Squeezing device and squeezing machine

A pressure cylinder and sleeve technology, which is applied in the field of squeezing devices and squeezing machines, can solve the problems that the squeezing machine cannot work continuously, the discharge procedure is complicated, and the liquid discharge cannot be smooth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

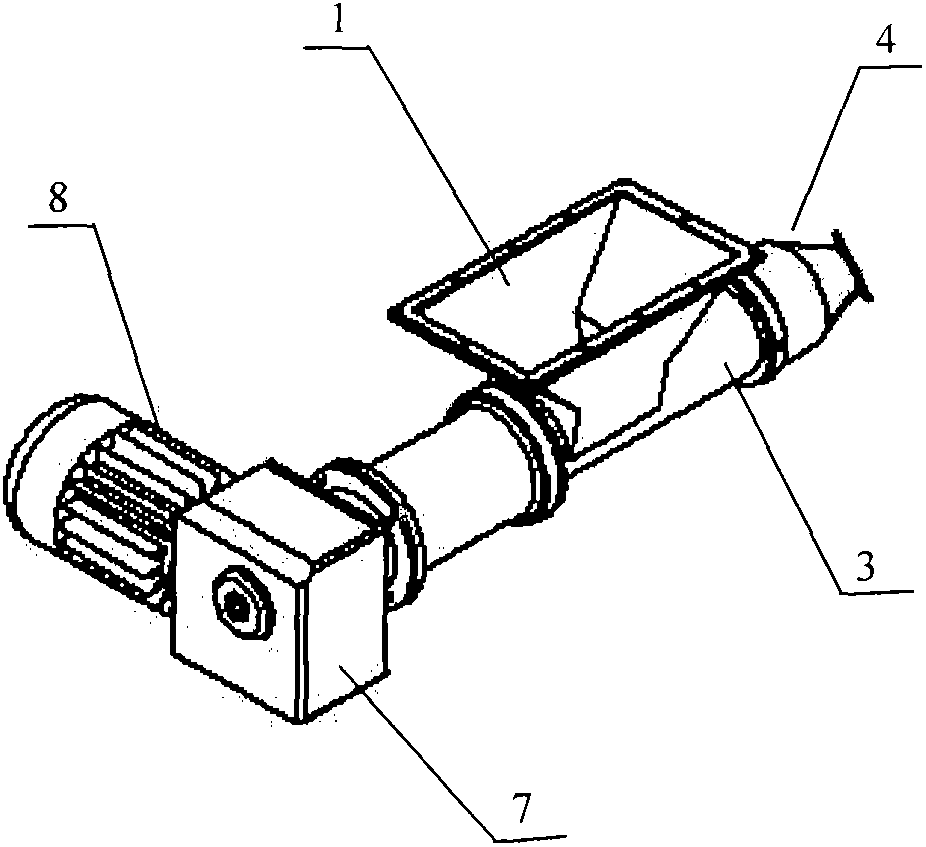

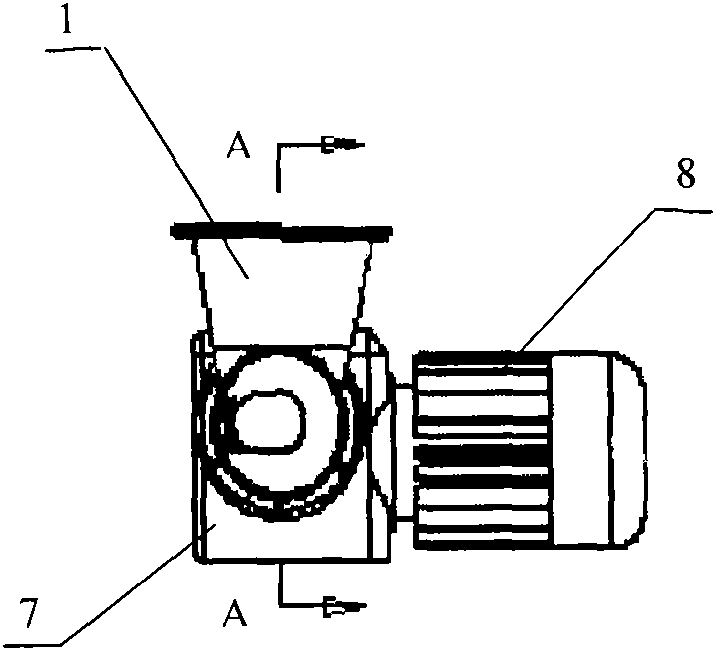

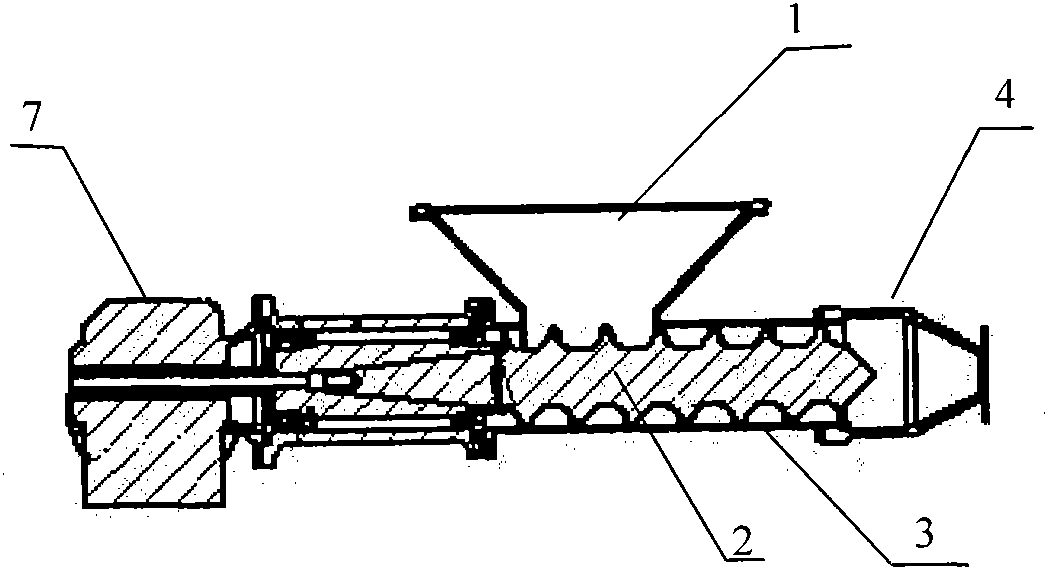

[0030] Such as Figure 1 to Figure 6 As shown, the present invention provides a squeezing device, which includes a feed port 1, a screw 2, a storage sleeve 3, a pressing sleeve 4, a screen cloth 5 and a discharge port 6, such as image 3 As shown, the screw rod 2 is installed in the storage sleeve 3, the upper wall of the storage sleeve 3 is provided with a feed port 1, one end of the storage sleeve 3 is fixed, and the other end is connected to the The pressing sleeve 4 is connected; one end of the screw 2 is connected to the fixed end of the storage sleeve 3, and the other end (which may be called the extrusion end) is suspended in the pressing sleeve 4, The shape of the other end is conical, and the apex angle of the axial section of the conical one end is 90°; as Figure 5 As shown, the pressing sleeve 4 is divided into a pressure cylinder 401 and a taper cylinder 402; a cylindrical screen 5 is installed in the pressure cylinder 401, and the two ends of the screen 5 are co...

Embodiment 2

[0040] The apex angle of the axial section of the conical end of the screw 2 is 90°, the shape of the tapered cylinder is a truncated cone, and the angle a between the two generatrixes of the axial section of the truncated cone is 40°. Other specific implementations are the same as in Example 1.

Embodiment 3

[0042] The apex angle of the axial section of the conical end of the screw 2 is 80°, the shape of the tapered cylinder is a truncated cone, and the angle a between the two generatrixes of the axial section of the truncated cone is 20°. Other specific implementations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com