Film stretching machine

A stretching film and auxiliary machine technology, applied in printing presses, general parts of printing machinery, printing and other directions, can solve the problems of no function, no printing function, etc., to achieve the effect of easy dismantling and increasing popularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

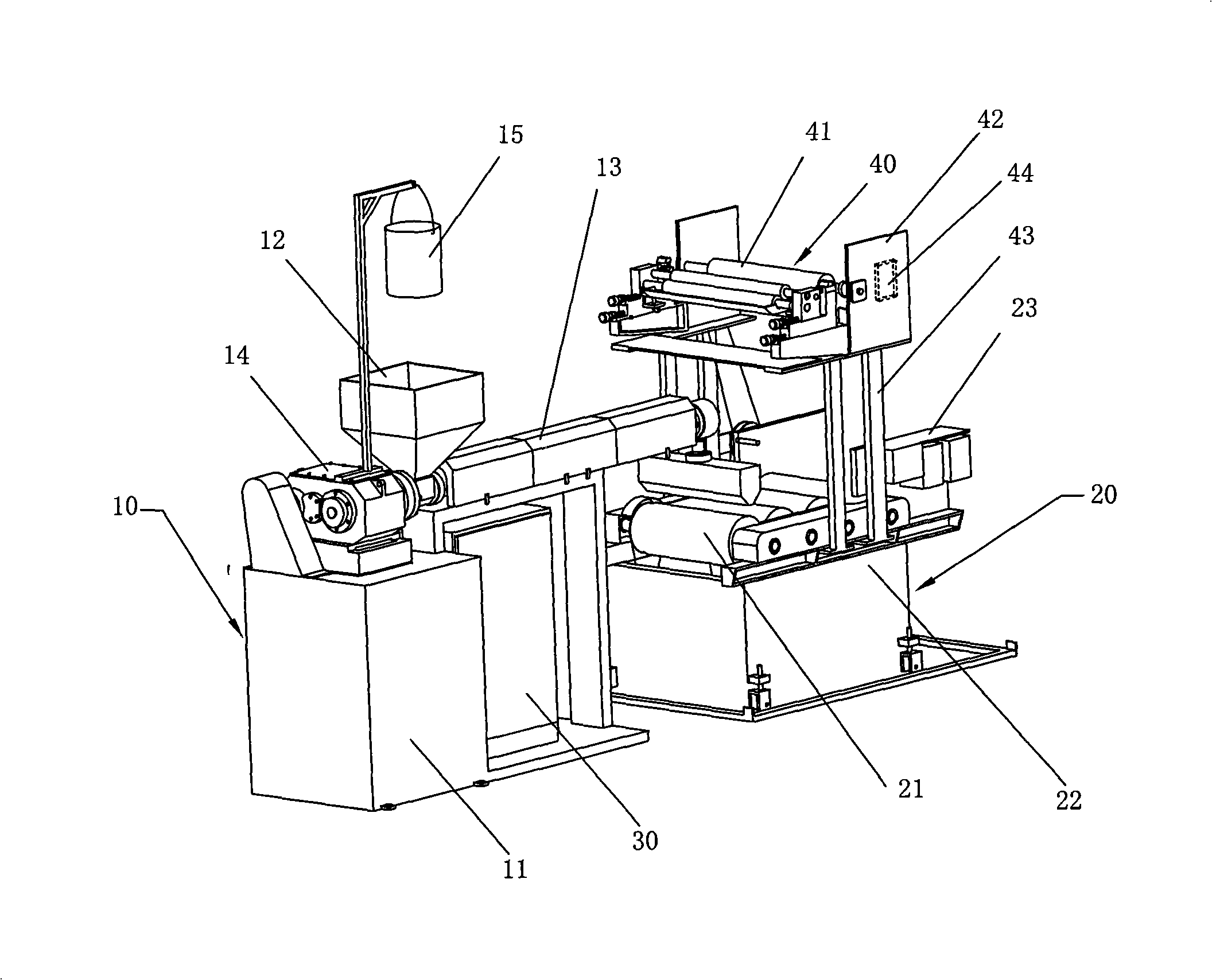

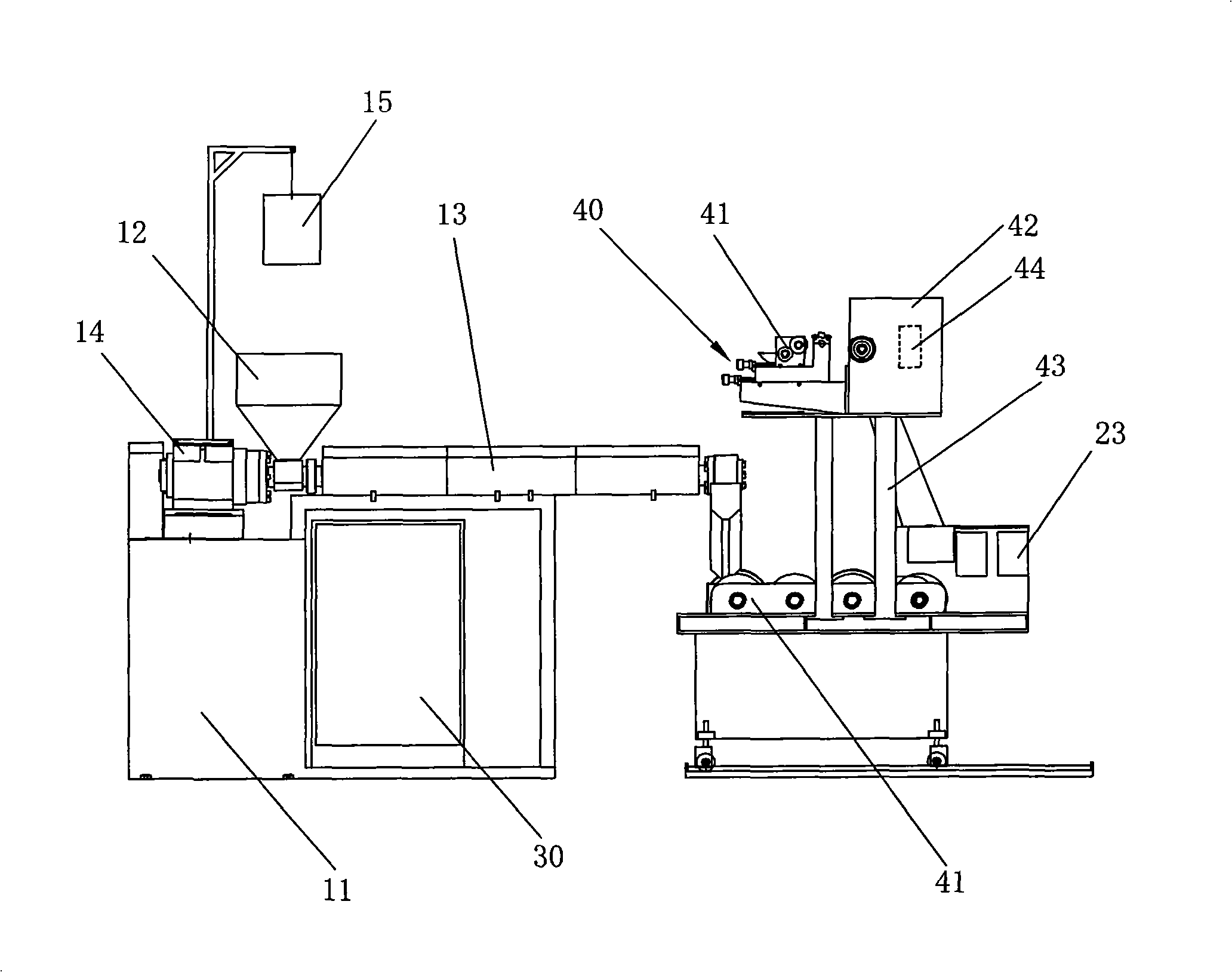

[0029] refer to Figure 1 to Figure 2 , the present invention is implemented like this:

[0030] A kind of stretching film machine, comprises main machine part 10, auxiliary machine part 20 and electrical control part 30, main machine part 10 is made up of main frame 11, feeding hopper 12, barrel screw 13 and speed reducer 14; Auxiliary machine part 20 is made up of The light roller transmission mechanism 21, the material receiving device 23 and the slide rail base 22 are composed, the barrel screw 13 is connected with the light roller transmission mechanism 21, the upper side of the auxiliary machine part 20 is equipped with a printing device 40, and the printing device 40 It consists of a printing plate roller 41 and an ink shelf 42 for holding ink. The ink shelf 42 is fixed above the auxiliary machine part 20 through a bracket 43. The printing device 40 is used to print various patterns according to different requirements. The ink shelf 42 is fixed on the slide rail base 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com