Environment-friendly ice making integrated machine

An all-in-one, environmentally friendly technology, used in ice manufacturing, refrigerators, leisure ice making, etc., can solve the problems of inconvenient transportation, installation and use, large size of the ice machine, and inability to reduce the size, etc., to achieve a compact and convenient structure. The effect of transportation and ease of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

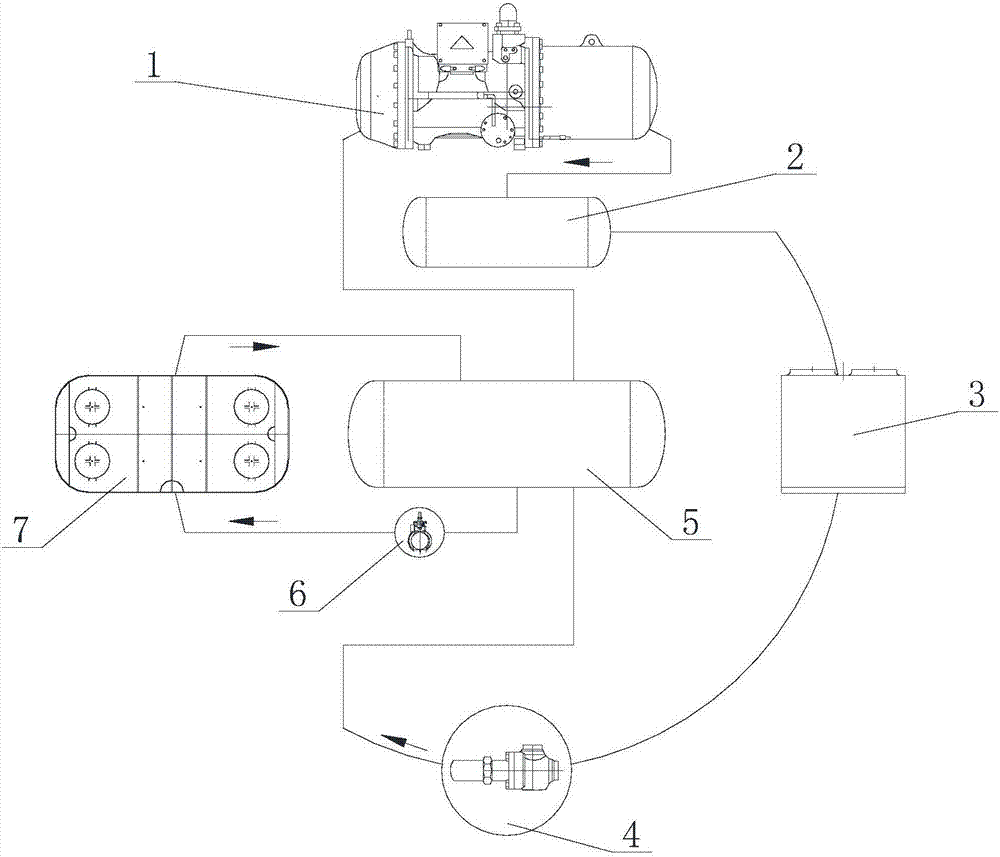

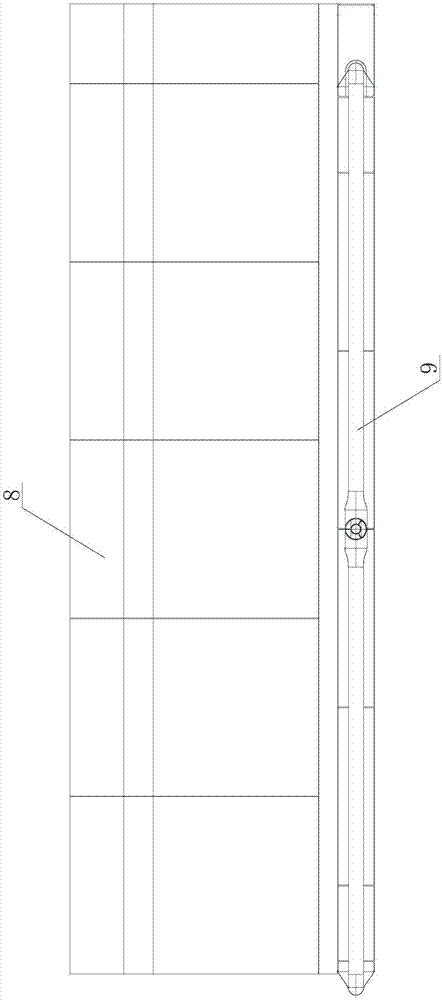

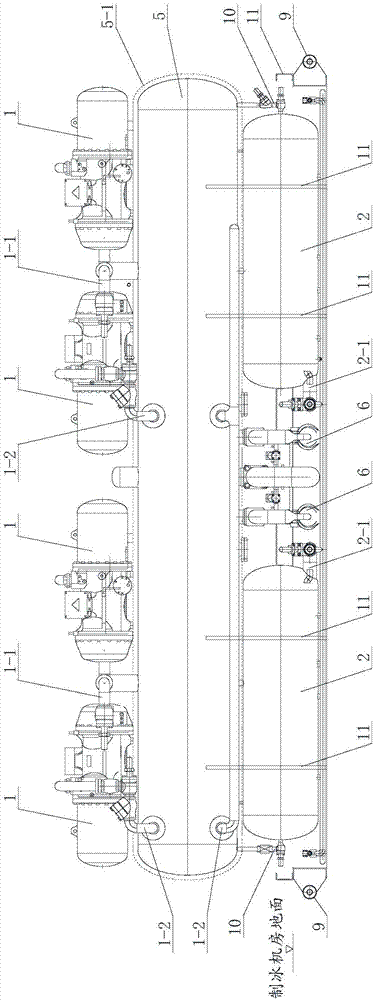

[0047] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown is an embodiment of the present invention. In this embodiment, the environmental protection integrated ice making machine includes a compressor 1, an oil separator 2 and a low-pressure circulation tank 5. The compressor 1, an oil separator 2 and a low-pressure circulation tank 5 pass refrigerant The conveying pipelines are connected in sequence, the oil separator 2 is located in the lower layer, the low-pressure circulation tank 5 is located in the middle layer, and the compressor 1 is located in the upper layer.

[0048] Such as image 3 , Figure 4 As shown, the width and length of the low-pressure circulation tank 5 completely absorb the width and length of the compressor 1 and the oil separator 2.

[0049] Through such a laminated design structure, the main components of the environmental protection ice-making integrated machine can be combined, the space of the unit can be fully utilized, the structure is compact,...

Embodiment 2

[0075] In this embodiment, the difference from embodiment 1 is that Figure 7 As shown, the throttle valve group 10 is provided with a parallel main path and a secondary path along the refrigerant conveying direction, and the main path is sequentially provided with a check valve 10-9, a filter 10-8, and an electronic throttle valve 10- 7 and the first shut-off valve 10-6, the inlet of the check valve 10-9 is the refrigerant inlet, and the outlet of the first shut-off valve 10-6 is the refrigerant outlet.

[0076] Such as Figure 7 As shown, the secondary path and the main path share the check valve 10-9, which also starts from the check valve 10-9, followed by the mechanical throttle valve 10-1, the refrigerant charging port 10-2 and the second stop The outlet of the valve 10-3 and the second stop valve 10-3 is the outlet of the refrigerant. A check valve can also be installed at the refrigerant charge port 10-2.

[0077] The primary path and the secondary path do not need to be o...

Embodiment 3

[0083] In this embodiment, as Picture 11 As shown, the inside of the oil separator 2 (high pressure tank) is divided into an oil and gas separation chamber 2-3 and a liquid storage tank 2-6. The refrigerant returning from the condenser 3 is first delivered to the liquid storage tank 2-6, and then passed through the throttle The valve group 10 is delivered to the low-pressure circulation tank 5.

[0084] Because the refrigerant returning from the condenser 3 may be in a gas-liquid mixed state, by designing such a high-pressure tank structure, on the one hand, the gas-liquid mixed refrigerant returning from the condenser 3 can be adjusted in the liquid storage tank 2-6. Let the liquid refrigerant be delivered to the throttle valve group 10, because the liquid refrigerant has a better throttling and pressure regulation effect. On the other hand, the high-pressure tank can be reasonably developed and utilized to make full use of the unit space and reduce the unit volume.

[0085] A h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com