Pole plate of lead-acid battery

A lead-acid battery and electrode plate technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of unreasonable current transfer, smooth flow, influence of battery capacity, poor performance, etc., and achieve reasonable current transfer, improved performance, and improved electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

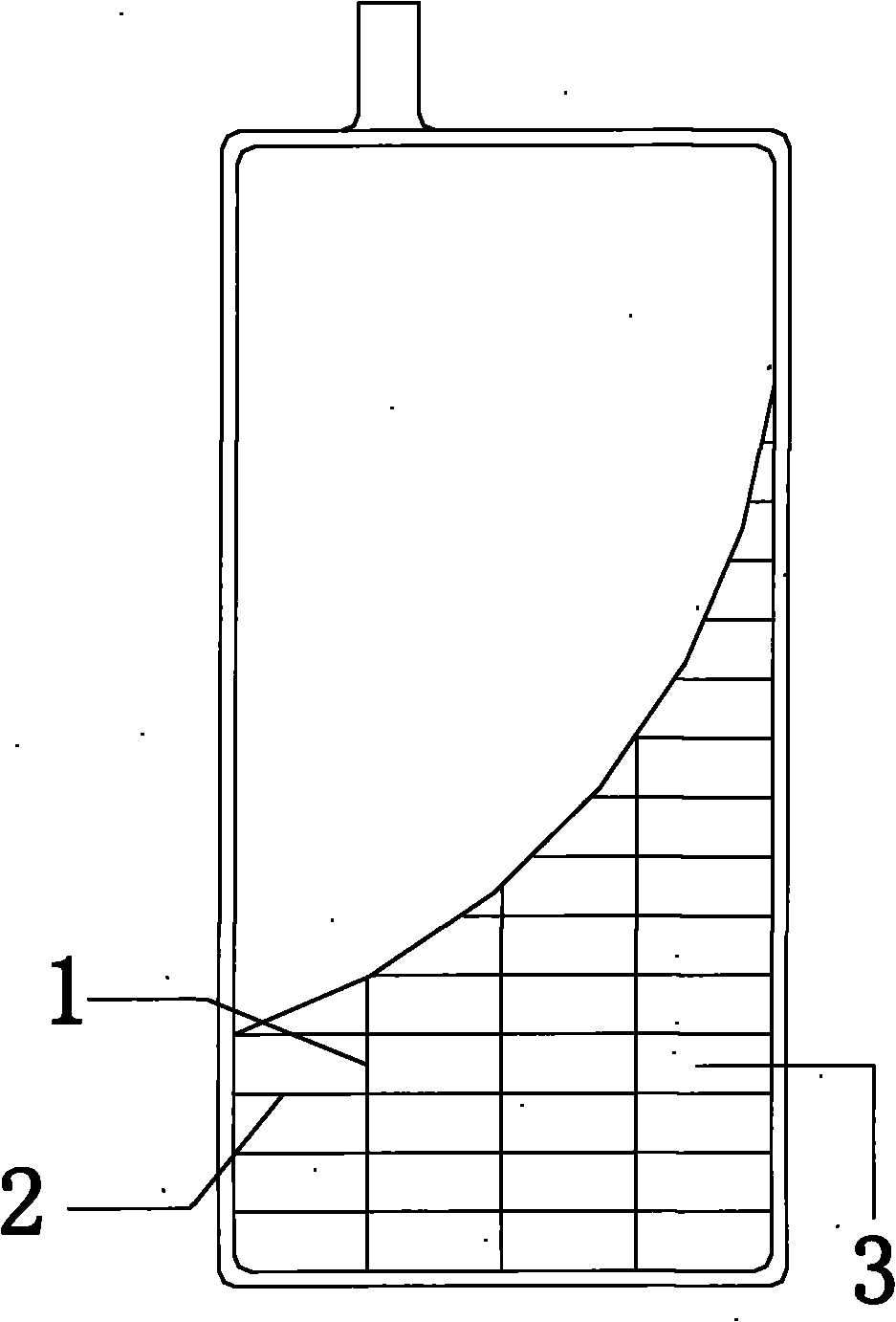

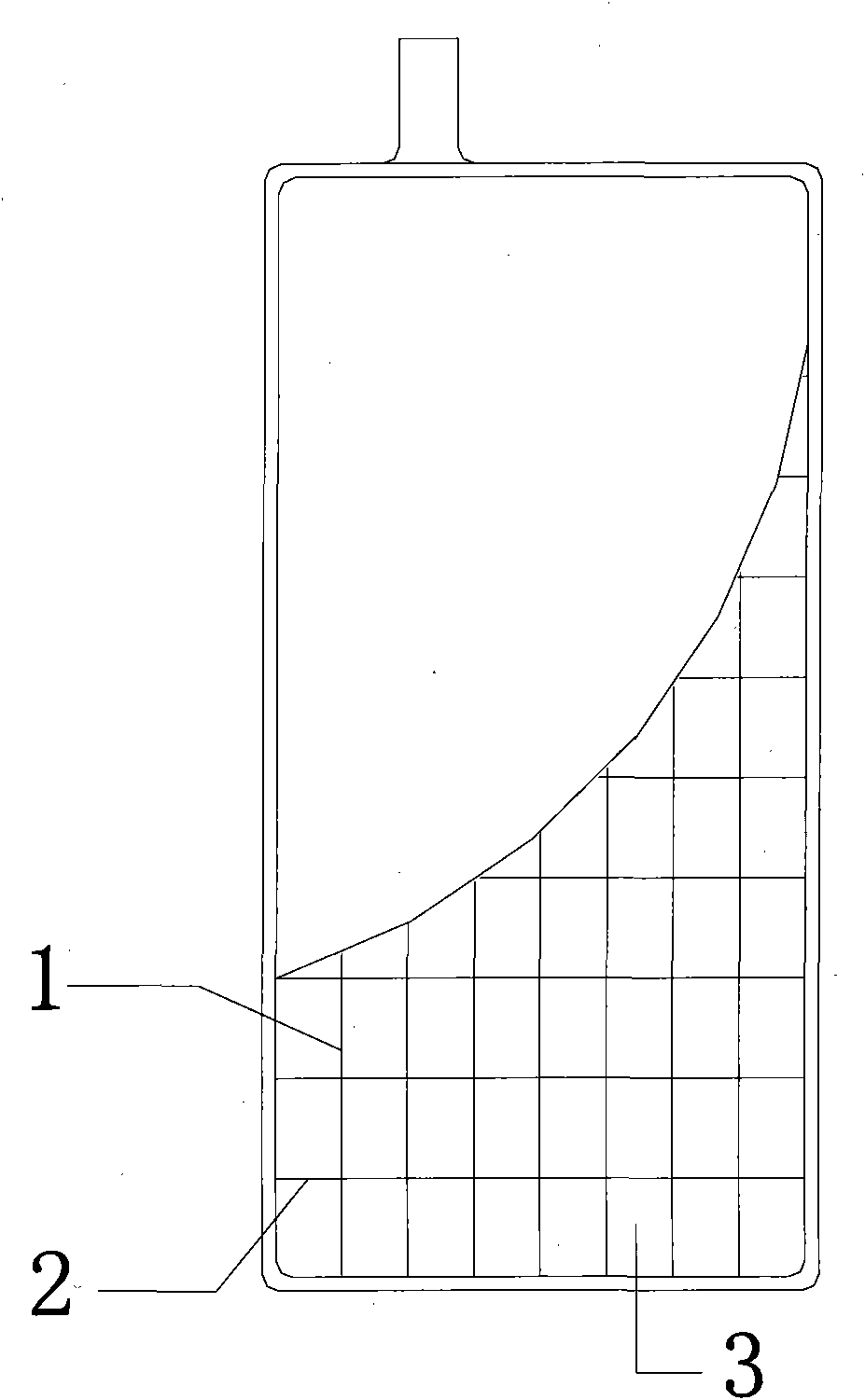

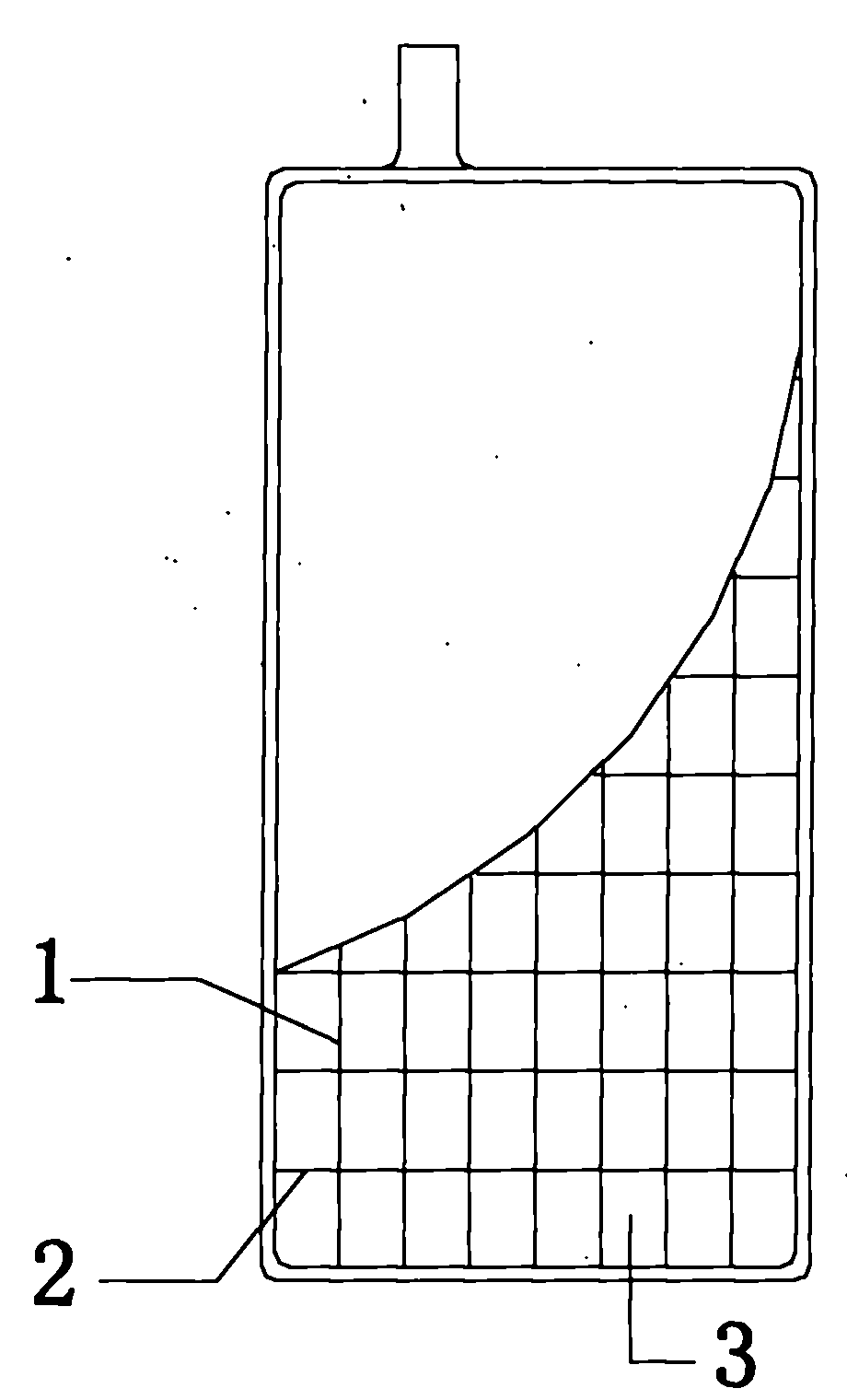

[0018] Such as figure 1 As shown, the lead-acid battery pole plate includes several longitudinally arranged vertical ribs 1 and several transversely arranged horizontal ribs 2, and the vertical ribs 1 and the horizontal ribs 2 are intersected to form a rectangular mesh 3, and the vertical ribs 3 of the rectangular mesh 3 The side length is greater than the transverse side length. The length of the longitudinal side of all rectangular meshes 3 is 1.6-1.9 times of the length of the transverse side, and the best structure is 1.7 times. Make the current smoothness the best and the lowest cost. All vertical ribs 1 are arranged vertically and parallelly, and all transverse ribs 2 are arranged horizontally and parallelly. The structure is the most reasonable and the performance is the best. Preferably, the number of all the vertical ribs 1 is 5-9, and 7 are optimally used. It can not only achieve good current flow, but also has a simple and reasonable structure.

[0019] The str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com