Battery and manufacturing method thereof

A battery and cell technology that is applied to secondary batteries, battery components, circuits, etc., and can solve problems such as liquid leakage, excessive gaps, and cell scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

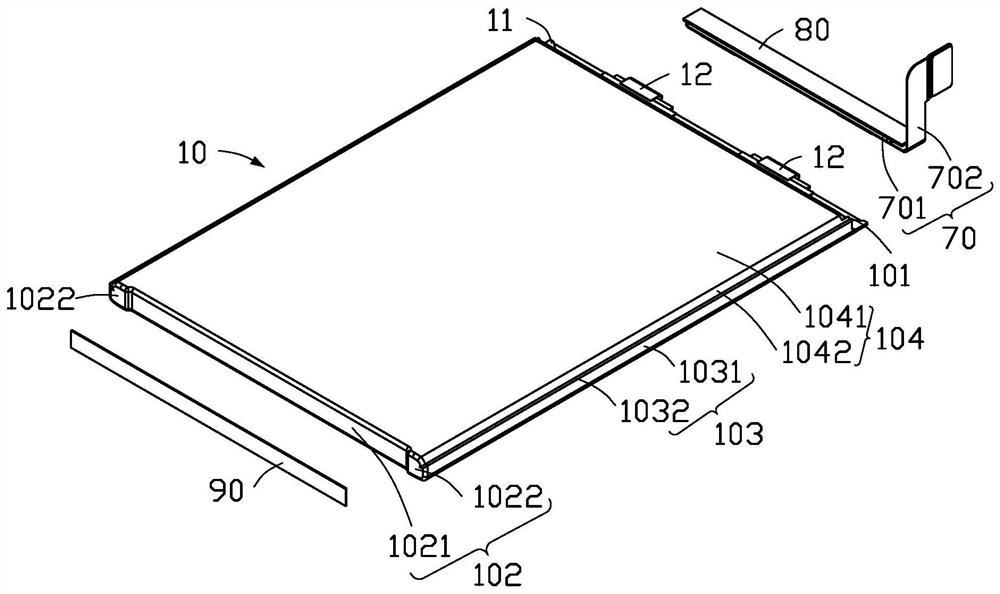

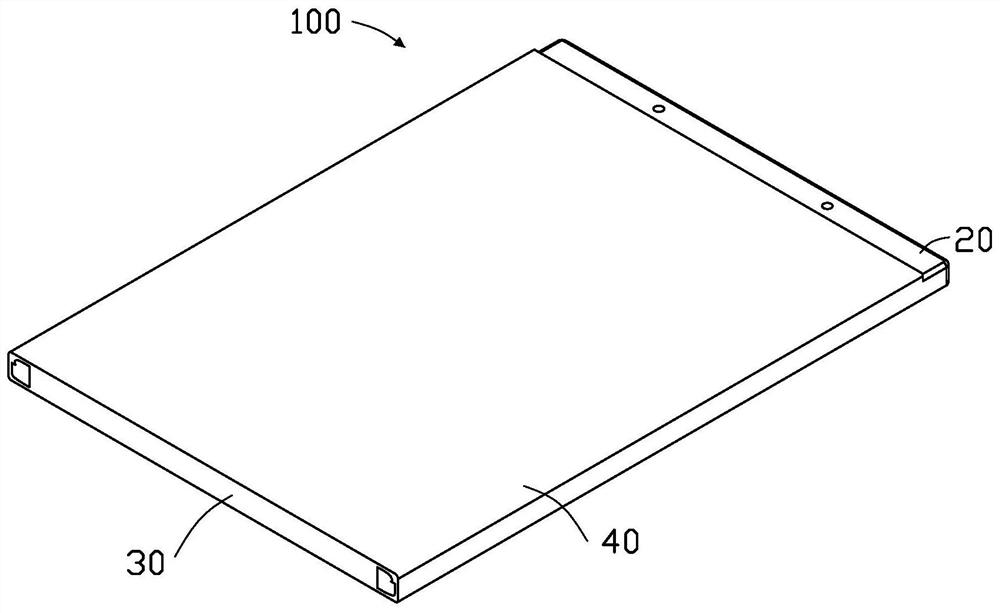

[0082] ginseng Figure 5 , the battery 100 includes a cell 10 , a first protection body 20 , a second protection body 30 and a third protection body 40 .

[0083] The first protection body 20 covers the top surface 101 . The second protection body 30 covers edges of the first region 1021 and the second region 1022 of the bottom surface 102 . The third protection body 40 covers the first edge region 1032 and the second edge region 1042 . Wherein, the third protection body 40 is connected between the first protection body 20 and the second protection body 30 to form a grid structure for protecting the electric core 10 .

Embodiment 2

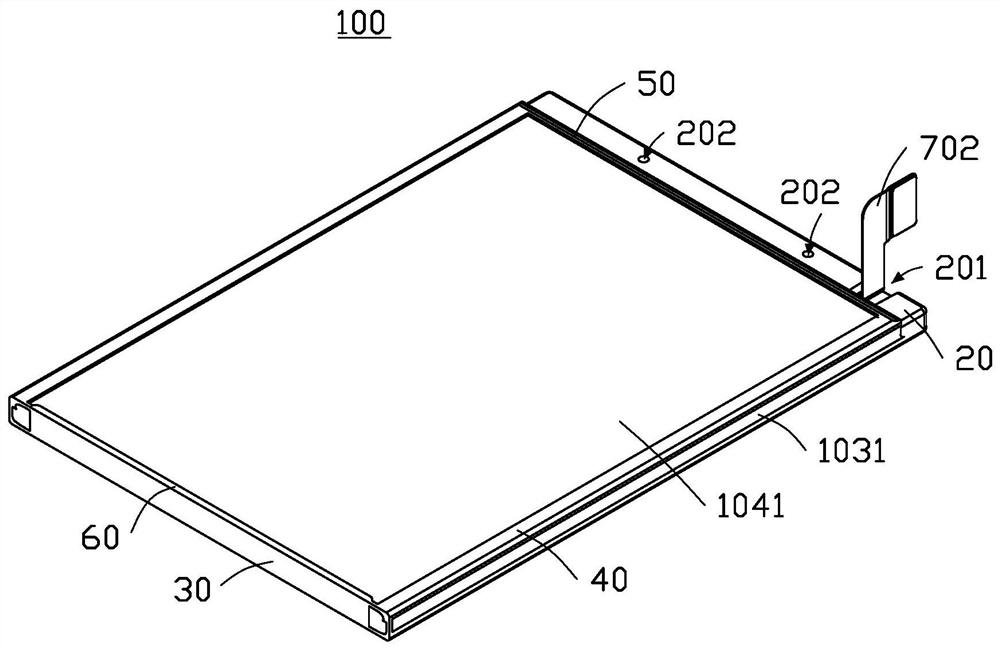

[0085] ginseng Figure 6 The difference between Embodiment 2 and Embodiment 1 is that the battery 100 in Embodiment 2 further includes a first protection portion 50 and a second protection portion 60 . The first protection portion 50 covers the edge of the first side 103 close to the top surface 101 and the edge of the second side 104 close to the top surface 101 . The second protection portion 60 covers the edge of the first side 103 close to the bottom 102 and the edge of the second side 104 close to the bottom 102 . Wherein, the first protection part 50 connects the first protection body 20 and the third protection body 40 , and the second protection part 60 connects the second protection body 30 and the third protection body 40 .

Embodiment 3

[0087] ginseng image 3 The difference between embodiment 3 and embodiment 2 is that the third protective body 40 in embodiment 3 further covers the first middle region 1031 and the second middle region 1041 . That is, the third protective body 40 in the second embodiment completely covers the first side 103 and the second side 104 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com