A carbon fiber/boron nitride flexible composite electrode and its preparation method and application

A boron nitride flexible and composite electrode technology, applied in the direction of fiber chemical characteristics, battery electrodes, circuits, etc., can solve the problems of reducing the electrochemical performance and flexibility of batteries, reducing the conductivity of electrode materials, etc., to improve electrochemical performance and improve Conductivity, the effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

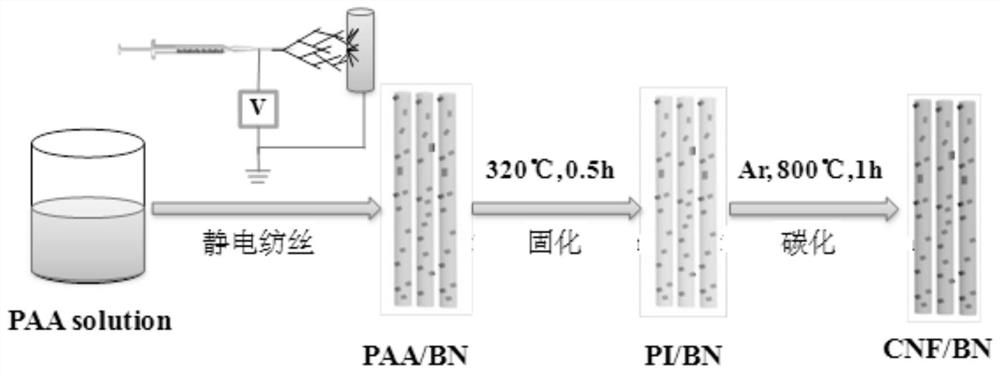

[0047] A method for preparing a carbon fiber / boron nitride flexible composite electrode, the steps are as follows:

[0048] (1) Preparation of polyamic acid / boron nitride spinning slurry:

[0049]Prepare the raw materials 4,4'-diaminodiphenyl ether, N,N-dimethylacetamide solvent and pyromellitic anhydride for the synthesis of polyamic acid according to a certain mass volume ratio, and then polyamic acid / boron nitride Prepare a certain amount of boron nitride based on the quality of the spinning slurry; dissolve 4,4'-diaminodiphenyl ether in N,N-dimethylacetamide solvent, add nitrogen to the above mixed solution Boron, add pyromellitic anhydride after ultrasonic treatment for a certain period of time, and continue to stir until the viscosity no longer increases; after the pyromellitic anhydride is completely dissolved, continue stirring the mixture for a certain period of time to obtain polyamic acid / boron nitride Spinning size (PAAsolution);

[0050] (2) Preparation of polya...

Embodiment 2

[0055] This embodiment provides a carbon fiber / boron nitride flexible composite electrode, and the doping amount of boron nitride is 1-10% of the mass of the carbon fiber / boron nitride flexible composite electrode.

[0056] The preparation method steps of the carbon fiber / boron nitride flexible composite electrode provided in this example with a boron nitride doping amount of 1-10% are as follows:

[0057] (1) Preparation of polyamic acid / boron nitride spinning slurry:

[0058] According to the mass volume ratio of 1.5g: 15ml: 1.64g, prepare the raw materials 4,4'-diaminodiphenyl ether, N,N-dimethylacetamide solvent and pyromellitic anhydride for the synthesis of polyamic acid, and then use polyamide Based on the quality of the acid / boron nitride spinning slurry, boron nitride with a doping amount of 1 to 10% is prepared, and the boron nitride is a boron nitride nanosheet with a particle size of 50 to 70 nm; the 4,4' - Dissolve diaminodiphenyl ether in N,N-dimethylacetamide s...

Embodiment 3

[0064] This embodiment provides a carbon fiber / boron nitride flexible composite electrode, and the doping amount of boron nitride is 3% of the mass of the carbon fiber / boron nitride flexible composite electrode.

[0065] The steps of the preparation method of the carbon fiber / boron nitride flexible composite electrode provided in this example with a boron nitride doping amount of 3% are as follows:

[0066] (1) Preparation of polyamic acid / boron nitride spinning slurry:

[0067] Prepare 1.5g of 4,4'-diaminodiphenyl ether, 15ml of N,N-dimethylacetamide solvent and 1.64g of pyromellitic anhydride as raw materials for the synthesis of polyamic acid, and then spin polyamic acid / boron nitride Prepare the boron nitride with a doping amount of 3% based on the quality of the silk slurry, and the boron nitride is a boron nitride nanosheet with a particle size of 50-70nm; 4,4'-diaminodiphenyl ether is dissolved in In the N, N-dimethylacetamide solvent, add boron nitride to the above mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com