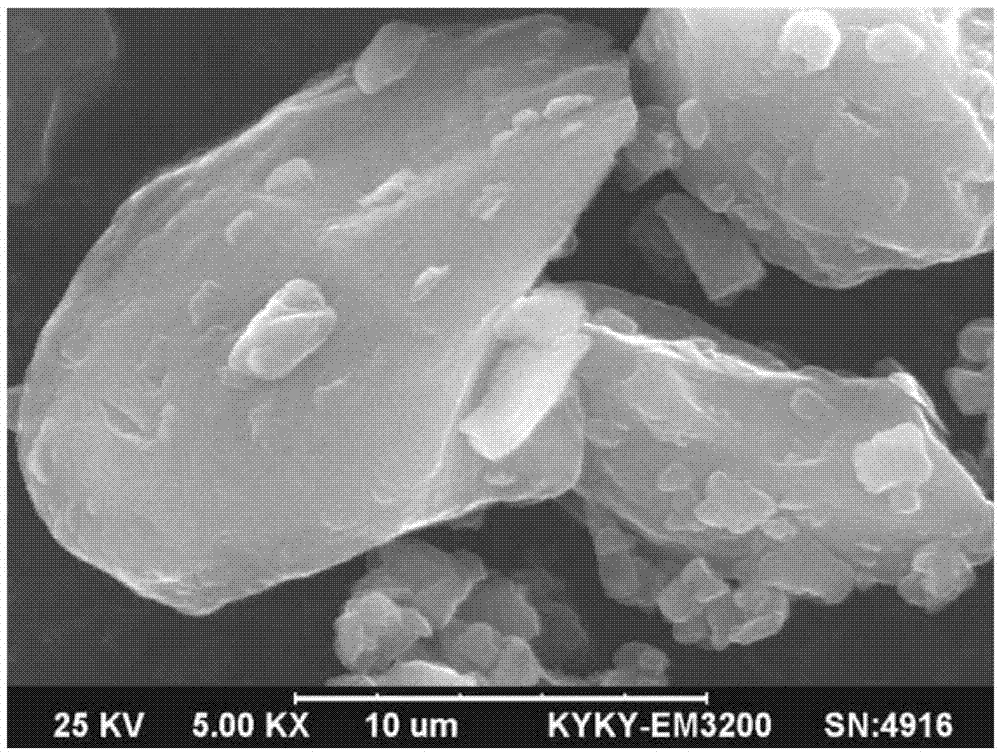

Embodiment 1

[0057] 1. Premix

[0058] 1) Mix natural graphite (average particle size D50 of 17 μm) and high-temperature pitch (average particle size D50 of 3 μm) at a mass ratio of 100:15; at the same time, 3% (mass percentage) graphitization catalyst silicon carbide can be added.

[0059] 2) Mix coke (average particle size D50 is 5 μm) and high-temperature pitch (average particle size D50 is 3 μm) at a mass ratio of 100:1; at the same time, 3% (mass percentage) graphitization catalyst can be added, such as silicon carbide and / or iron oxides.

[0060] 3) Mix the materials obtained in 1) and 2) uniformly at a mass ratio of 100:30 to obtain a mixture;

[0061] 2. Reaction

[0062] 1) The above-mentioned mixture is introduced into a pressure-resistant heating reaction vessel that can be completely sealed and has a stirring function, and N 2 Or replace the air in the reaction vessel with Ar for 1 hour; seal the reaction vessel and start to heat up; raise the temperature to 400°C at a rate ...

Embodiment 2

[0069] 1. Premix

[0070] 1) Mix artificial graphite (average particle size D50 of 17 μm) and high-temperature pitch (average particle size D50 of 3 μm) at a mass ratio of 100:15; at the same time, 3% (mass percentage) graphitization catalyst silicon carbide can be added.

[0071] 2) Mix coke (average particle size D50 is 5 μm) and high-temperature pitch (average particle size D50 is 3 μm) at a mass ratio of 100:1; at the same time, 3% (mass percentage) graphitization catalyst can be added, such as silicon carbide and / or iron oxides.

[0072] 3) Mix the materials obtained in 1) and 2) uniformly at a mass ratio of 100:30 to obtain a mixture;

[0073] 2. Reaction

[0074] 1) The above-mentioned mixture is introduced into a pressure-resistant heating reaction vessel that can be completely sealed and has a stirring function, and N 2 Or replace the air in the reaction vessel with Ar for 1 hour; seal the reaction vessel and start to heat up; raise the temperature to 400°C at a ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com