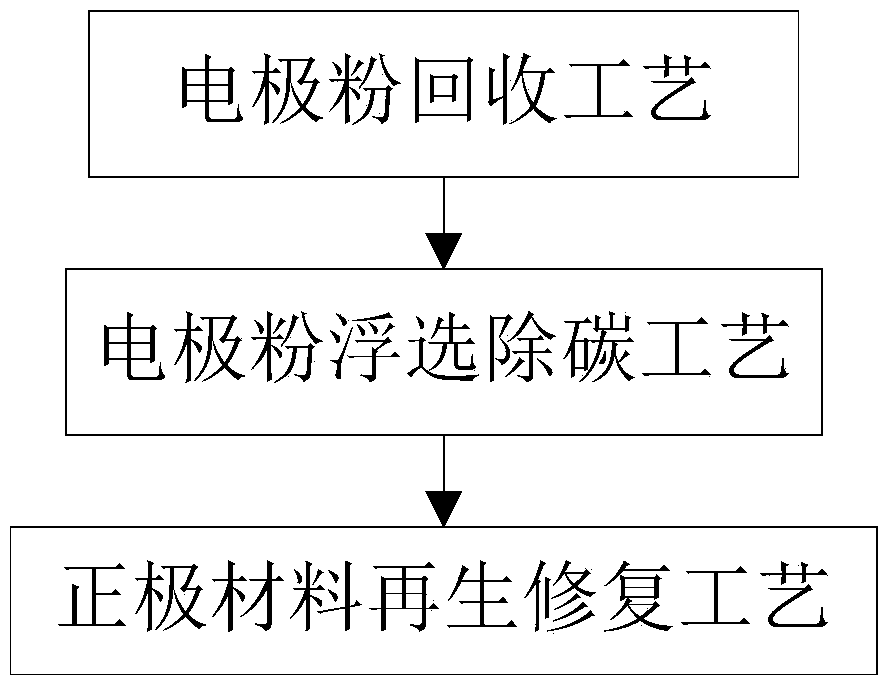

Recycling process of positive electrode materials of waste batteries

A cathode material and waste battery technology, which is applied in the recycling process of waste battery cathode material and the field of battery recycling, can solve the problems of inability to separate the regeneration effect, immature recycling technology, and discarding waste batteries, so as to achieve effective resource reuse and cost reduction. Controllable and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

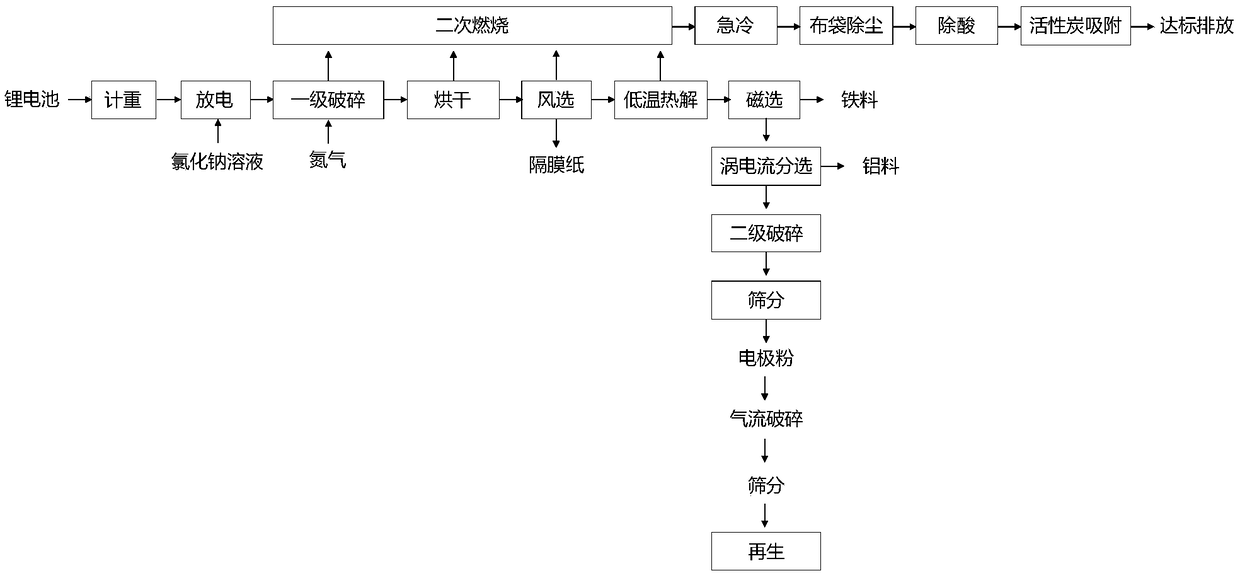

Method used

Image

Examples

Embodiment 1

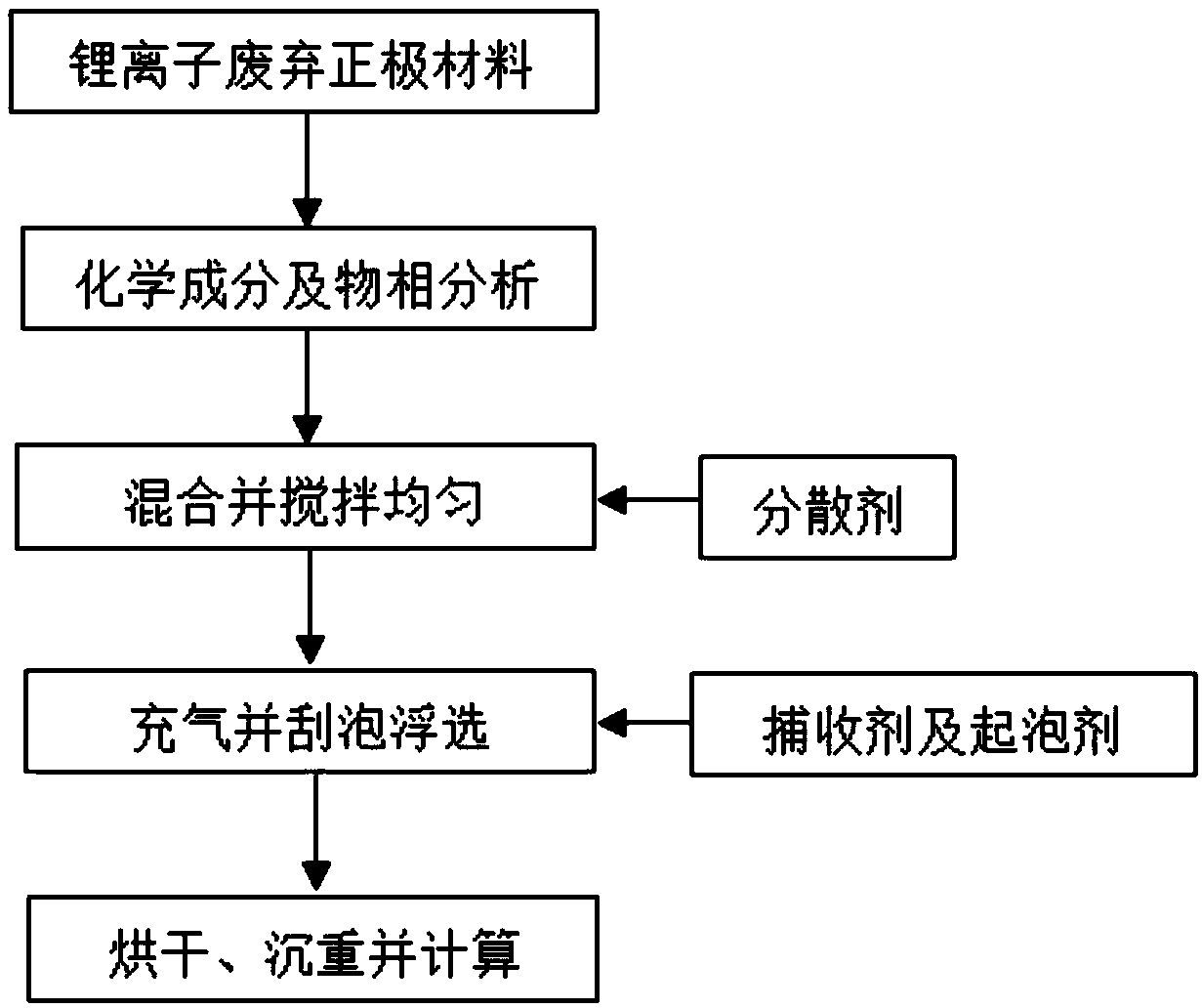

[0090]Example 1 of electrode powder flotation carbon removal: In this example, flotation and carbon removal will be carried out on the positive electrode material of the waste Ni-Co-Mn ternary lithium ion battery. The specific steps are as follows:

[0091] SO1. Determine the content of each chemical component and the phase composition of carbon in the waste cathode material of lithium-ion batteries through chemical multi-element and phase analysis. The carbon content in the cathode material is 21.43%, and the main form of carbon is graphite.

[0092] SO2. Prepare 25% concentration of polyethylene glycol aqueous solution as a dispersant for subsequent use, and additionally reserve a 1:1 mixture of kerosene and oxalic acid as a collector, and terpineol oil as a foaming agent.

[0093] SO3. Weigh 40g of the lithium-ion battery waste positive electrode material into the flotation cell of the flotation machine, and add 120g of distilled water according to a solid-to-liquid ratio of...

Embodiment 2

[0098] Example 2 of electrode powder flotation carbon removal: In this example, flotation and carbon removal will be carried out on the waste Ni-Co-Mn ternary lithium-ion battery positive electrode material. The specific steps are as follows:

[0099] SO1. adopt exactly the same waste lithium ion positive electrode material as in Example 1, with a carbon content of 21.43%;

[0100] SO2. Prepare a 25% aqueous solution of sodium hexametaphosphate as a dispersant, and prepare a 1:1 mixture of kerosene and tartaric acid as a collector, and diethyl ether as a foaming agent.

[0101] SO3. Weigh 40g of lithium-ion battery waste positive electrode material into the flotation cell of the flotation machine, and add 120g of distilled water according to a solid-to-liquid ratio of 1:3, add 20ml of sodium hexametaphosphate aqueous solution as a dispersant and stir for 5min, well mixed;

[0102] SO4. Start the tank heating device of the flotation machine, and set the temperature of the mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com