Ultraviolet curing offset printing ice flower effect ink and its preparation method and application

A technology of curing glue and ultraviolet light, used in inks, applications, household appliances, etc., can solve problems such as adverse operator health, low production efficiency, environmental pollution, etc., achieve fast curing speed, reduce ink costs, and cross-linking degree. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

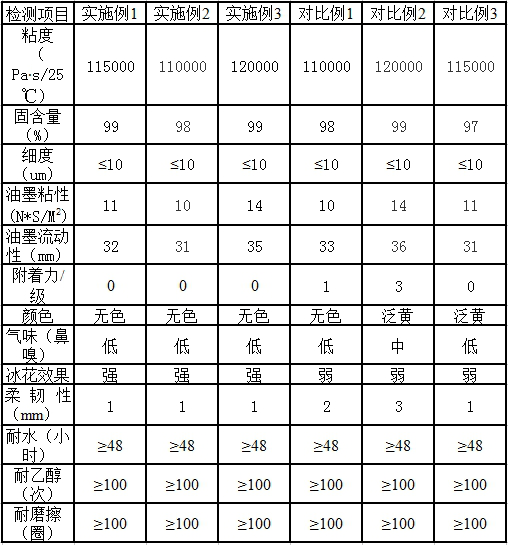

Examples

Embodiment 1

[0034] S1. Add 10.5 kg of dipentaerythritol hexaacrylate, add 40 kg of EBECRYL811 polyester acrylate resin at a stirring speed of 800 rpm, then increase the rotating speed to 1600 rpm, control the temperature ≤ 85°C, and stir for 40 minutes Until the dissolution is complete, the semi-finished product is obtained after cooling to 25 degrees Celsius;

[0035] S2. Add 15 kg of 10,000 mesh talc powder, 10 kg of Lanco 1792 polytetrafluoroethylene wax powder, 5 kg of M fumed silica, and 0.5 kg of 24,000 silicone dispersant to the semi-finished product. The stirring speed is 800 rpm, stirring for 15 minutes; then increase the rotating speed to 1600 rpm, stirring for 40 minutes until the dispersion is uniform, the fineness is qualified, and the next step is carried out after cooling down to 25 degrees Celsius;

[0036] S3. Then reduce the speed to 600 rpm, add 1 kg of TPO initiator, 7 kg of macromolecular photoinitiator, and 1 kg of 2700 organic silicon slip agent, mix well, stir for ...

Embodiment 2

[0038] S1. Add 15 kg of dipentaerythritol hexaacrylate, add 50 kg of EBECRYL811 polyester acrylate resin at a stirring speed of 800 rpm, then increase the rotating speed to 1600 rpm, control the temperature ≤ 85°C, and stir for 40 minutes Until the dissolution is complete, the semi-finished product is obtained after cooling to 25 degrees Celsius;

[0039] S2. Add 10 kg of 10,000 mesh talc powder, 9 kg of Lanco 1792 polytetrafluoroethylene wax powder, 5 kg of M fumed silica, and 0.5 kg of 24,000 silicone dispersant to the semi-finished product. The stirring speed is 800 rpm, stirring for 15 minutes; then increase the rotating speed to 1600 rpm, stirring for 40 minutes until the dispersion is uniform, the fineness is qualified, and the next step is carried out after cooling down to 25 degrees Celsius;

[0040] S3. Reduce the rotation speed to 600 rpm, add 2 kg of TPO initiator, 8 kg of macromolecular photoinitiator, and 0.5 kg of 2700 organic silicon slip agent, mix well, stir f...

Embodiment 3

[0042] S1. Add 8 kg of dipentaerythritol hexaacrylate, add 60 kg of EBECRYL811 polyester acrylate resin at a stirring speed of 800 rpm, then increase the rotating speed to 1600 rpm, control the temperature ≤ 85°C, and stir for 40 minutes Until the dissolution is complete, the semi-finished product is obtained after cooling to 25 degrees Celsius;

[0043] S2. Add 10 kg of 10,000 mesh talc powder, 6 kg of Lanco 1792 polytetrafluoroethylene wax powder, 5 kg of M fumed silica, and 1 kg of 24,000 silicone dispersant to the semi-finished product. The stirring speed is 800 rpm, stirring for 15 minutes; then increase the rotating speed to 1600 rpm, stirring for 40 minutes until the dispersion is uniform, the fineness is qualified, and the next step is carried out after cooling down to 25 degrees Celsius;

[0044] S3. Then reduce the speed to 600 rpm, add 3 kg of TPO initiator, 6 kg of macromolecular photoinitiator, and 1 kg of 2700 organic silicon slip agent, mix well, stir for 20 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com