Tail gas purification system for fuel train

A technology for exhaust gas purification and trains, which can be used in exhaust devices, combustion engines, internal combustion piston engines, etc., and can solve problems such as life-threatening safety, poor combustion conditions, and insufficient fuel combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

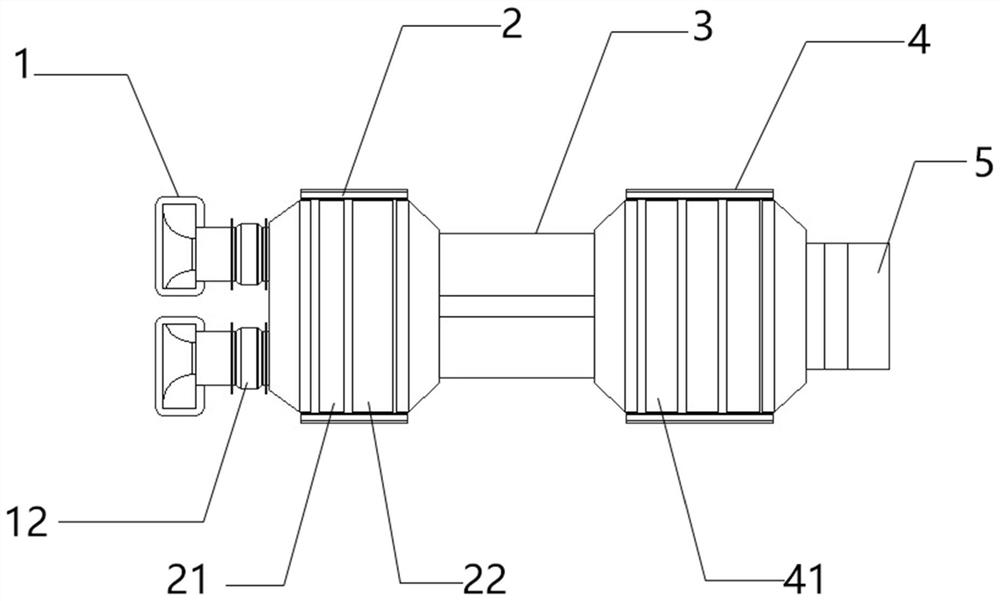

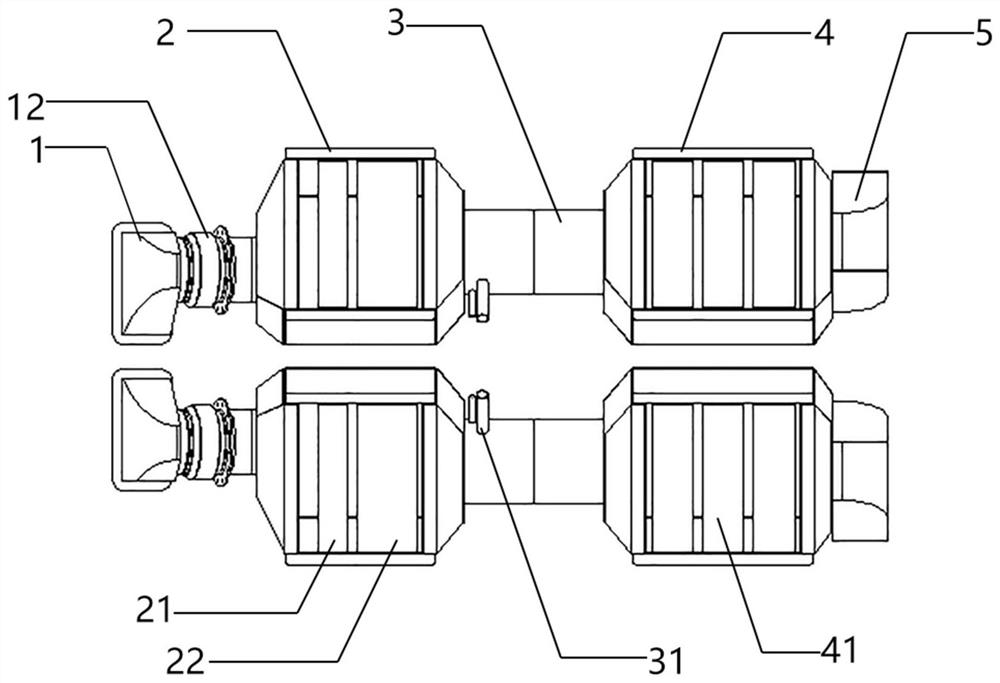

[0028] Such as figure 1 As shown, a fuel train exhaust gas purification system is characterized in that it includes an intake unit 1, a catalytic oxidation filter unit 2, a urea mixing chamber 3, a catalytic reduction unit 4 and an exhaust unit 5, and the entire purification system is installed on the train On a fuel engine, wherein the air intake unit 1 is connected to a turbocharger.

[0029] As a possible implementation, the air intake unit 1 is directly connected to the exhaust port 11 of the engine, and the exhaust gas of the engine is introduced into the exhaust gas purification system, and the exhaust gas will pass through the catalytic oxidation filter unit 2, the urea mixing The chamber 3 and the catalytic reduction unit 4 are finally discharged from the exhaust unit 5 .

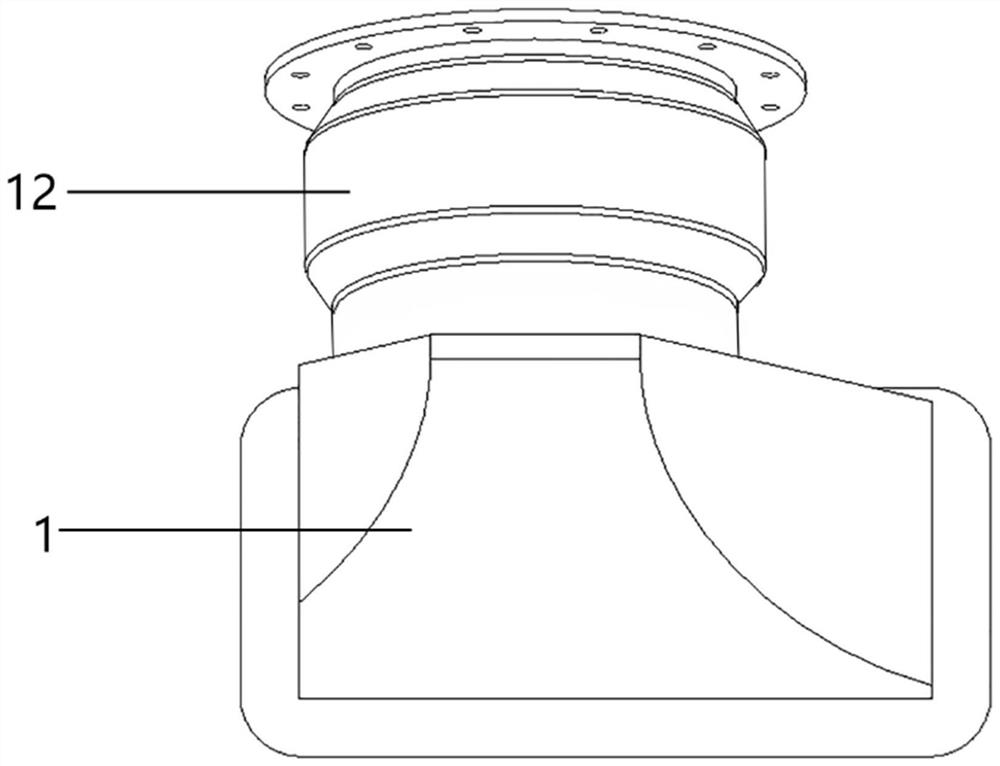

[0030] Such as image 3 As shown, as a possible implementation, the air intake unit 1 and the catalytic oxidation filter unit 2 are connected by a section of bellows 12, since the entire purificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com