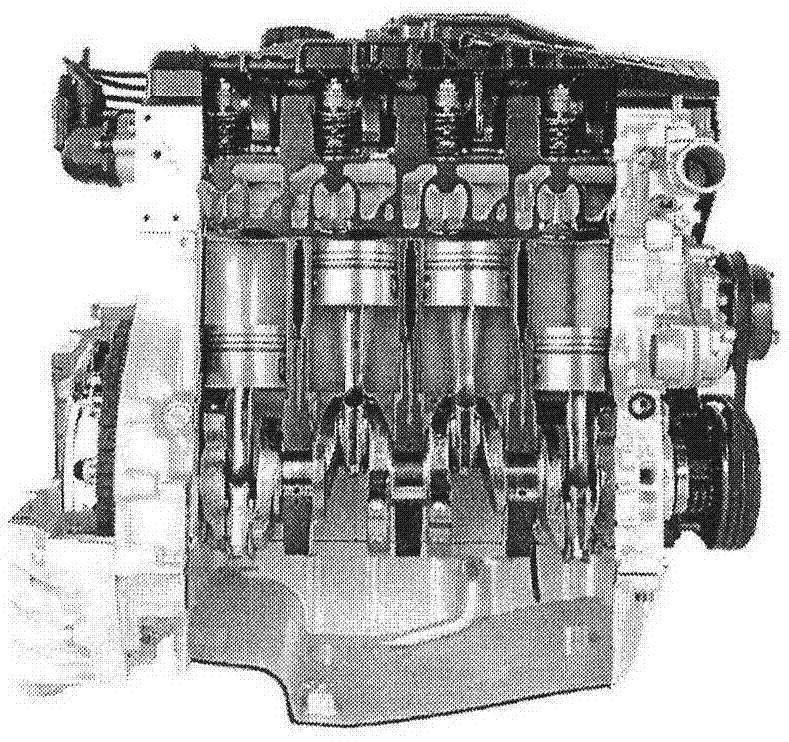

Piston type straight shaft internal combustion engine

An internal combustion engine, piston-type technology, applied in mechanical equipment, machines/engines, etc., can solve the problems of high impact force, low output efficiency, unreasonable meshing of half-gear frame and half-gear shaft, and achieve the effect of avoiding collision and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

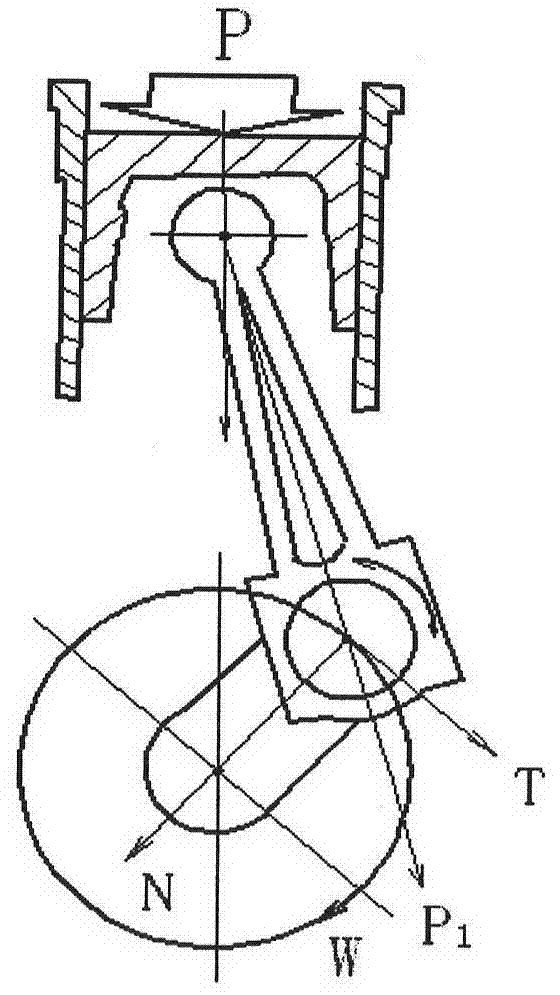

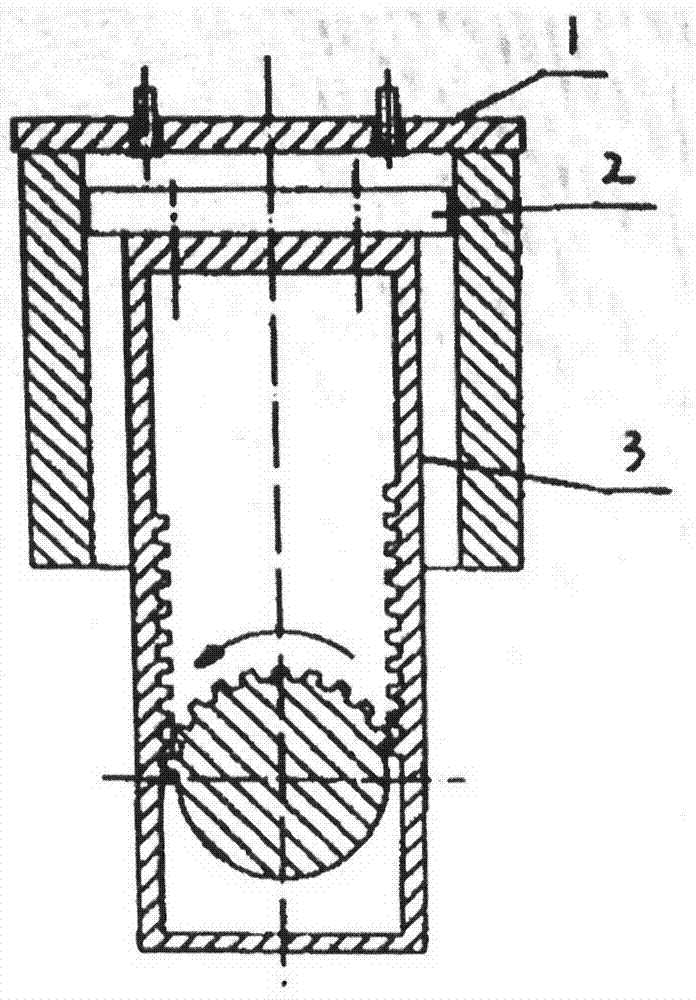

[0047] The first embodiment of frame-tooth straight-shaft internal combustion engine

[0048] This embodiment is a single-cylinder internal combustion engine, and the engine in the embodiment is improved on the basis of the New Century 125 scooter engine. Figure 4 For the schematic diagram of the whole machine of this embodiment, the parts of the invention part have, the straight shaft of the double half-wheel combination, see Figure 5 5-1 in, double track gear frame Figure 7 Figure 8 , tooth frame, Figure 9 , stabilizing spring, see Figure 4 4-2 in, inertia wheel, see Figure 44-3 in, and chassis, see Figure 4 , the remaining parts still continue to use the parts in the original engine, and the radius length of the sector gear has also adopted the crankshaft radius length of the original motorcycle engine, that is, the stroke of the piston is identical with the stroke of the original engine in the present embodiment.

[0049] Figure 5 5-1 in this embodiment is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com