Sensor for use in a plastics processing machine and method for operating such a sensor

A technology of sensors and processing machines, which is applied to register/instruct the work of machines, instruments, time registers, etc., and can solve the problems of lack of large-scale application, hindering computing work, and large computing workload of control devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

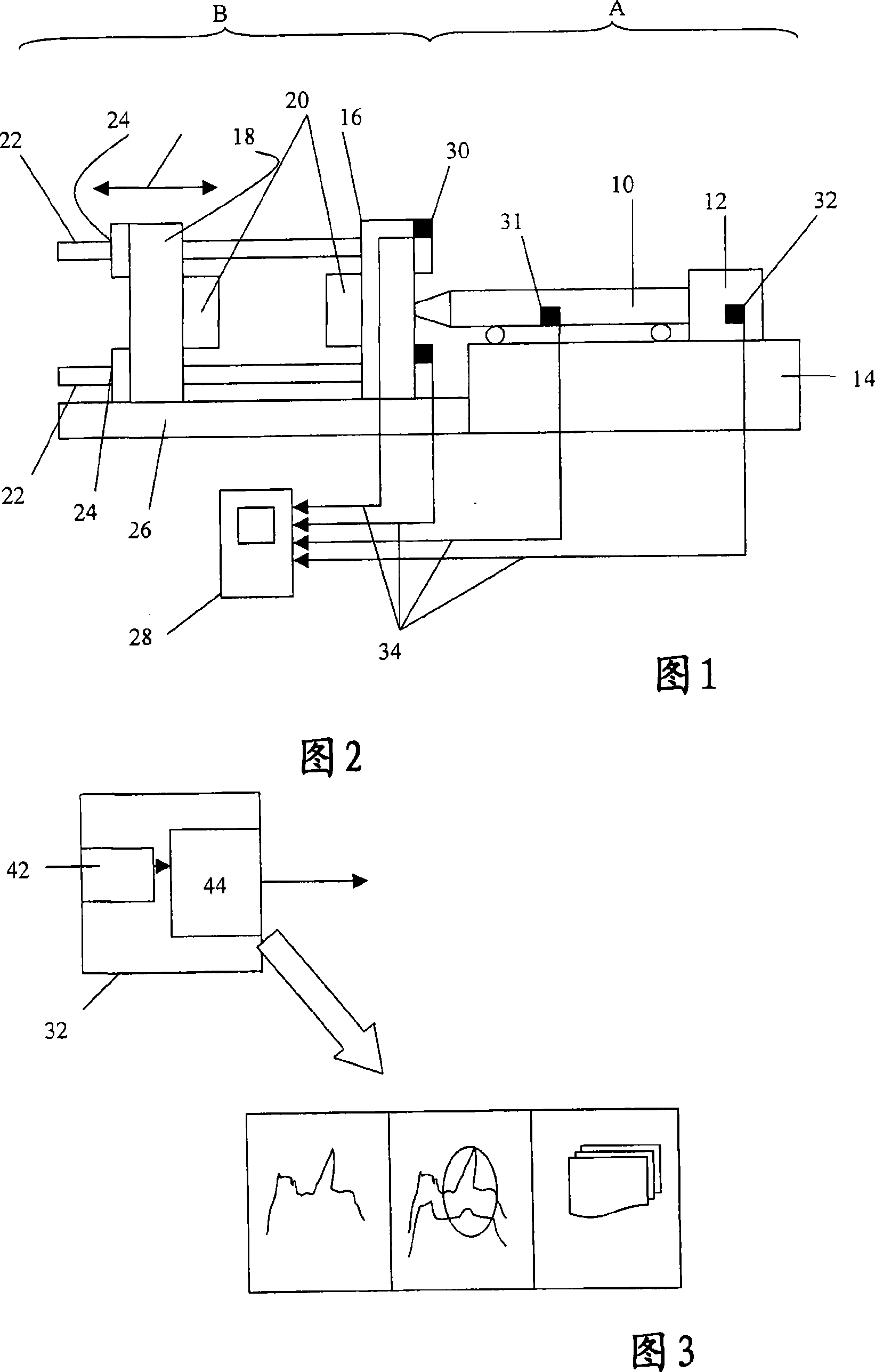

[0023] FIG. 1 shows a schematic view of an injection molding machine with a plasticizing unit and a clamping unit, which are arranged in areas A (plasticizing unit) and B (closing unit). The plasticizing unit in area A comprises a plasticizing cylinder 10 mounted reciprocally on a bed 14 and comprising an electric drive 12 at its end. The clamping unit in area B has, in a known manner, two platens, namely a fixed platen 16 and a movable platen 18 , to which a mold half 20 is fastened in each case. The formwork 18 is traversed by four beams 22 , of which only two are visible in FIG. 1 . The movable formwork 18 can be fixed relative to the crossbeam 22 by means of locking elements 24, so that in the closed state of the clamping unit a clamping pressure can be applied with hydraulic pressure pads mounted on the stationary formwork. Sensors 30 , 31 and 32 are fastened on the two pressure pads and on the plasticizing cylinder 10 as well as on the electric drive 12 .

[0024] A se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com