Buffer filling agent applied to interior of corrugated layer of high-strength corrugated board

A technology of corrugated cardboard and corrugated layer, which is applied in the field of cardboard manufacturing and processing, can solve the problems of small influence of temperature and influence on strength, and achieve the effects of improving moisture absorption capacity, prolonging service life, and high environmental protection standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

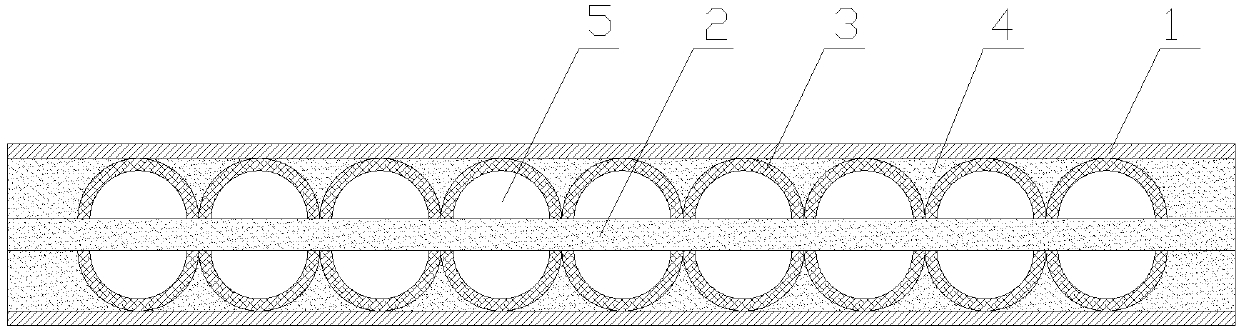

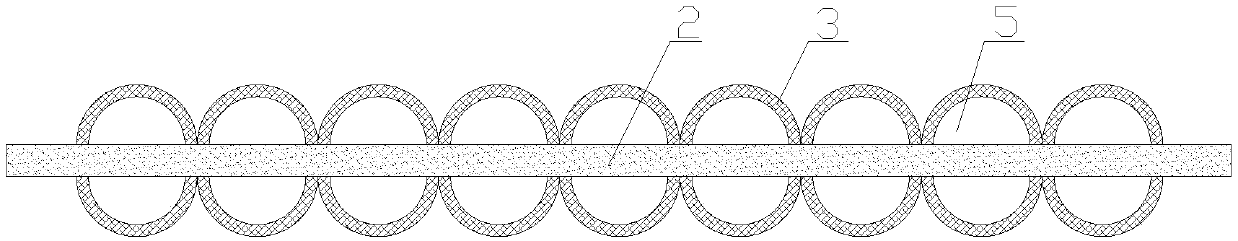

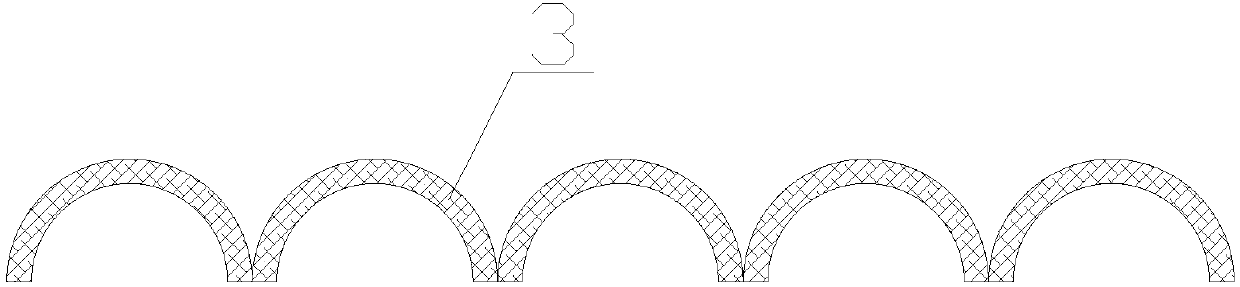

[0058] Such as Figure 1-Figure 3 Shown as: a high-strength corrugated cardboard, which is composed of cardboard paper 1, partition board 2 and corrugated paper 3. The cardboard paper 1 is provided with two upper and lower pieces, and the partition board 2 is arranged in the middle of the cardboard paper 1. Corrugated paper 3 is arranged on both sides of the partition plate 2. The corrugated paper 3 has a continuous semi-circular arc structure. A hemispherical hollow buffer cavity 5 is formed between the corrugated paper 3 and the partition board 2, and between the corrugated paper 3 and the cardboard paper 1 Filled with glue 4, and the corrugated paper 3 is provided with filler;

[0059] The thickness of the cardboard paper 1 is half the thickness of the partition plate 2;

[0060] The thickness of corrugated paper 3 is the same as that of cardboard paper 1;

[0061] The thickness of the corrugated paper 3 is half the thickness of the partition plate 2;

[0062] The filler in the c...

Embodiment 2

[0066] Such as Figure 1-Figure 3 Shown: a high-strength corrugated paperboard, through the cooperation of the partition plate 2 and the corrugated paper 3, the symmetrical corrugated paper 3 can improve the supporting strength, and the semicircular arc structure strengthens the supporting force of the corrugated paper 3, The cardboard 1 plays a better supporting role, and the partition plate 2 can also act as a reinforcing rib to fix the corrugated paper 3, provide stress points for the corrugated paper 3, and also play a firm role. The glue 4 between the corrugated paper 3 and the corrugated paper 1 can increase the firmness between the corrugated paper 1 and the corrugated paper 3 and improve the overall strength of the corrugated paper.

Embodiment 3

[0068] The filler in the corrugated paper can play a very good reinforcement effect on the corrugated paper and provide a buffer effect. Not only that, it can also dehumidify the space inside the corrugated paper. The use of the corrugated paper after dehumidification is more obvious;

[0069] Buffer filler used in the corrugated layer of high-strength corrugated cardboard, prepared from the following components: 80 parts of ABS plastic particles, 1 part of lapis lazuli powder, 1 part of halogen-free flame retardant synergist, 1.5 parts of ethylene propylene rubber , Lubricant 0.2 part, antioxidant 0.1 part, initiator 1 part, graphite lubricant 0.2 part, polypropylene staple fiber 5 parts, dimethyl silicone oil 0.5 part, perchloroethylene 5 parts, sodium silicate 1.5 parts, rigidity 1 part of talcum powder, 0.5 part of surfactant, 3 parts of cryolite powder;

[0070] The above-mentioned ABS plastic particles are modified before use, and the ABS plastic particles are mixed with glyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com