Flame-retardant environment friendly PET thermal shrinkage material and preparation thereof

A heat-shrinkable and environmentally friendly technology, which is applied in the field of heat-shrinkable materials and its preparation, can solve the problems of poor flame-retardant performance of PET heat-shrinkable tubes, and achieve the effects of good fire-proof flame-retardant performance and good safety precautions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

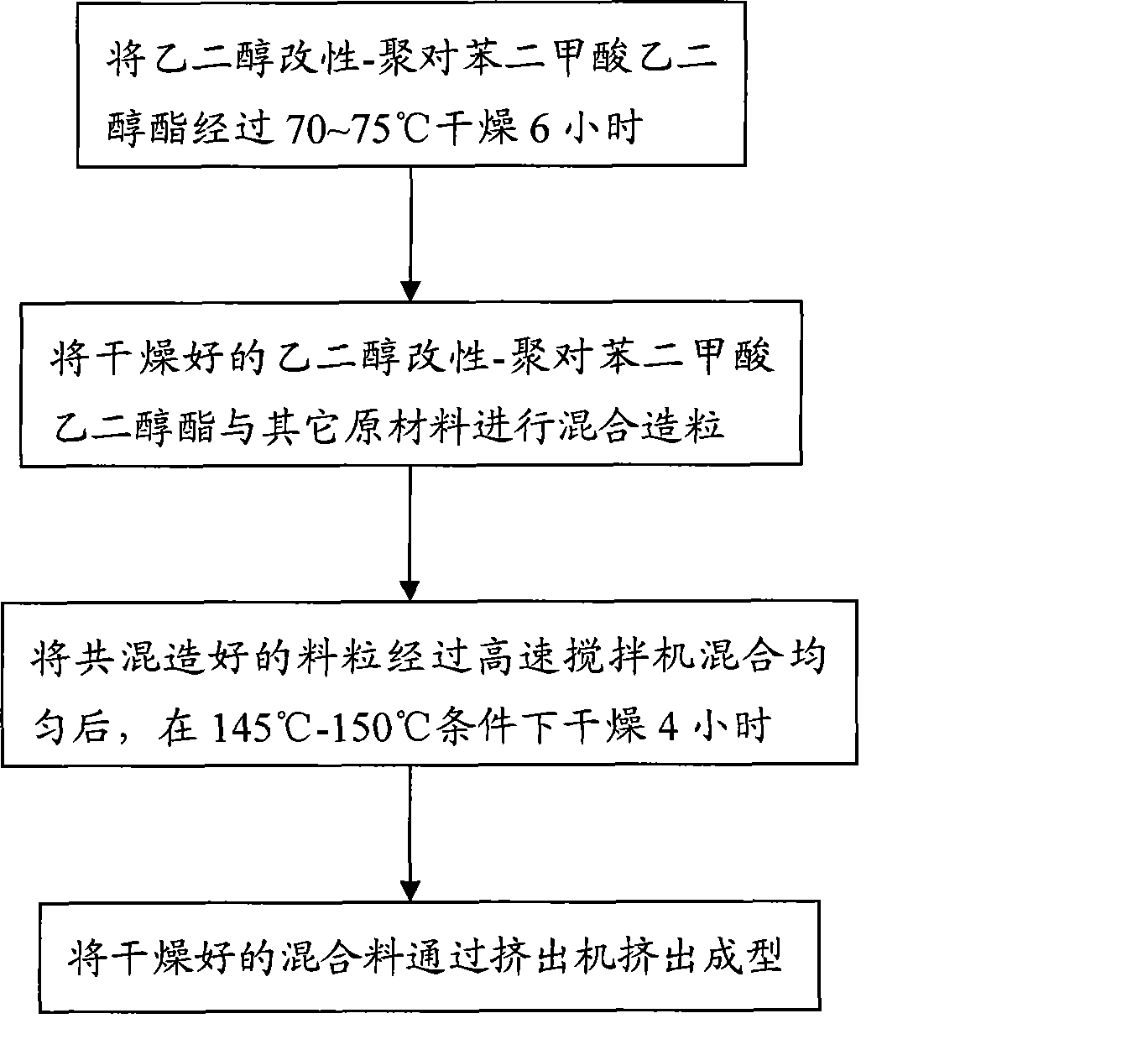

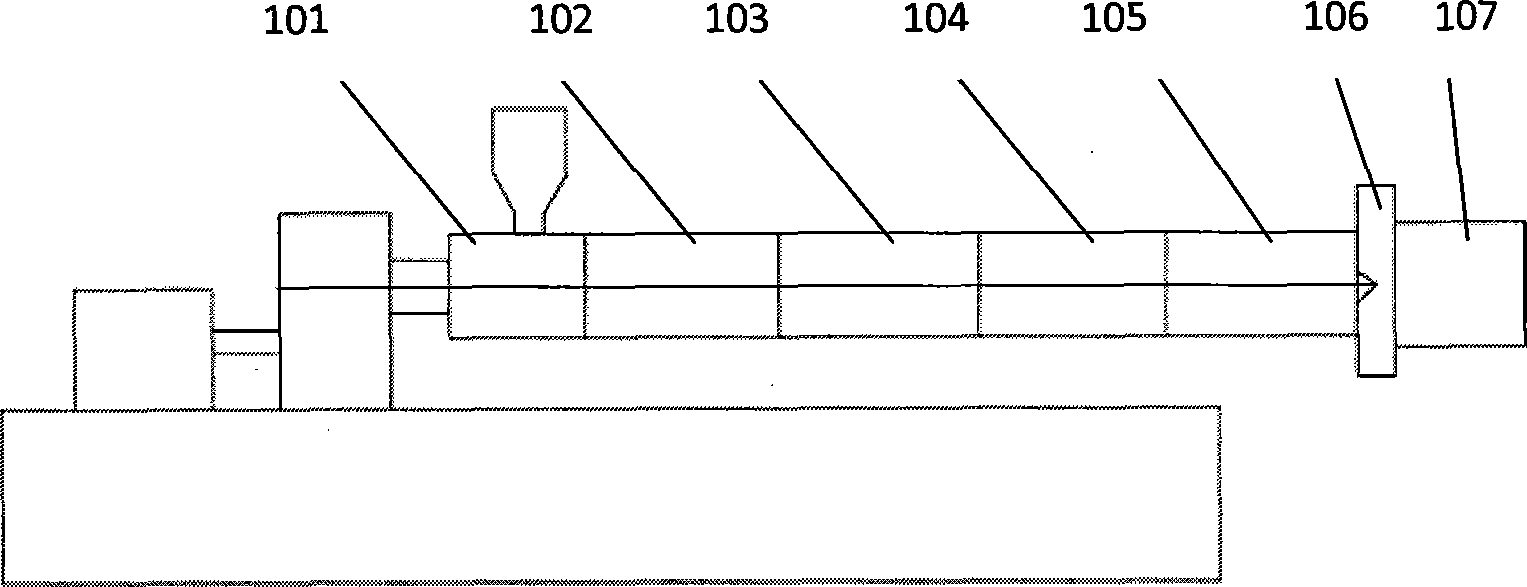

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Polyethylene terephthalate (PET): 48%, ethylene glycol modified-polyethylene terephthalate (PETG): 24%, polybutylene terephthalate (PBT): 8%, thermoplastic elastomer (TPE): 1.95%, phosphate ester flame retardant: 18% and lubricant: 0.05%.

Embodiment 2

[0021] Example 2: Polyethylene terephthalate (PET): 45%, ethylene glycol modified-polyethylene terephthalate (PETG): 28%, polybutylene terephthalate (PBT): 8%, thermoplastic elastomer (TPE): 1.95%, phosphate ester flame retardant: 17% and lubricant: 0.05%.

Embodiment 3

[0022] Example 3: Polyethylene terephthalate (PET): 50%, ethylene glycol modified-polyethylene terephthalate (PETG): 25%, polybutylene terephthalate (PBT): 8%, thermoplastic elastomer (TPE): 1.45%, phosphate ester flame retardant: 15.5% and lubricant: 0.05%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com