Recovering and utilizing device for rain in factory area

A technology of rainwater collection and rainwater, which is applied to the configuration of water supply devices, drinking water devices, and water supply pools, to achieve the effects of saving consumption, improving environmental protection standards, and alleviating water resource scarcity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

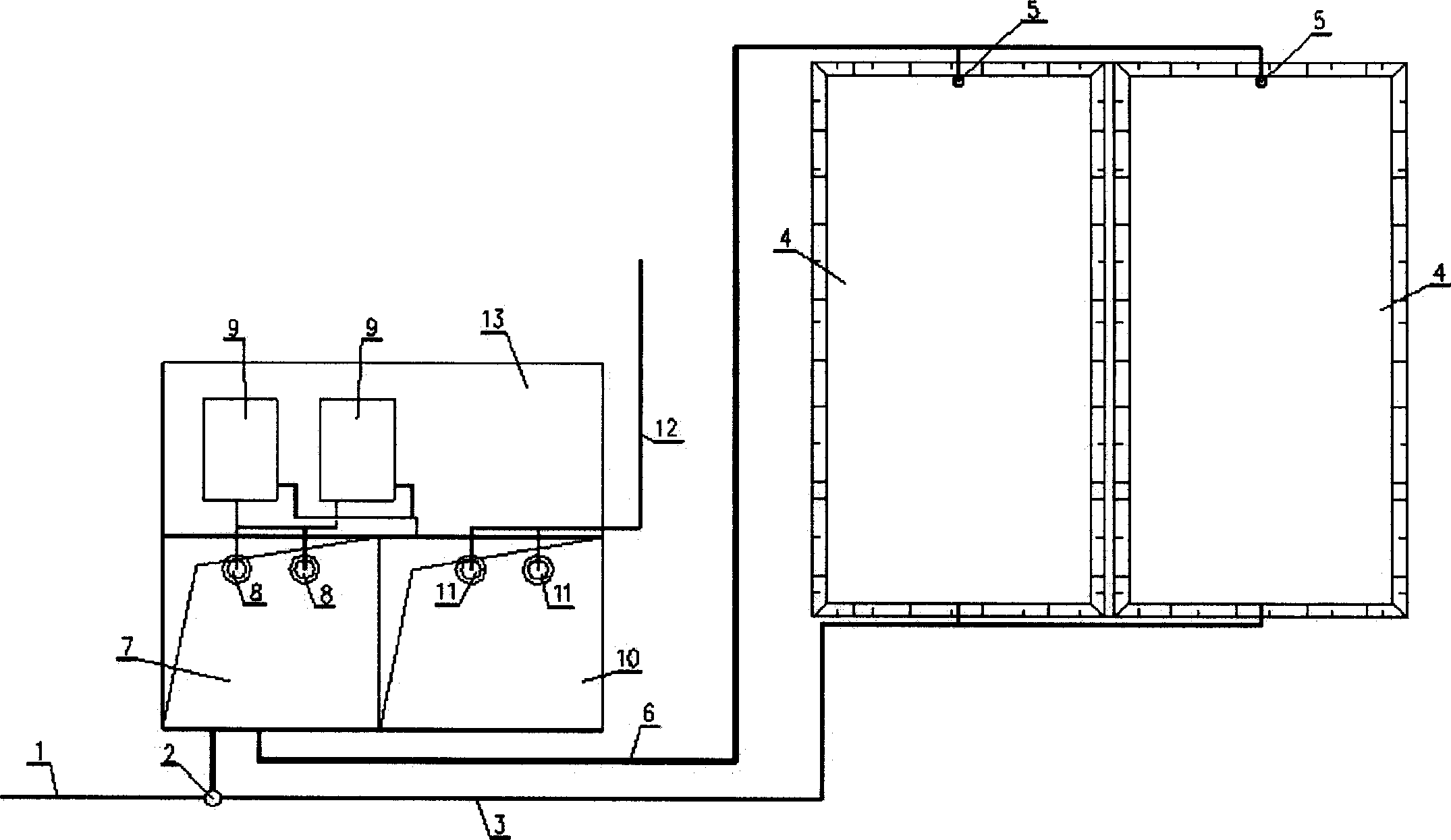

[0009] Embodiments of the present invention: as figure 1 As shown, the interception well 2, the regulating pool 7, the reuse pool 10, the sewage treatment room 13, and the sewage treatment room 13 are installed with wastewater treatment equipment 9 in the factory. The multiple is 2 to 3; a sedimentation tank 4 is set outside the factory, and its volume is determined according to the local rainfall and evaporation. The amount of evaporated water on the surface of the sedimentation tank for one year. Anti-leakage measures should be set for the settling tank; production wastewater and rainwater collection pipes 1 are buried in the factory area, and the production wastewater and rainwater collection pipes 1 are connected to the interception well 2 and to the regulating pool 7; one end of the rain drainage pipe is connected to the interception well 2 Connect, the other end is connected with the settling tank 4; Install the rainwater return water lifting pump 5 in the settling tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com