System and method for incinerating oil sludge by utilizing pulverized coal fired boiler of power station

A pulverized coal boiler and oil sludge technology, which is applied in the field of coal-fired boilers, achieves the effects of high thermal efficiency, saving infrastructure equipment and operation and maintenance costs, and high incineration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

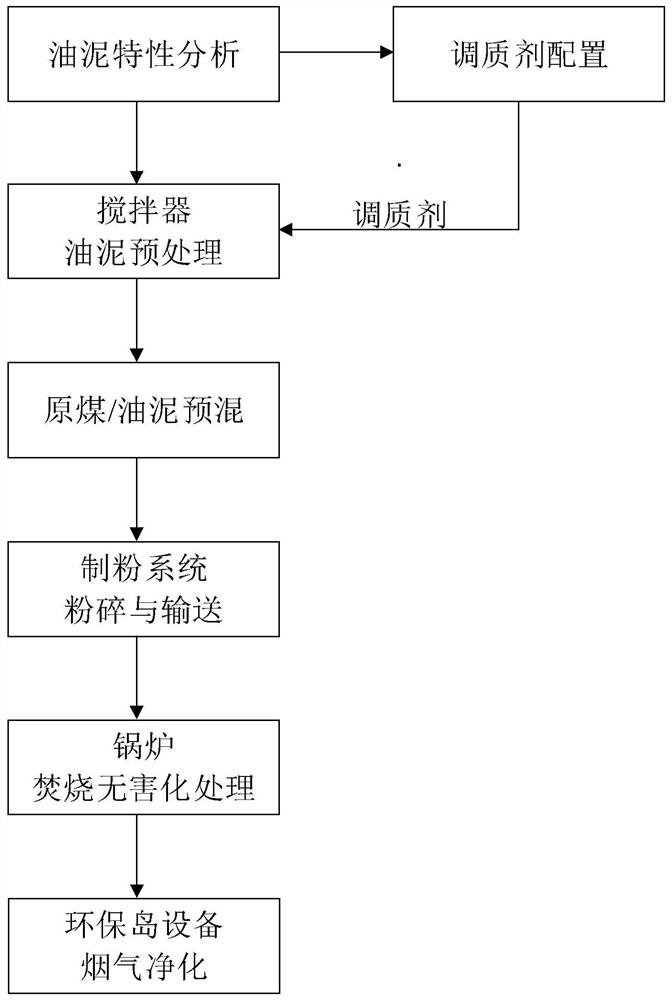

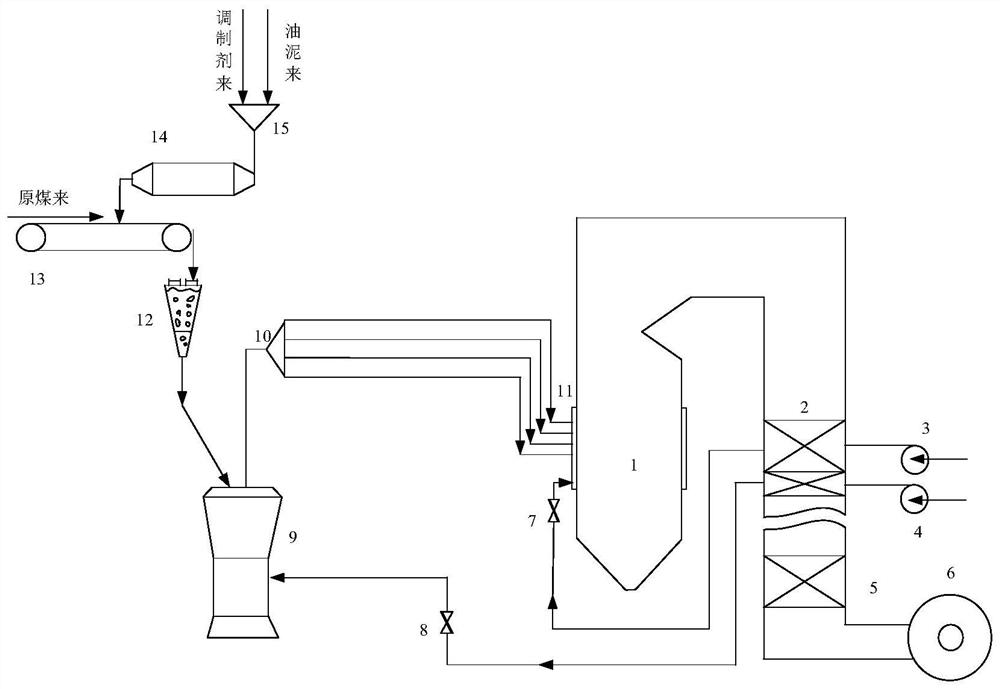

Method used

Image

Examples

example

[0036] Such as image 3 The oil sludge as a by-product of an oil production well is composed of 60% oil, 8% water, 7% solid combustibles, and about 25% other non-combustible substances such as ash, with a calorific value as high as 33MJ / kg. Due to the high oil content of this sludge, it has the characteristics of high calorific value. However, due to its large molecular weight of oil, the viscosity of the oil on the whole is high, and transportation is difficult and poses a greater safety risk. On the other hand, moisture and non-combustible substances also contain certain toxic and harmful substances, which need to be harmlessly treated at high temperatures. By adopting the method of the present invention, the following steps can be adopted for incineration, so as to realize the comprehensive utilization of the calorific value of the oil sludge and the harmless treatment of harmful substances.

[0037] First, as mentioned above, the main physical and chemical indicators of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com