Composite floorboard and fabrication method

A production method and technology for composite floors, which are applied to layered products, floors, buildings, etc., can solve the problems of short service life of the floor, damage to the waterproof membrane layer, affecting the waterproof performance, etc., and achieve strong waterproofness and strong adhesion to deformation. Degree, the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The novel composite floor and its production method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

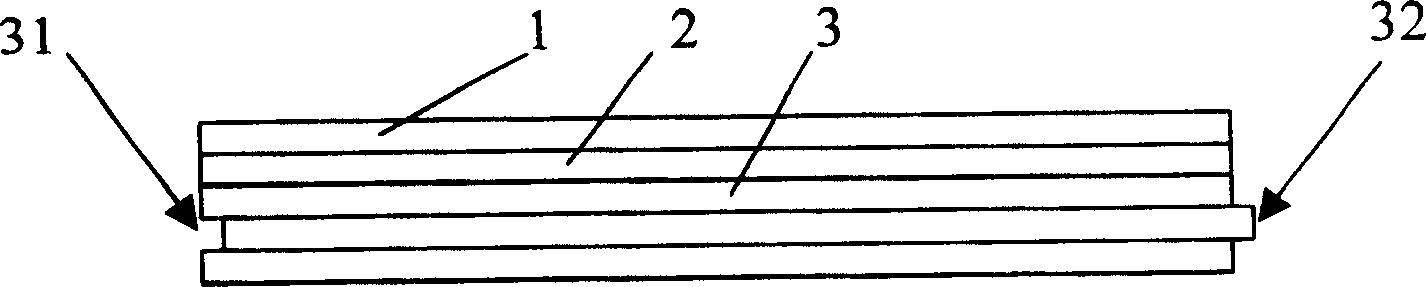

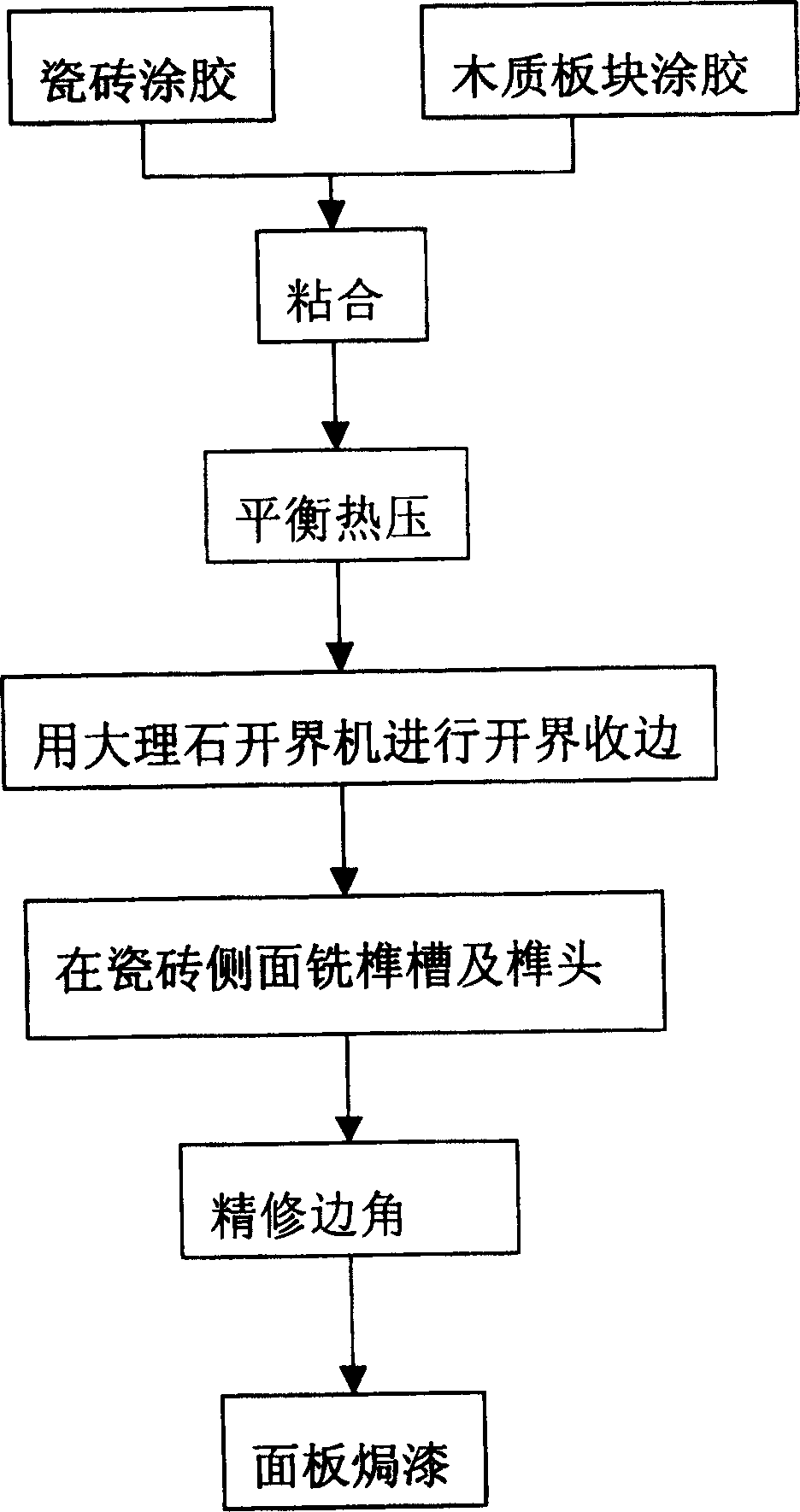

[0023] Such as figure 1 As shown, the new composite floor is composed of an upper wooden panel layer 1 and a lower tile substrate 3. A strong adhesive bonding layer 2 is formed between the wooden panel layer 1 and the tile substrate 3. The adhesive used in the bonding layer is a tension adhesive. Viscosity should be greater than 90Kg / cm 2 . The thickness of the wooden panel layer is 2mm-6mm, preferably 3mm-4mm, and the thickness of the ceramic tile substrate 3 is 10mm-15mm. There are tenon grooves 31 and tenon heads 32 on the four sides of the tiles. The tenon grooves 31 and the tenon heads 32 are located on the two opposite sides of the tiles. The width of the tenon grooves 31 and the tenon head 32 should be as consistent as possible. ±0.05mm, otherwise, when installing the floor, becau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com