Frozen NFC fruit juice pre-melting tunnel

A tunnel and pre-thaw technology, applied in the fields of food science, food preservation, food heat treatment, etc., can solve the problems affecting the quality and shelf life of NFC juice, high environmental requirements, and large space occupation, so as to shorten the pre-thaw and thaw time, Long shelf life and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation

[0026] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

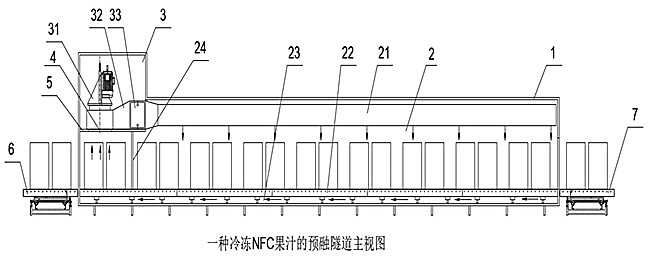

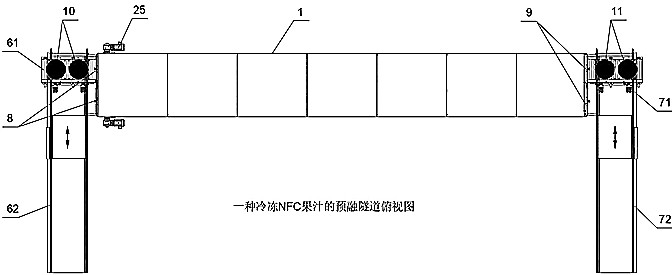

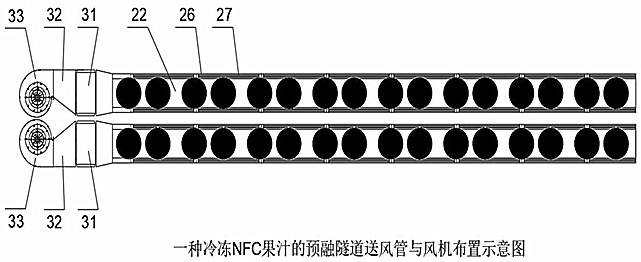

[0027] Such as figure 1 As shown, the pre-melting tunnel includes an enclosure structure 1, a pre-melting chamber 2, a fan room 3, a feeding device 6, and a discharging device 7. The enclosure structure 1 is combined into a box, the pre-melt chamber 2 and the blower chamber 3 are inside the enclosure structure 1, and the feeding device 6 and the discharge device 7 are arranged outside the enclosure structure.

[0028] Enclosing structure 1 is a double-layer stainless steel polyurethane board insulation structure. The pre-melted tunnel is composed of multiple modular double-layer stainless steel polyurethane board insulation structures. The double-layer stainless steel polyurethane board insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com