Patents

Literature

92results about How to "Effective pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

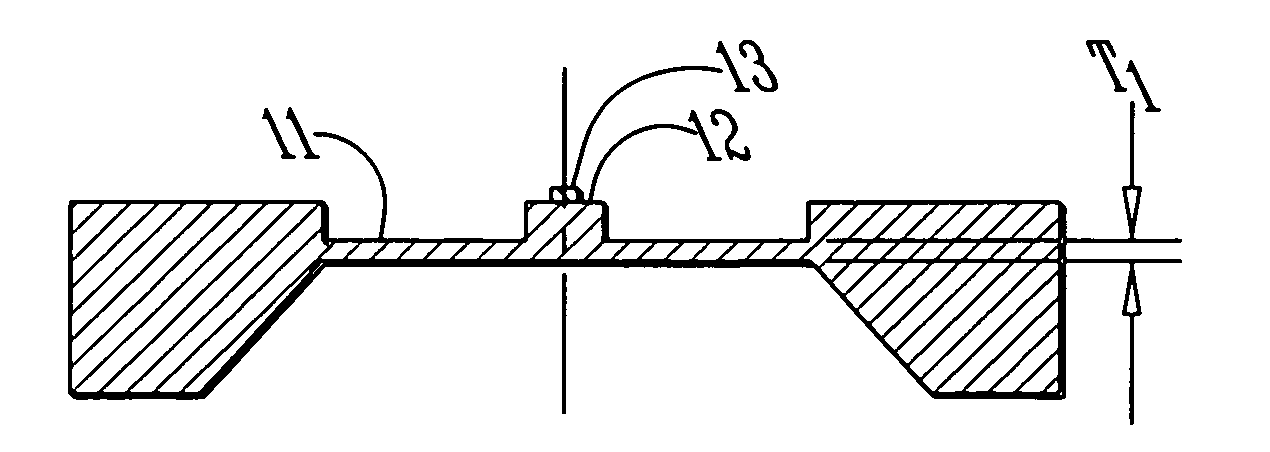

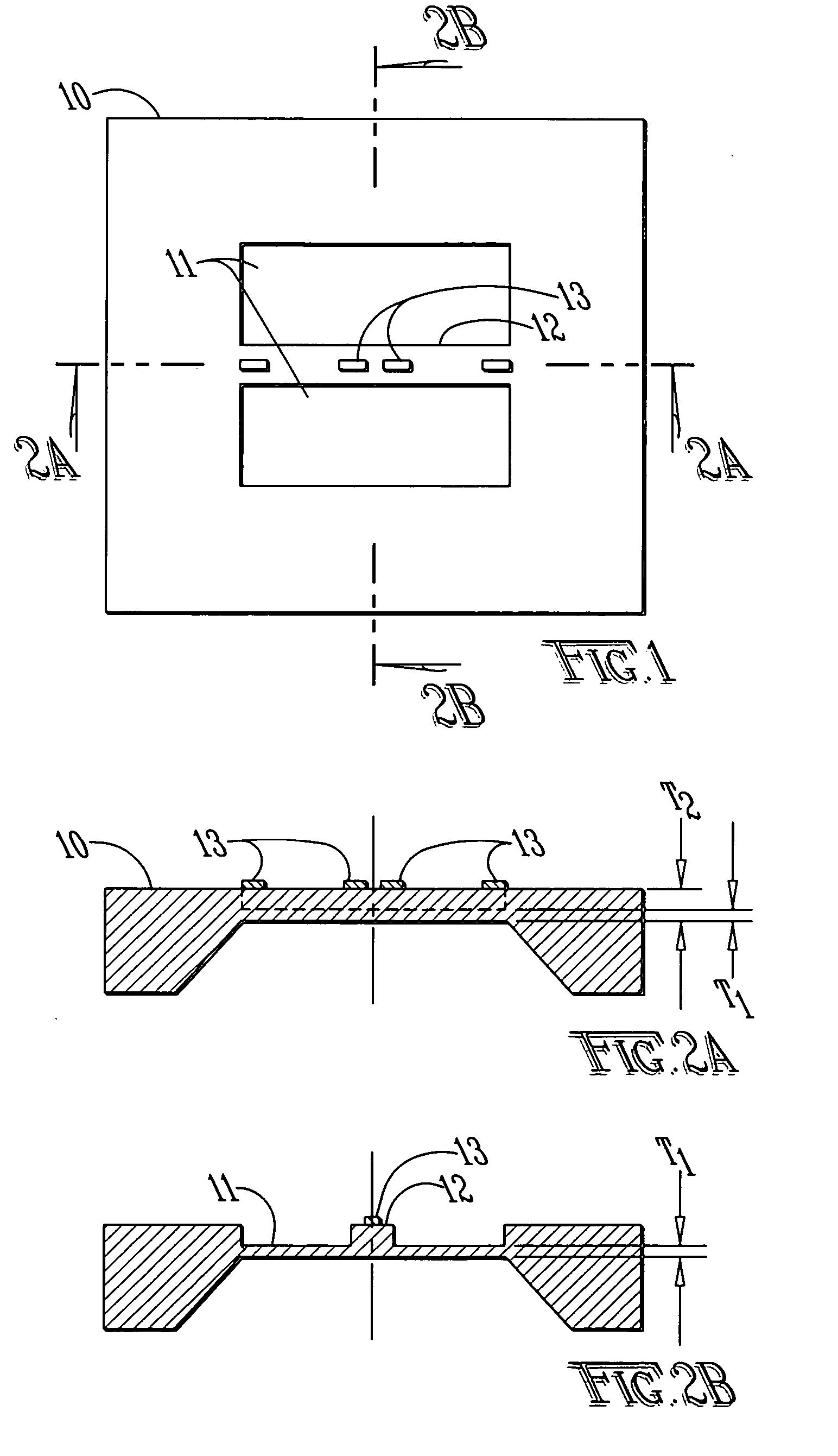

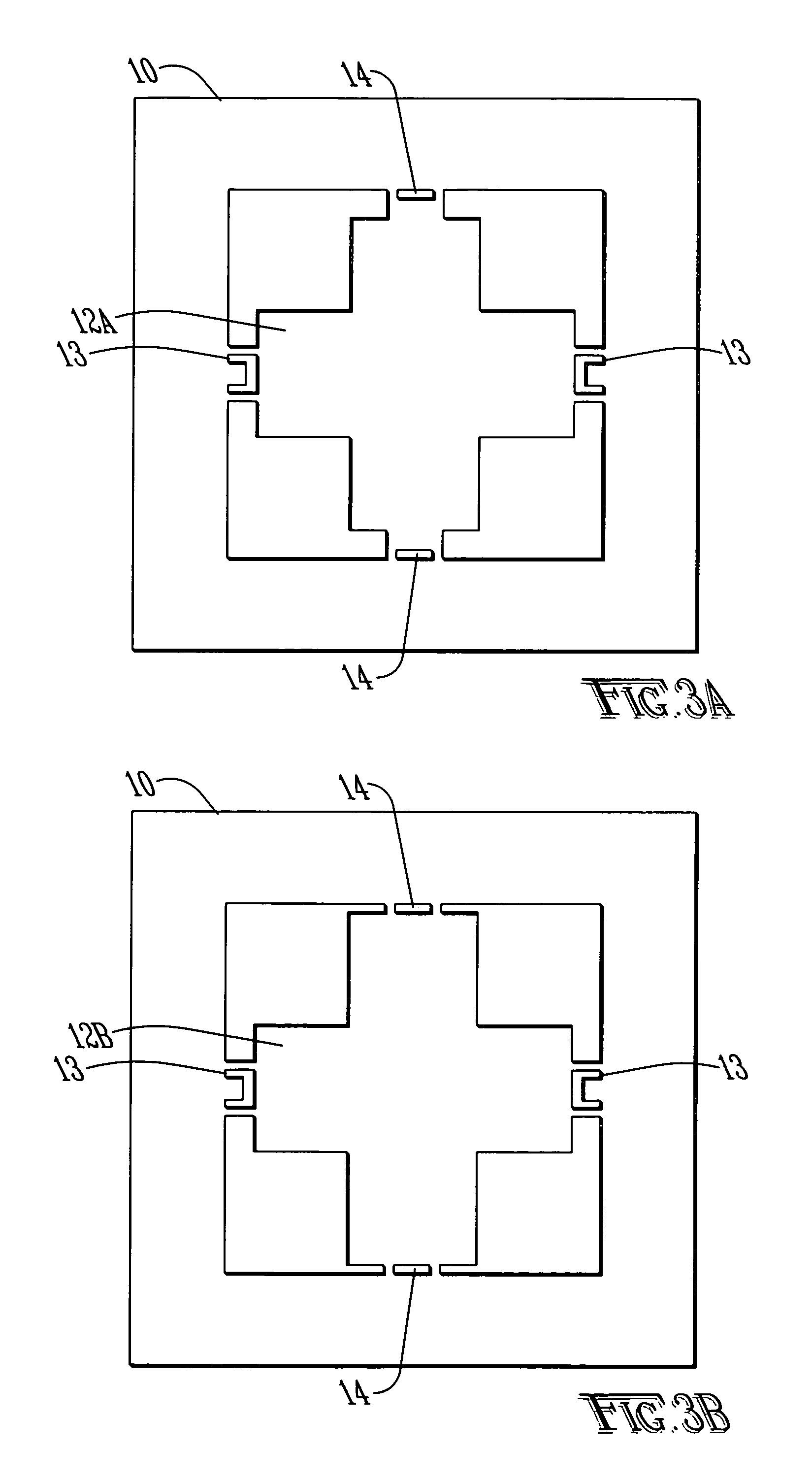

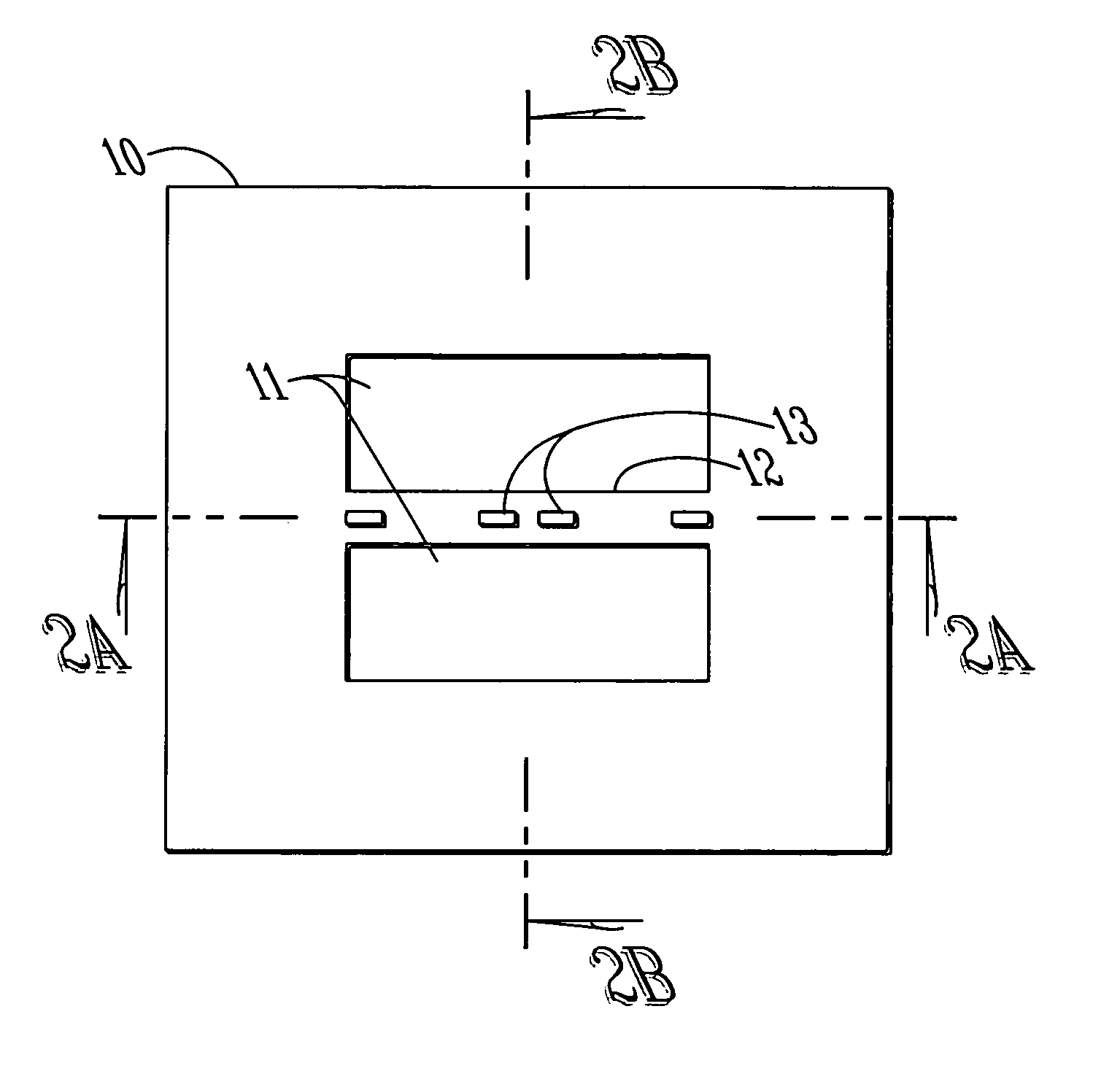

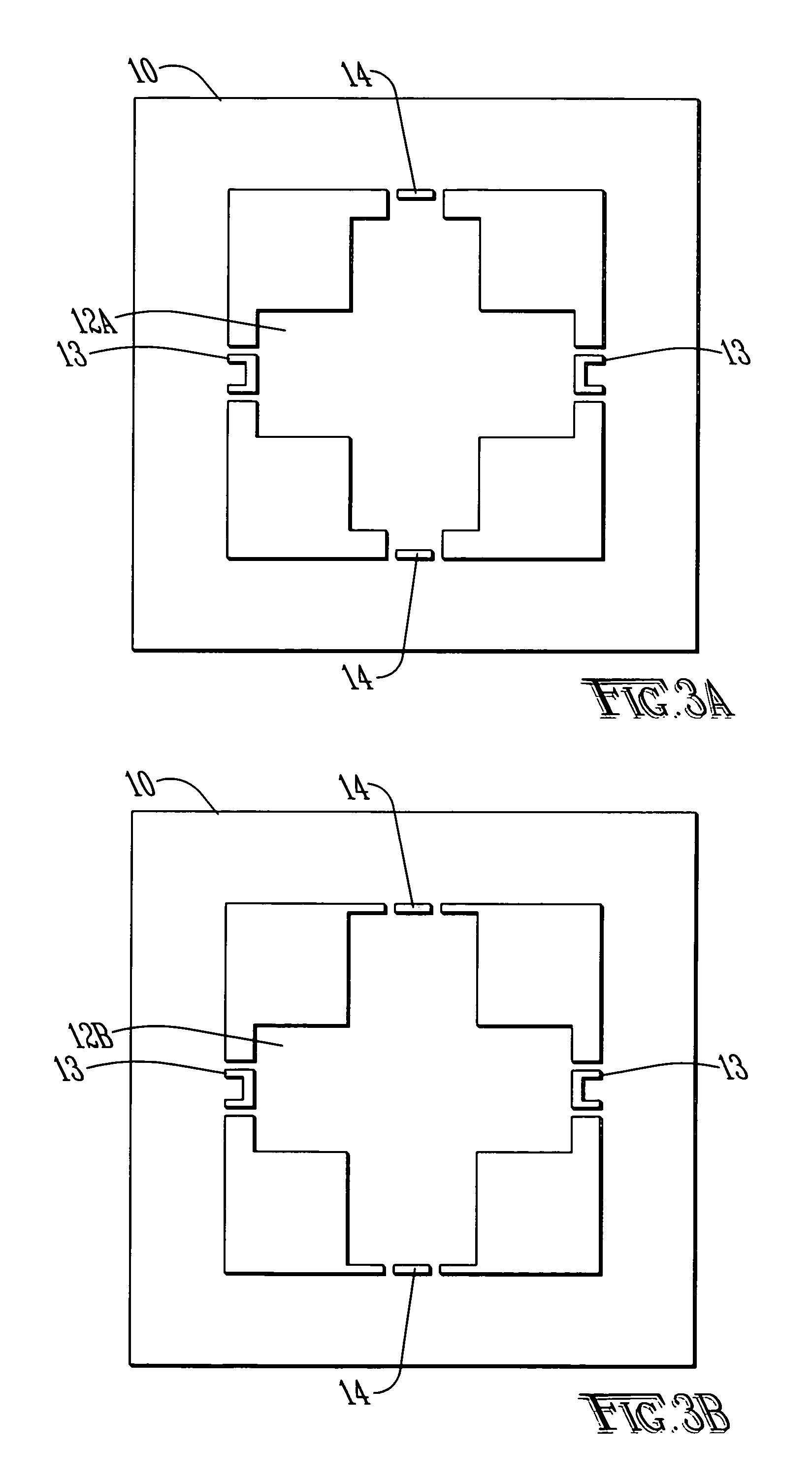

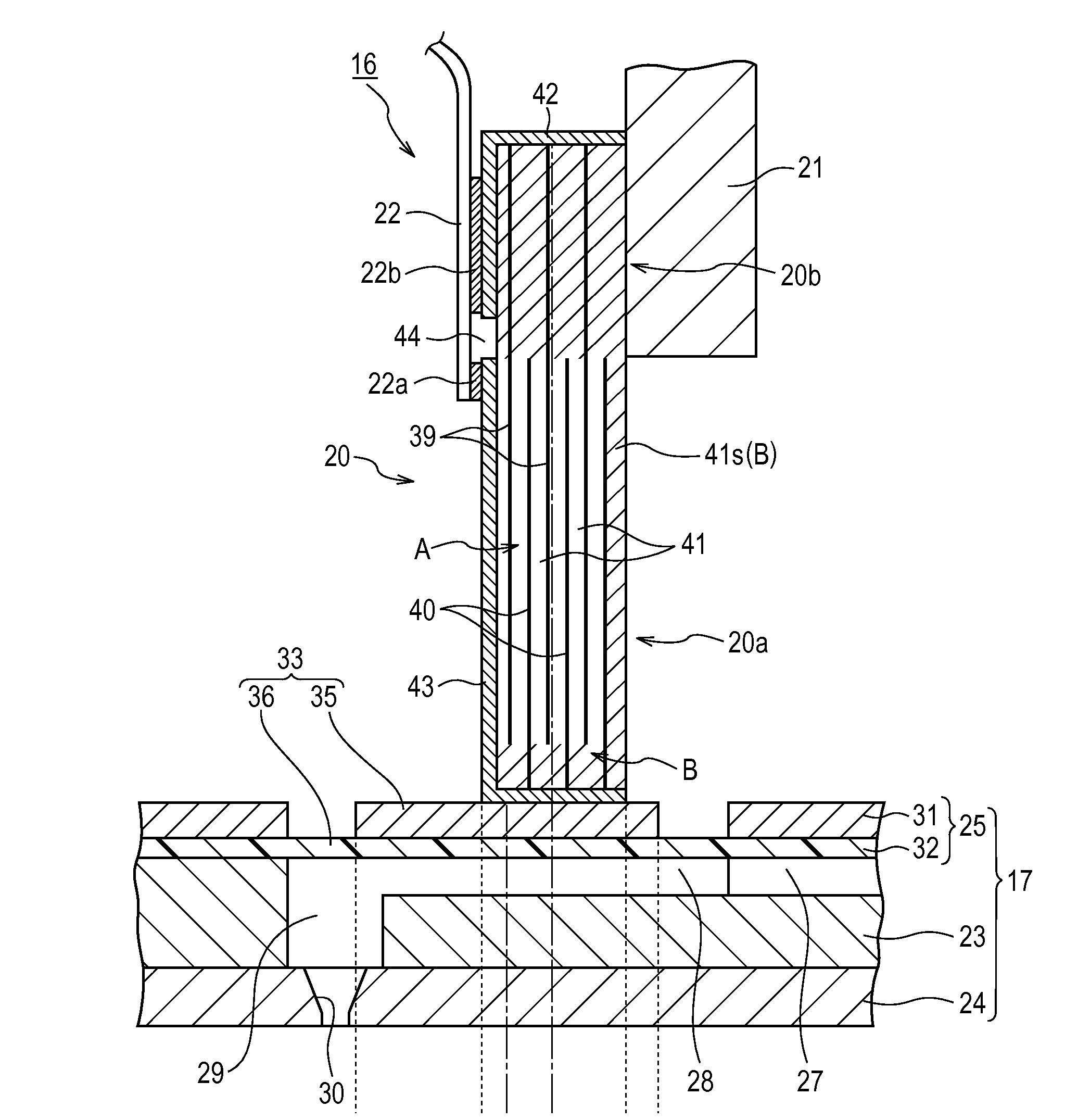

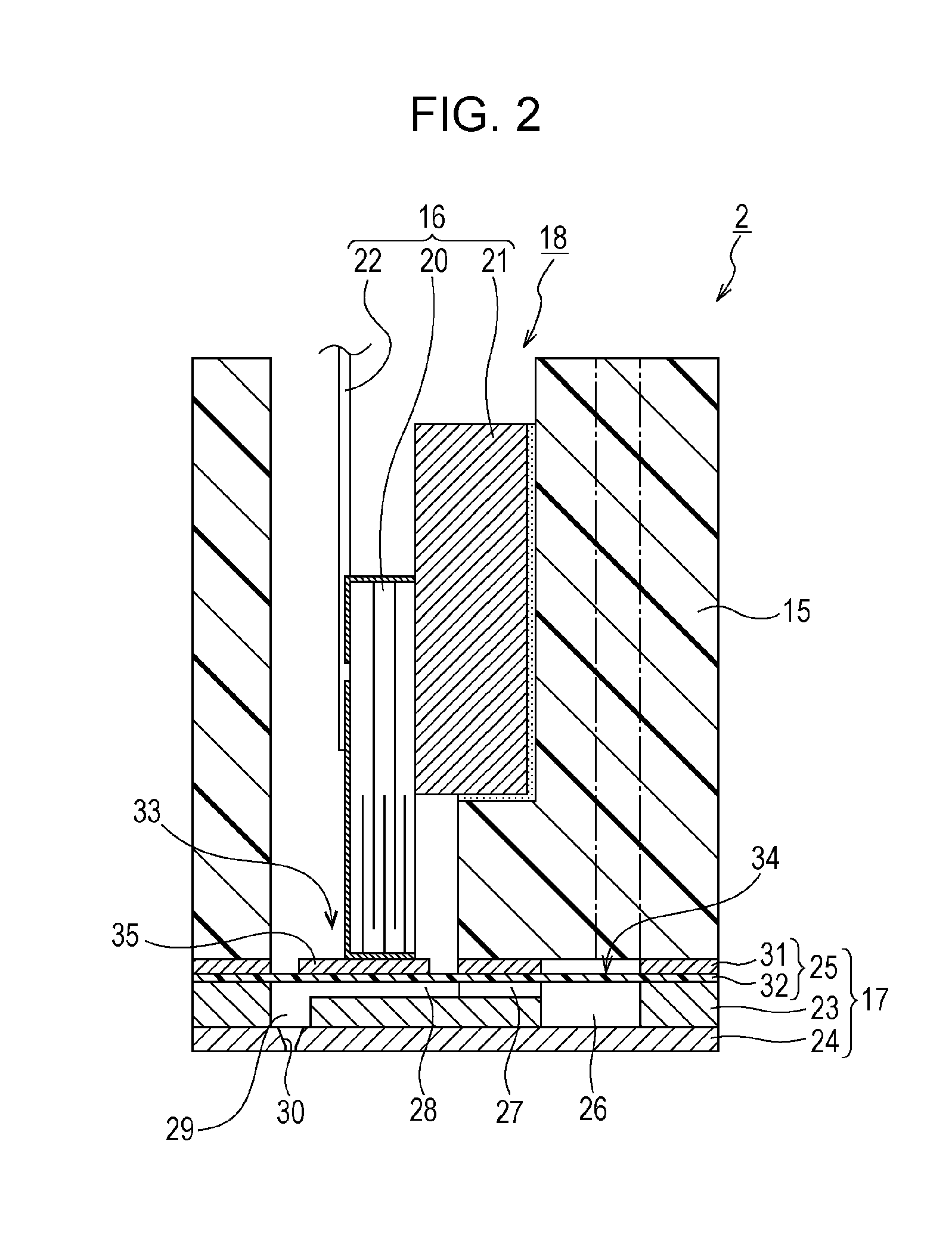

Composite MEMS pressure sensor configuration

ActiveUS20060144153A1Control deflectionReduce gravity errorFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesCantilevered beamMems pressure sensor

A pressure sensor assembly comprised of a single and dual layer diaphragm with integrated force sensing flexure, such as a cantilever beam. Strain gages are positioned on the force sensing beam. The pressure forces the diaphragm to deflect. The deflection is constrained by the beam, which is compelled to bend. The bending induces strains in strain gages located on the beam. The strain gages are connected in a Wheatstone bridge configuration. When a voltage is applied to the bridge, the strain gages provide an electrical output signal proportional to the pressure. Composite diaphragm—beam pressure sensors convert pressure more efficiently and improve sensor performance.

Owner:BROSH AMNON

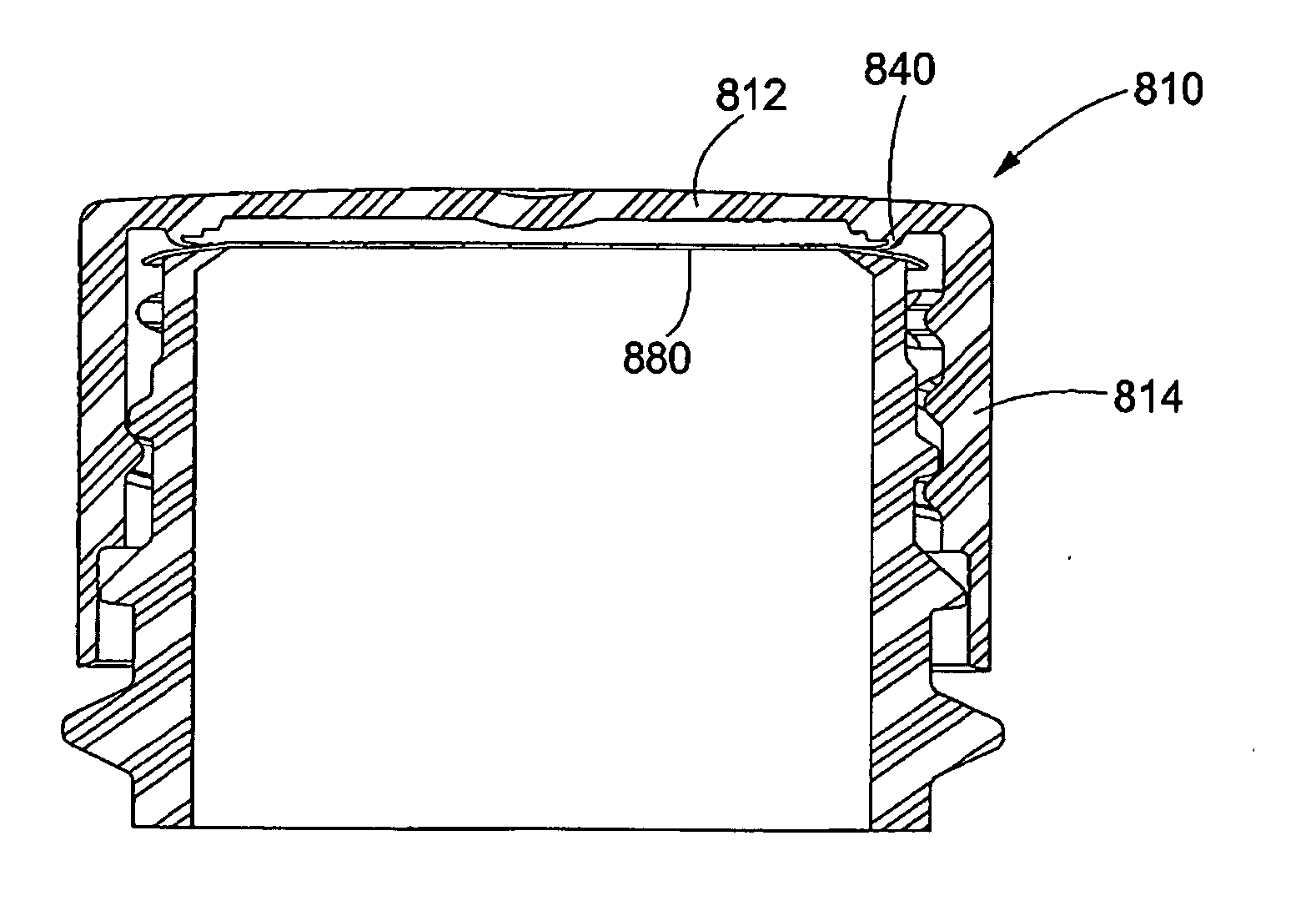

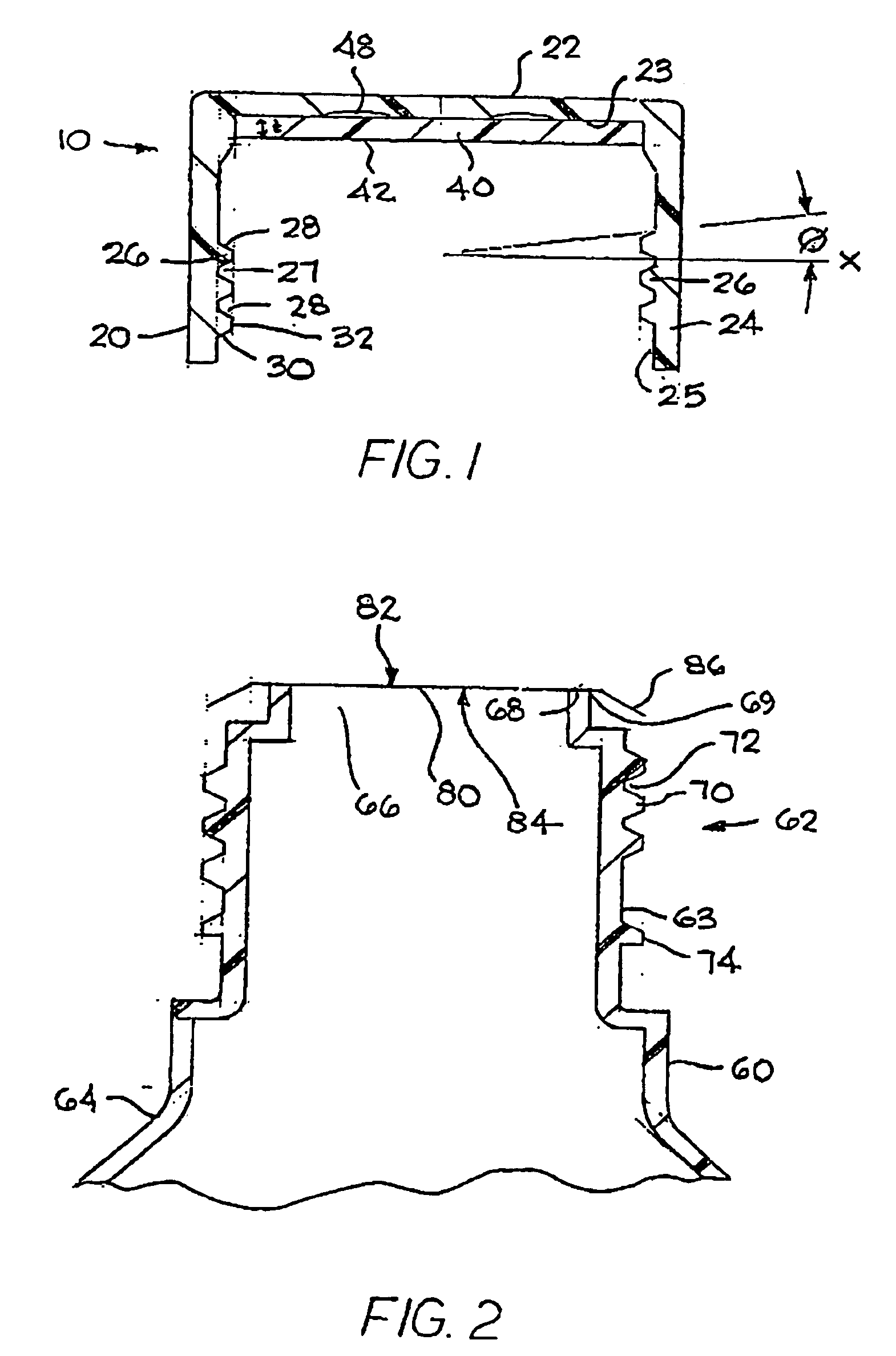

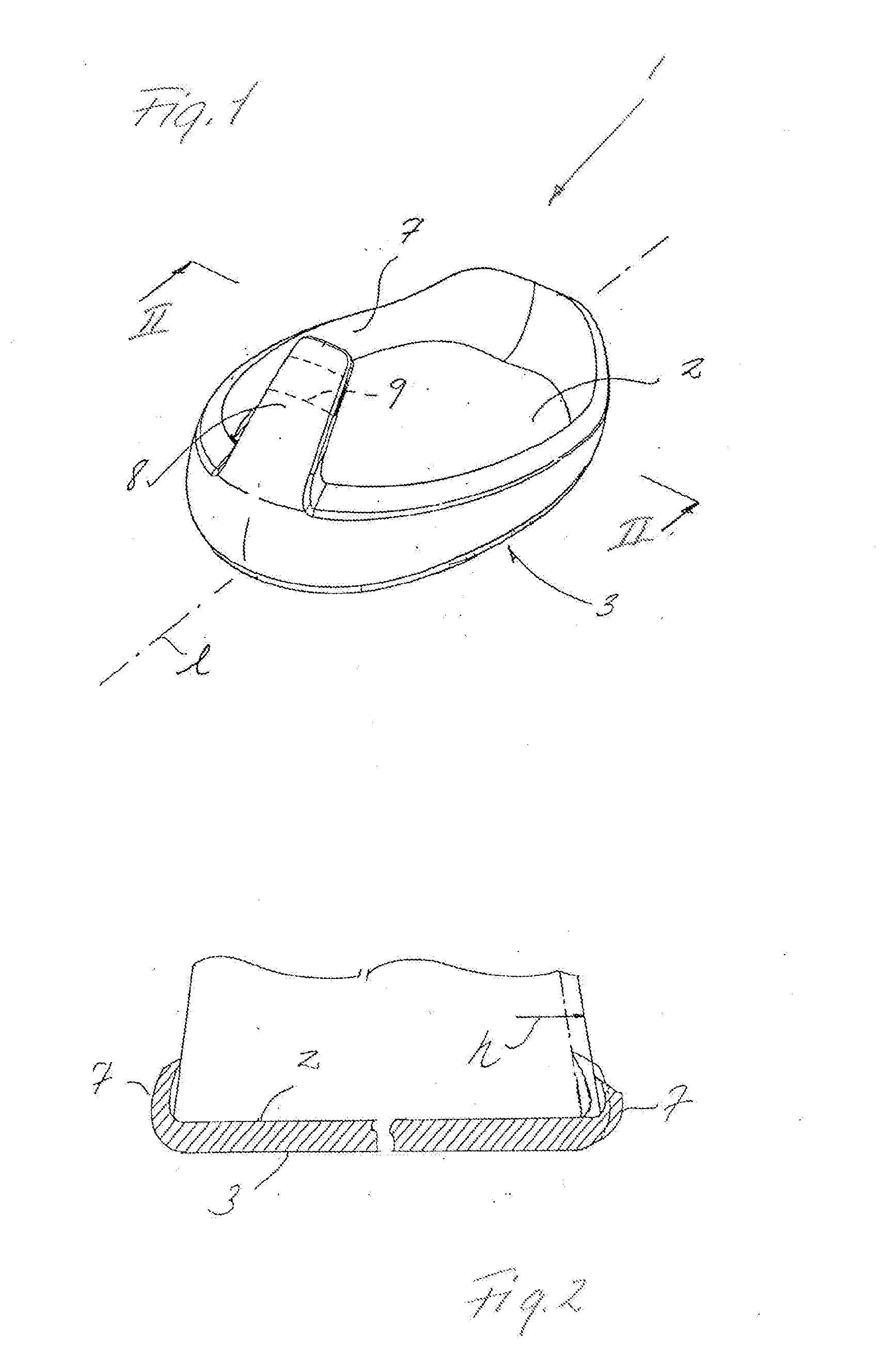

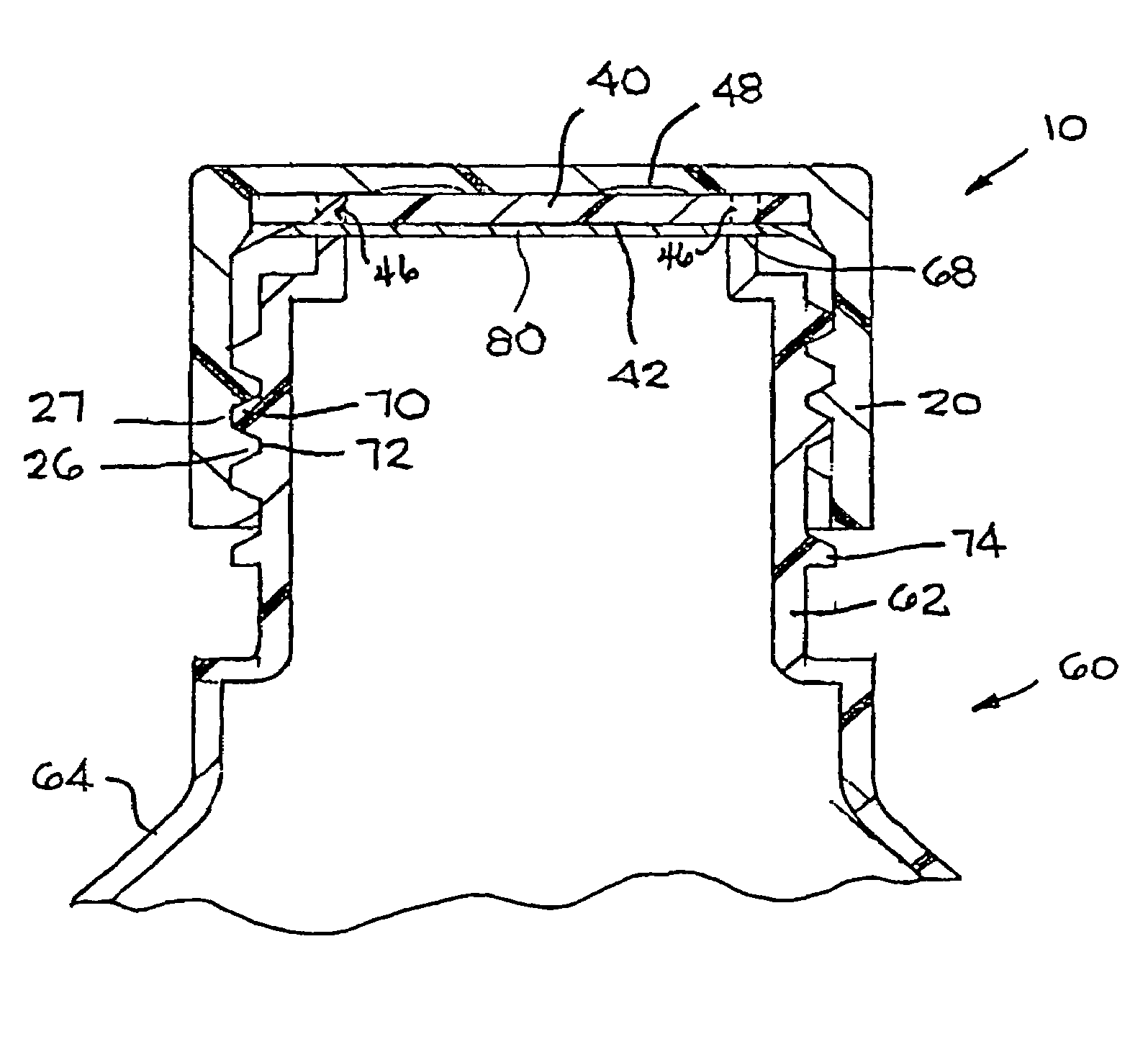

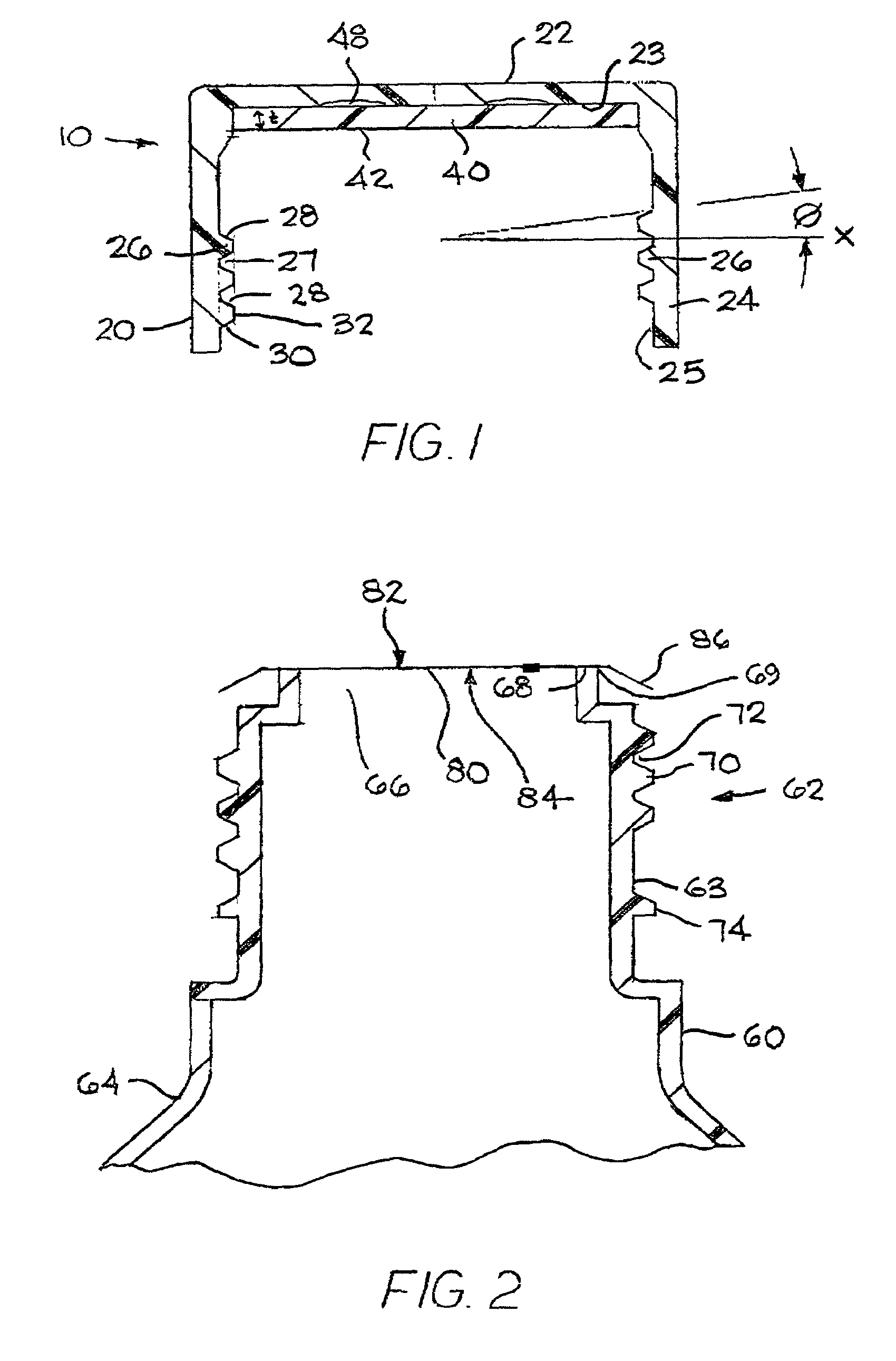

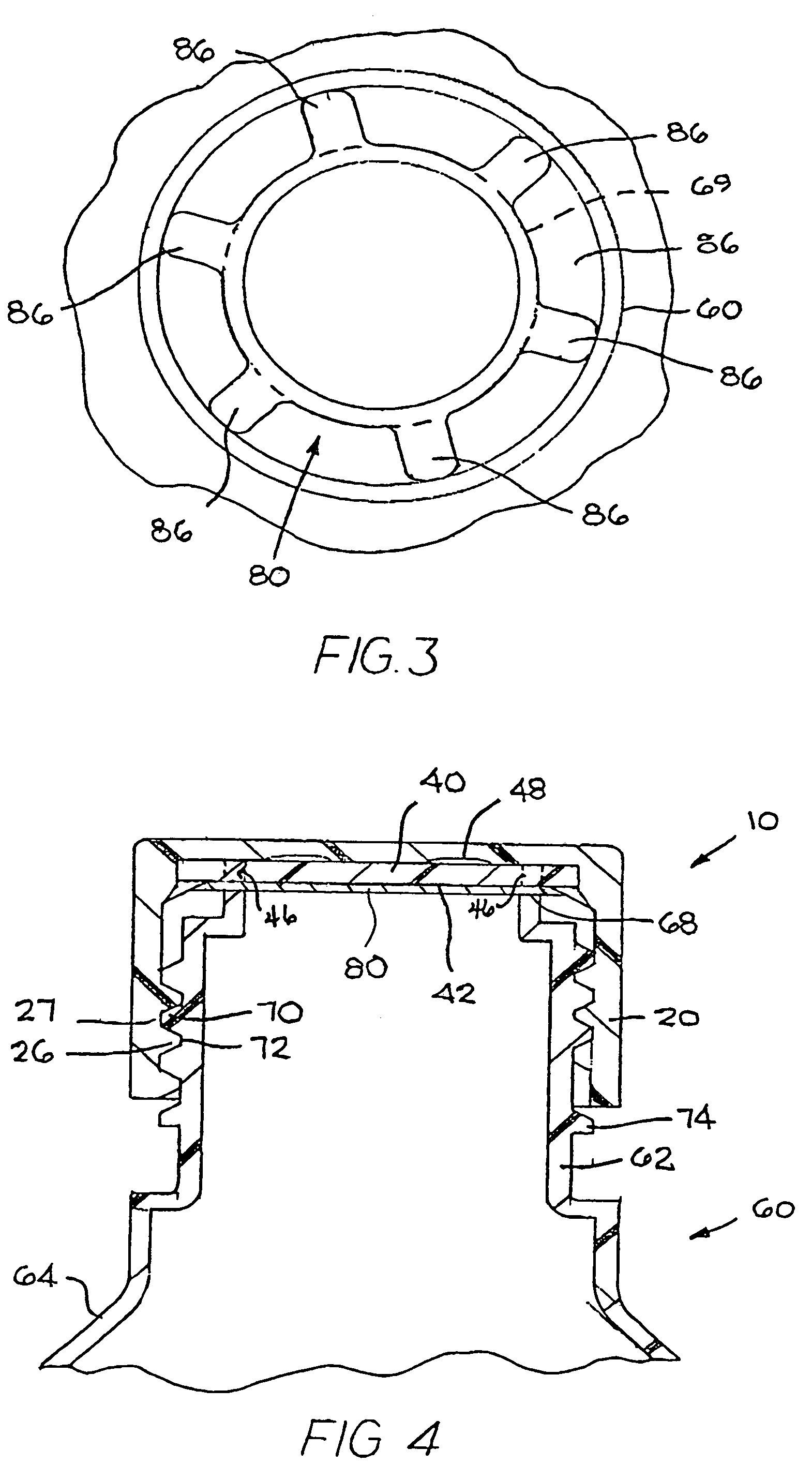

Closure for a Retort Processed Container Having a Peelable Seal

InactiveUS20070125785A1Effective pressurePrevent leakageCapsClosure using stoppersEngineeringMechanical engineering

A closure for maintaining pressure against a seal affixed to a container lip during a thermal sterilization process includes a top wall and an annular skirt depending from said top wall, at least one retaining structure extending from the annular skirt, a reseal structure rotatably disposed above said retaining structure and adjacent said top wall, an inner seal rotatably disposed above the retaining structure and beneath a lower surface of said reseal structure, wherein said inner seal and said reseal structure are both rotatable relative to said closure.

Owner:BERRY PLASTICS CORP

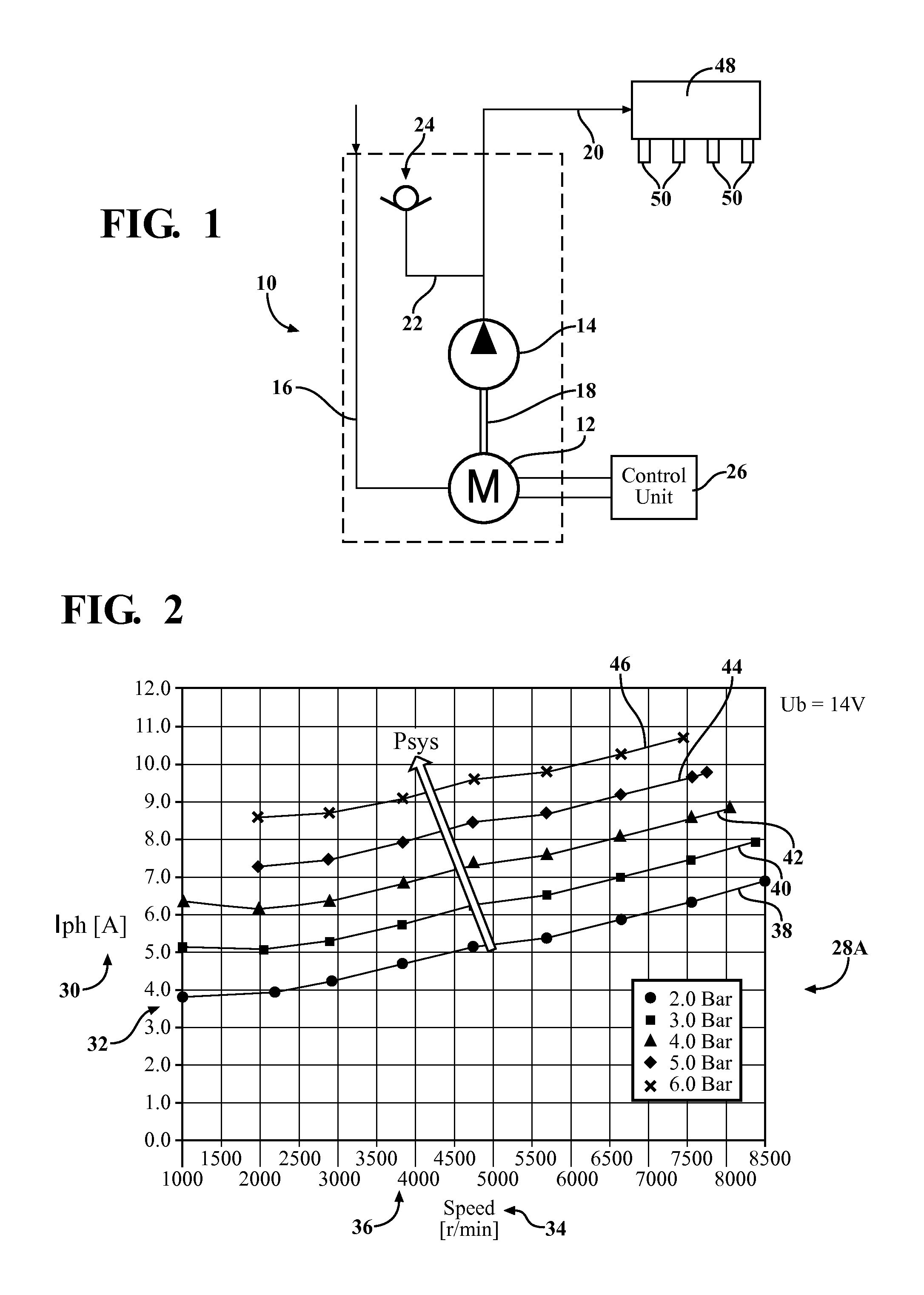

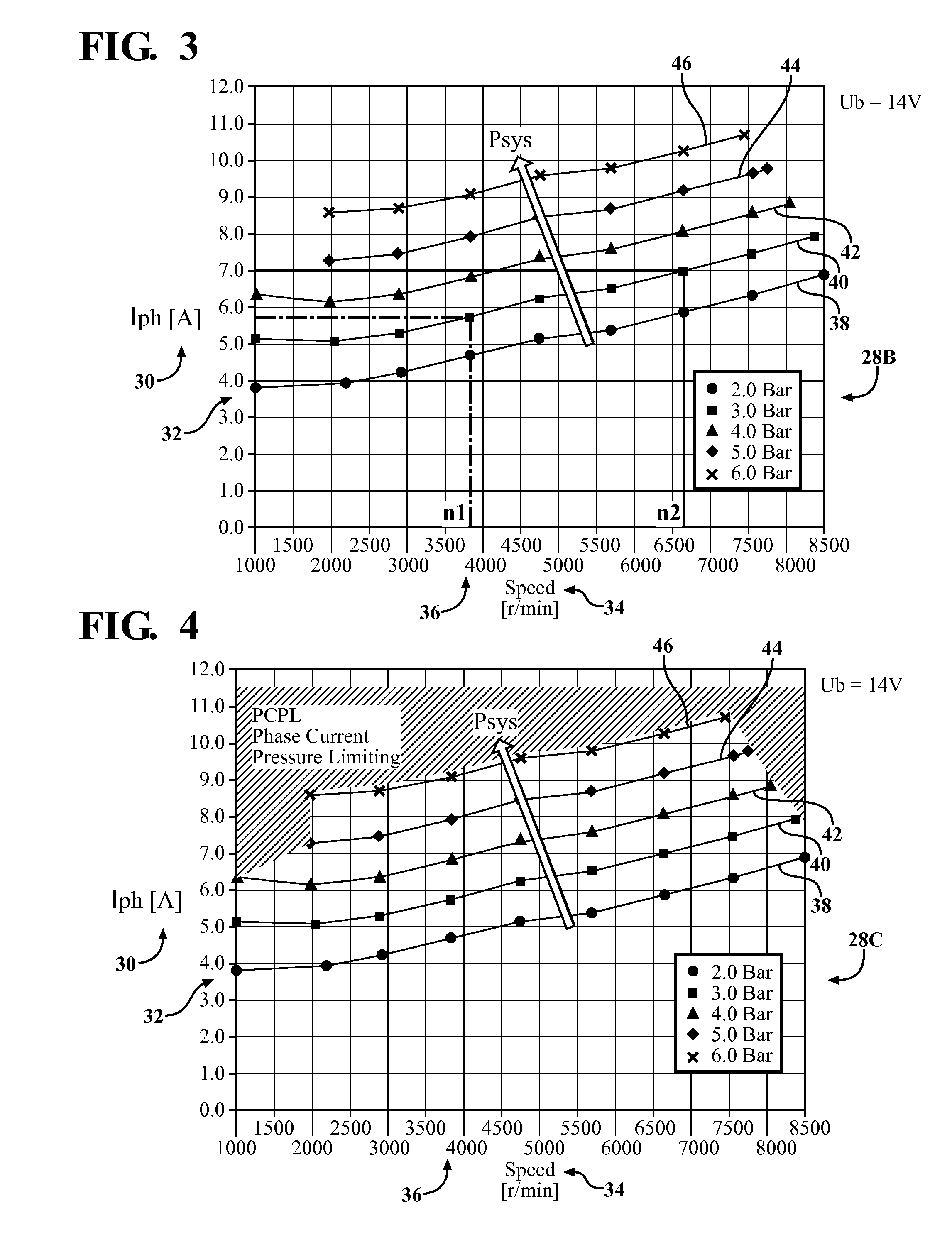

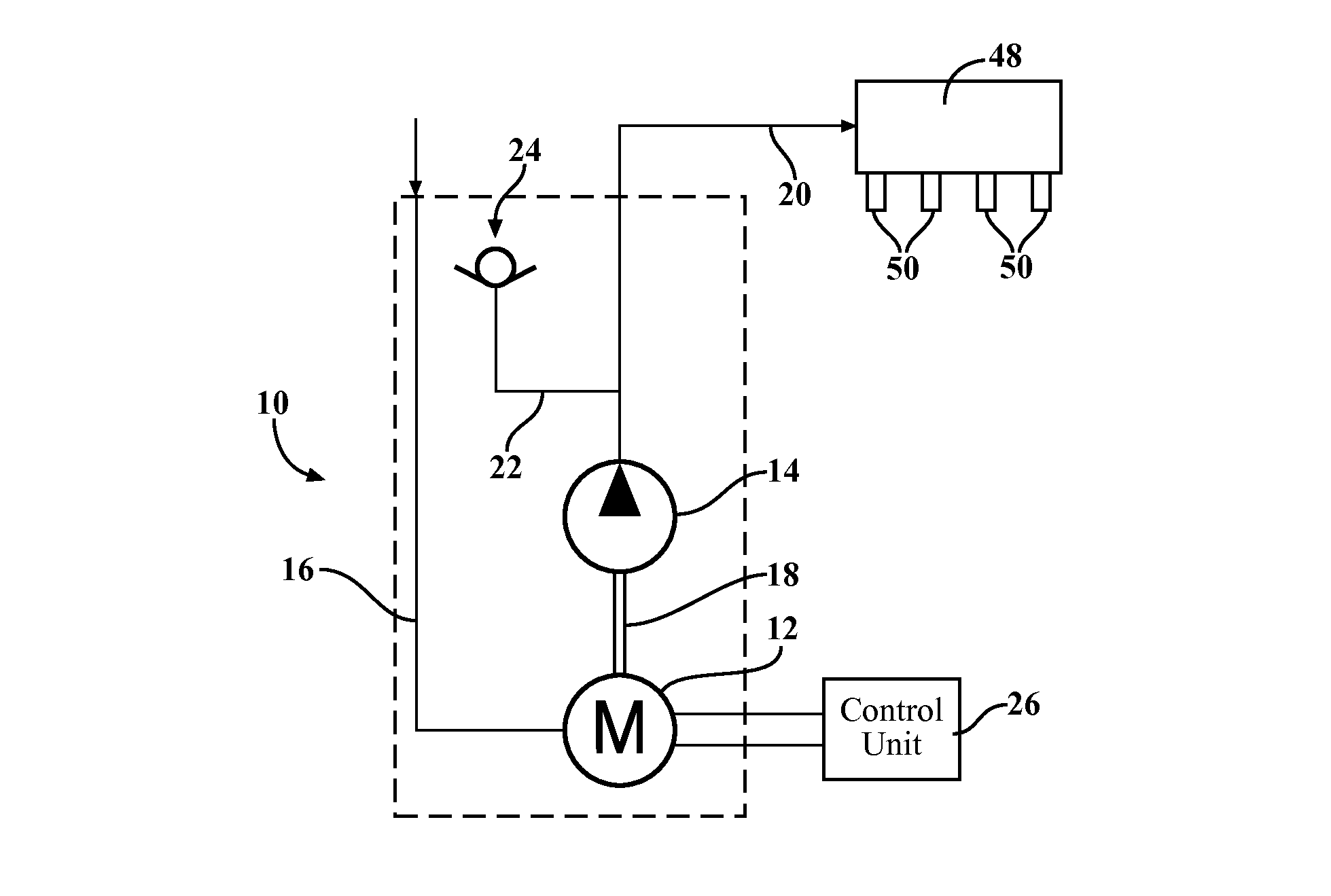

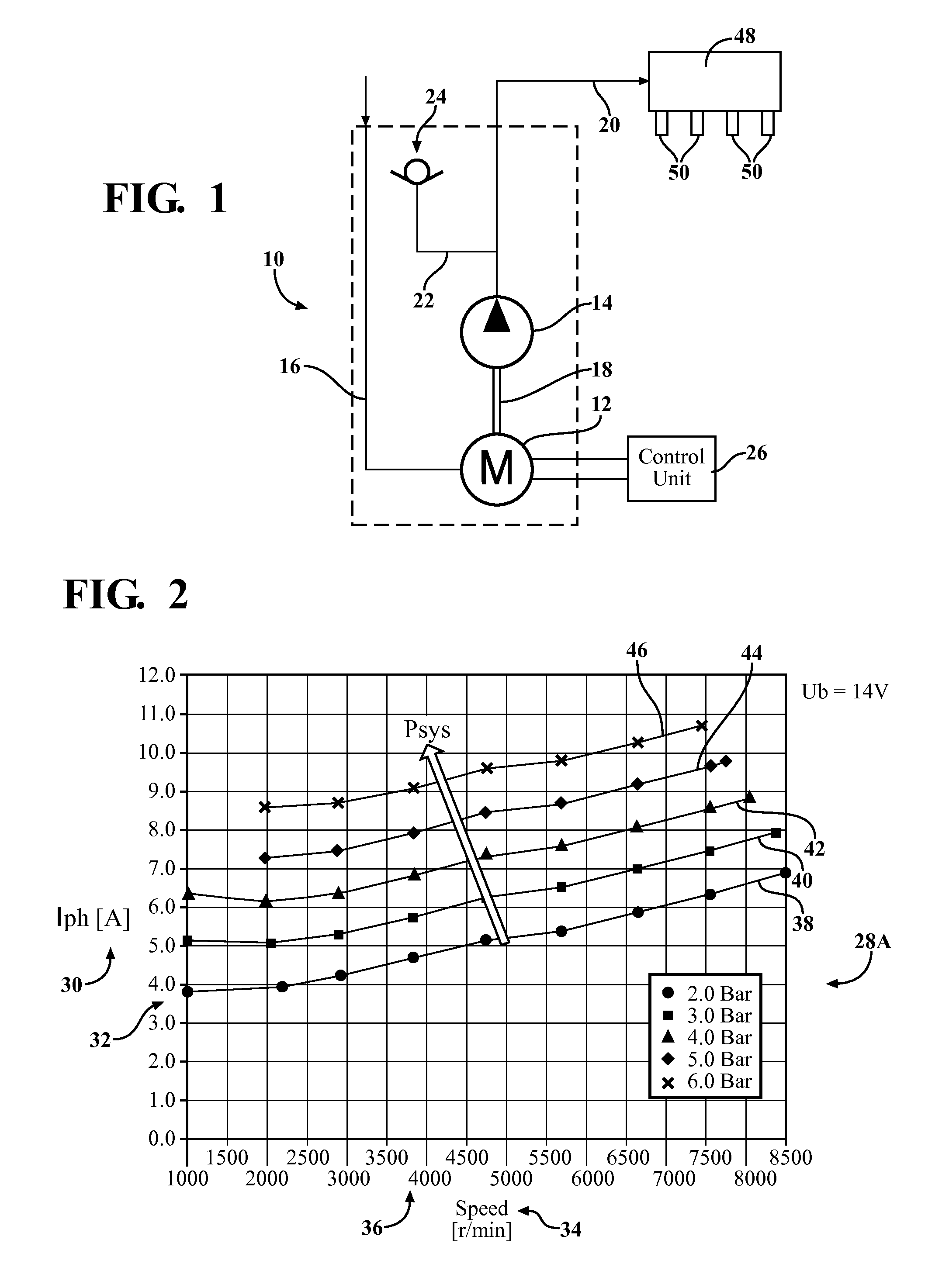

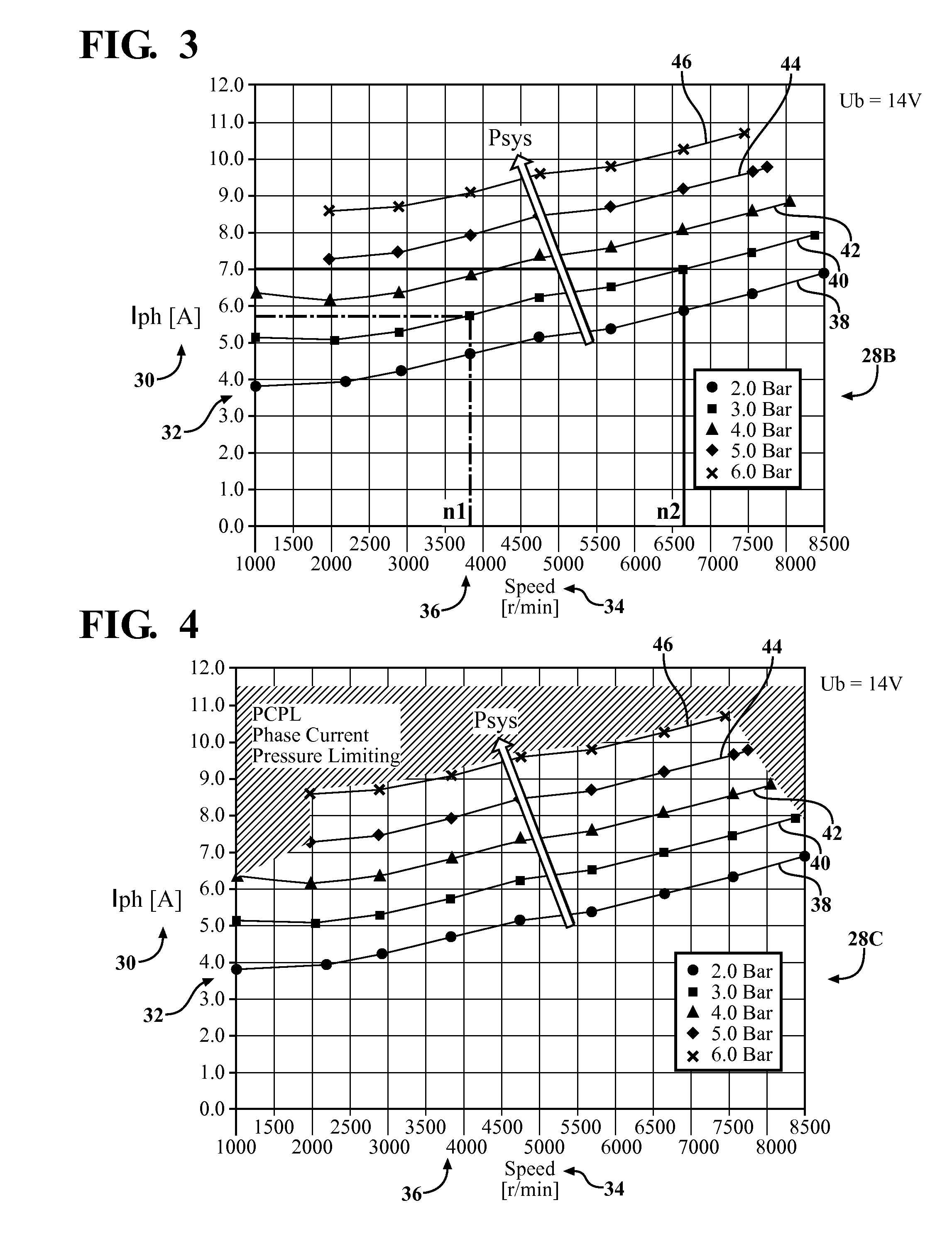

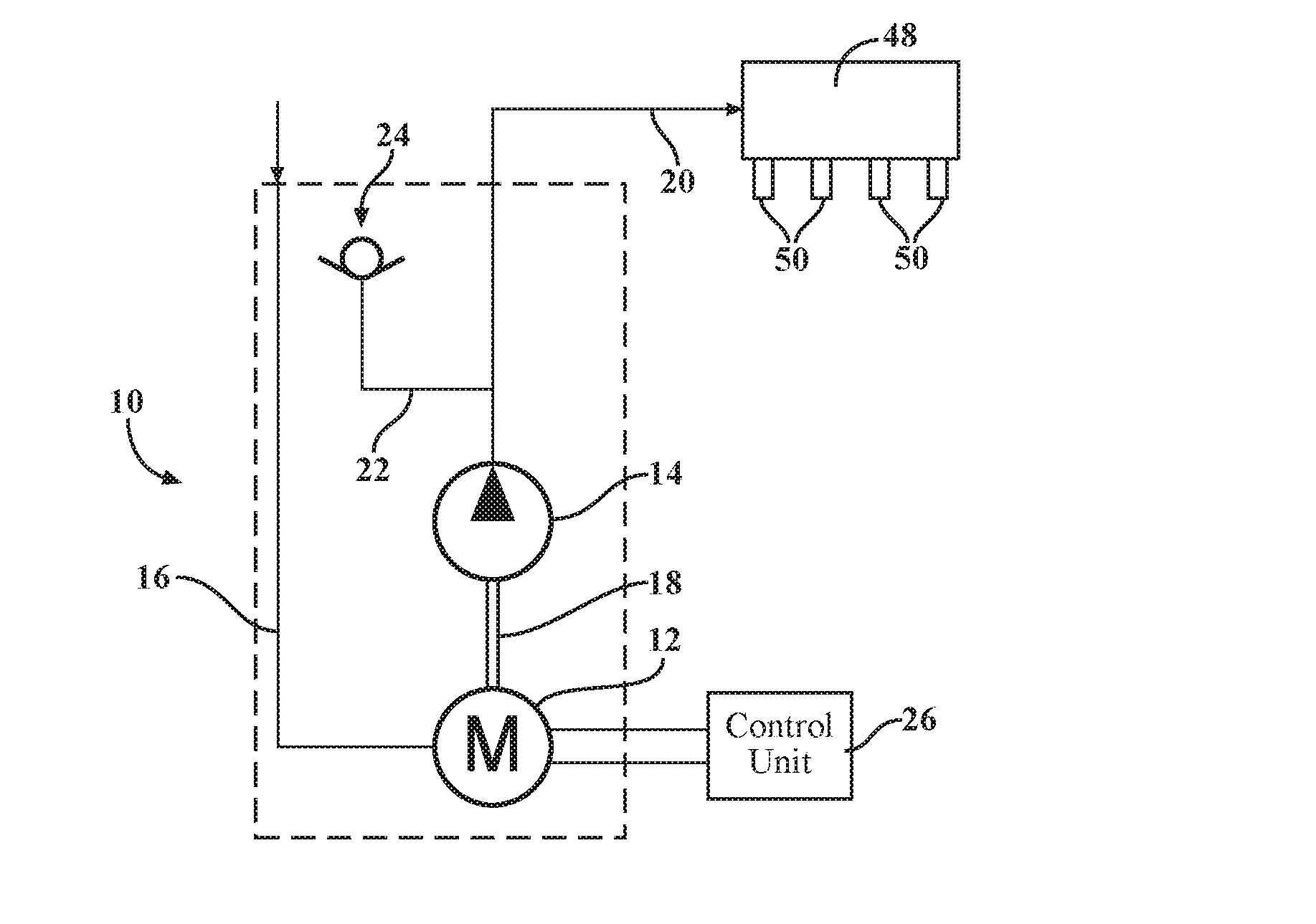

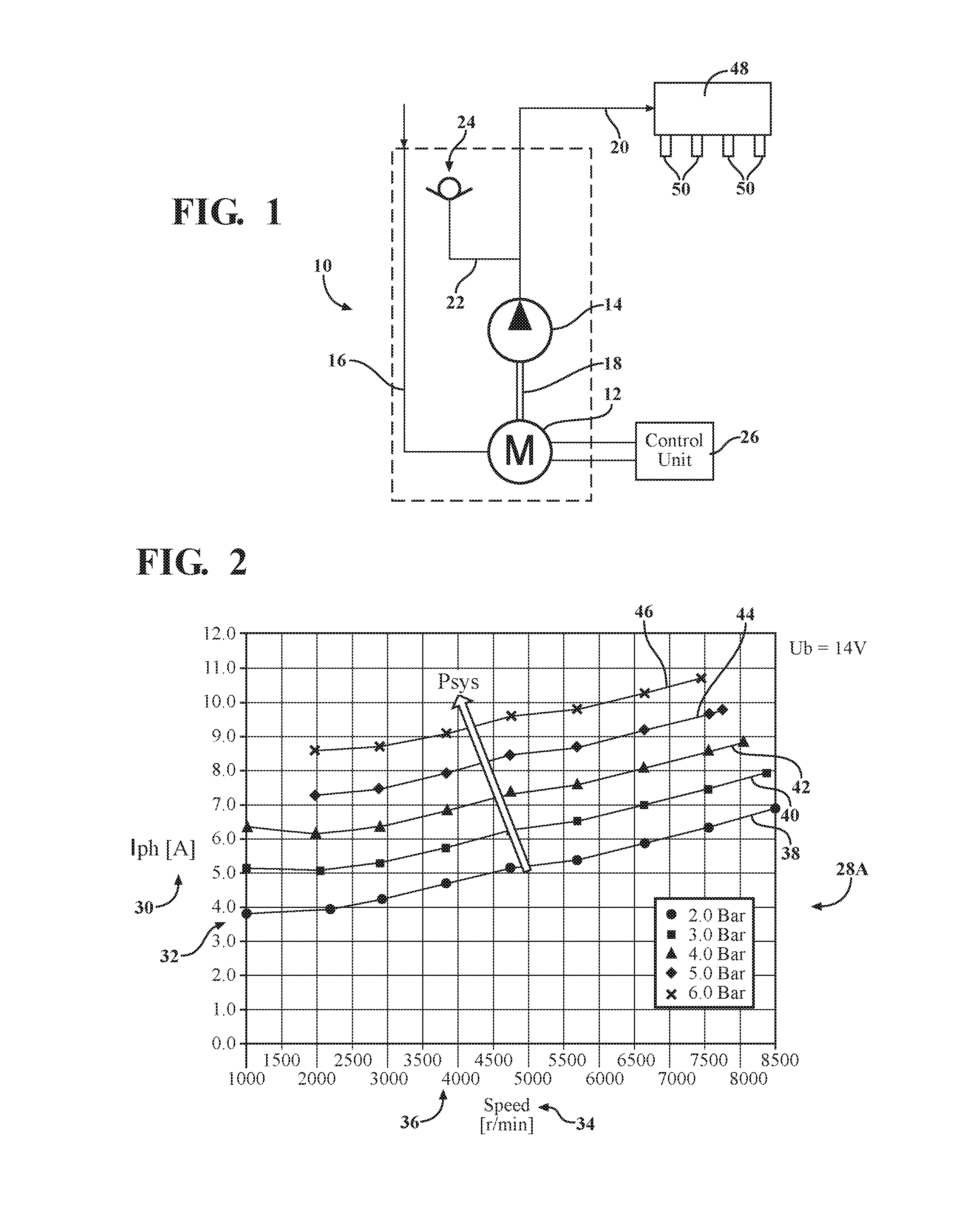

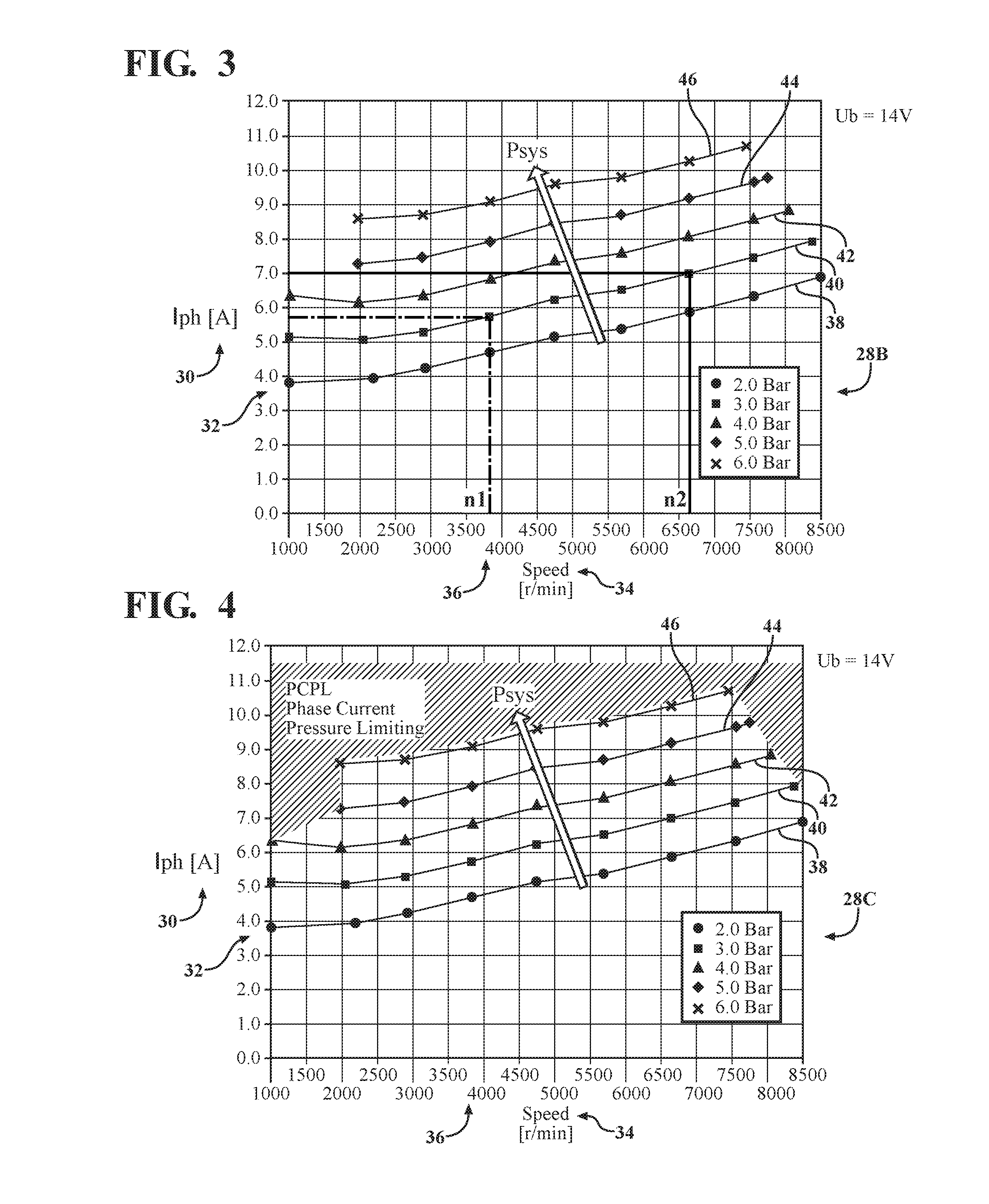

Pressure control by phase current and initial adjustment at car line

A closed loop control system for a fuel pump based on characteristics of speed, pressure, and current. The pressure generated by the pump system is increased at the point in time when the pump system is working against a dead head system (i.e., coasting) to a level that a calibration valve is opened to a determined working point. By measuring the characteristic phase current as a function of the speed, the characteristic is able to be compared, with the pre-calibrated value of the hardware to perform an error compensation algorithm. The error compensation is overlaid with the standard pressure characteristic as a function of speed and phase current, and uses the pre-calibrated opening pressure value (i.e., the inflection point) of the calibration valve and / or in addition the change of the speed to the initial (first calibration), or to a sliding average therefrom.

Owner:VITESCO TECH USA LLC

Composite MEMS pressure sensor configuration

ActiveUS7290453B2Control deflectionMaximizes strainFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesMems pressure sensorEngineering

A pressure sensor assembly comprised of a single and dual layer diaphragm with integrated force sensing flexure, such as a cantilever beam. Strain gages are positioned on the force sensing beam. The pressure forces the diaphragm to deflect. The deflection is constrained by the beam, which is compelled to bend. The bending induces strains in strain gages located on the beam. The strain gages are connected in a Wheatstone bridge configuration. When a voltage is applied to the bridge, the strain gages provide an electrical output signal proportional to the pressure. Composite diaphragm—beam pressure sensors convert pressure more efficiently and improve sensor performance.

Owner:BROSH AMNON

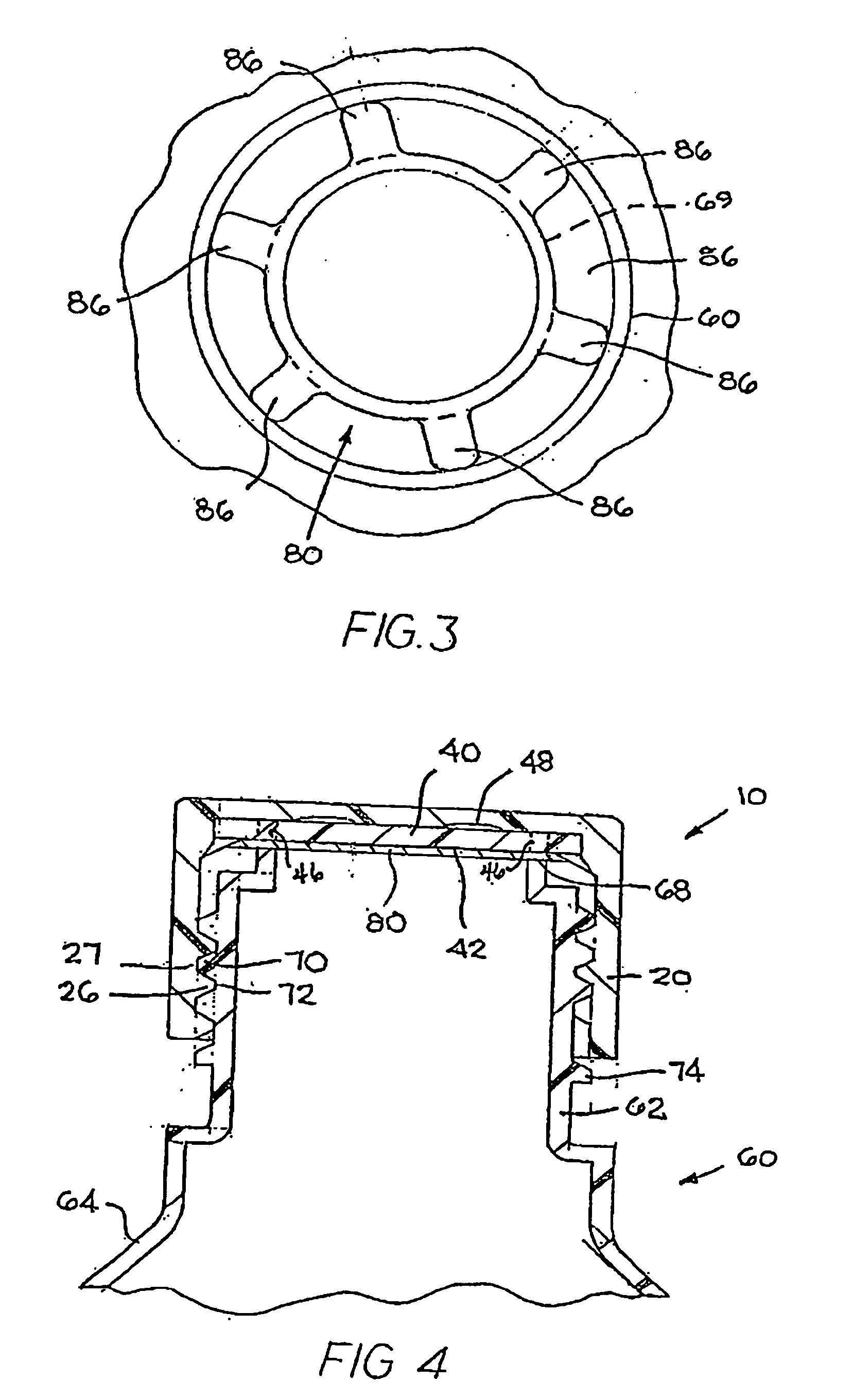

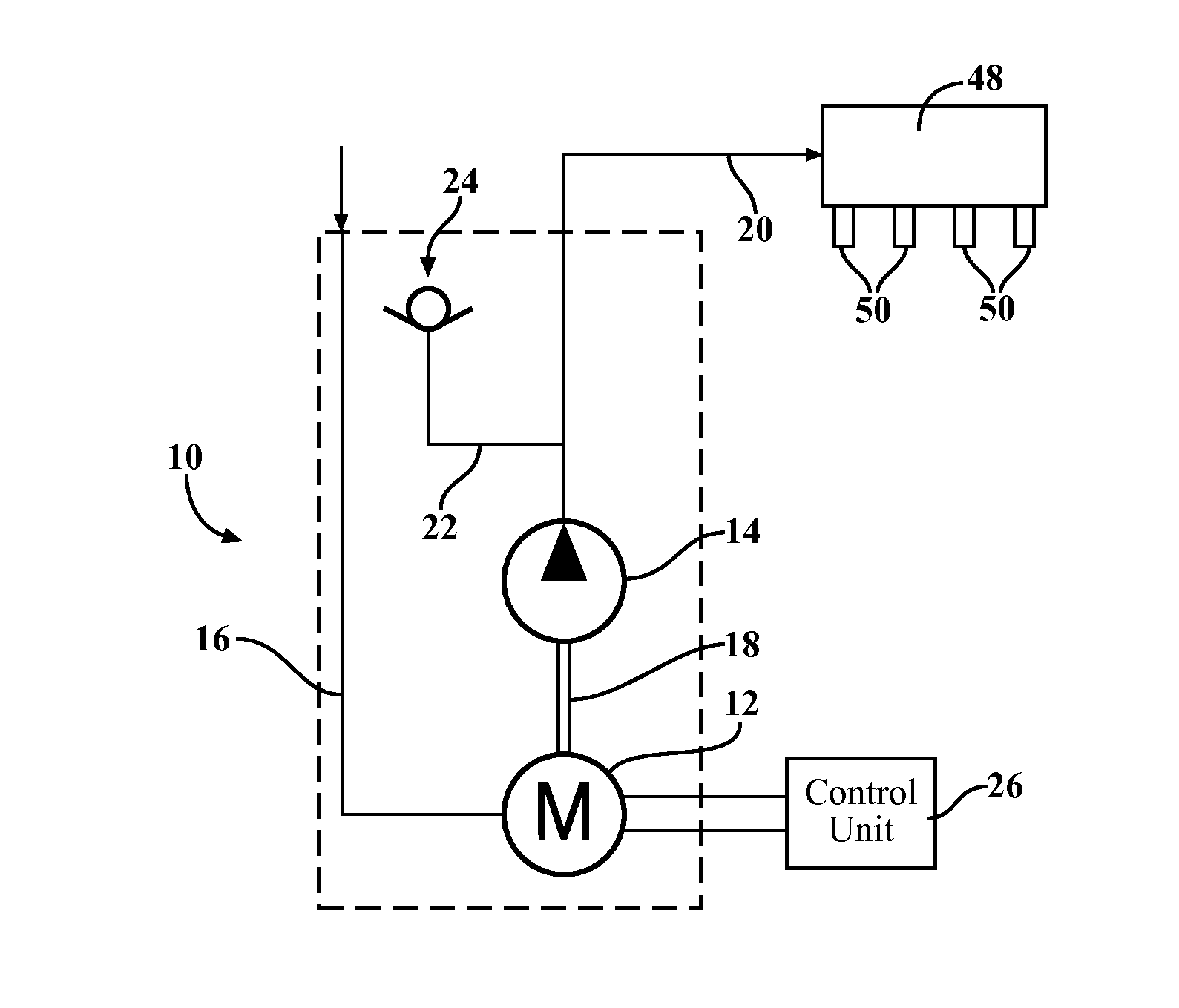

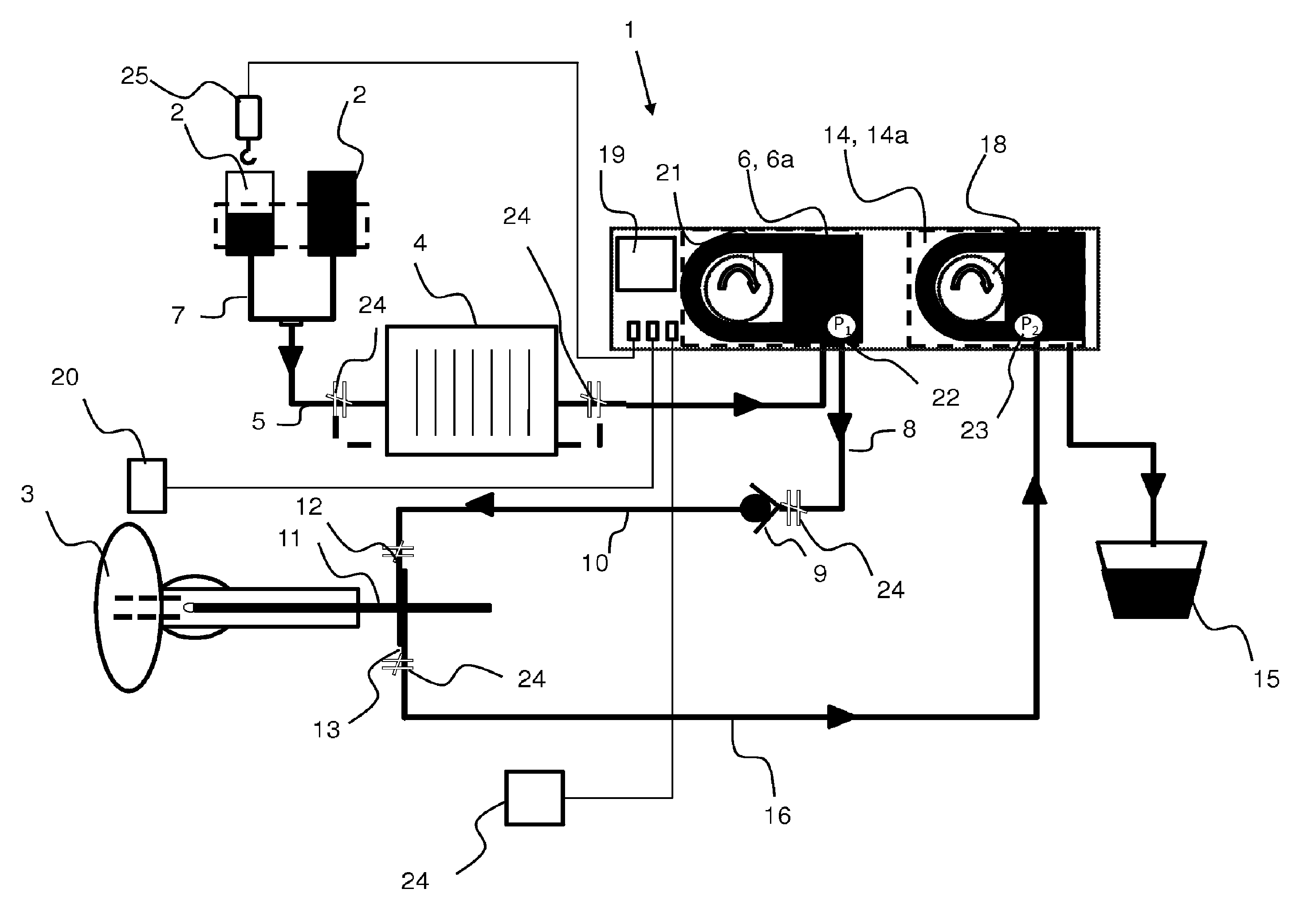

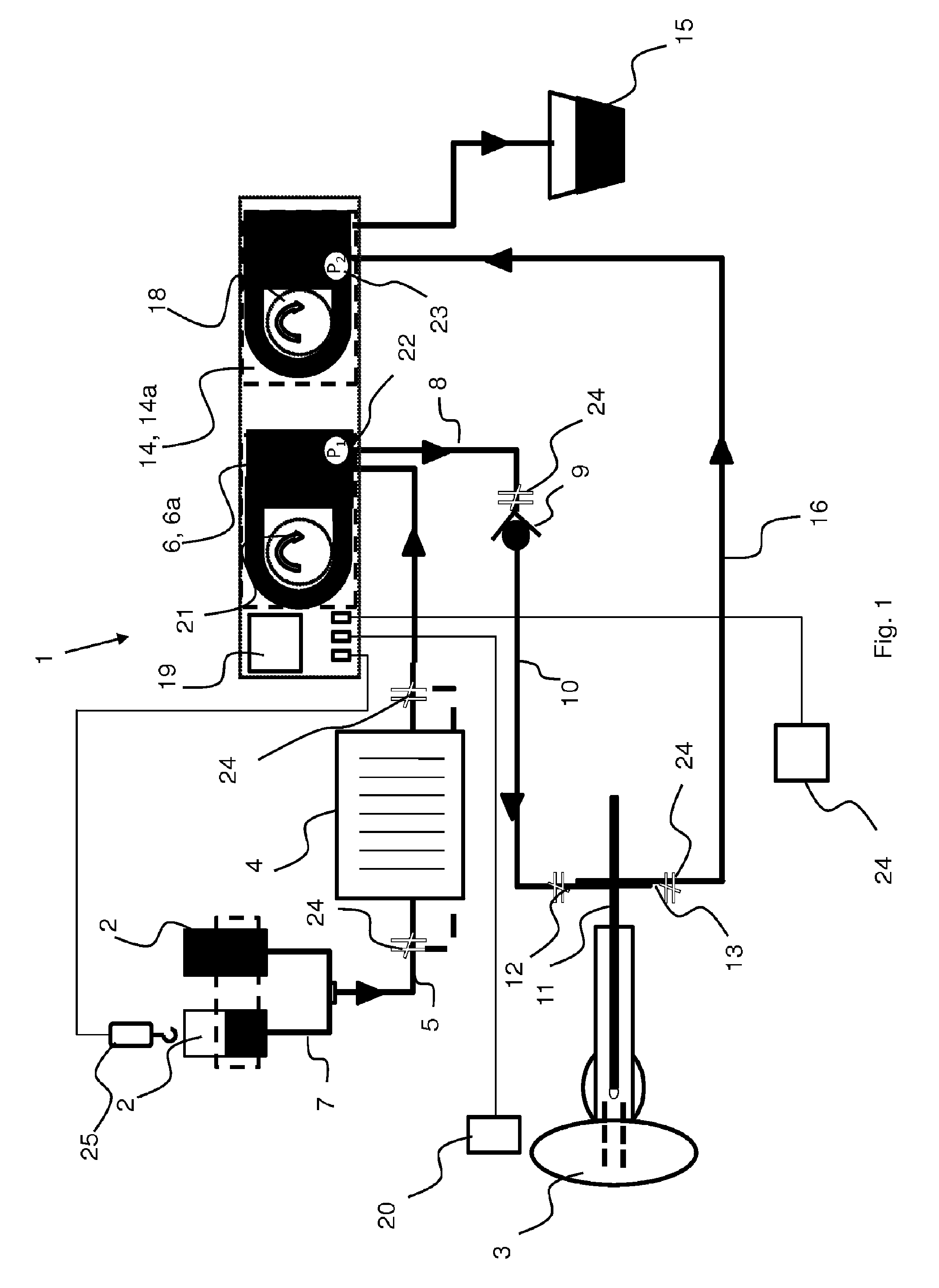

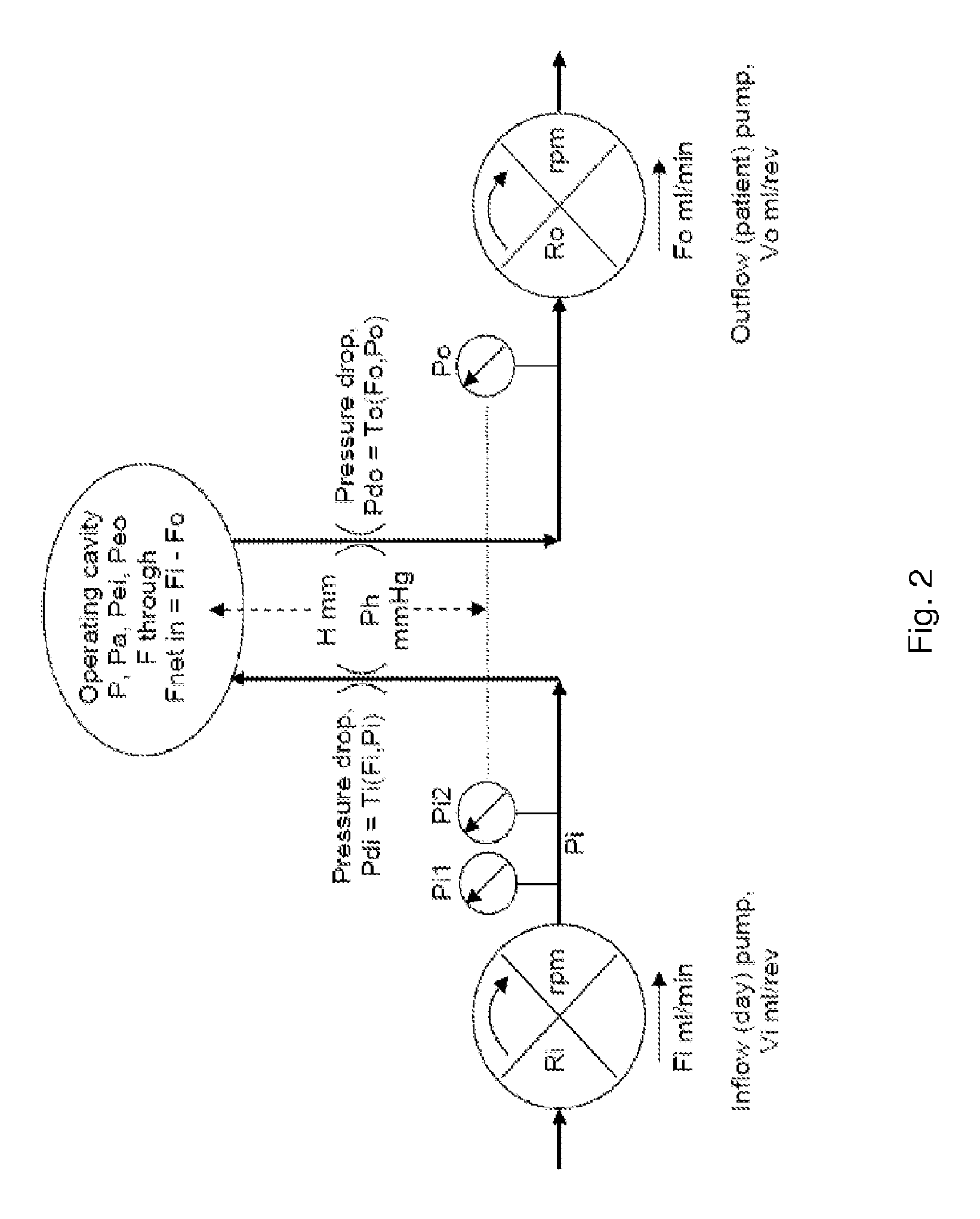

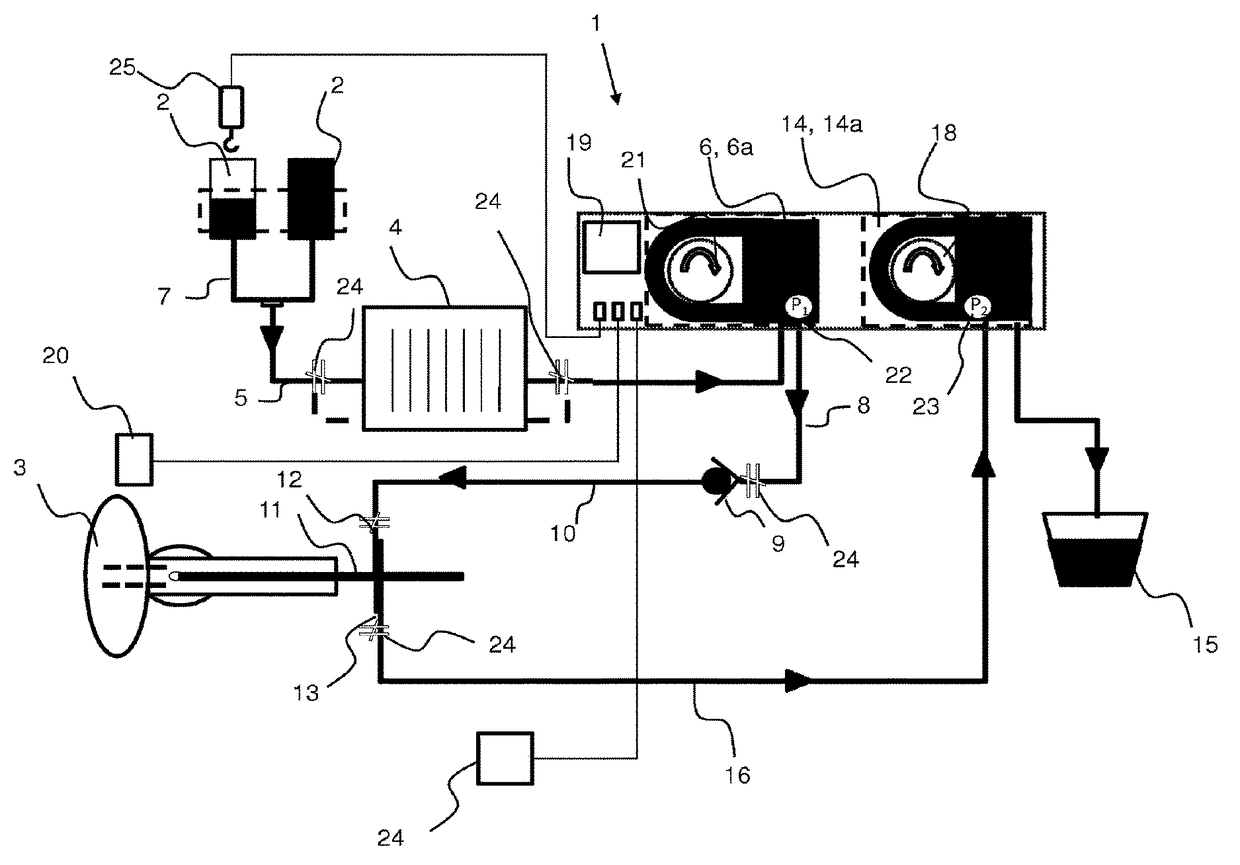

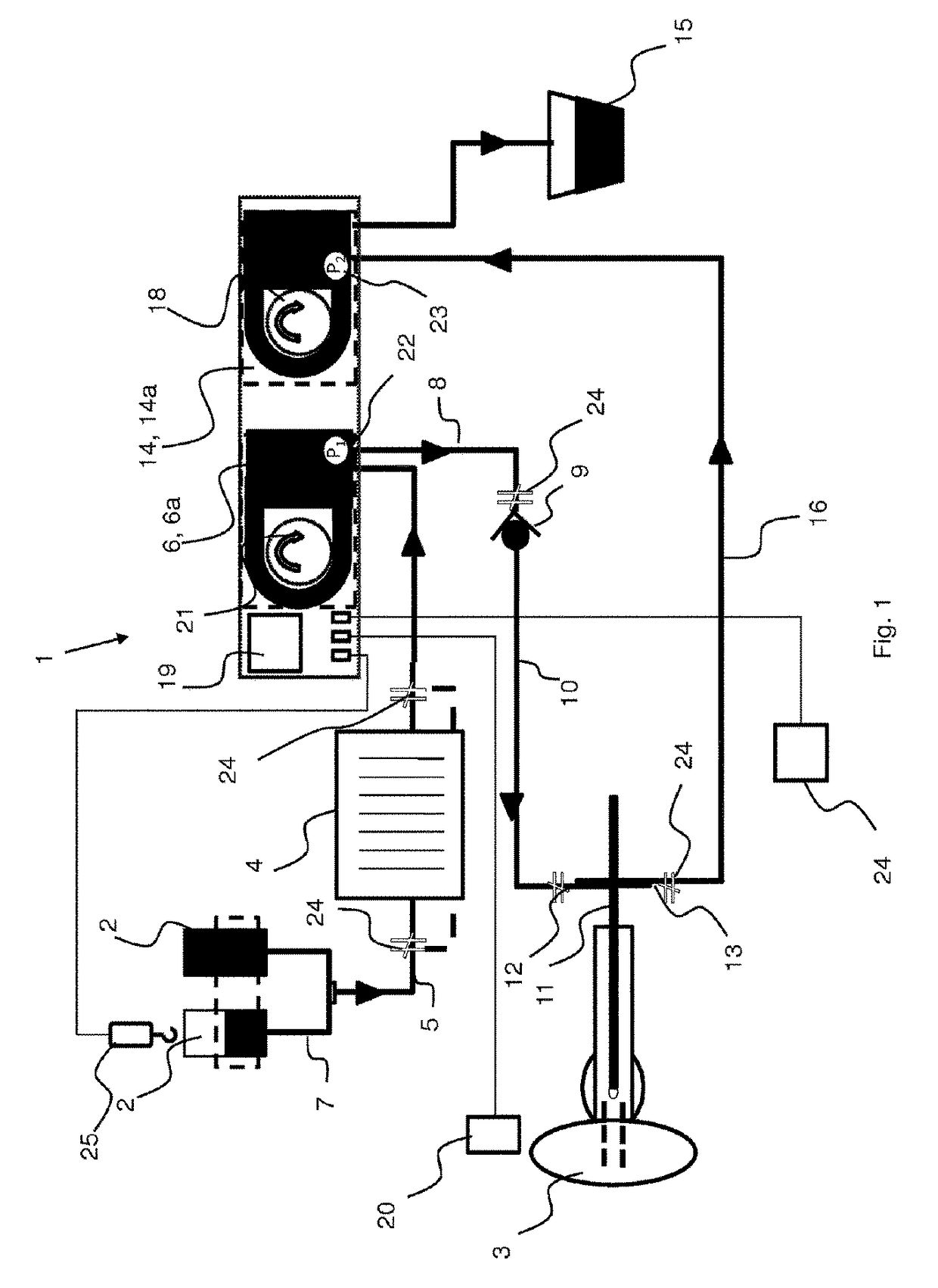

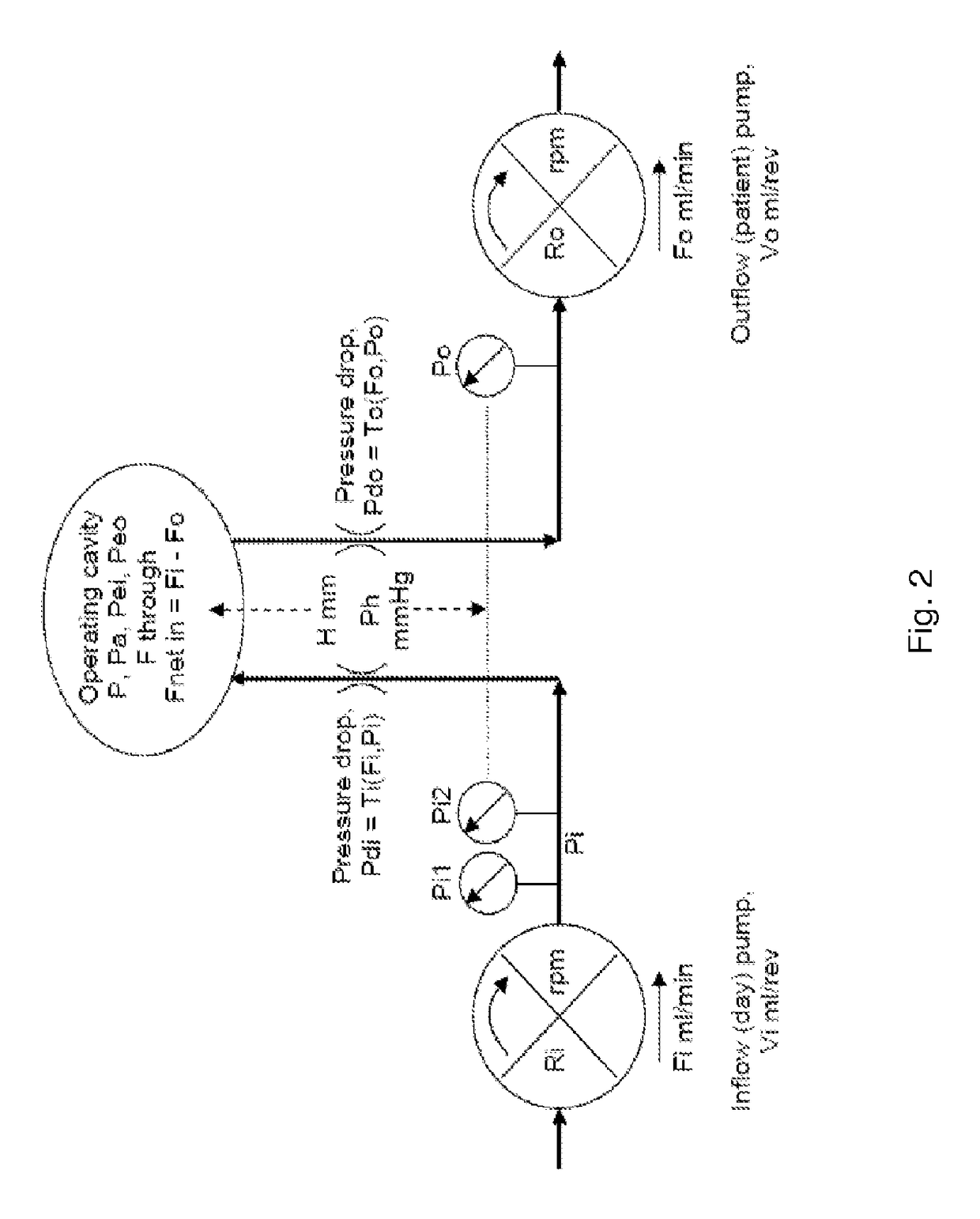

Device for irrigation and insufflation with blood pressure dependent pressure control

ActiveUS20150290387A1Reduce disadvantagesEffective pressureCannulasEnemata/irrigatorsControl signalCorrelation factors

A device for irrigation and / or insufflation during endoscopic surgery / procedures in a body cavity, comprising a first fluid pump device to deliver fluid to the body cvity, a second fluid pump device to move fluid from the body cavity, a control unit connected to the first and / or second fluid pump device, a blood pressure measuring device, wherein the control unit to derives a control signal based on a signal from the blood pressure measuring device, and sends the control signal to the first fluid and / or second fluid pump device, wherein the control signal is derived by processing the signal from the blood pressure measuring device using a correlation factor in the device, dependent on the relationship between a blood pressure measurement signal, and a perfusion pressure of the body cavity, wherein the first and / or second fluid pump device controls the pressure in the body cavity based on the control unit's control signal.

Owner:BONVISI

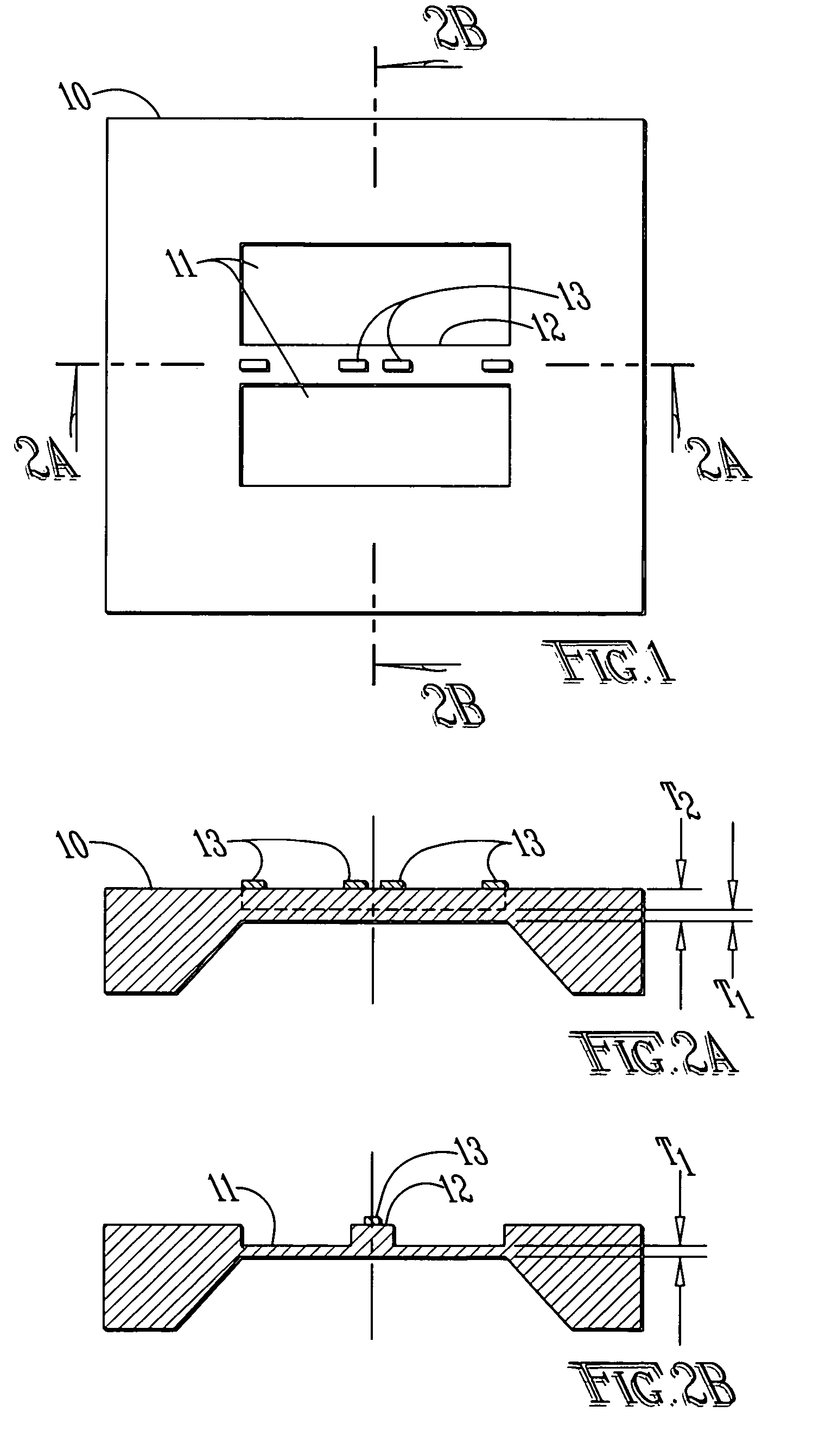

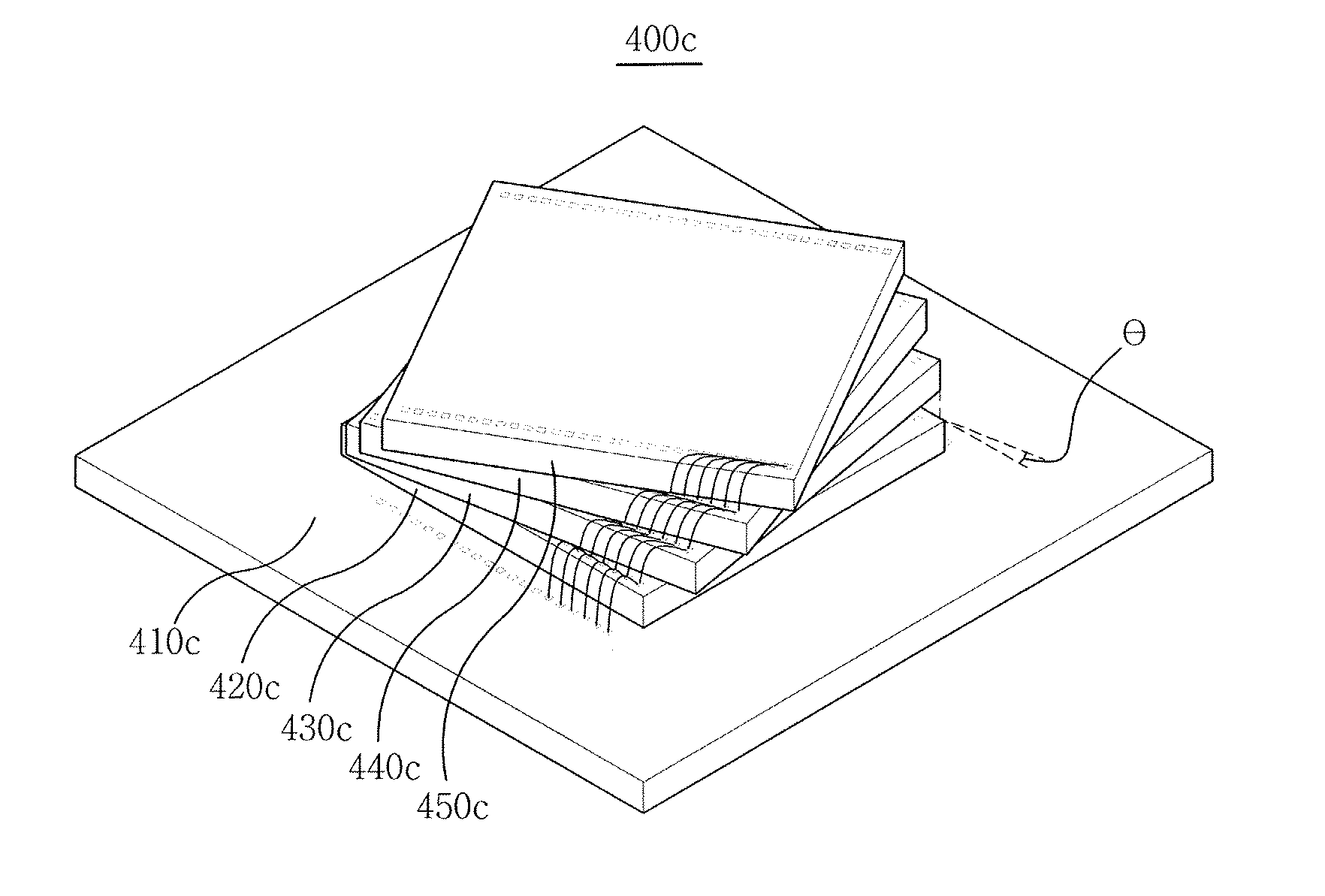

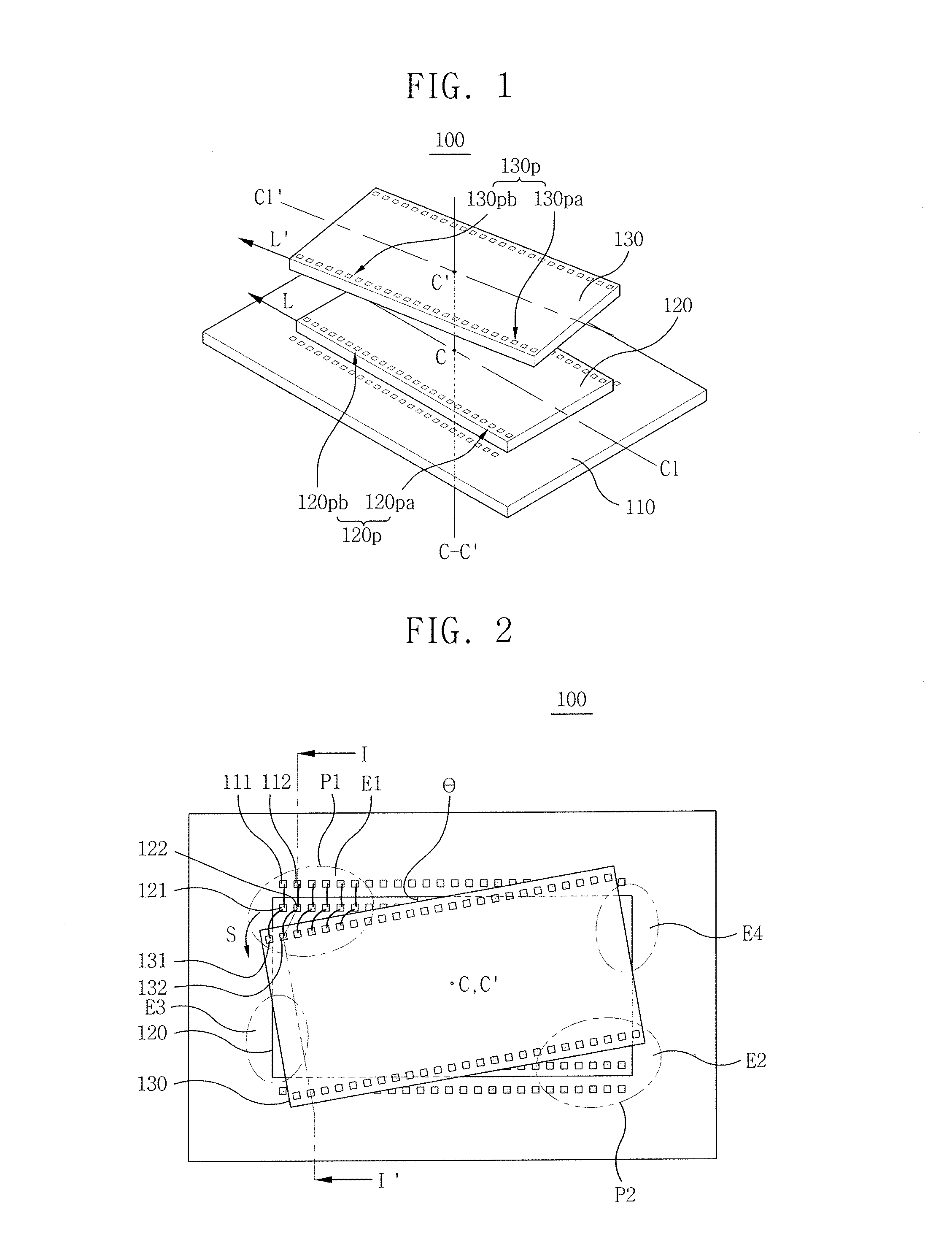

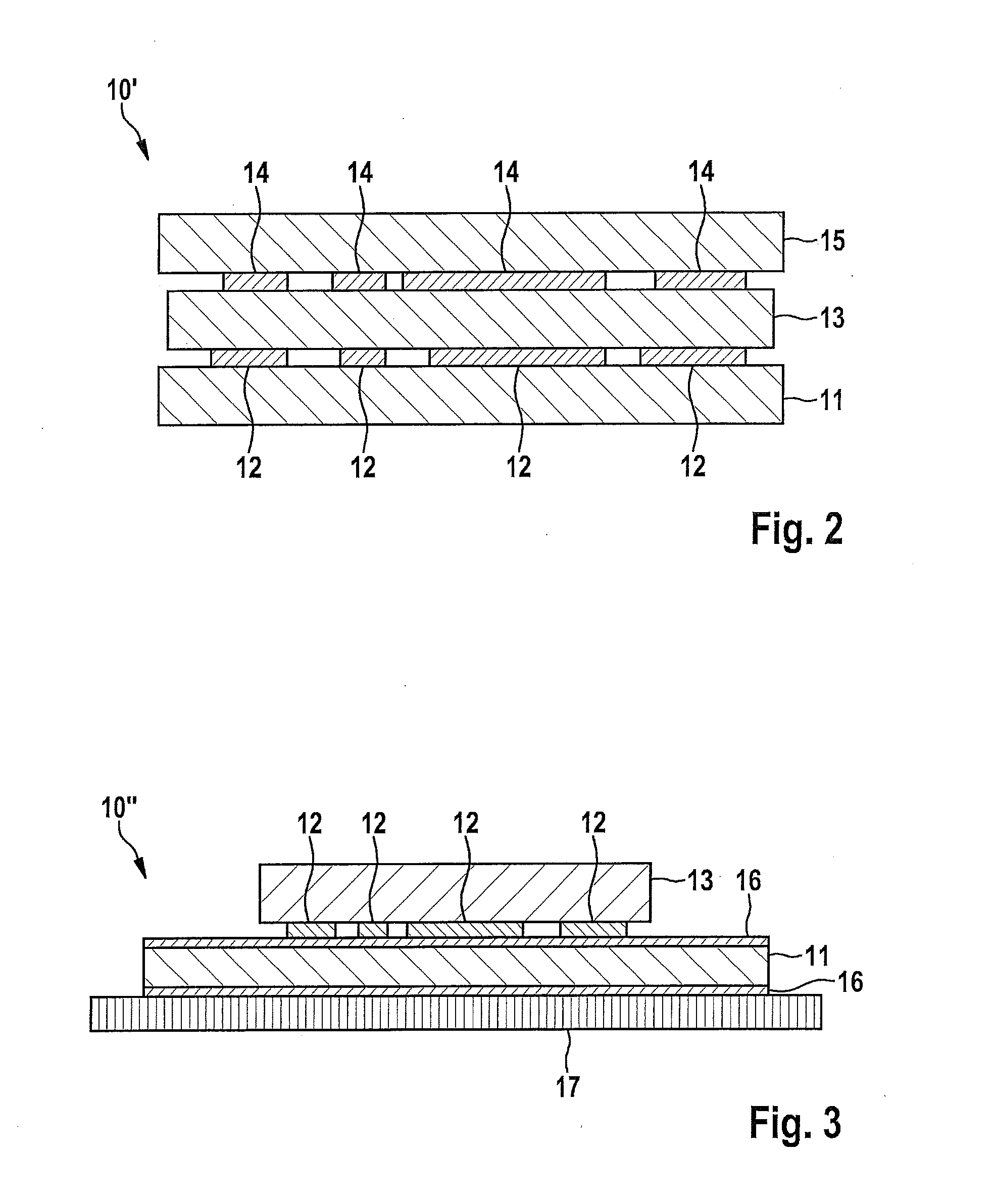

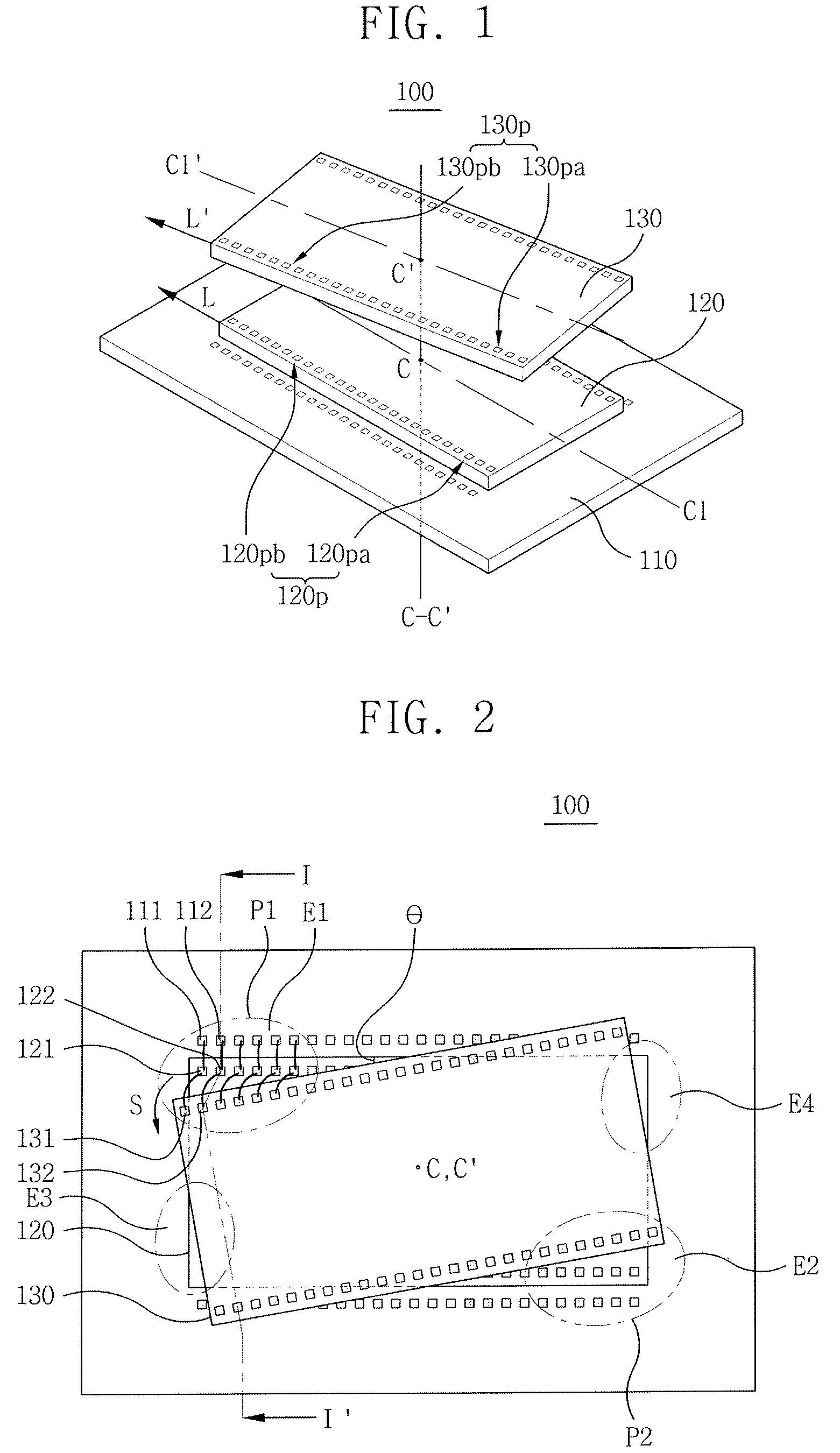

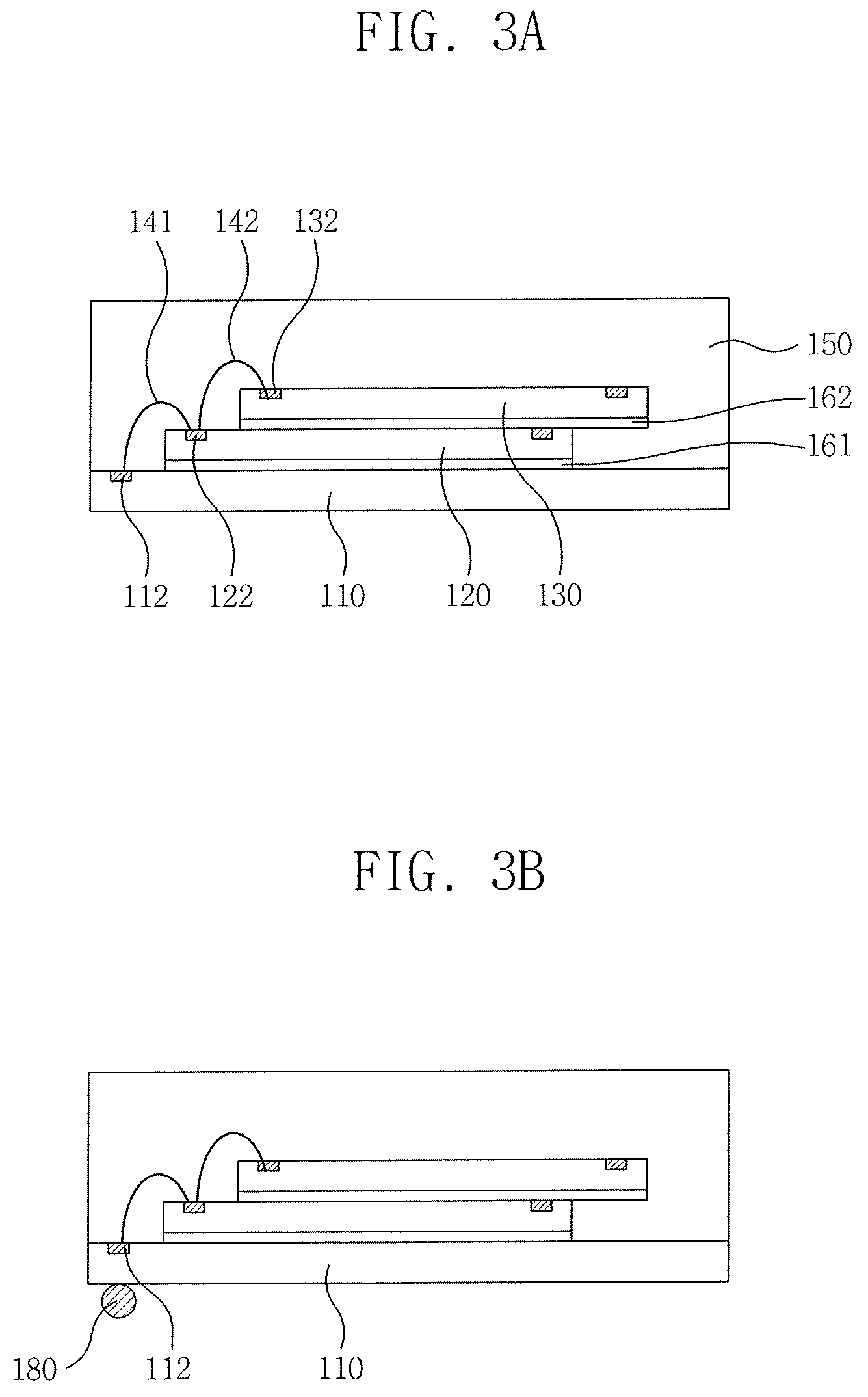

Semiconductor package having a stacked structure

ActiveUS20120001347A1Increase capacityGood yieldSemiconductor/solid-state device detailsSolid-state devicesElectronic systemsSemiconductor package

A semiconductor package includes a substrate, a first semiconductor chip stacked on the substrate and a second semiconductor chip stacked on the first semiconductor chip. In the semiconductor package, the second semiconductor chip is rotated to be stacked on the first semiconductor chip. The semiconductor package is used in an electronic system.

Owner:SAMSUNG ELECTRONICS CO LTD

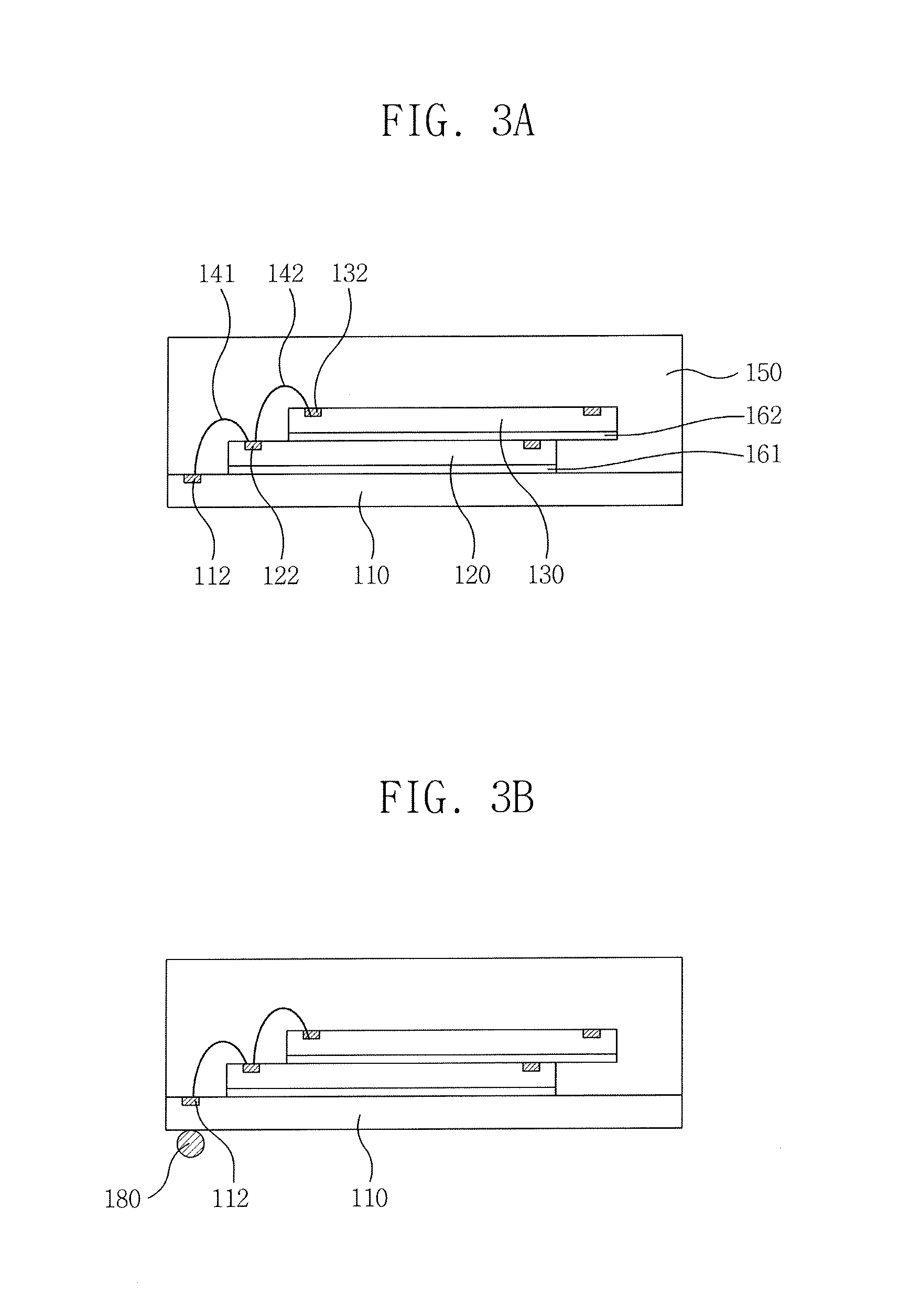

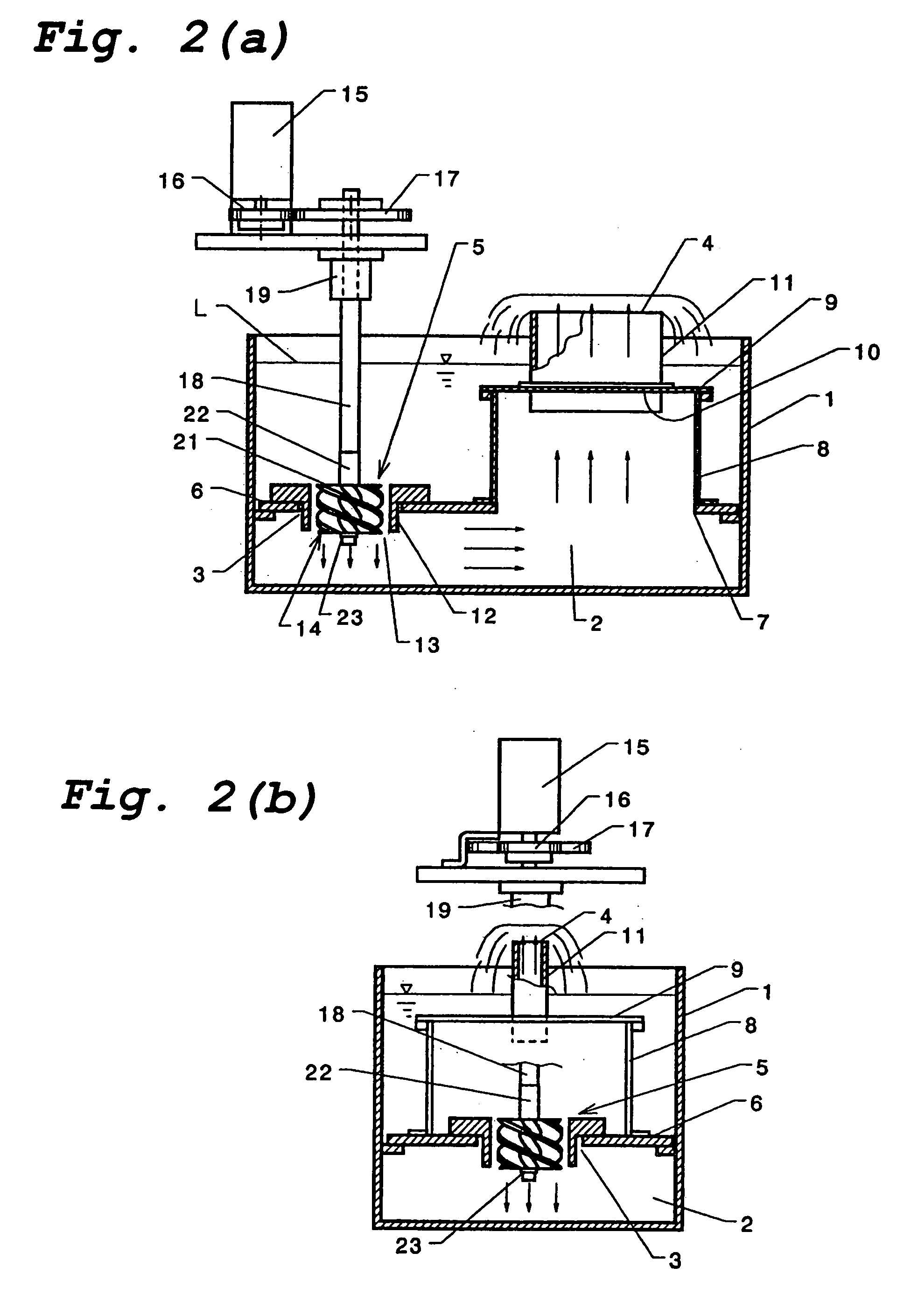

Wave Soldering Tank

ActiveUS20080093417A1Efficiently and uniformly appliedIncrease pressureGas flame welding apparatusSolder feeding devicesImpellerHelical blade

A wave soldering tank includes a soldering tank body for housing molten solder and a solder feed chamber disposed within the soldering tank body. An axial-flow, multiple-blade screw-type pump is disposed so as to draw molten solder into the solder feed chamber through an inlet and discharge the molten solder through an outlet. In a preferred embodiment, the pump includes a rotatable hub and a plurality of helical blades secured to the hub at equal intervals in the circumferential direction of the hub, each of the blades overlapping an adjoining one of the blades when the blades are viewed in the axial direction of the impeller.

Owner:SENJU METAL IND CO LTD

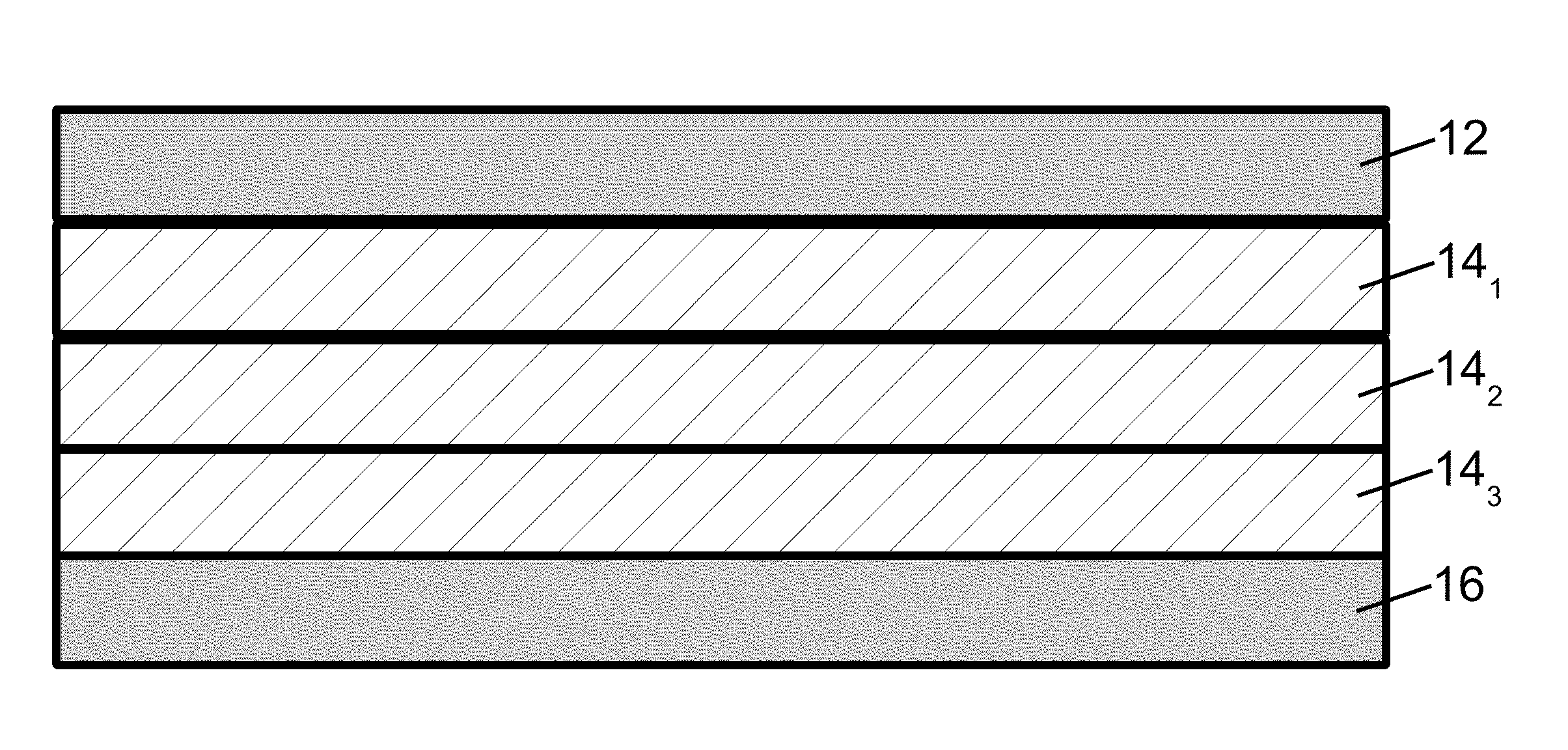

Metal laminate with metallurgical bonds and reduced density metal core layer and method for making the same

ActiveUS20160101599A1Not be eliminateEffective pressureHot-dipping/immersion processesExtrusion containersOxideDensity reduction

A stiff, lightweight metal laminate includes a first continuous metal layer, a second continuous metal layer, and a reduced density metal core layer disposed between the first and second continuous metal layers. The reduced density metal core layer comprises a core metal and has an average density that is less than the density of the core metal. Planar metallurgical bonds secure the first and second continuous metal layers to the reduced density metal core layer. The metal laminate may be manufactured by press rolling the reduced density metal core layer sandwiched between the two continuous metal layers, after removing or overcoating the native oxide layer on each layer surface that contacts another layer in the metal laminate.

Owner:MATERION

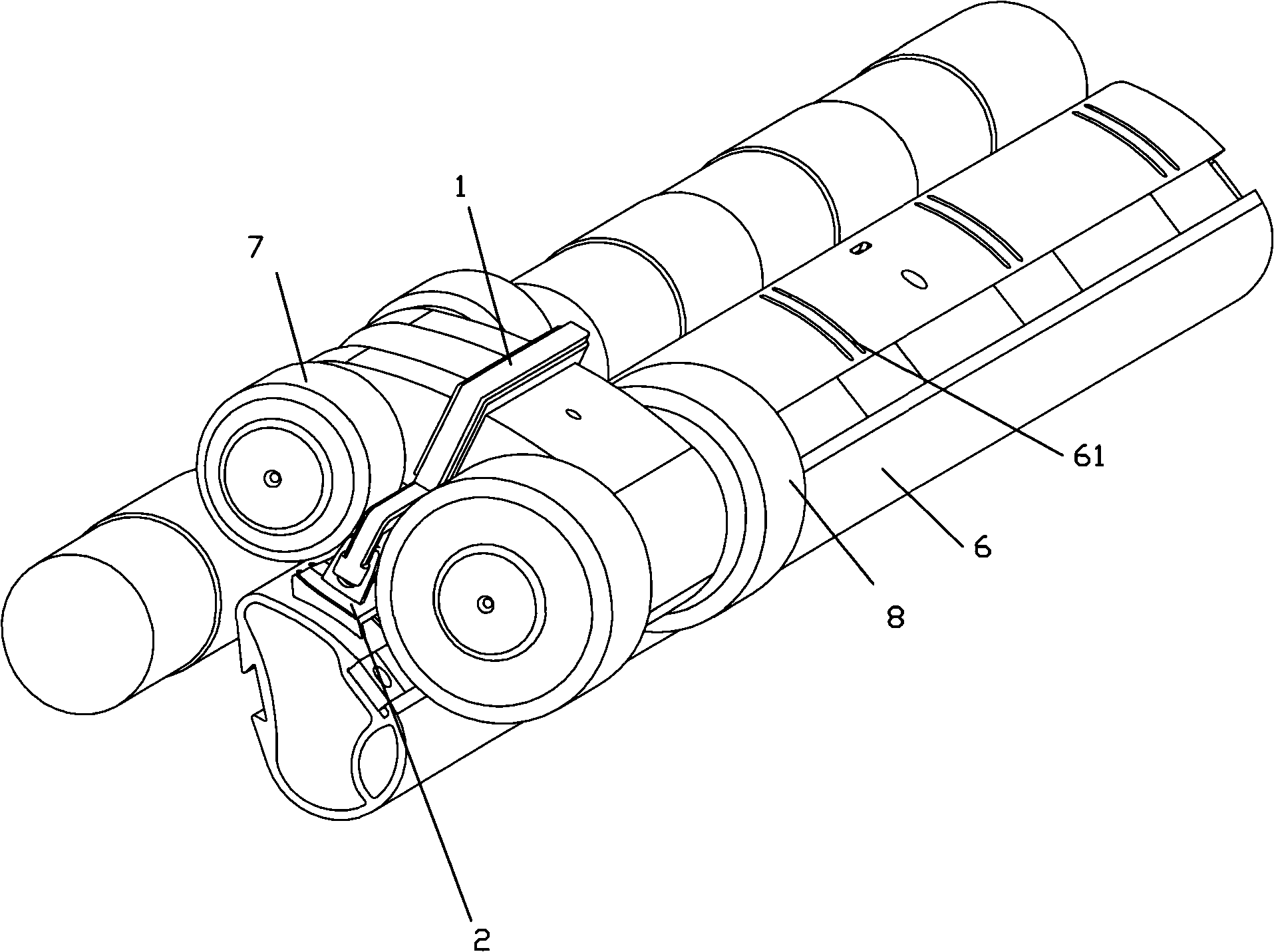

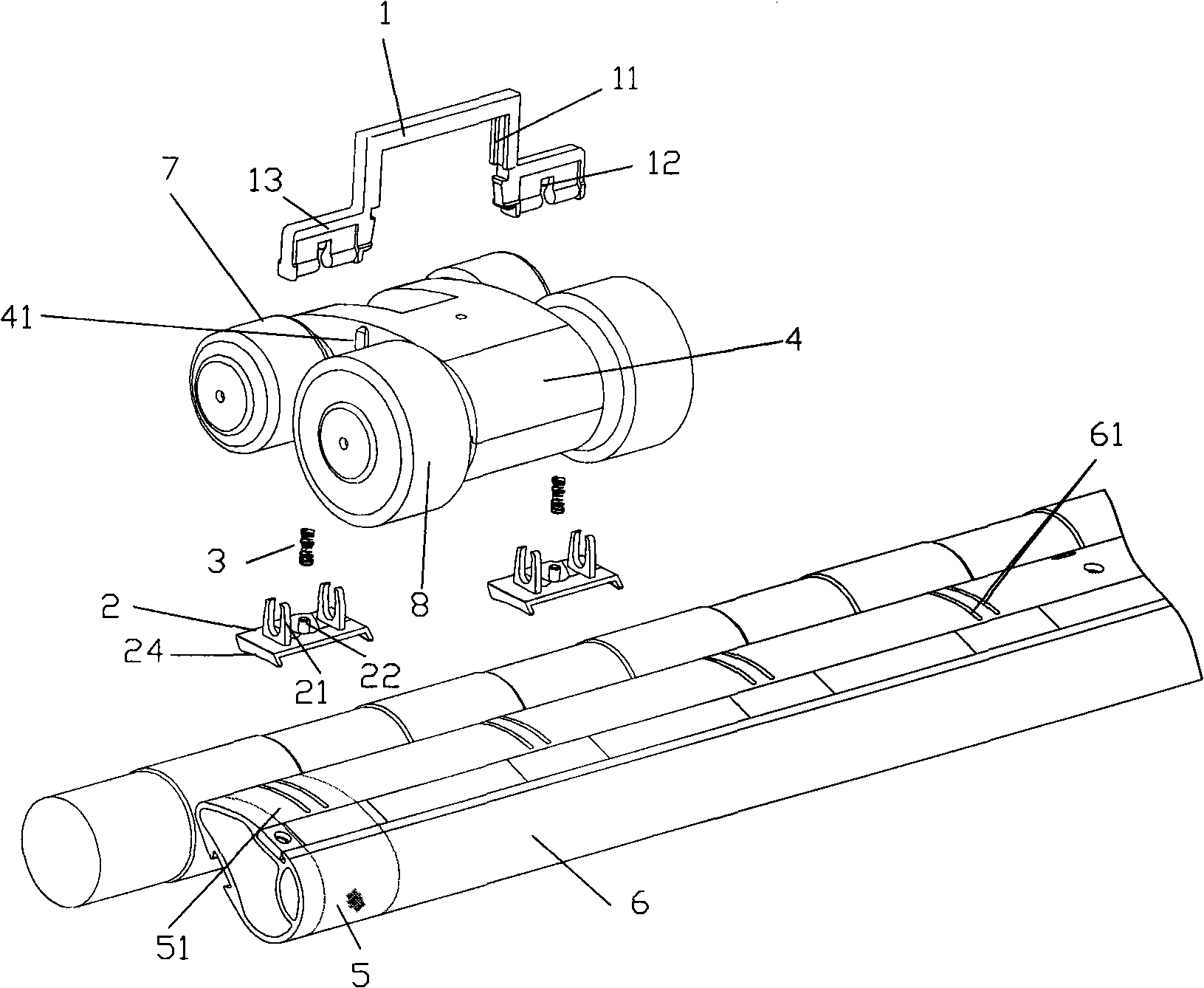

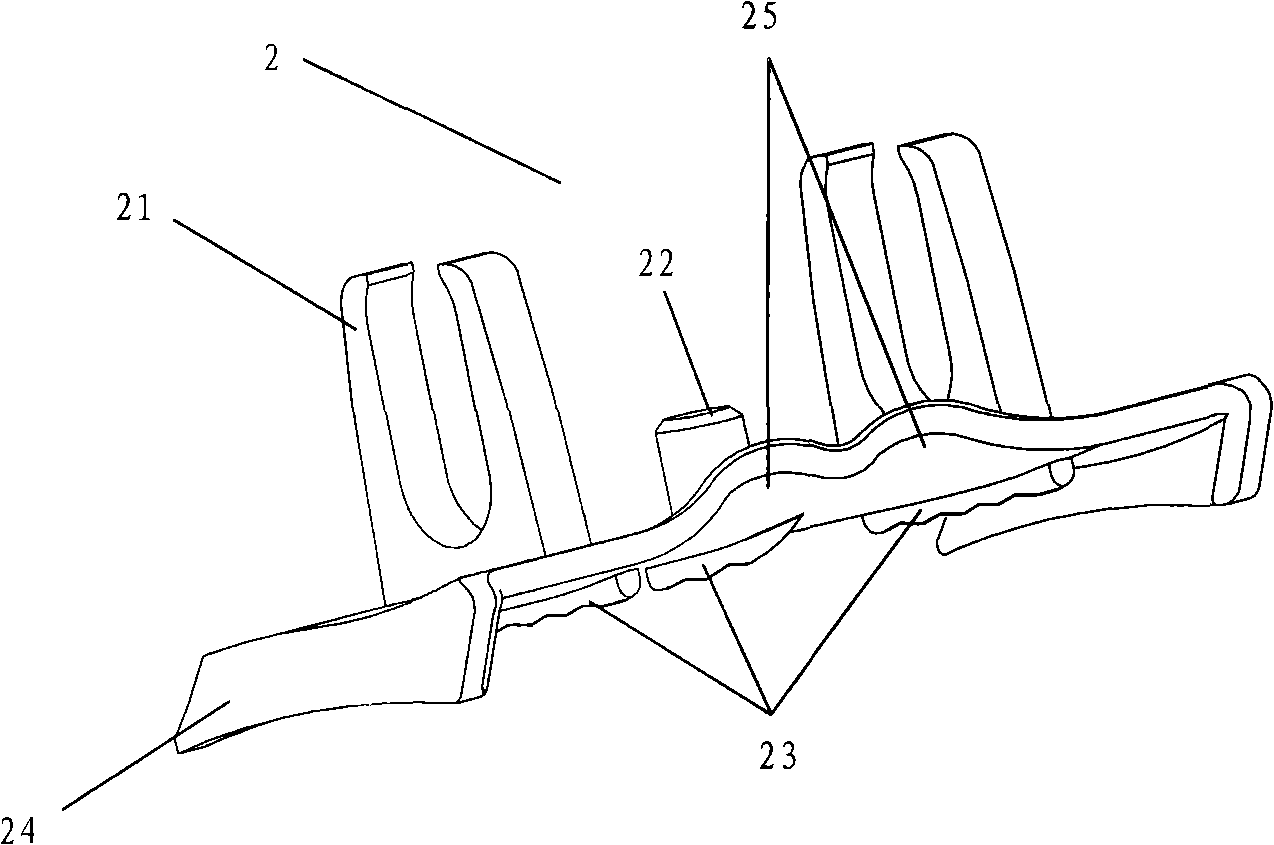

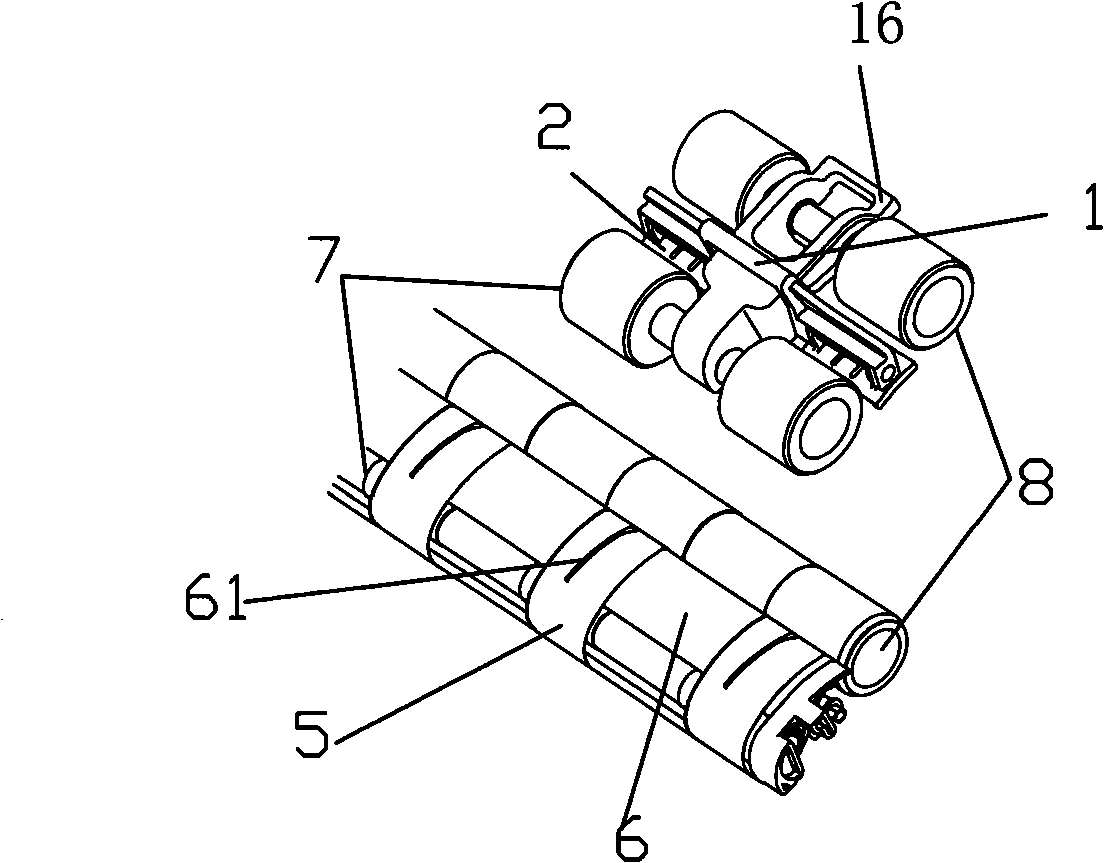

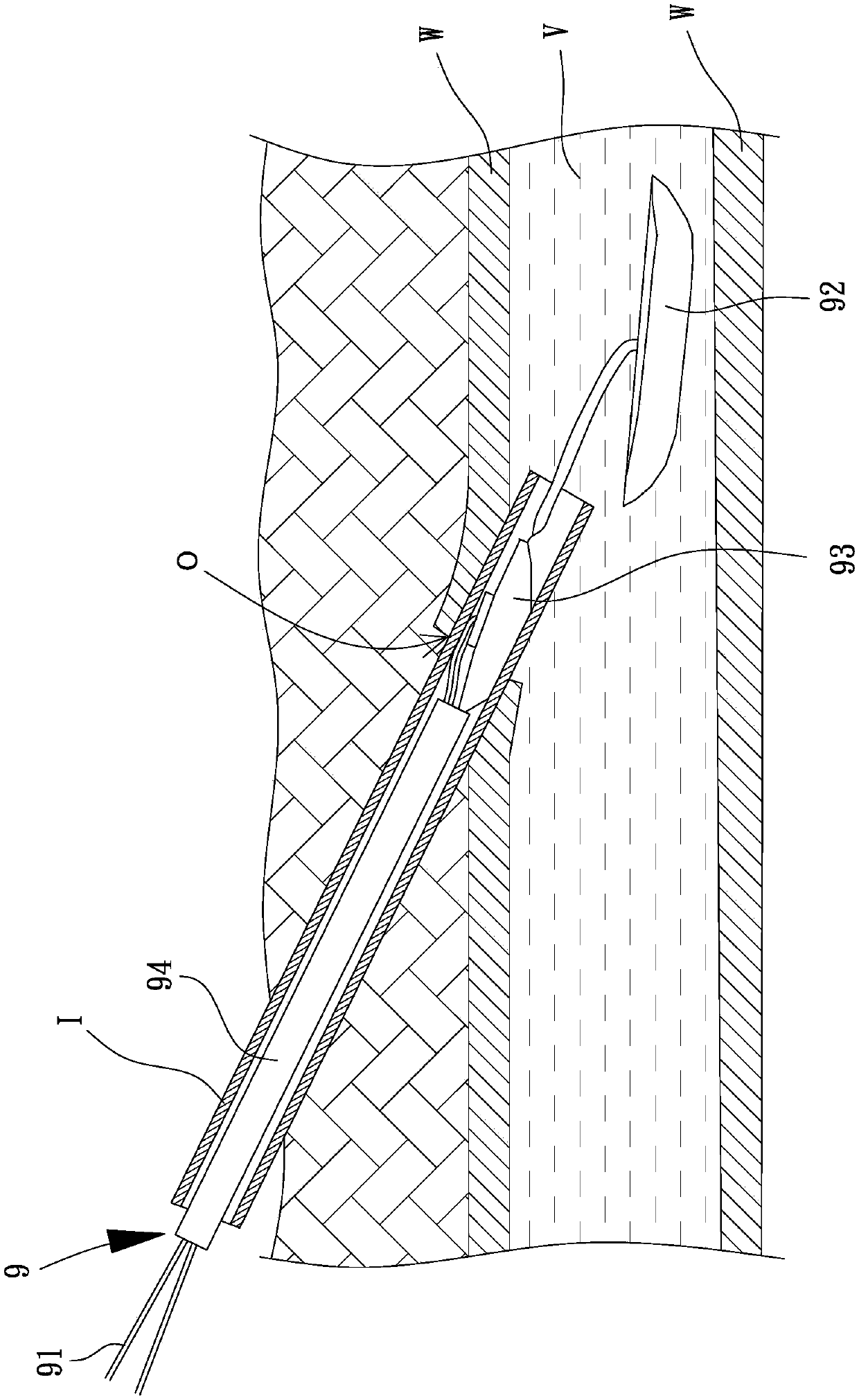

Yarn-collecting device for compact spinning

A yarn assembling apparatus for tight spin includes a bracket and a yarn assembling plate, wherein, a couple of protuberances are provided on both sides of the bracket, the protuberance and bracket center are in mirror symmetry, a groove is provided on the bracket for snapping with a boss on a wheel box, a couple of grippers are provided on the yarn assembling plate and are snapped with the corresponding protuberance on the bracket, a couple of feet are provided on the lower part of the yarn assembling plate, yarn assembling airflow guide tendons are provided in the feet, the height of the yarn assembling airflow guide tendons is lower than that of the feet, and the height difference is larger than the thickness of the conveyer band. The invention has advantages that a yarn assembling apparatus is between a drawing roller and a gripping roller, spans the conveyer band and elastically supports on a slide surface; the airflow before entering the suction duct can implement orienting and effective press to the strand of fibers by guiding of the guide tendon on the yarn assembling plate, thereby the airflow is effectively utilized above the strand of fibers, the negative-pressure is reduced and the energy consumption is saved. The yarn assembling apparatus allows the two strands of fibers to be not easy to unite and wind, by guiding of three airflow guide tendon on the yarn assembling plate when the yarn assembling apparatus spins the compound yarn, thereby improving the compound yarn quality.

Owner:YUNSHENG HLDG GRP

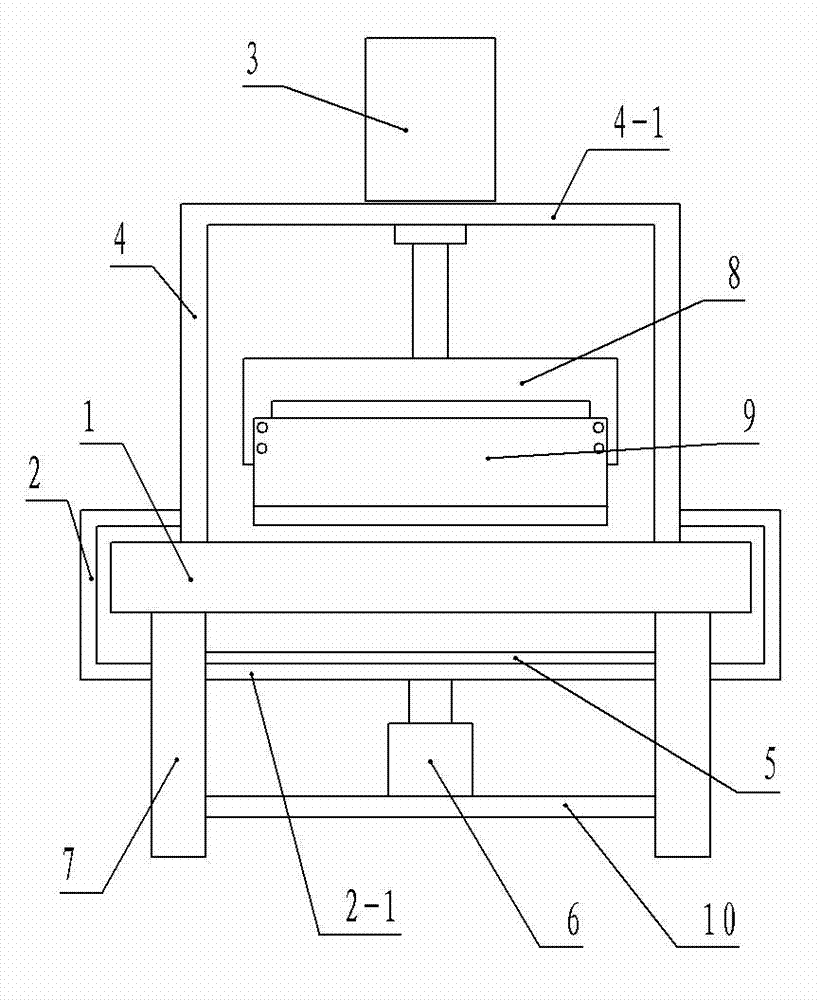

Automatic paper cutter

InactiveCN104493861AEasy to operateImprove efficiencyMetal working apparatusElectromagnetic valvePower switching

The invention discloses an automatic paper cutter and belongs to the technical field of paper cutting equipment. The automatic paper cutter comprises a frame provided with a cutting platform and supporting legs, and a cutter controlled through a first air cylinder is mounted above the cutting platform through a support frame stretching across the cutting platform; the cutting platform is transversely sleeved with a square press box controlled through a second air cylinder, and the first air cylinder and the second air cylinder are connected through an electromagnetic valve and a power switch. By the arrangement, operating trouble can be solved, and problems that efficiency is low and a pressure plate cannot be pressed tightly resulting in the fact that notches of paper are not perpendicular during cutting and production quality is affected are solved.

Owner:柳州市柳江区联华纸制品厂

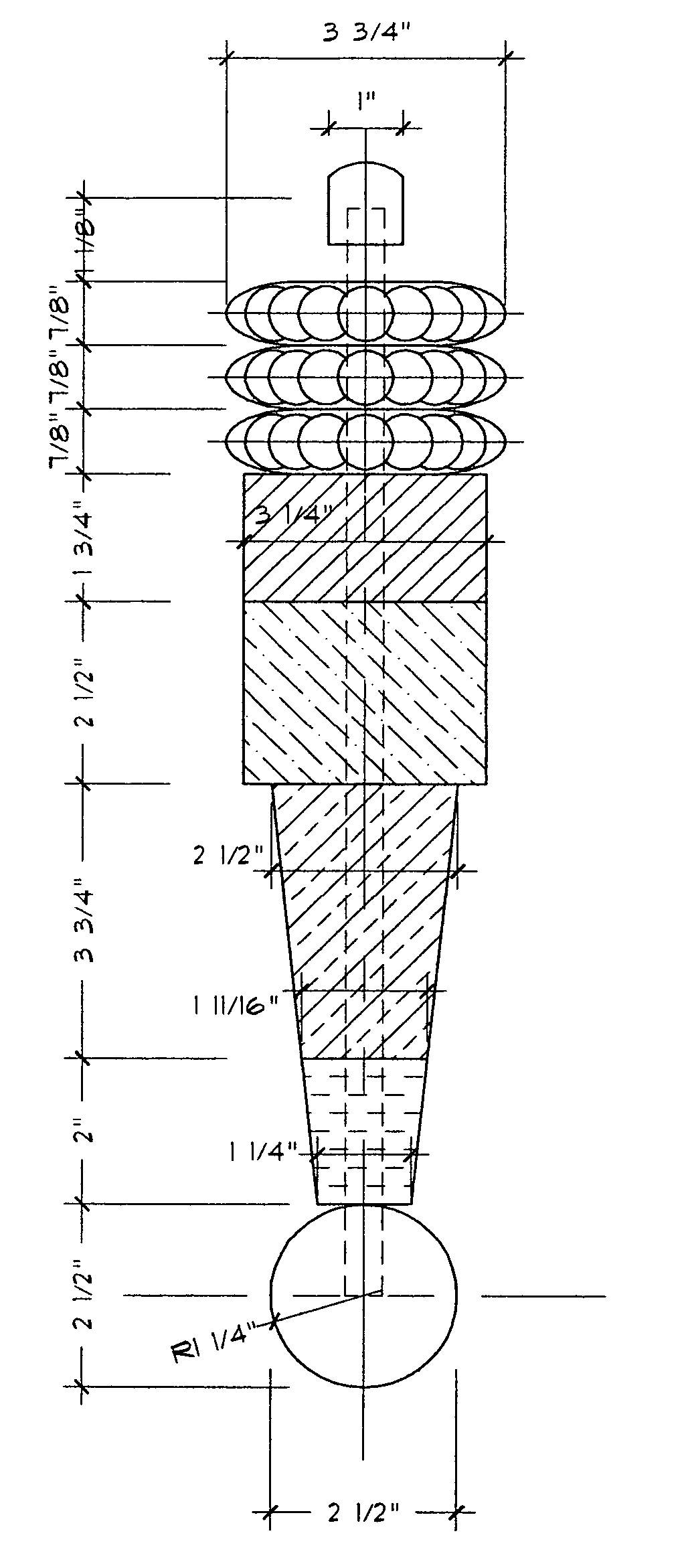

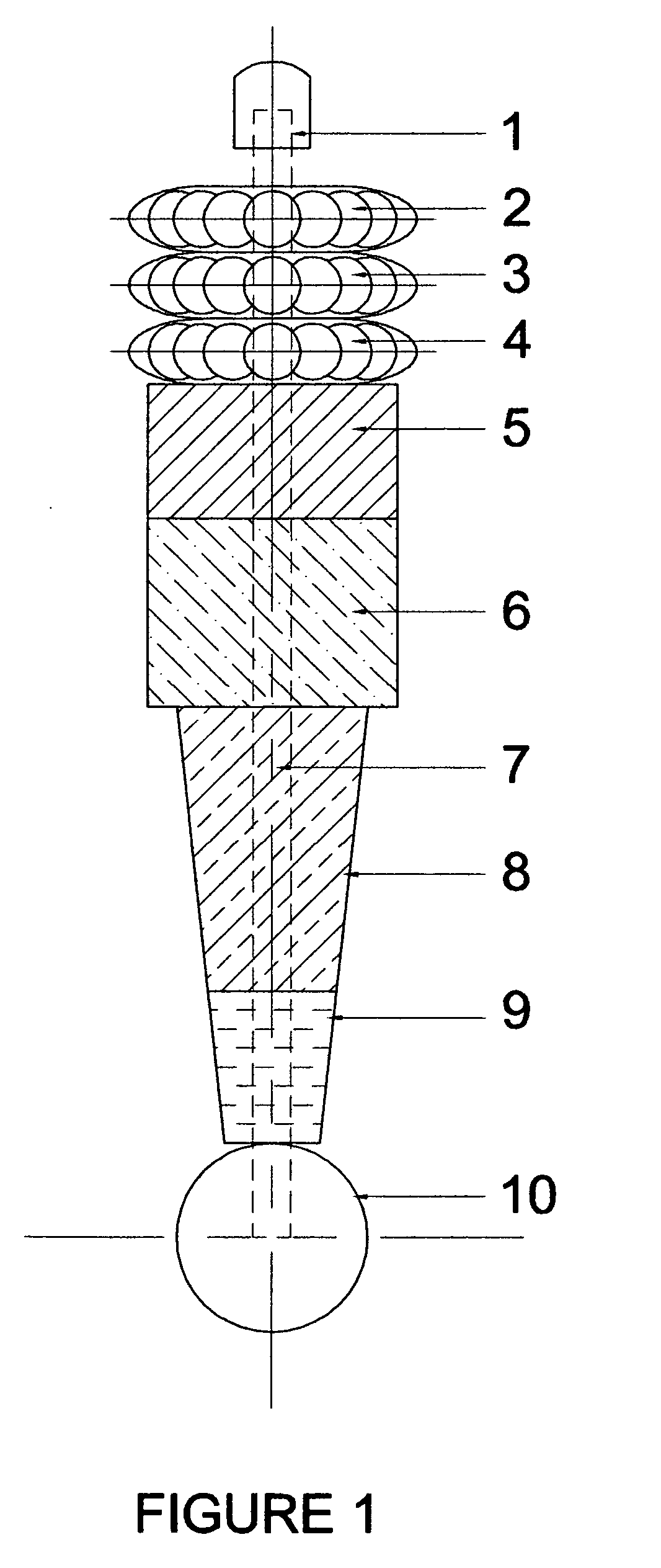

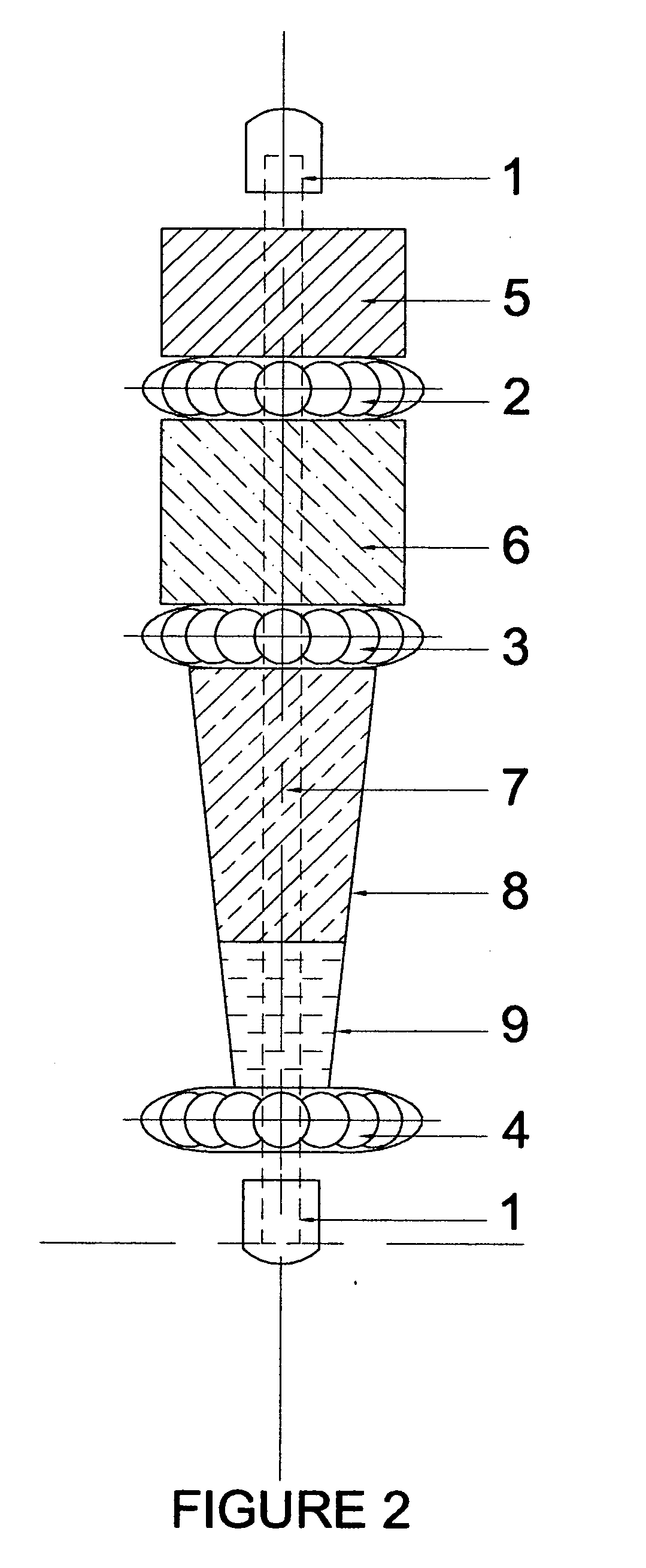

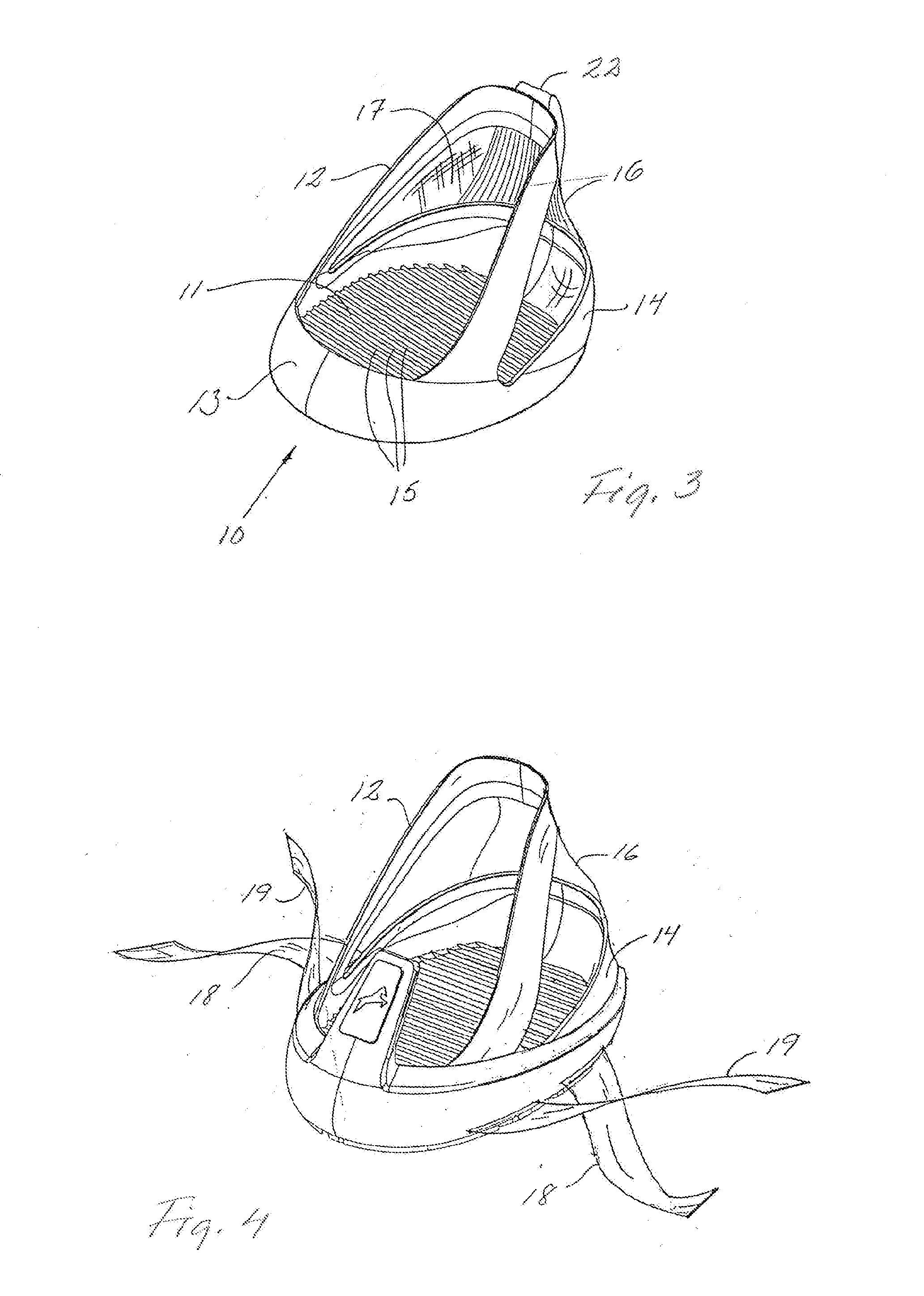

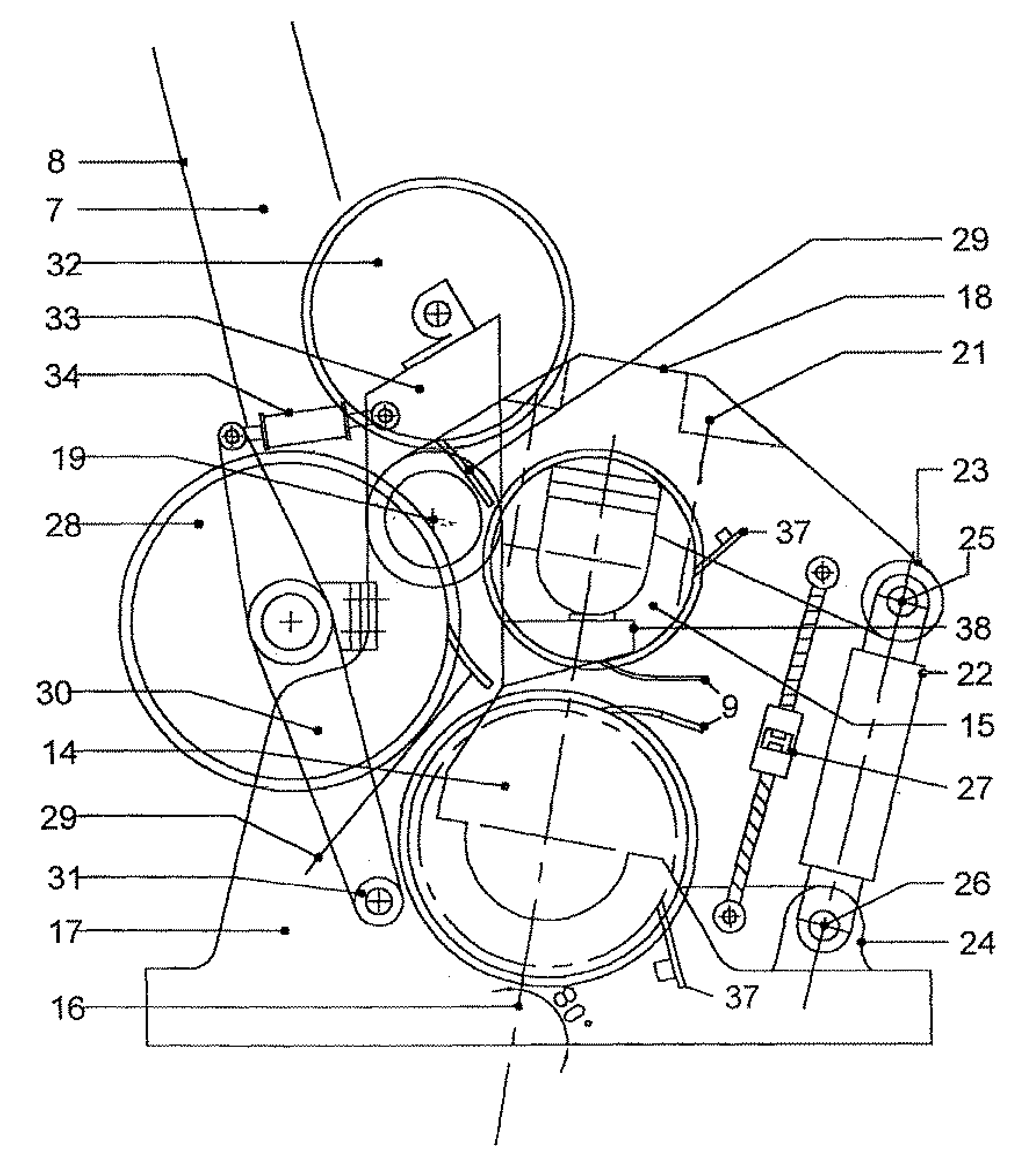

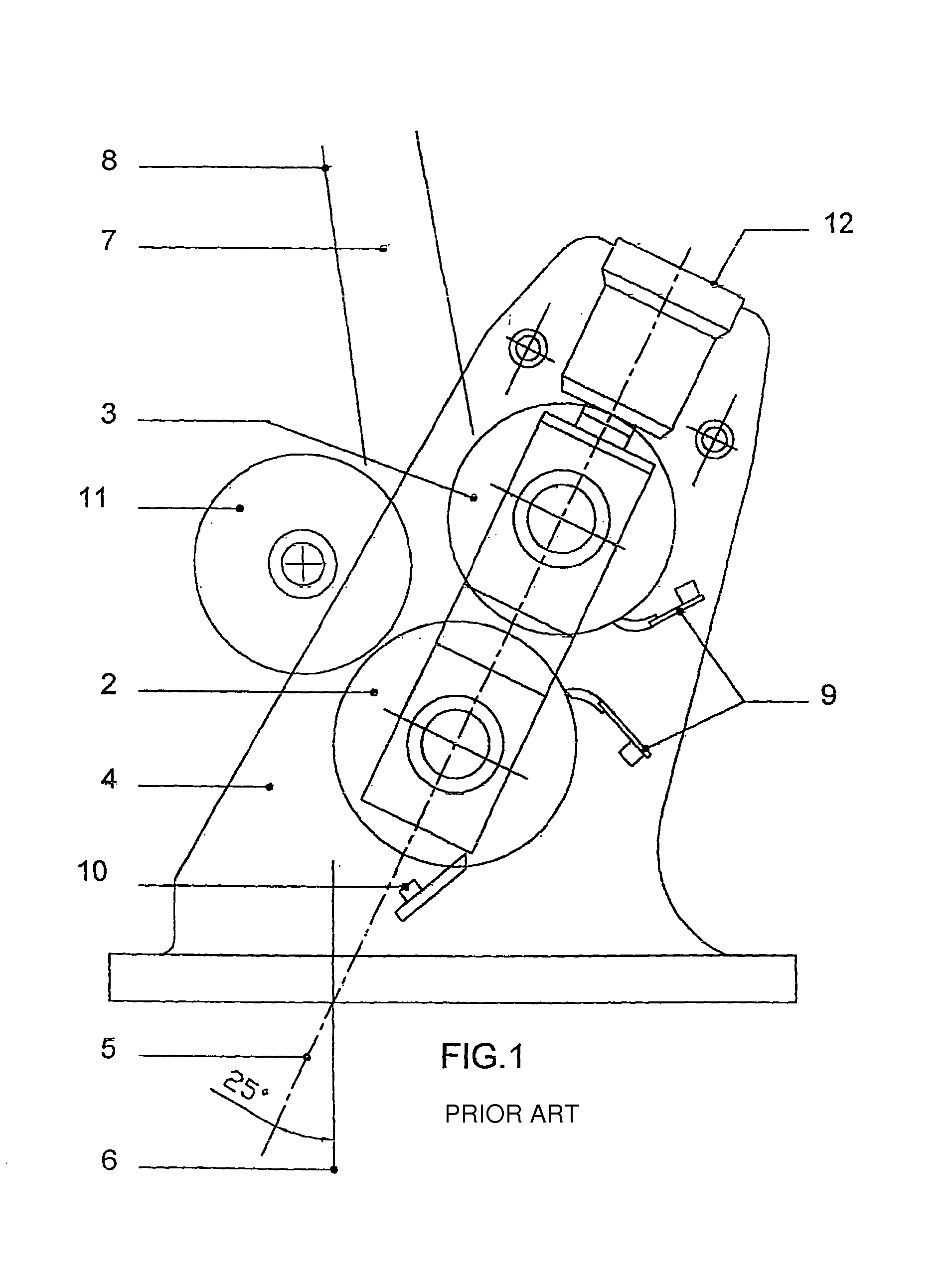

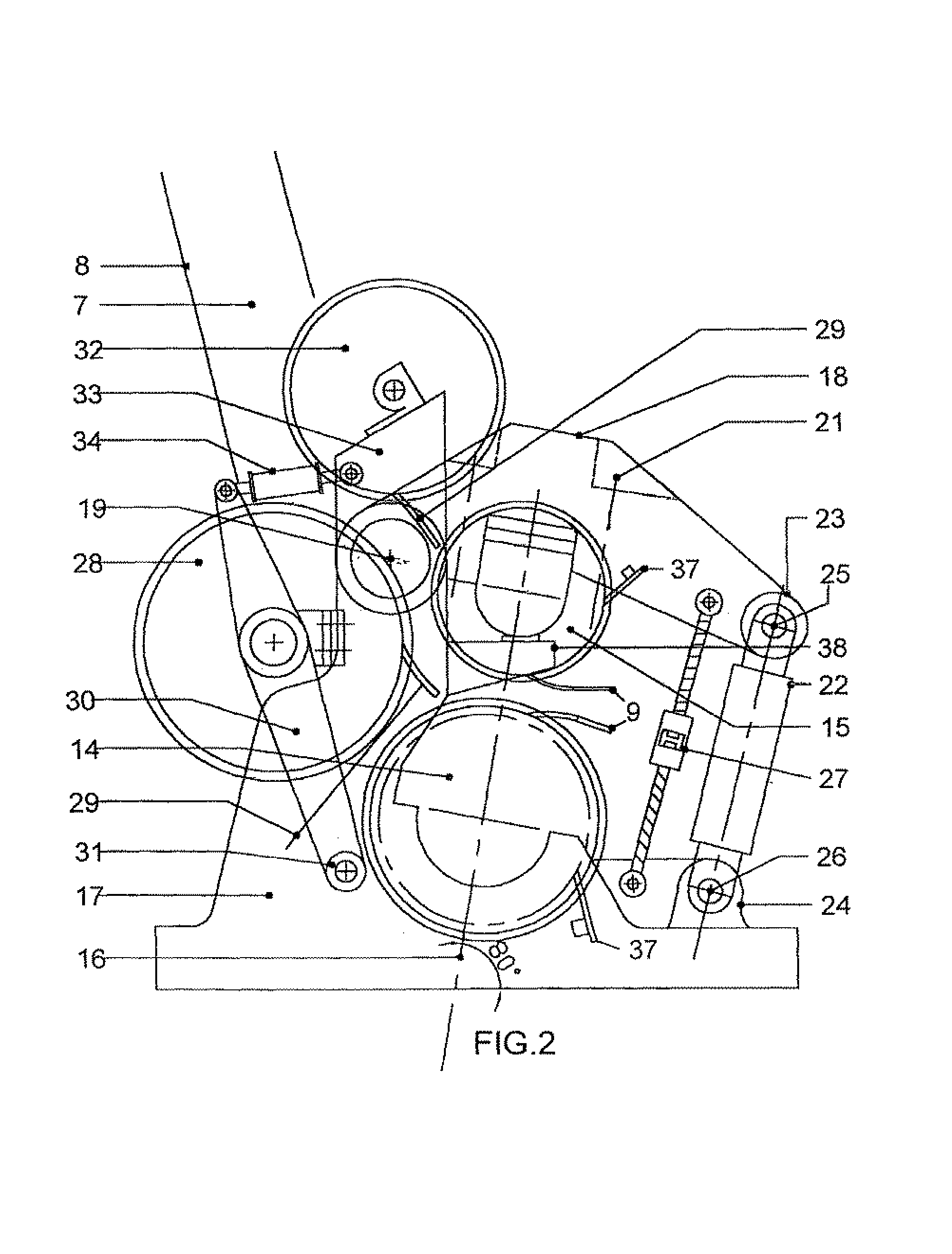

Interchangeable pressure therapy tool

InactiveUS20120238925A1Improve abilitiesWeight increaseDevices for locating reflex pointsRoller massageTherapeutic MassageHand held

The present invention is a hand-held interchangeable pressure therapy tool containing a center rod (7), three polyurethane wheels (2, 3, 4), a threaded polyurethane removable knob (1), two neoprene foam cylindrical pads (5, 6), a solid rubber ball housing an internal threaded cap (10) and two neoprene handle sleeves (8, 9).The components of the device can be interchanged and ordered differently on the center rod (7) which gives the invention multiple therapeutic massage tools which can be used in numerous ways to provide musculoskeletal relief. It can be adjusted for anyone and be used effectively anywhere. Therapists and individual users of the invention have many tools included in the device making the device effective for any situation, safe and easy to use.

Owner:WINKLEY CHRISTOPHER THOMASON

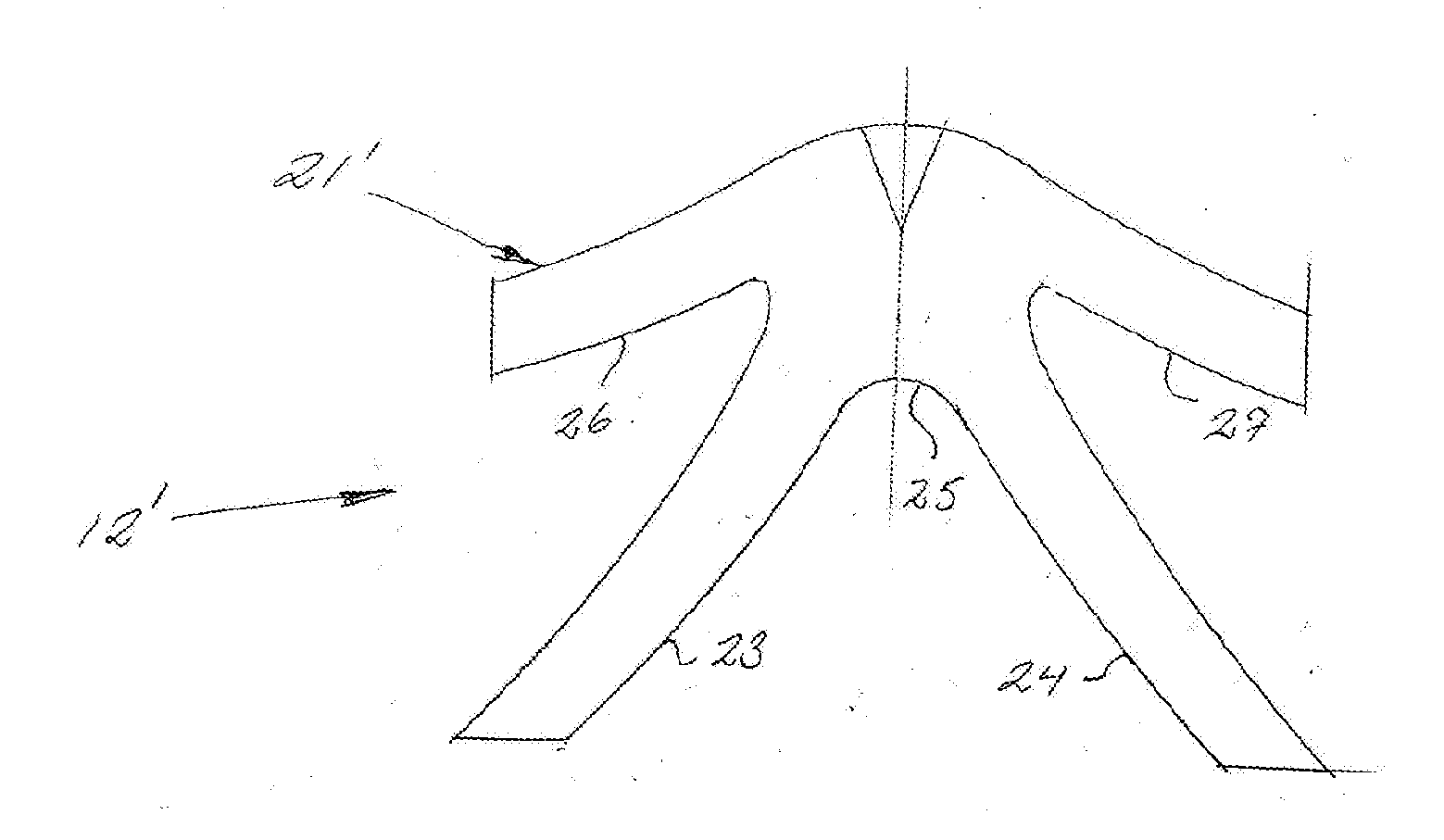

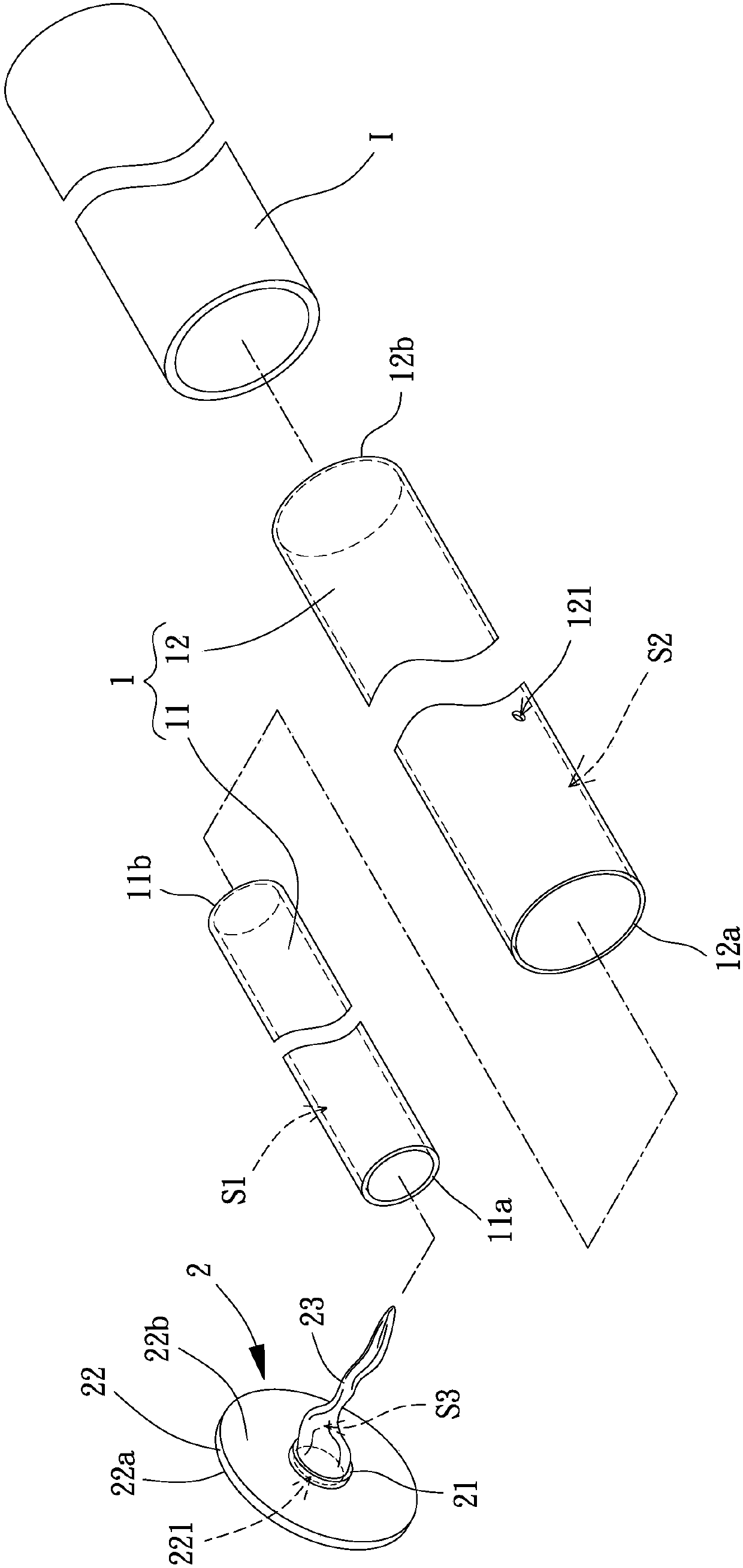

Ligament support for hooves

ActiveUS20150238344A1Reduce weightCautious to carryVeterinary bandagesNon-surgical orthopedic devicesFetlockPastern joint

Ligament support (12, 12′) for hooves, mountable on a hoof and in the mounted position effective for backing up the suspensory ligament between the hoof and the fetlock, including an elastic element (23-24-25) the length of which is adapted to run via the pastern of the hoof, from an anchor point situated on the inside of the hoof to an anchor point situated on the outside of the hoof, and which, in an area located to the pastern, is coupled to an elastic cuff (2 I′) mountable around the leg.

Owner:SHINGS

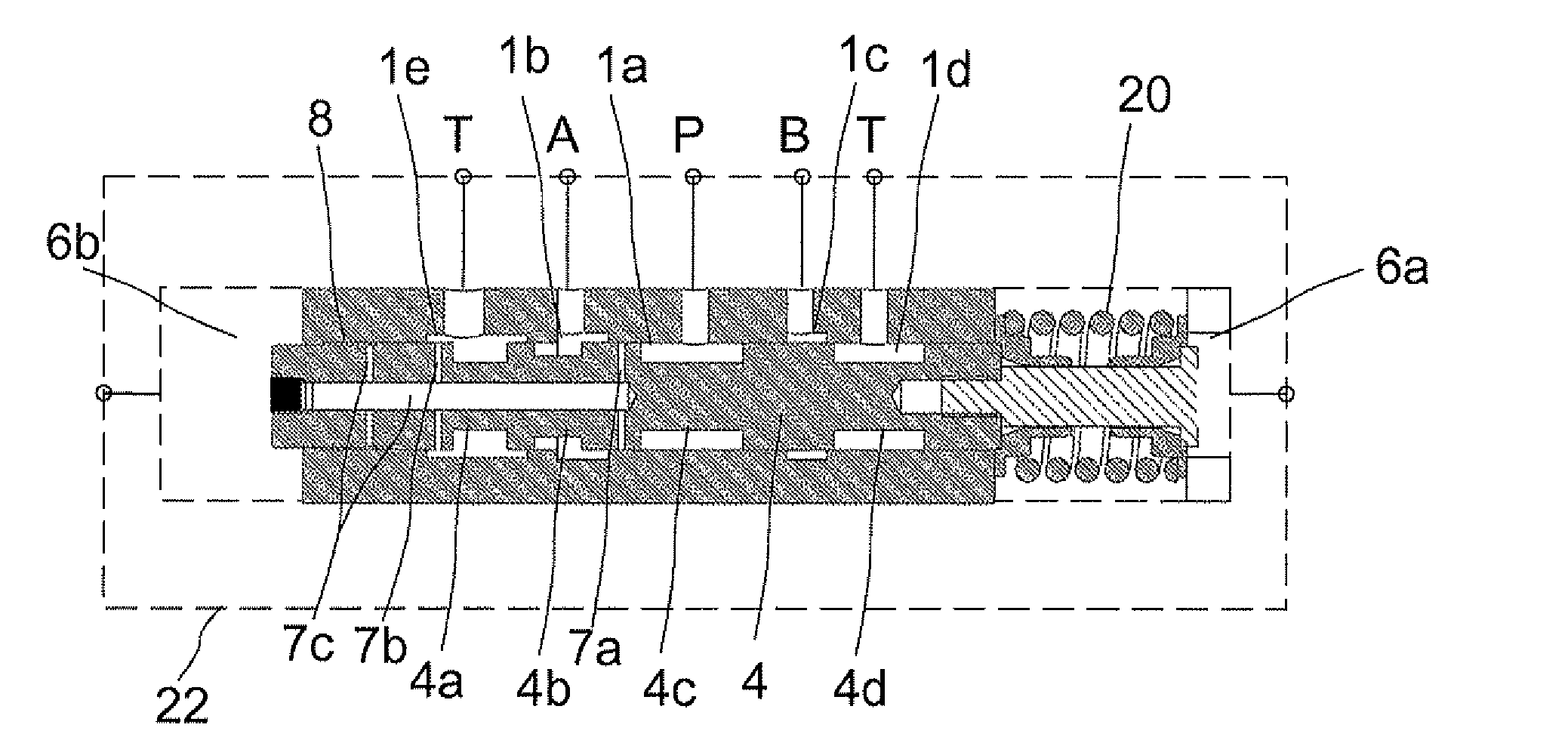

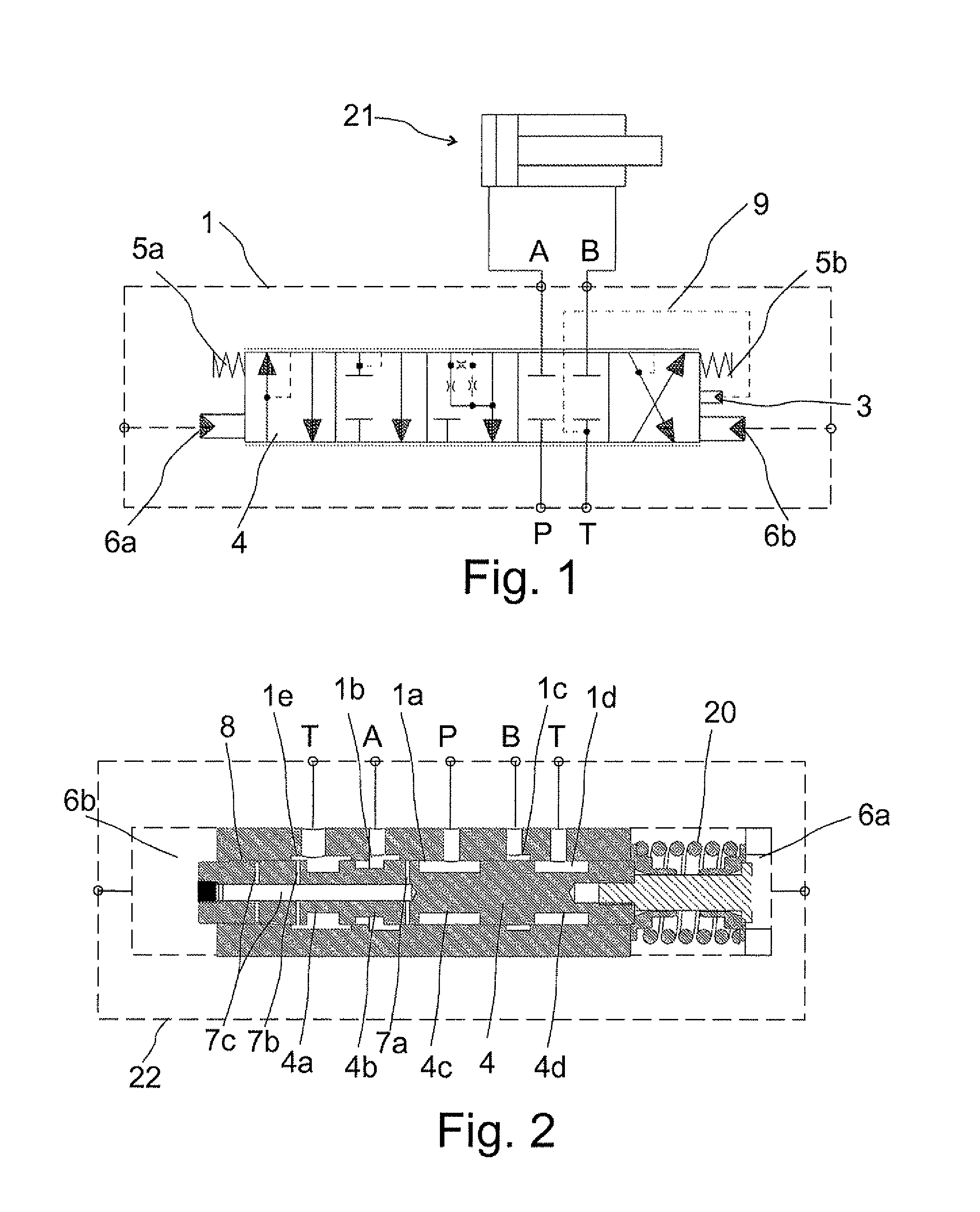

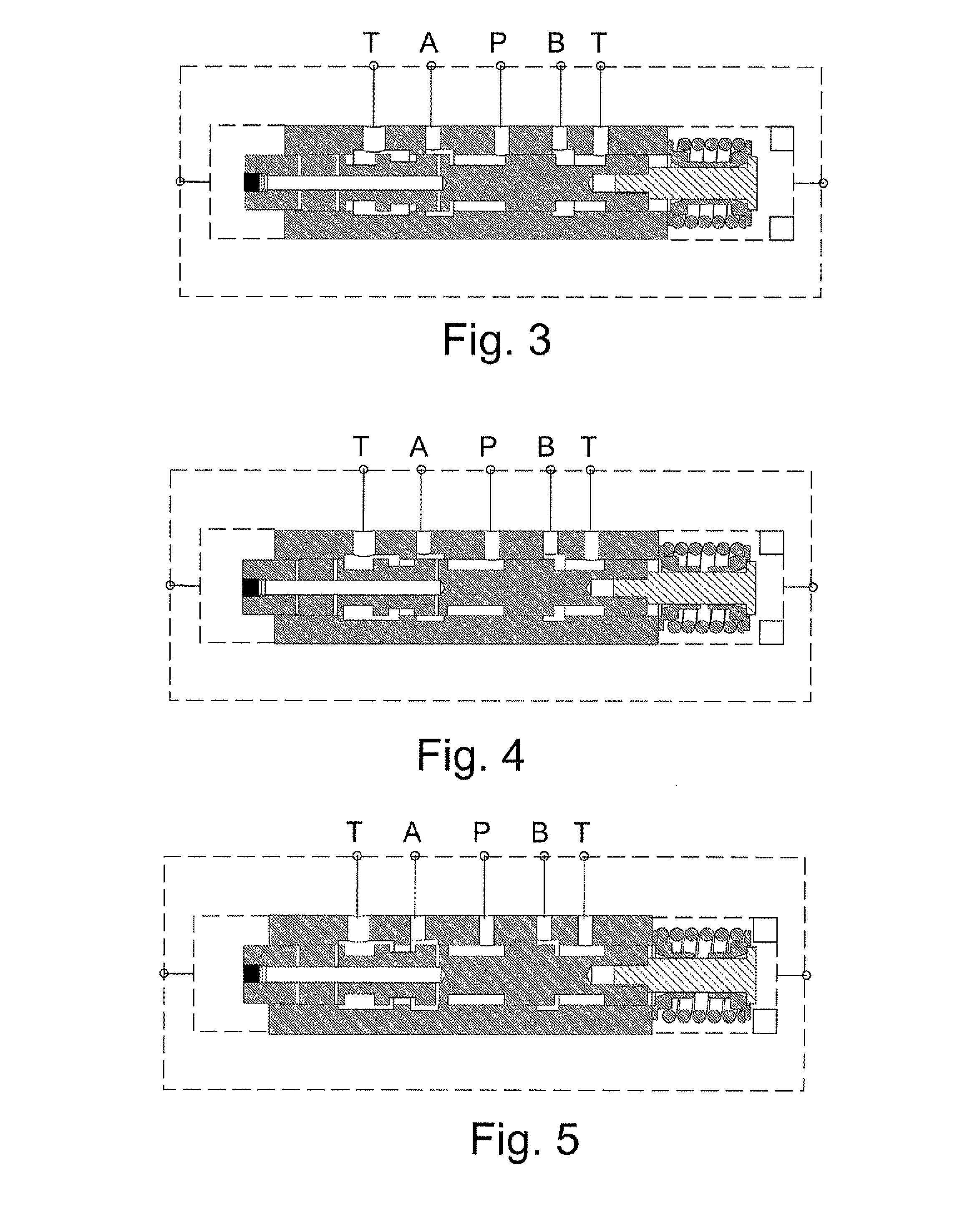

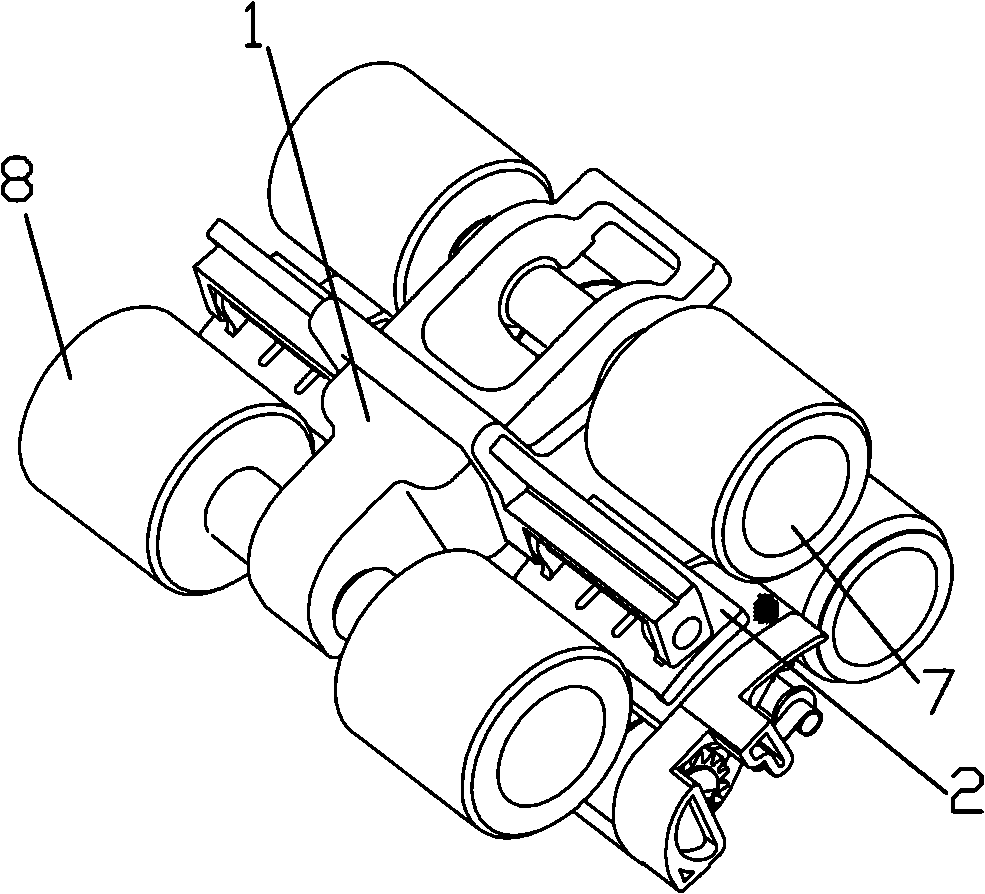

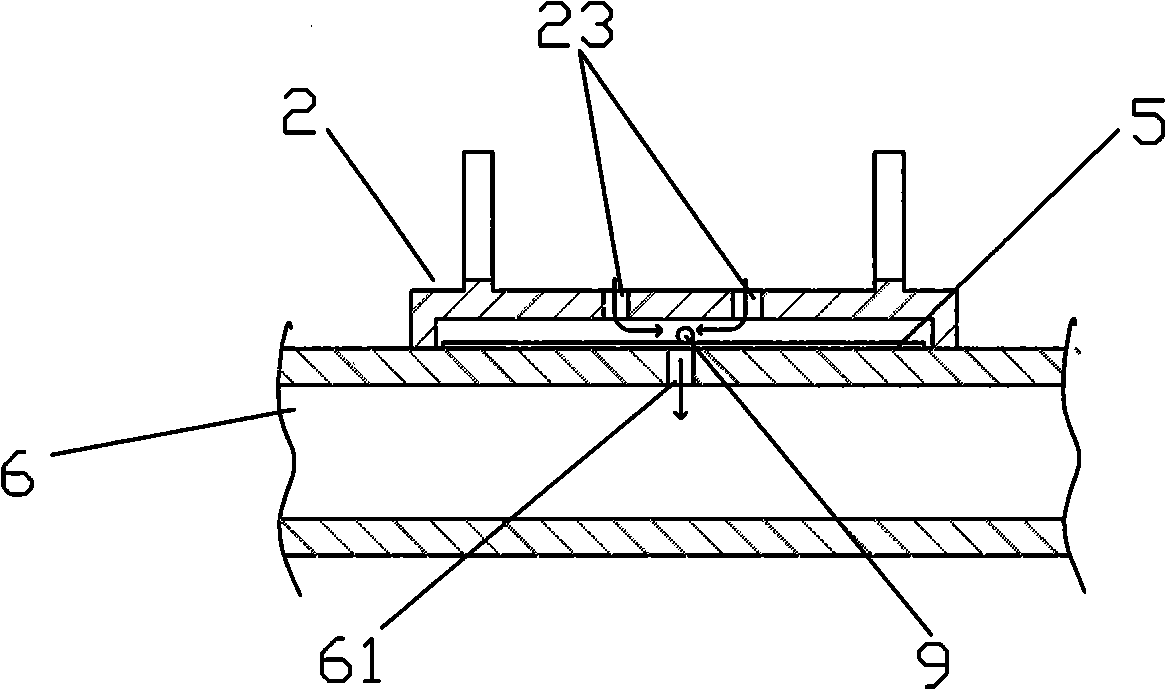

Directional valve equipped with pressure control

ActiveUS20130276915A1Effective pressureOperating means/releasing devices for valvesServomotor componentsEngineeringActuator

A directional valve for controlling an actuator by a pressurized medium, including: a pressure port; a work port; a tank port; a spool moving axially inside the directional valve; a first position of the spool, in which the spool tends to be set, and a second position, to which the spool can be moved by a pilot control force and in which the spool opens the flow of pressurized medium from the pressure port to the work port. The directional valve further includes a feedback chamber in which the pressure generates a feedback force effective on the spool and opposite to the pilot control force. In its second position, the spool guides the pressure of the work port to the feedback chamber, and in the second position, the directional valve generates a feedback force proportional to the pressure of the work port, moving the spool to shut off the flow.

Owner:PARKER HANNIFIN MFG FINLAND

Yarn-collecting device for compact spinning

A yarn accumulation device for compact spinning is arranged between a draft roller and a holding roller, which comprises a yarn accumulation aeroscopic plate and a fixation apparatus. The yarn accumulation aeroscopic plate fixed on a fixation apparatus is provided with two yarn accumulation air long guide holes in parallel each other. The yarn accumulation air long guide holes are in parallel with a pumping seam on an accumulation tube, which are also in a symmetrical arrangement on both sides of the pumping seam. Both ends of the lower part of the polymer yarn air long guide hole are provided with a pair of support legs, spanned a conveyor belt, fit tightly and supported on a sliding surface. The invention has the advantages that the yarn accumulation device is disposed between the draft roller and the holding roller, spanned the conveyor belt and flexibly supported on the sliding surface. Through the guide of the air guide hole on the yarn accumulation aeroscopic plate, the air before entering the pumping channel can be in the implementation of directional effective pressing to the strips. The air above the strips is effectively utilized, thus the negative pressure is reduced and the energy is saved.

Owner:YUNSHENG HLDG GRP

Pressure control by phase current and initial adjustment at car line

A closed loop control system for a fuel pump based on characteristics of speed, pressure, and current. The pressure generated by the pump system is increased at the point in time when the pump system is working against a dead head system (i.e., coasting) to a level that a calibration valve is opened to a determined working point. By measuring the characteristic phase current as a function of the speed, the characteristic is able to be compared, with the pre-calibrated value of the hardware to perform an error compensation algorithm. The error compensation is overlaid with the standard pressure characteristic as a function of speed and phase current, and uses the pre-calibrated opening pressure value (i.e., the inflection point) of the calibration valve and / or in addition the change of the speed to the initial (first calibration), or to a sliding average therefrom.

Owner:VITESCO TECH USA LLC

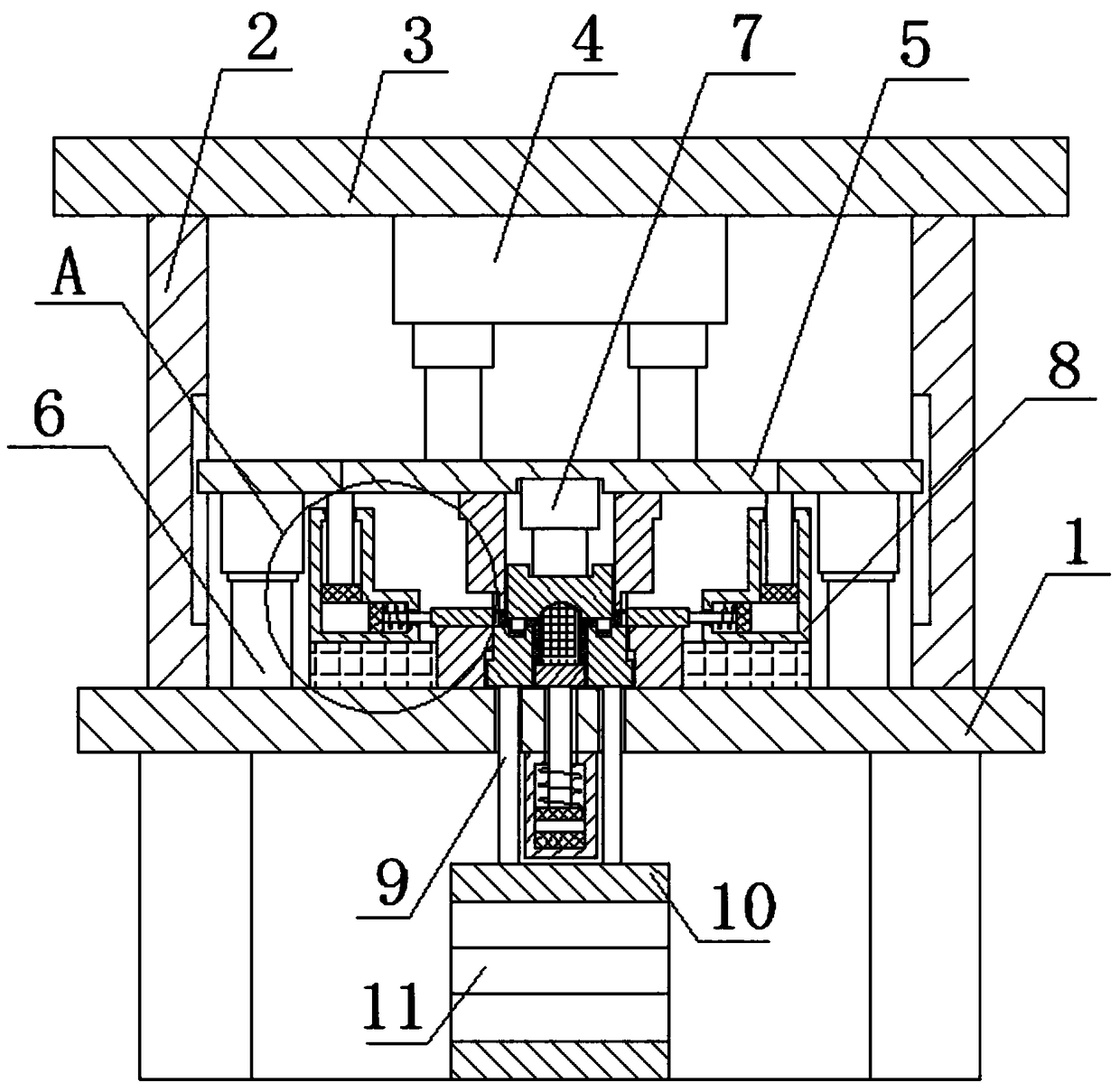

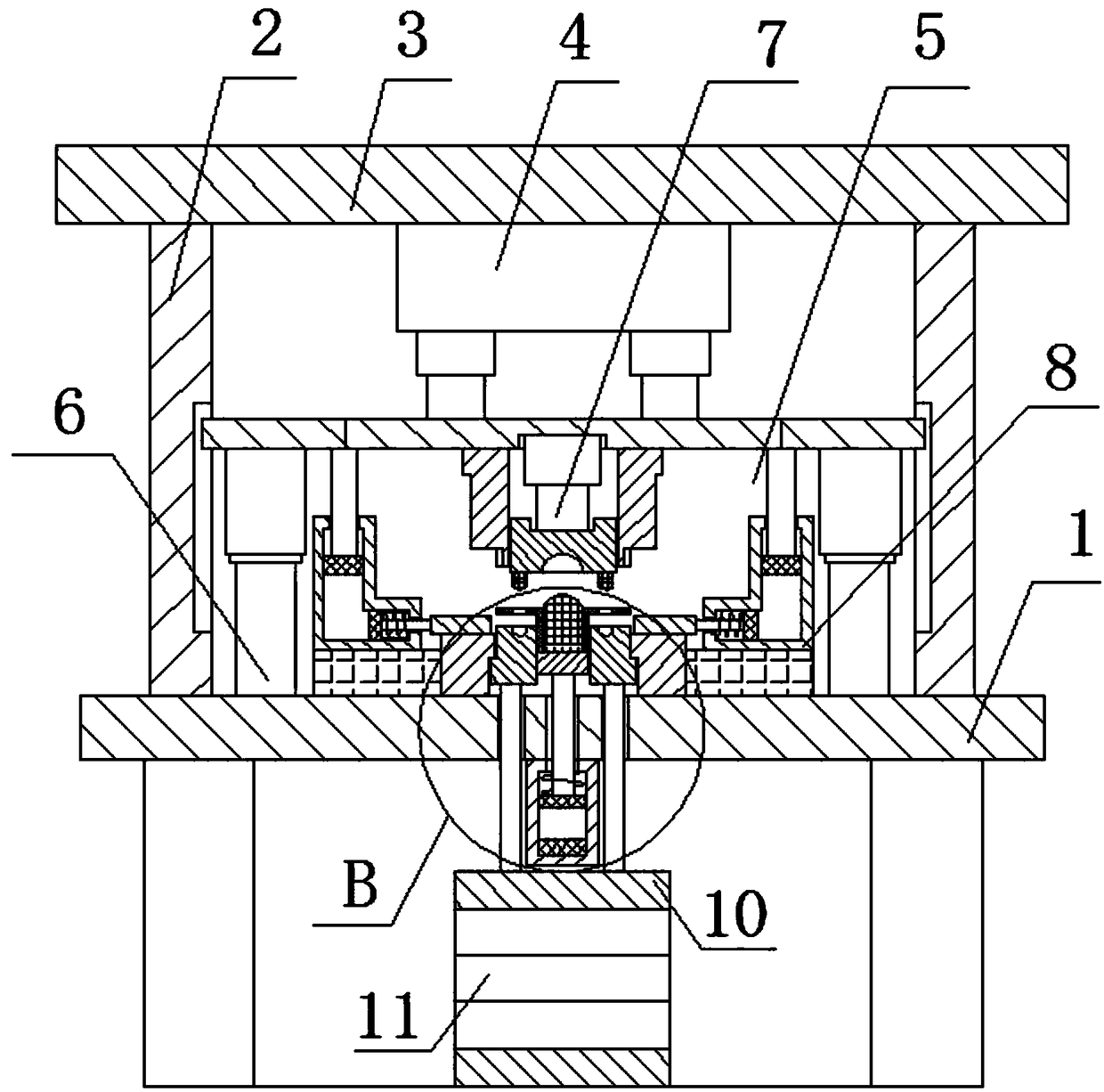

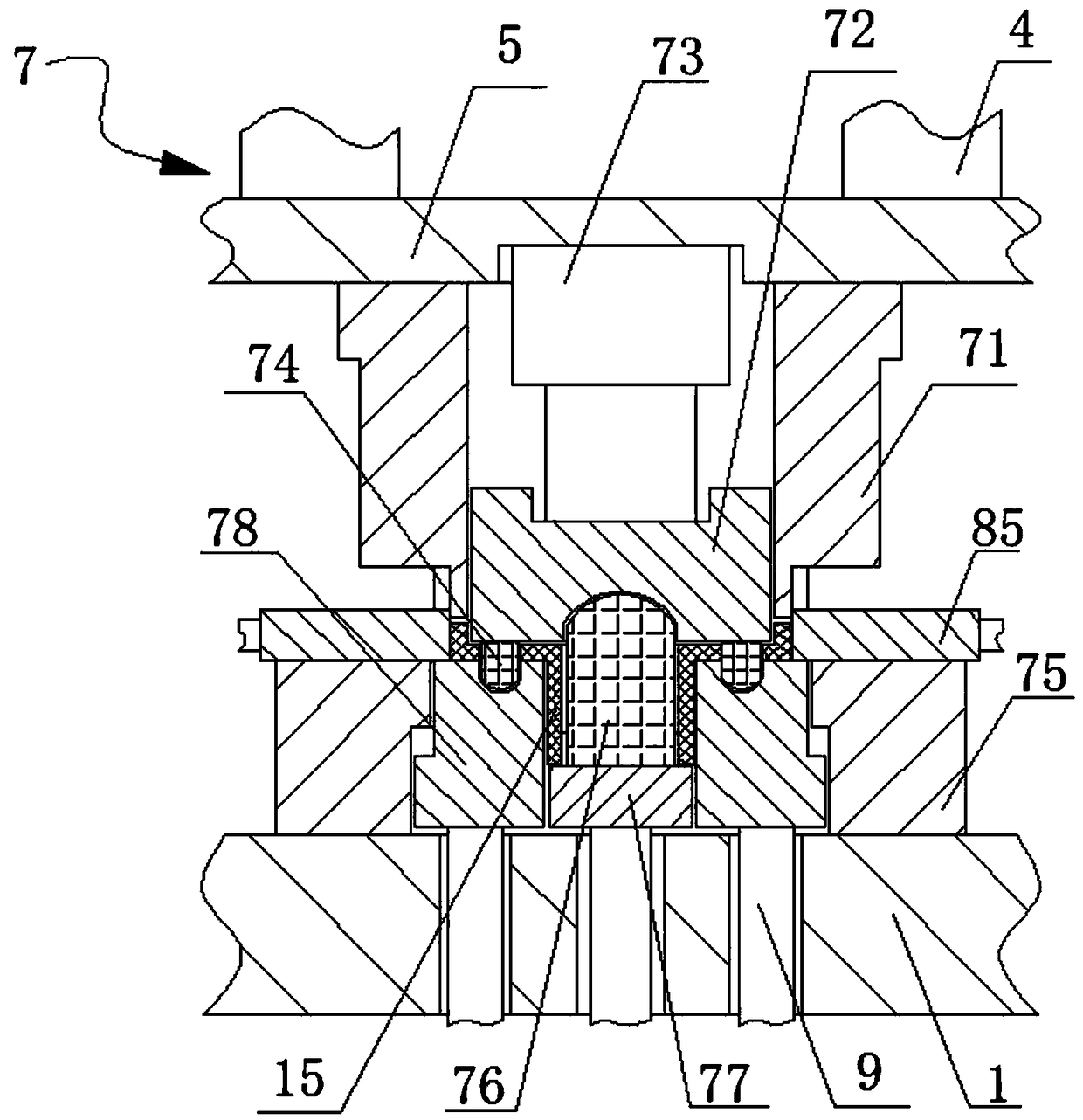

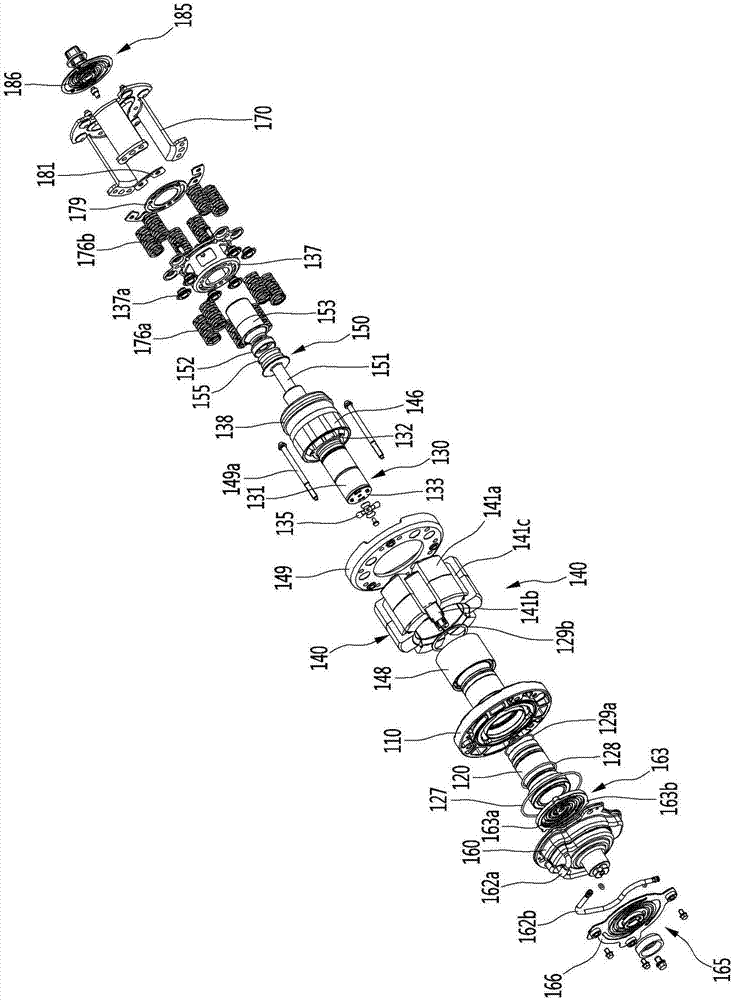

Washing machine clutch flange punch forming technology

The invention provides a washing machine clutch flange punch forming technology. A punch platform, four supporting feet vertically connected to the lower end of the punch platform, two supporting plates vertically and symmetrically connected to the upper end of the punch platform, a top plate vertically connected to the upper ends of the two supporting plates, and a hydraulic cylinder fixedly connected to the middle of the lower end of the top plate are included, and the output end of the hydraulic cylinder is vertically connected with the upper end of a pressing moving plate; shortcomings inthe prior art can be overcome, design is reasonable, the structure is compact, the material and the structure of a flange disc are changed, the material is changed into easily-purchased SPCC cold rollsteel from expensive zinc alloy, a center gear is changed into a smooth shaft sleeve, the problem that dimensional tolerance of the center gear is high in requirement is solved, strength of a flangedisc made of the SPCC cold roll steel is improved by few times compared with strength before improvement, deforming and breaking are not prone to happening, the quality of the flange disc is greatly improved, and the production efficiency of the flange disc is improved.

Owner:宁国市金泰金属制品有限公司

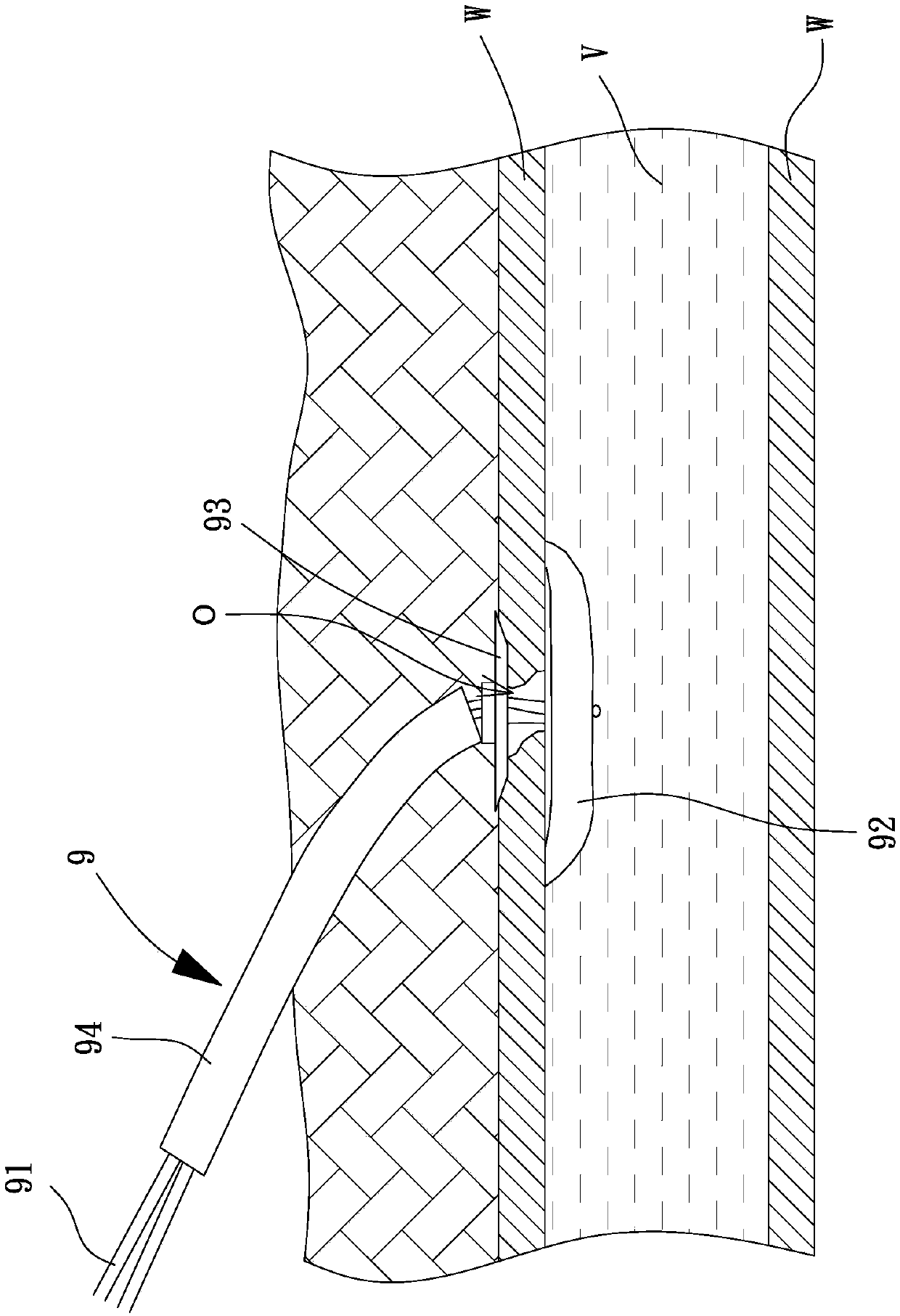

Vascular puncture sealing device

InactiveCN107789023AEffective hemostasisReduced surgical stepsSurgeryPharmaceutical containersSurgeryBlood vessel

Owner:周佳蓉

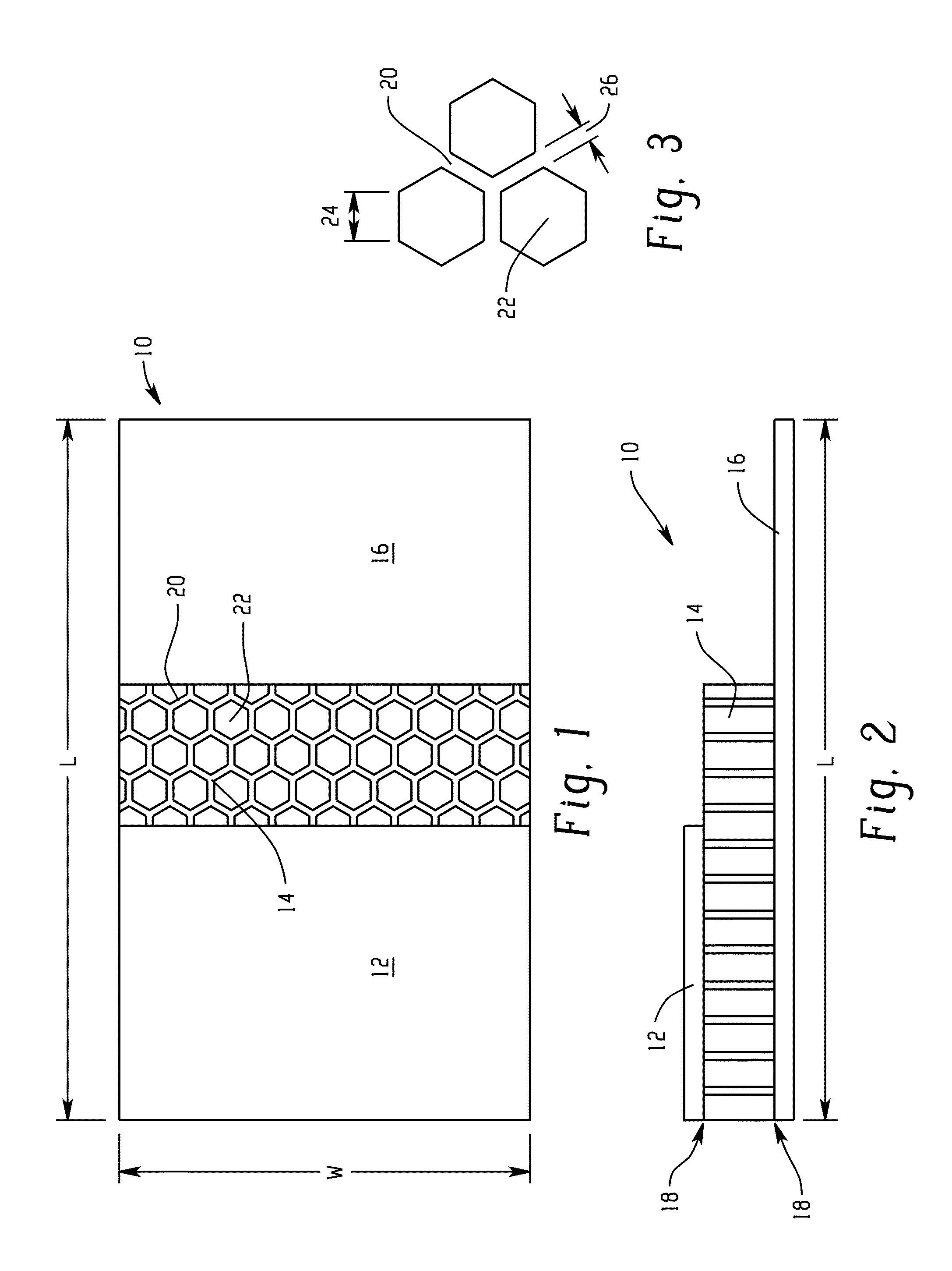

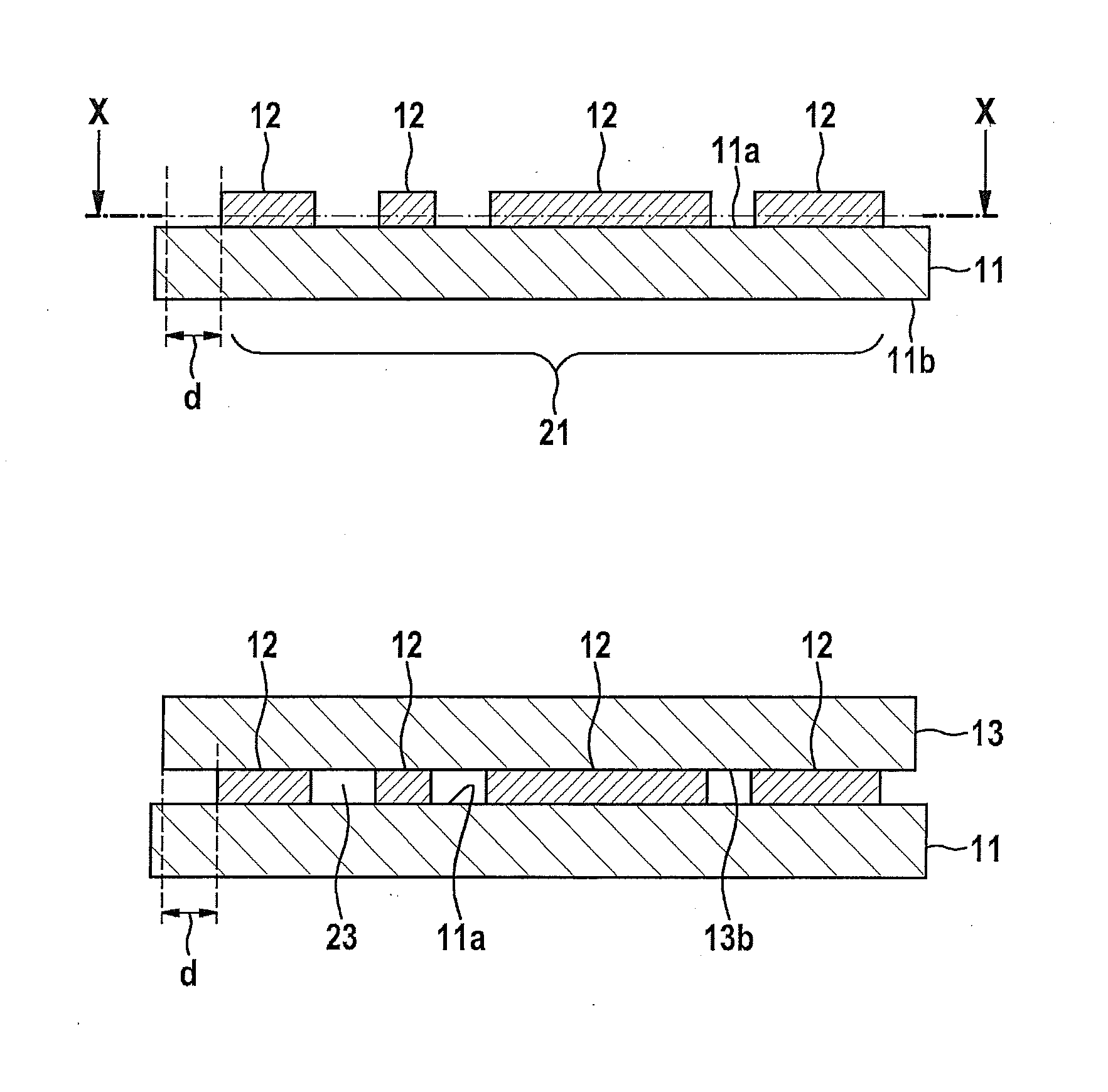

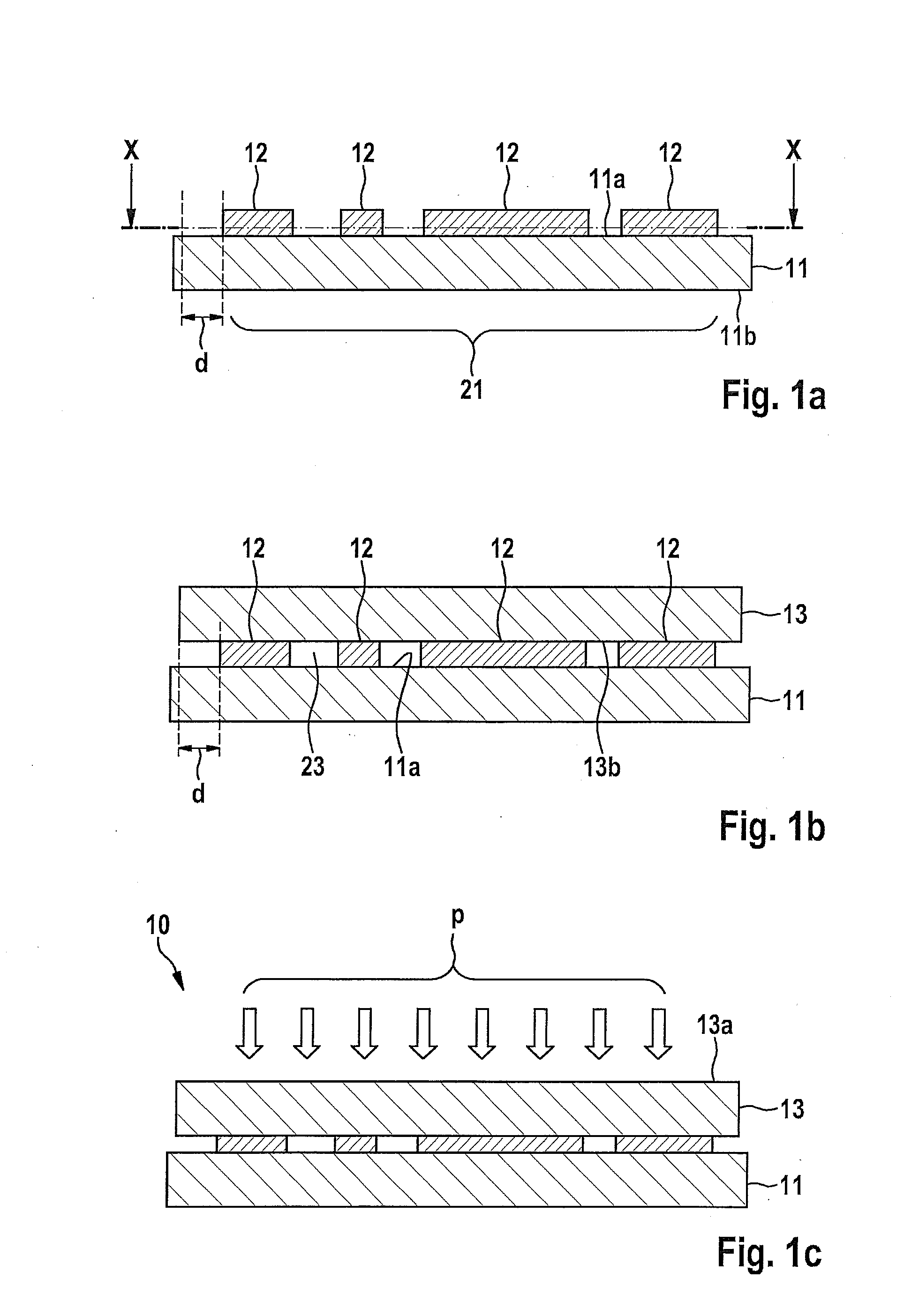

Method for Producing Structured Sintered Connection Layers, and Semiconductor Element Having a Structured Sintered Connection Layer

ActiveUS20140225274A1Satisfactory electric connectionSatisfactory thermal connectionSemiconductor/solid-state device detailsSolid-state devicesSurface coverMechanical tension

A method for producing a sinter layer connection between a substrate and a chip resulting in an electric and thermal connection therebetween and in reduced mechanical tensions within the chip. The method produces a sinter layer by applying a multitude of sinter elements of a base material forming the sinter layer in structured manner on a contact area of a main surface of a substrate; placing a chip to be joined to the substrate on the sinter elements; and heating and compressing the sinter elements to produce a structured sinter layer connecting the substrate and chip and extending within the contact area, the surface coverage density of the sinter elements on the substrate in a center region of the contact area being greater than the surface coverage density of the sinter elements in an edge region of the contact area, and at least one through channel, extending laterally as to the substrate's main surface being provided towards the contact area's edge. A large-area sinter element is situated in the contact area's center region, and circular sinter elements is situated in a contact area edge region. The sinter elements may also have notches. Also described is a related device.

Owner:ROBERT BOSCH GMBH

Two roll sugarcane crushing mill

Owner:NIKAM BHAUSAHEB BAPURAO

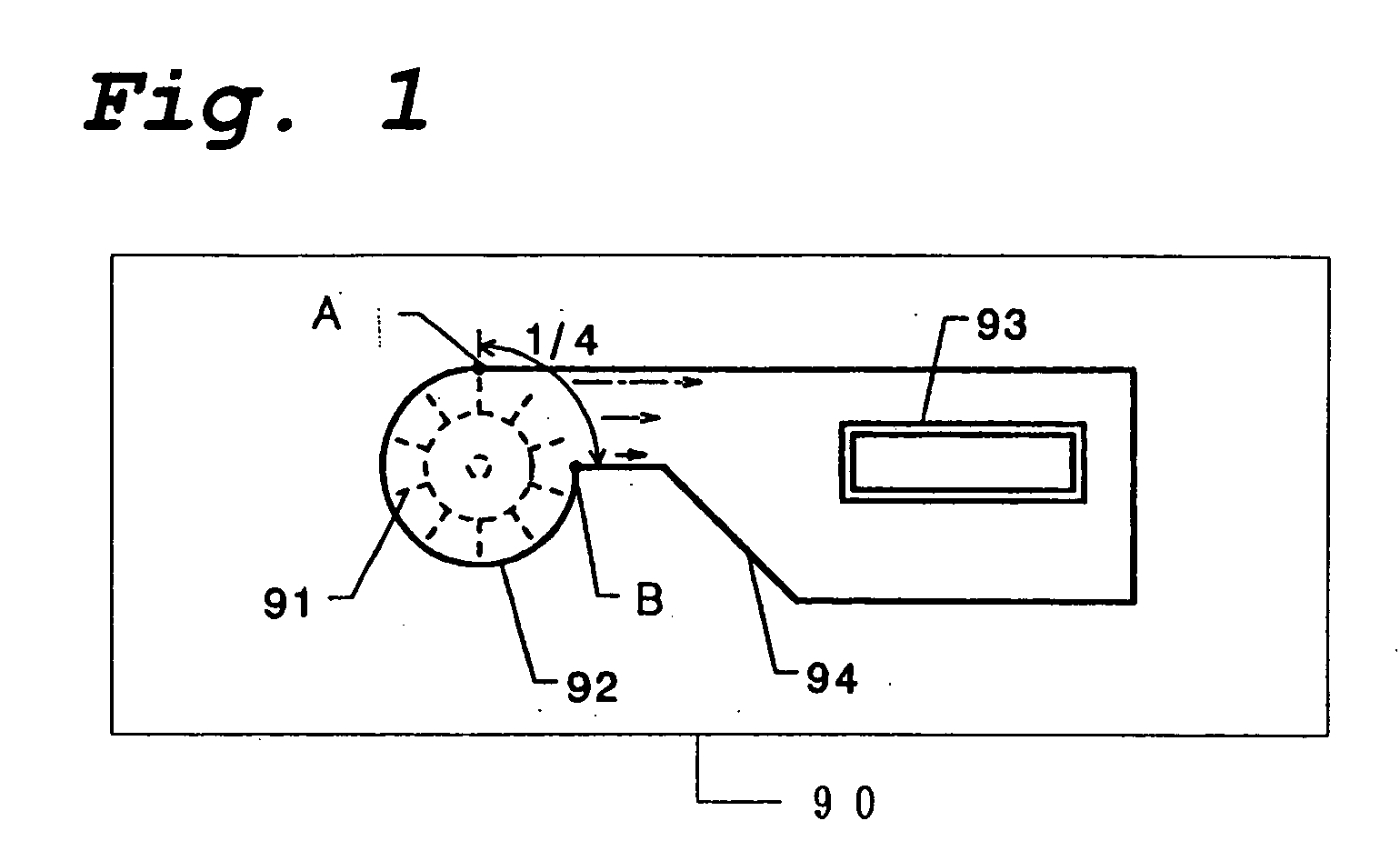

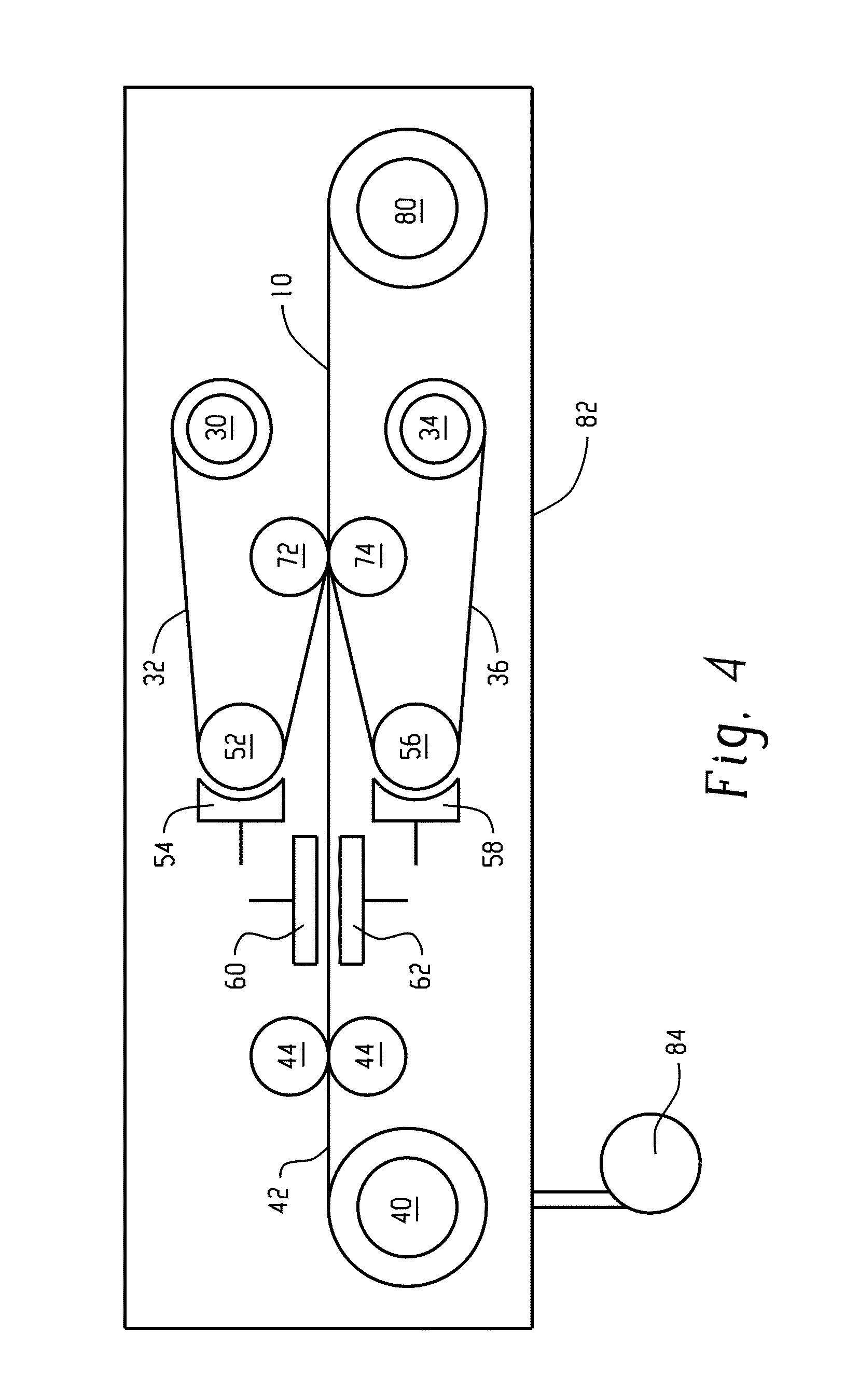

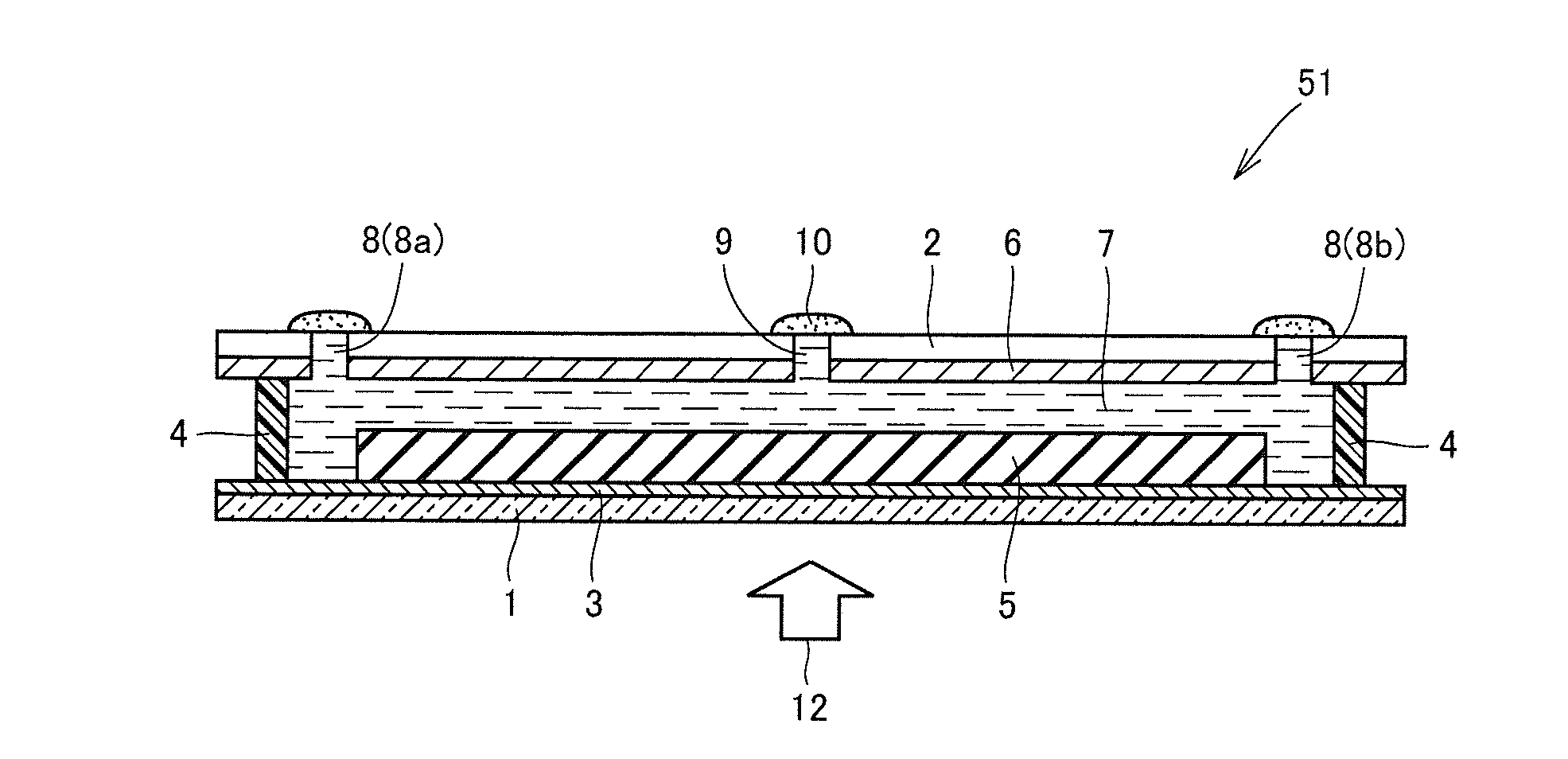

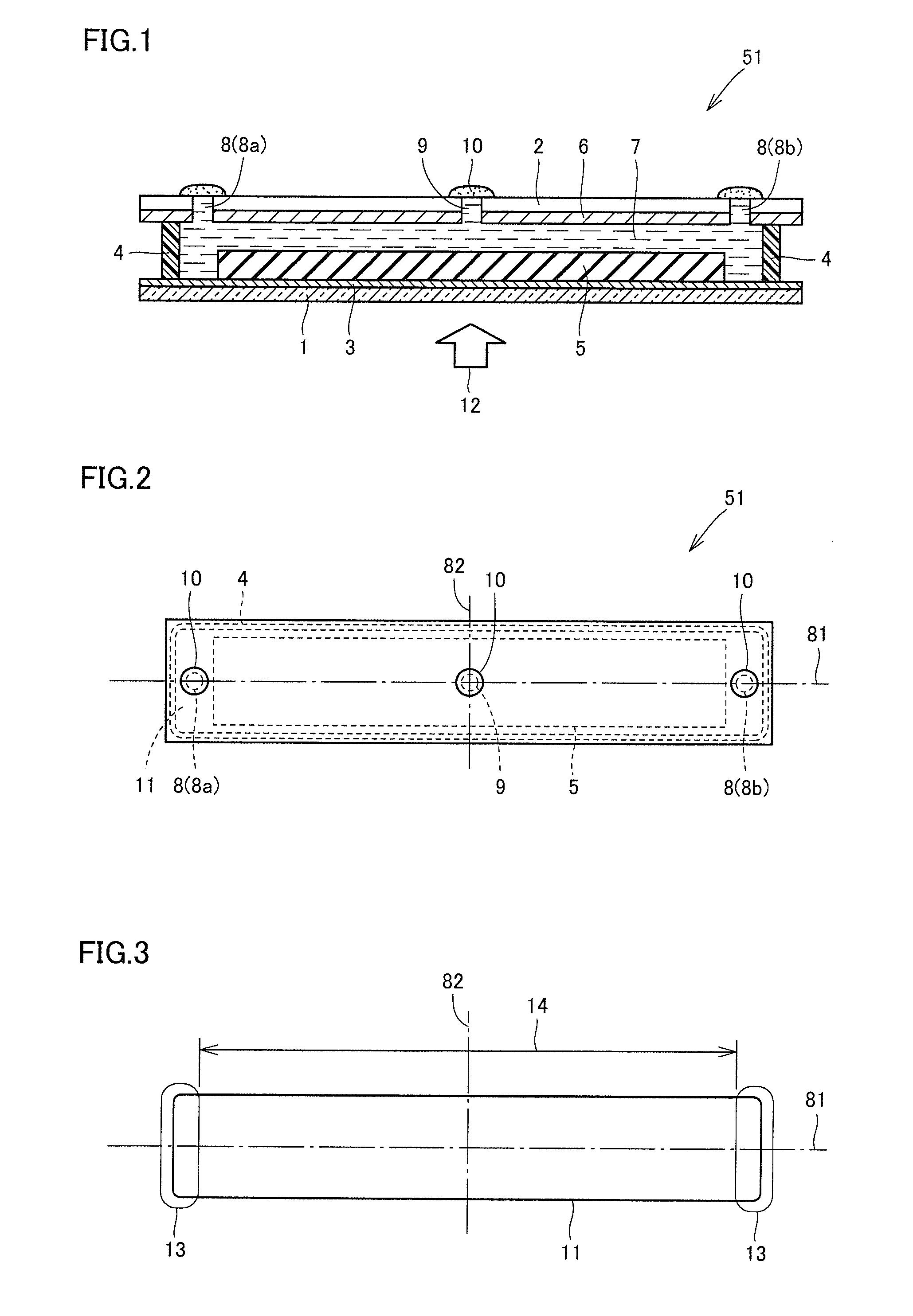

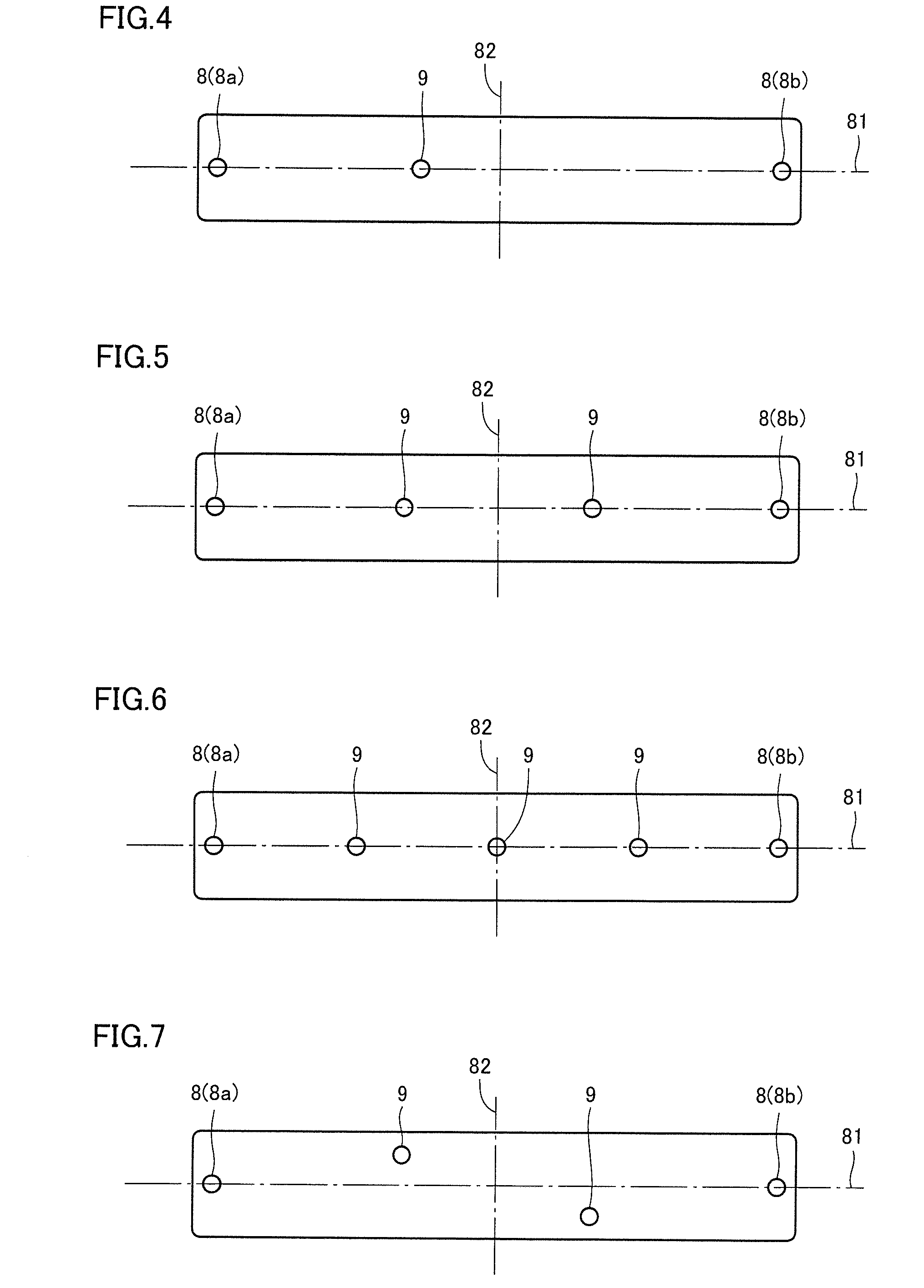

Solar cell and solar cell module

InactiveUS20120298176A1Reduce internal pressureEffective pressureElectrolytic capacitorsPV power plantsEngineeringPhotoelectric conversion

A solar cell includes a light transmissive substrate, a supporting substrate, a photoelectric conversion part and a counter electrode disposed between the light transmissive substrate and the supporting substrate in such a manner that they are spaced from each other; an electrolyte part disposed between the light transmissive substrate and the supporting substrate while being in contact with the photoelectric conversion part and the counter electrode, and a sealing part that surrounds and seals the electrolyte part in such a manner that the electrolyte part is retained within an electrolyte disposition region. First openings that make the electrolyte part communicate with the outside are provided at least in one end part in the electrolyte disposition region, and at least one second opening that makes the electrolyte part communicate with the outside is provided in the middle part in the electrolyte disposition region. The first and second openings are sealed.

Owner:SHARP KK

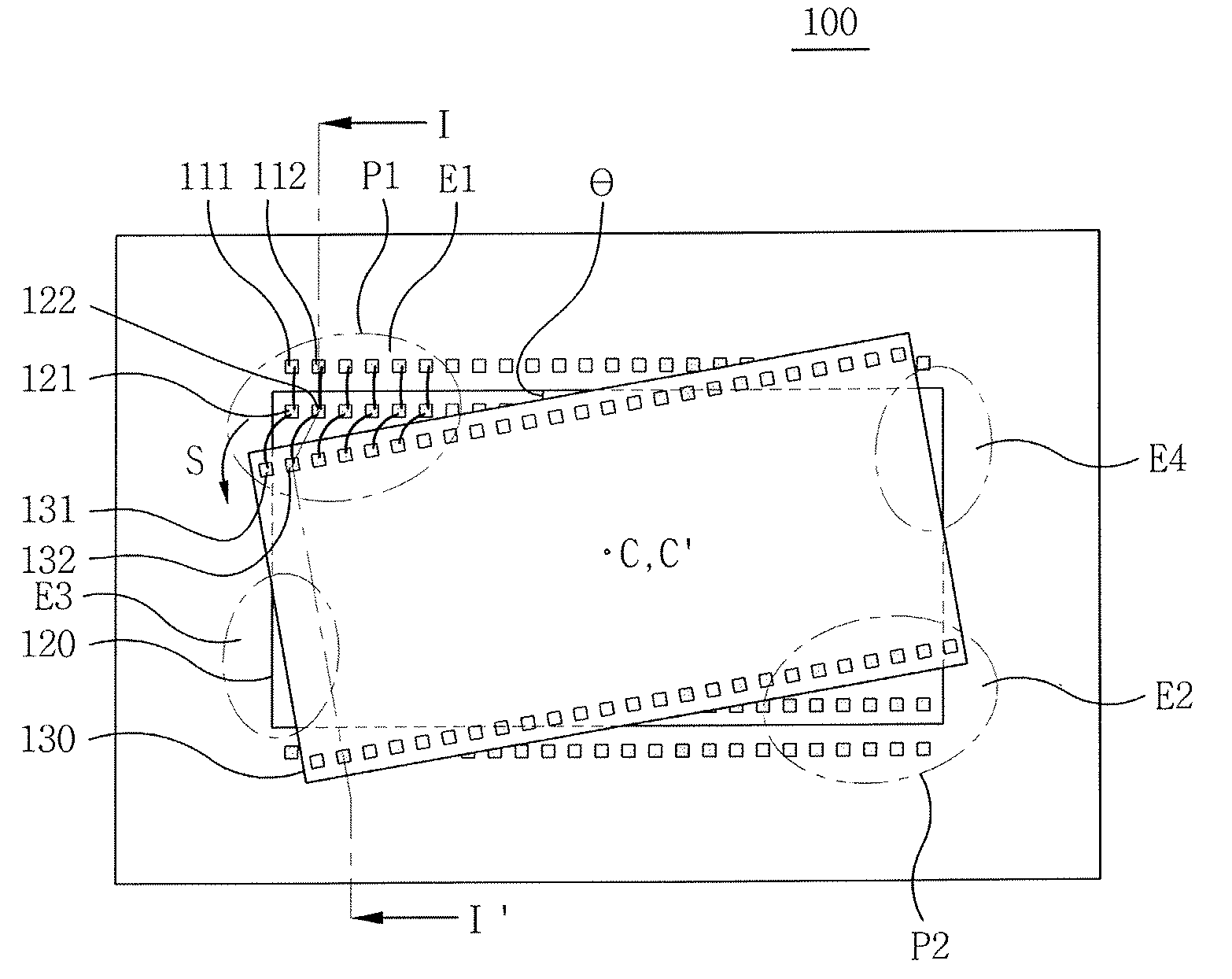

Semiconductor package having a stacked structure

ActiveUS8487452B2Increase capacityGood yieldSemiconductor/solid-state device detailsSolid-state devicesElectronic systemsSemiconductor chip

A semiconductor package includes a substrate, a first semiconductor chip stacked on the substrate and a second semiconductor chip stacked on the first semiconductor chip. In the semiconductor package, the second semiconductor chip is rotated to be stacked on the first semiconductor chip. The semiconductor package is used in an electronic system.

Owner:SAMSUNG ELECTRONICS CO LTD

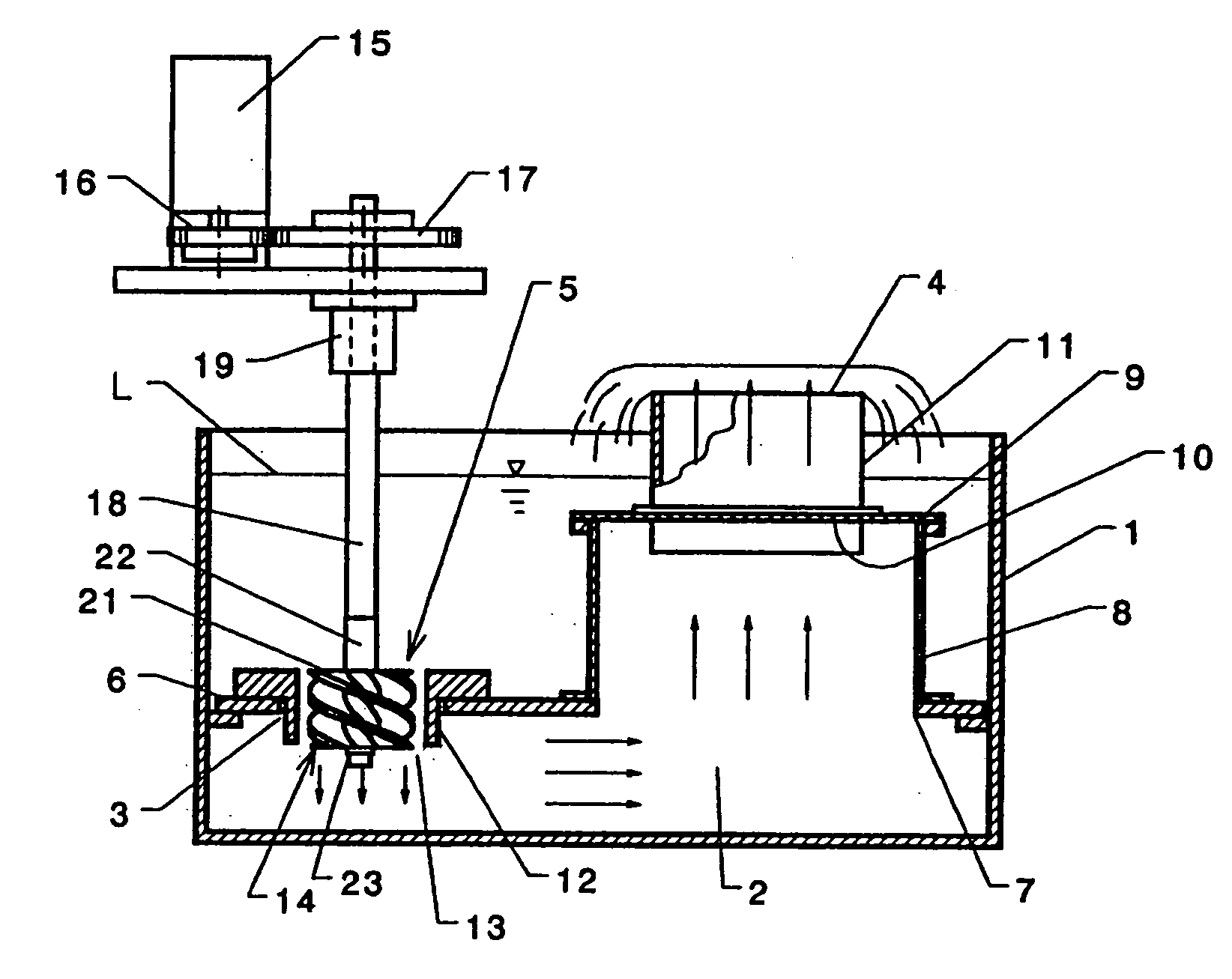

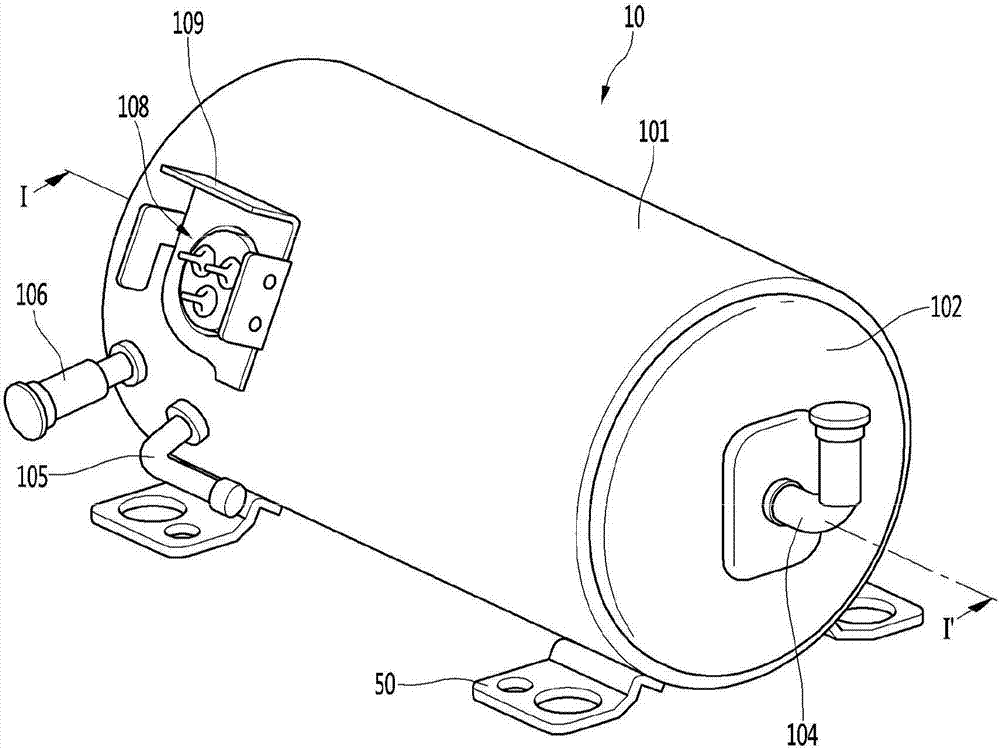

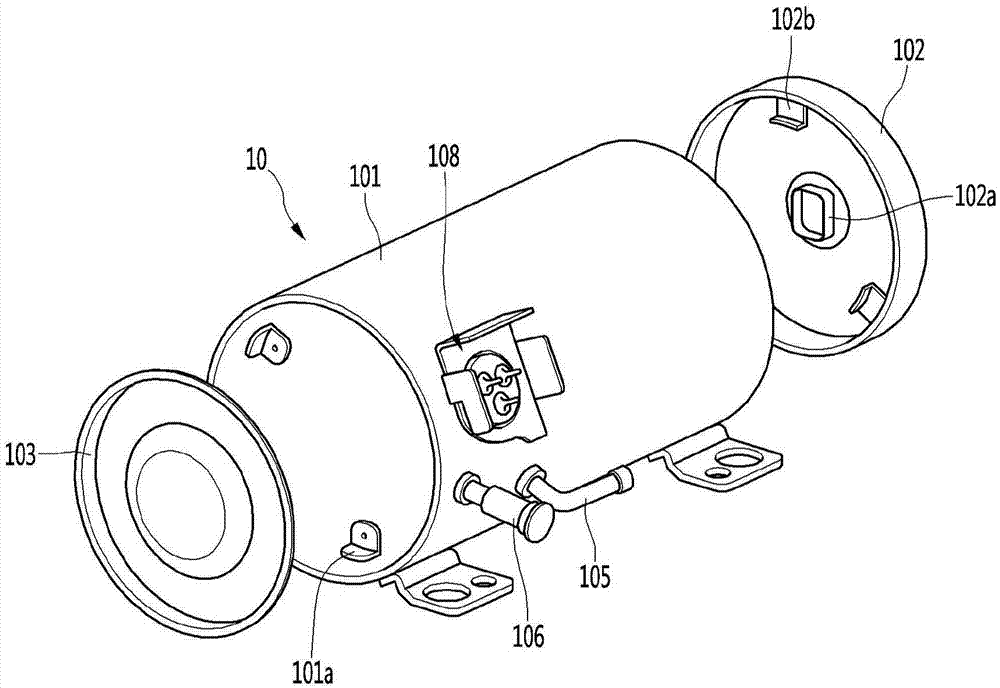

Linear compressor

InactiveCN107339224AReduce sizeIncrease internal storagePositive displacement pump componentsPiston pumpsReciprocating motionLinear compressor

A linear compressor comprises: a piston (130) that reciprocates in an axial direction; a cylinder (120) into which the piston (130) is inserted and which defines a compression space (P) for a refrigerant; a frame (110) coupled to an outer side of the cylinder (120); a cylinder groove (121e) defined on an outer circumferential surface of the cylinder (120); and a sealing member (129a) provided in the cylinder groove (121e), the sealing member (129a) being pressed by the frame (110); wherein a space between the outer circumferential surface of the cylinder (120) and an inner circumferential surface of the frame (110) includes: a gas pocket (110b) through which a refrigerant flows; and a sealing pocket (110c) in which the sealing member is provided.

Owner:LG ELECTRONICS INC

Pressure control by phase current and initial adjustment at car line

A closed loop control system for a fuel pump based on characteristics of speed, pressure, and current. The pressure generated by the pump system is increased at the point in time when the pump system is working against a dead head system (i.e., coasting) to a level that a calibration valve is opened to a determined working point. By measuring the characteristic phase current as a function of the speed, the characteristic is able to be compared, with the pre-calibrated value of the hardware to perform an error compensation algorithm. The error compensation is overlaid with the standard pressure characteristic as a function of speed and phase current, and uses the pre-calibrated opening pressure value (i.e., the inflection point) of the calibration valve and / or in addition the change of the speed to the initial (first calibration), or to a sliding average therefrom.

Owner:VITESCO TECH USA LLC

Closure for a retort processed container having a peelable seal

InactiveUS7431168B2Prevent seal separationPrevent leakageCapsClosure using stoppersPositive pressureEngineering

The present development is for a closure which provides a liner for abutting a surface and maintaining an effective pressure against a peelable seal affixed to a container lip as the sealed container is exposed to relatively high temperature and pressure conditions. The liner which abuts a surface of the seal sandwiches the seal between the liner and the container lip. The liner defines a resting thickness at ambient temperature and pressure conditions and is made from a material capable of being compressed to a thickness less than the resting thickness and of recovering to a recovery thickness sufficient to allow the liner to maintain a positive pressure against the seal upon exposure to elevated temperatures, elevated pressure, or a combination of elevated temperature and elevated pressure.

Owner:BERRY PLASTICS CORP

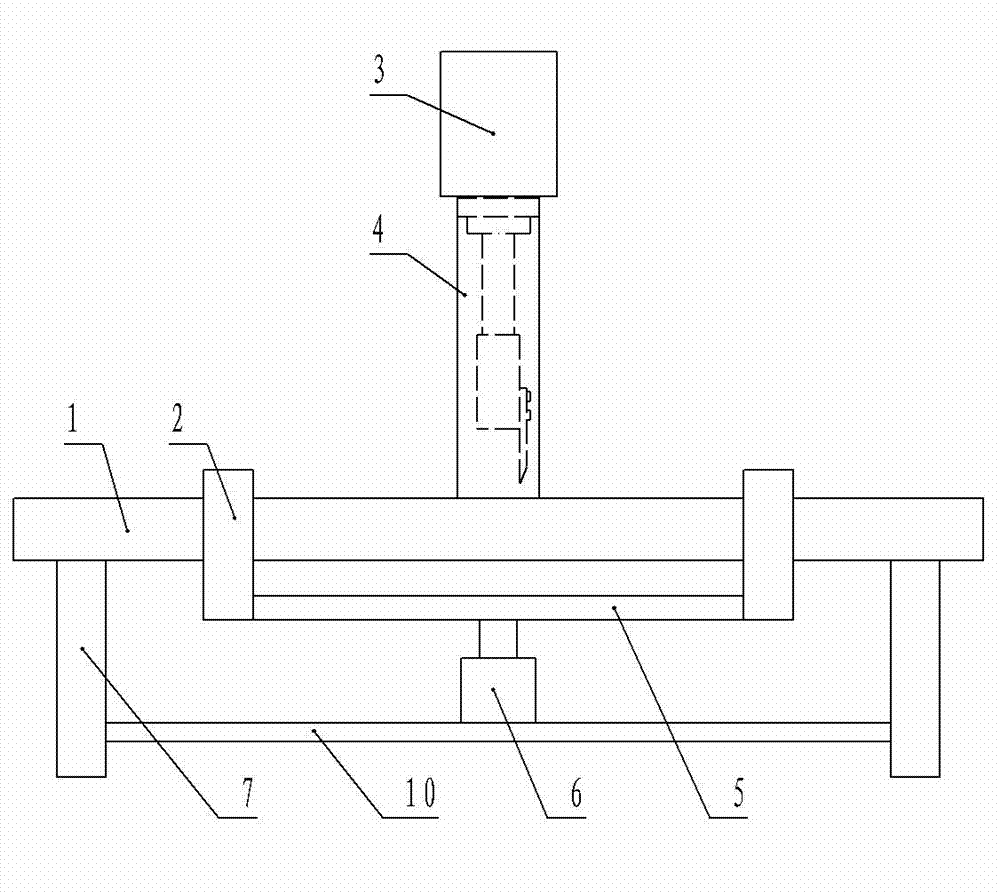

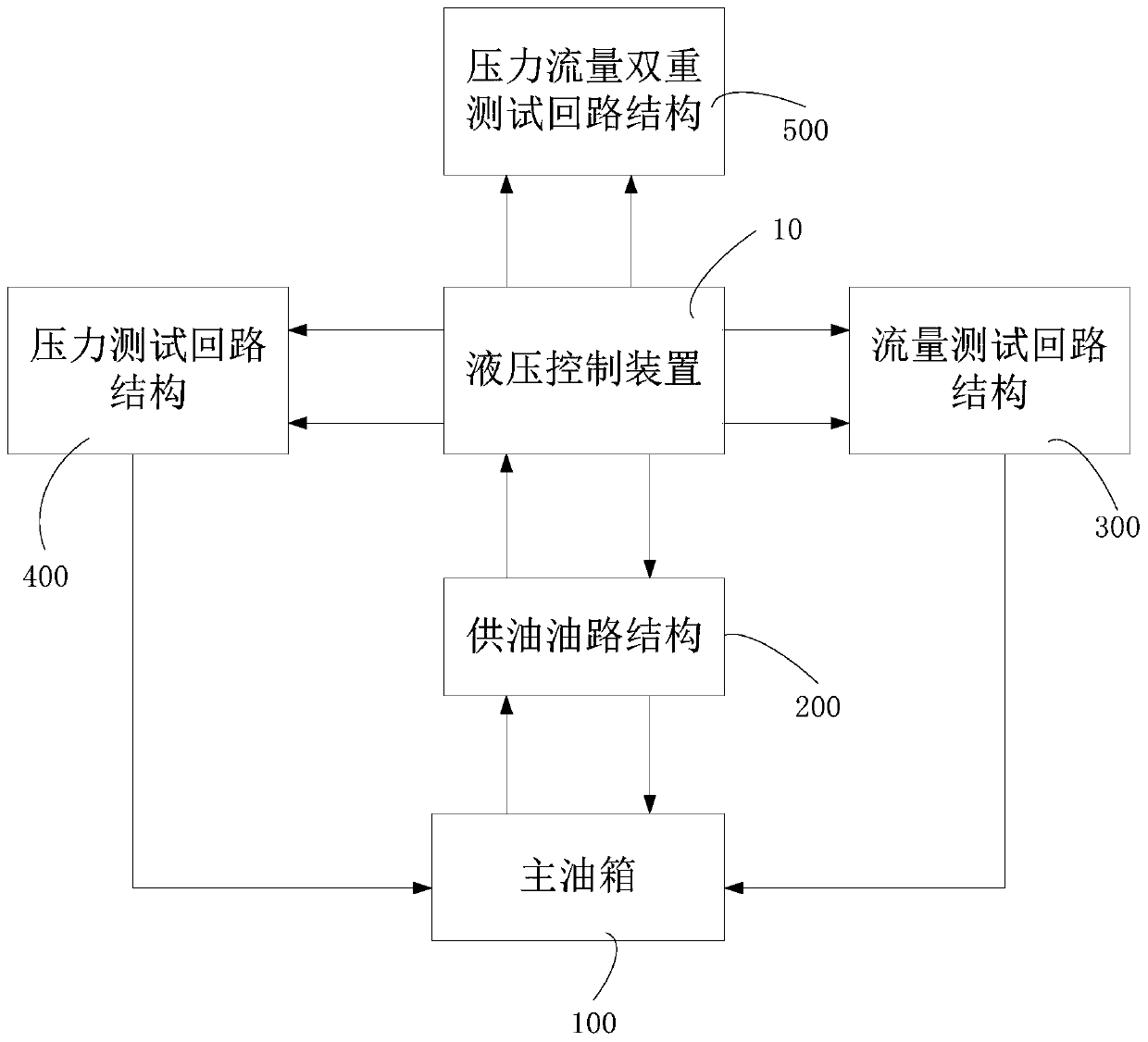

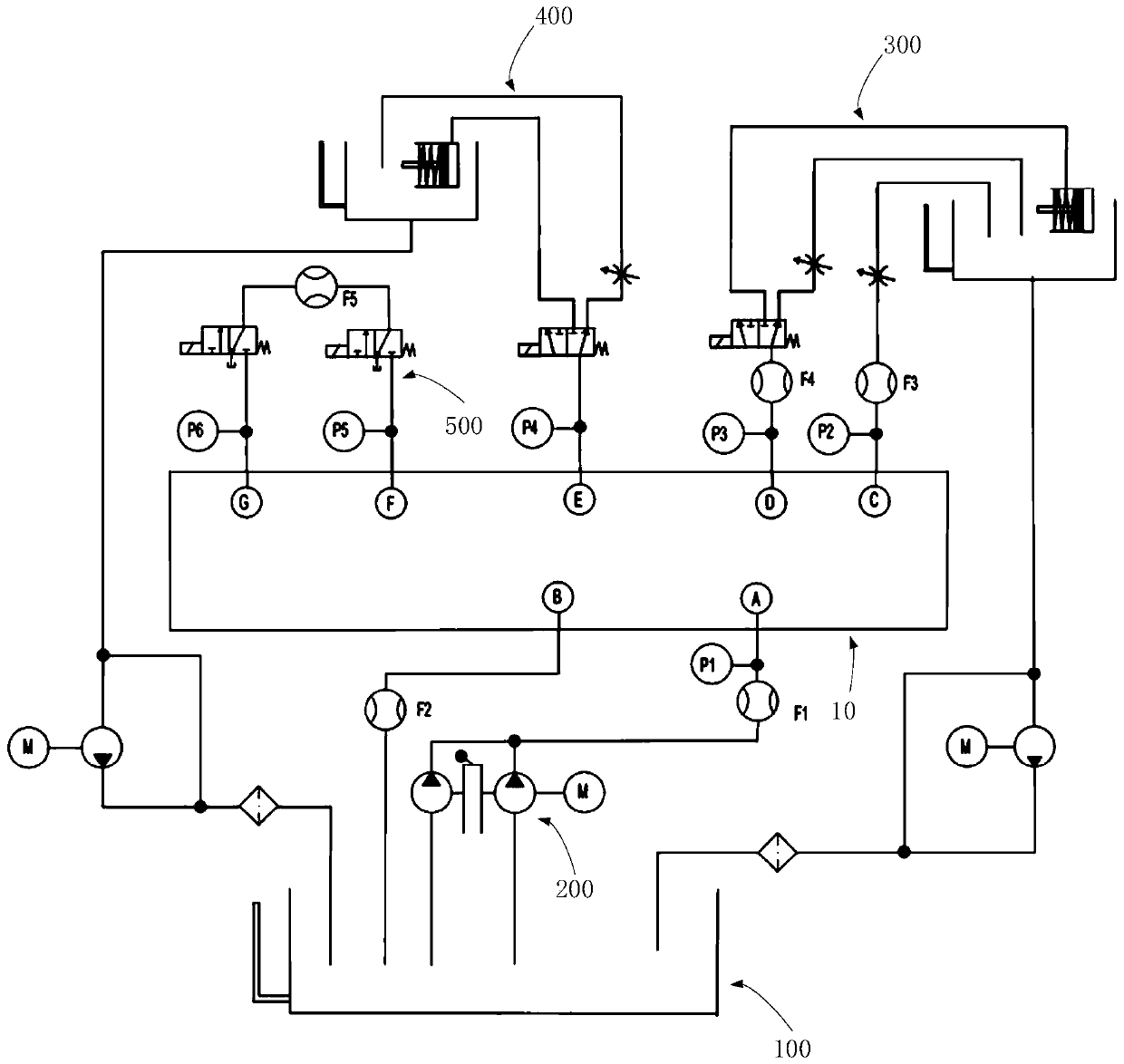

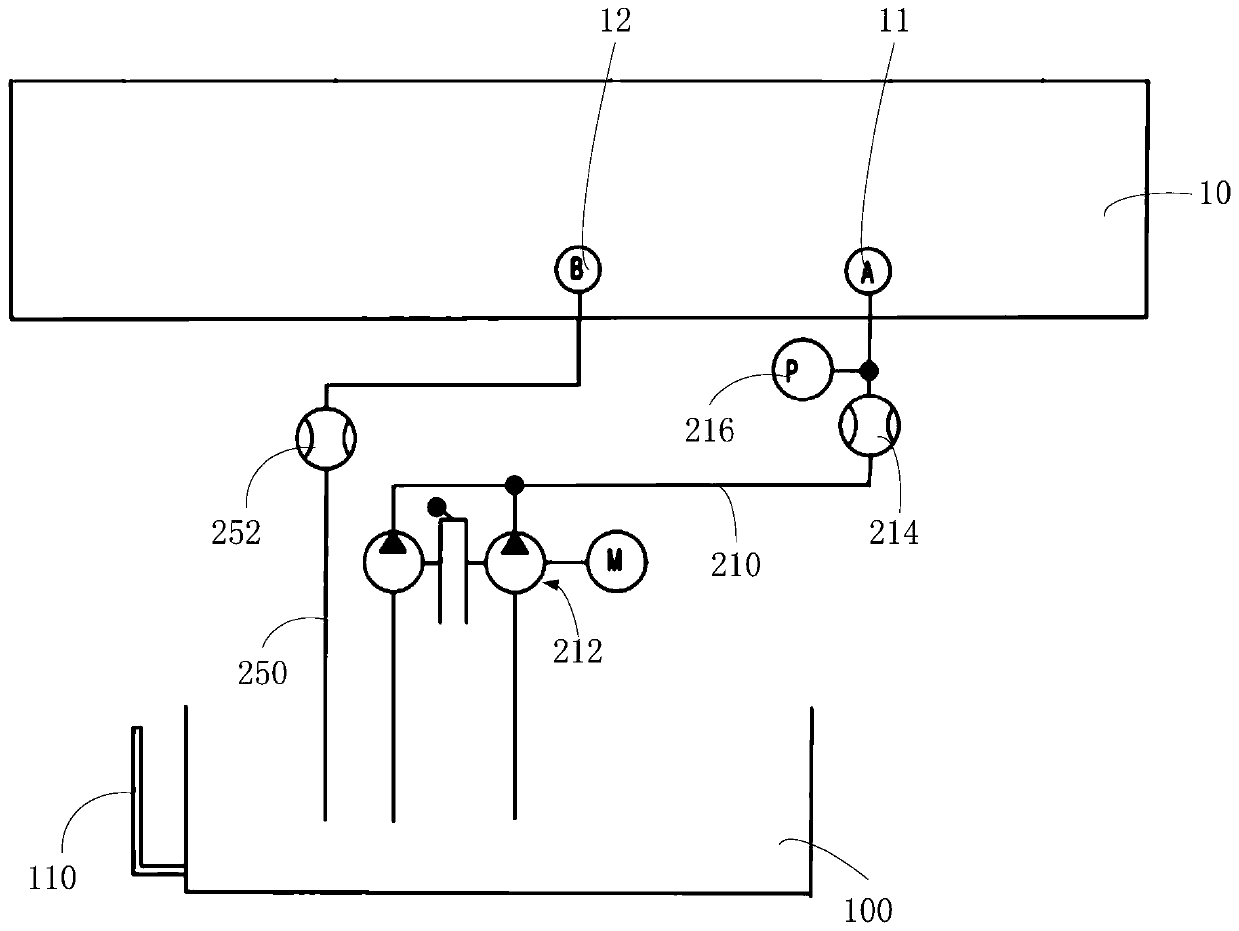

Test system of hydraulic control device of gearbox

ActiveCN110886742AEffective pressureEffective flow testFluid-pressure actuator testingHydraulic pressureHydraulic control

The invention relates to a test system of a hydraulic control device of a gearbox. The test system comprises a main oil tank, an oil supply oil way structure, a flow test loop structure and a pressuretest loop structure, wherein the oil supply oil way structure is in circular communication with the main oil tank and the hydraulic control device; the flow test loop structure is in communication with the main oil tank and the hydraulic control device; the pressure test loop structure is in communication with the main oil tank and the hydraulic control device; the flow test loop structure comprises a flow test oil tank, a flow test oil way and a flow test oil return oil way; the flow test oil way is in communication between the hydraulic control device and the flow test oil tank; the flow test oil return oil way is in communication between the flow test oil tank and the main oil tank; the pressure test loop structure comprises a pressure test oil tank, a pressure test oil way and a pressure test oil return oil way; the pressure test oil way is in communication between the hydraulic control device and the pressure test oil tank; and the pressure test oil return oil way is in communication between the pressure test oil tank and the main oil tank. The test system aims to solve the problems that an effective and reliable test system is lacked in the prior art, and the successful development efficiency of the hydraulic control device is influenced.

Owner:ANHUI XINGRUI GEAR TRANSMISSION

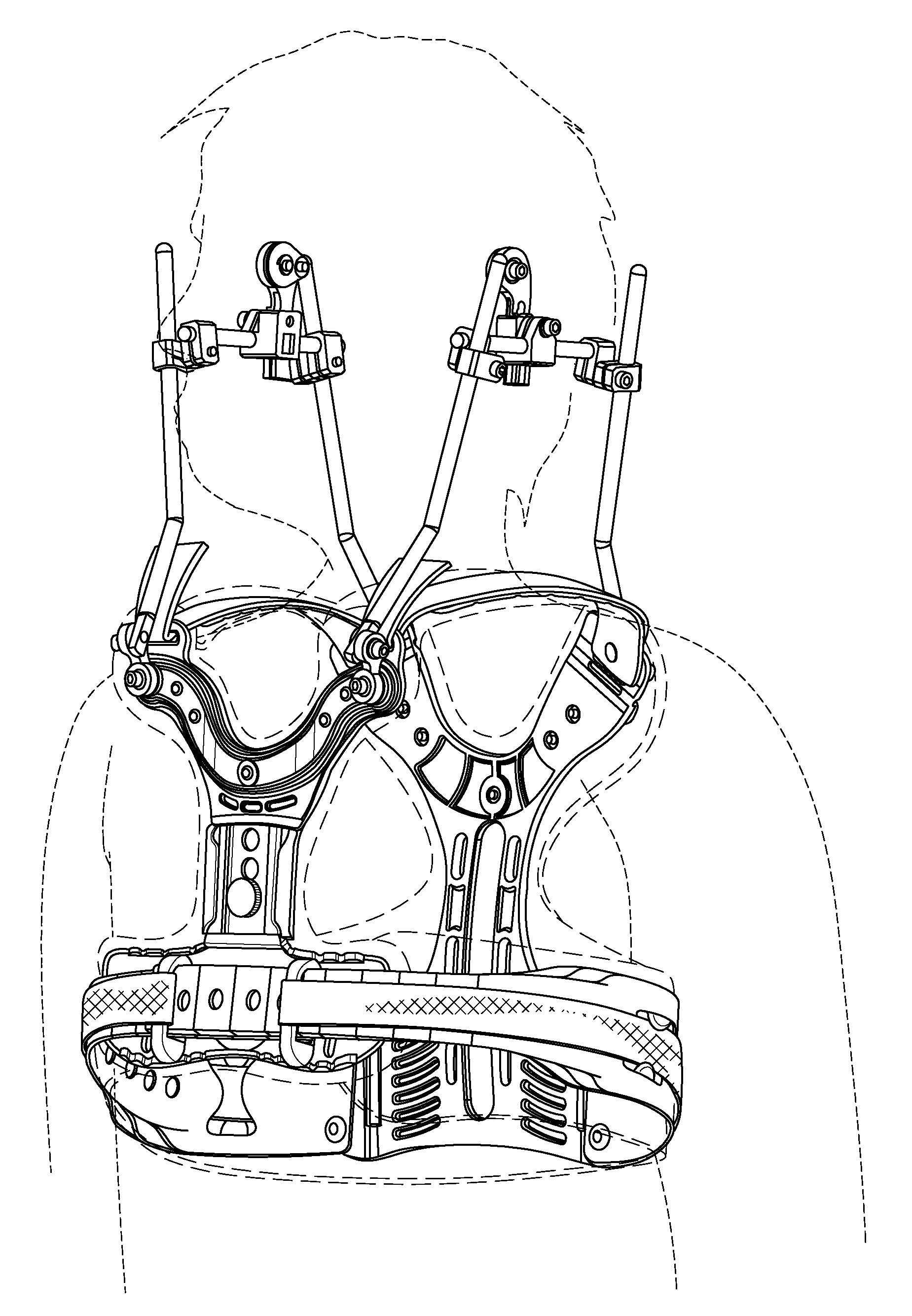

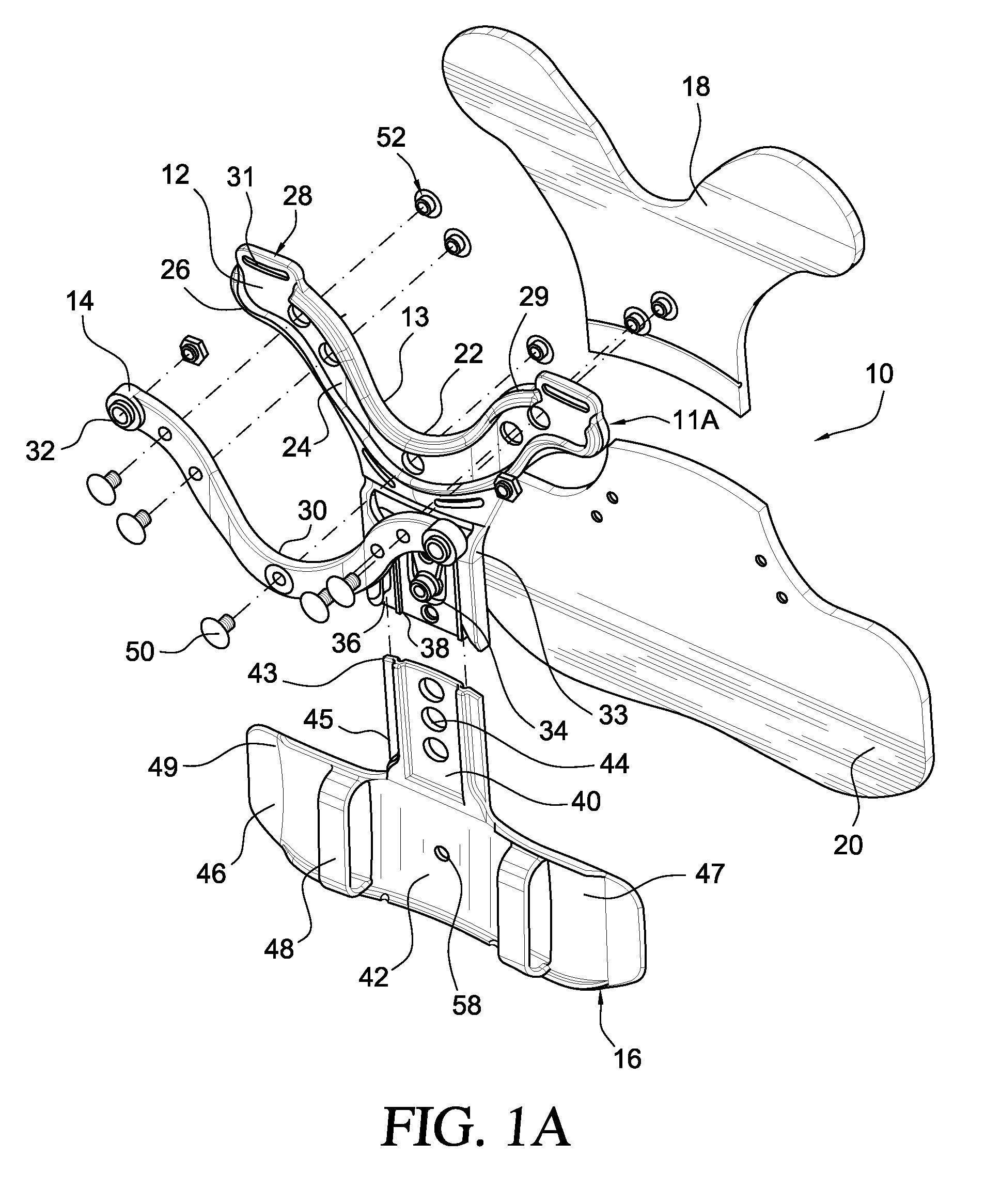

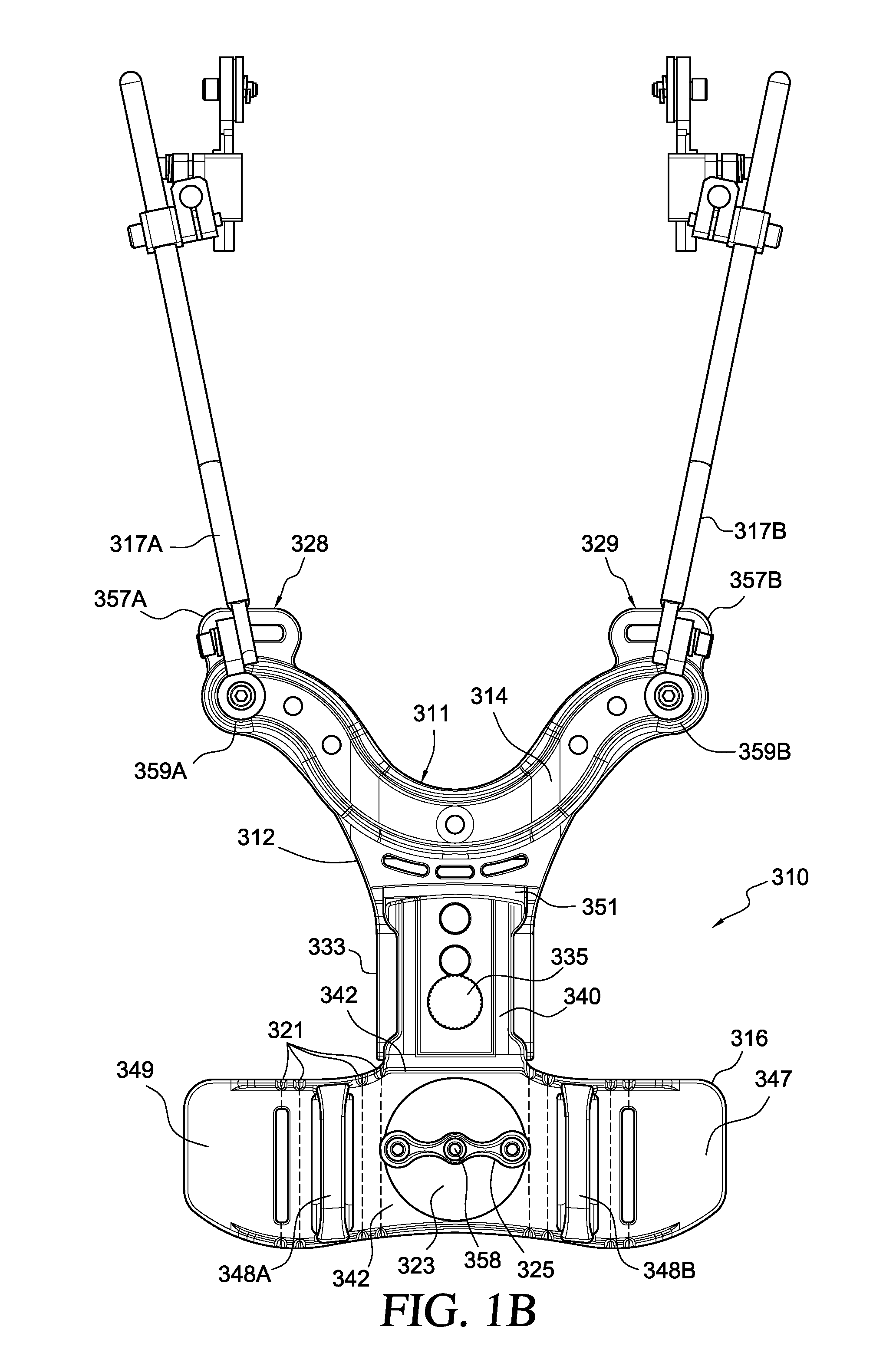

Immobilization device

An immobilization device including an anterior component including a two-dimensional shaped section contoured to a shape of the human chest and an anterior outwardly bowed area relative to the two-dimensional shaped anterior section generally corresponding to the sternum of the wearer. The device also includes a posterior component including a two-dimensional shaped section contoured to a shape of the human back and a posterior outwardly bowed area relative to the two-dimensional shaped section corresponding to the spinal column of the wearer, with elongate cushion elements connected to and extending within a width of the posterior outwardly bowed area. A strapping system connects both the anterior and posterior components to one another.

Owner:OSSUR HF

Device for irrigation and insufflation with blood pressure dependent pressure control

ActiveUS9901670B2Reduce disadvantagesEffective pressureCannulasEnemata/irrigatorsCorrelation factorControl signal

A device for irrigation and / or insufflation during endoscopic surgery / procedures in a body cavity, comprising a first fluid pump device to deliver fluid to the body cavity, a second fluid pump device to move fluid from the body cavity, a control unit connected to the first and / or second fluid pump device, a blood pressure measuring device, wherein the control unit derives a control signal based on a signal from the blood pressure measuring device, and sends the control signal to the first fluid and / or second fluid pump device, wherein the control signal is derived by processing the signal from the blood pressure measuring device using a correlation factor in the device, dependent on the relationship between a blood pressure measurement signal, and a perfusion pressure of the body cavity, wherein the first and / or second fluid pump device controls the pressure in the body cavity based on the control unit's control signal.

Owner:BONVISI

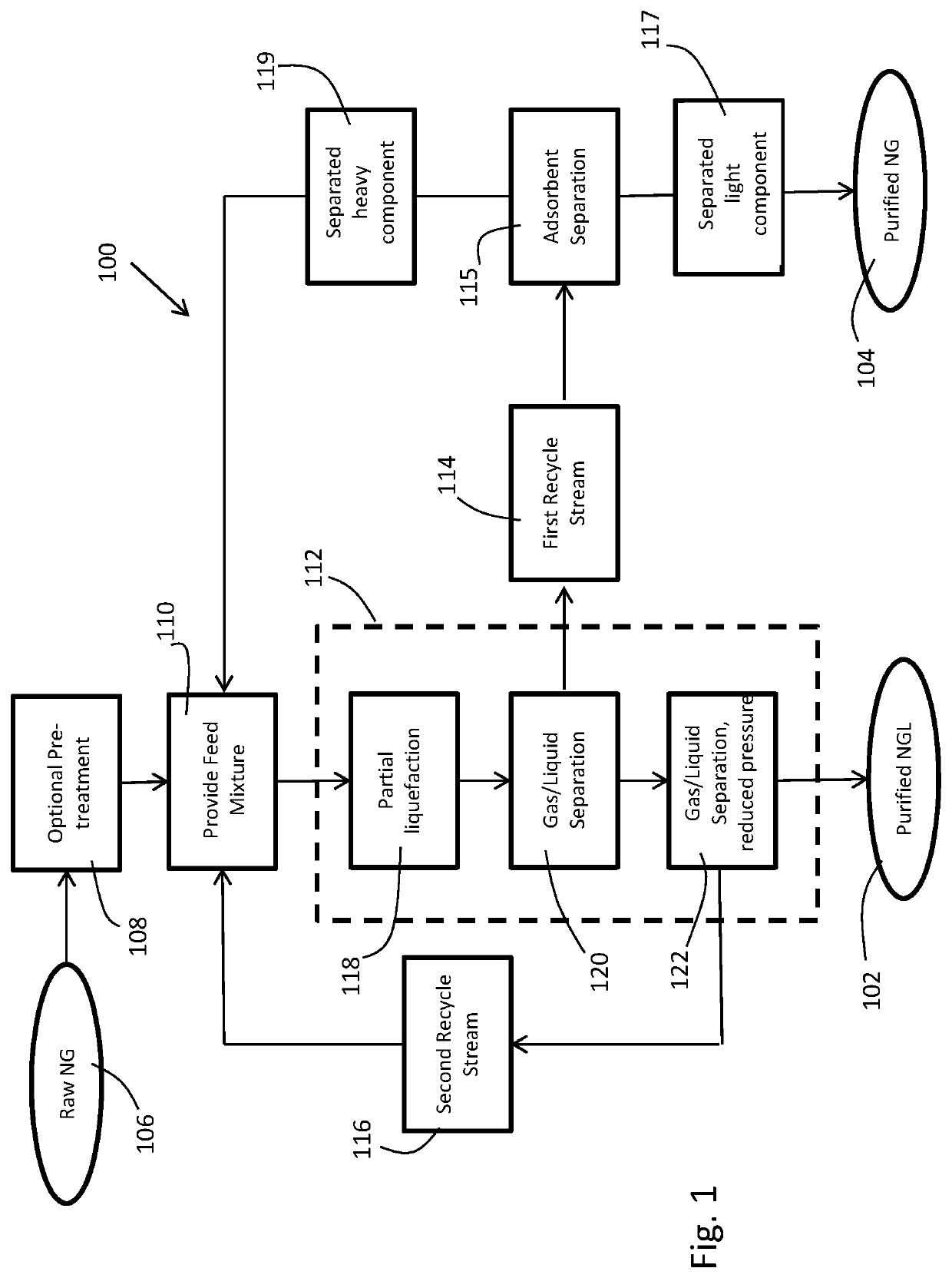

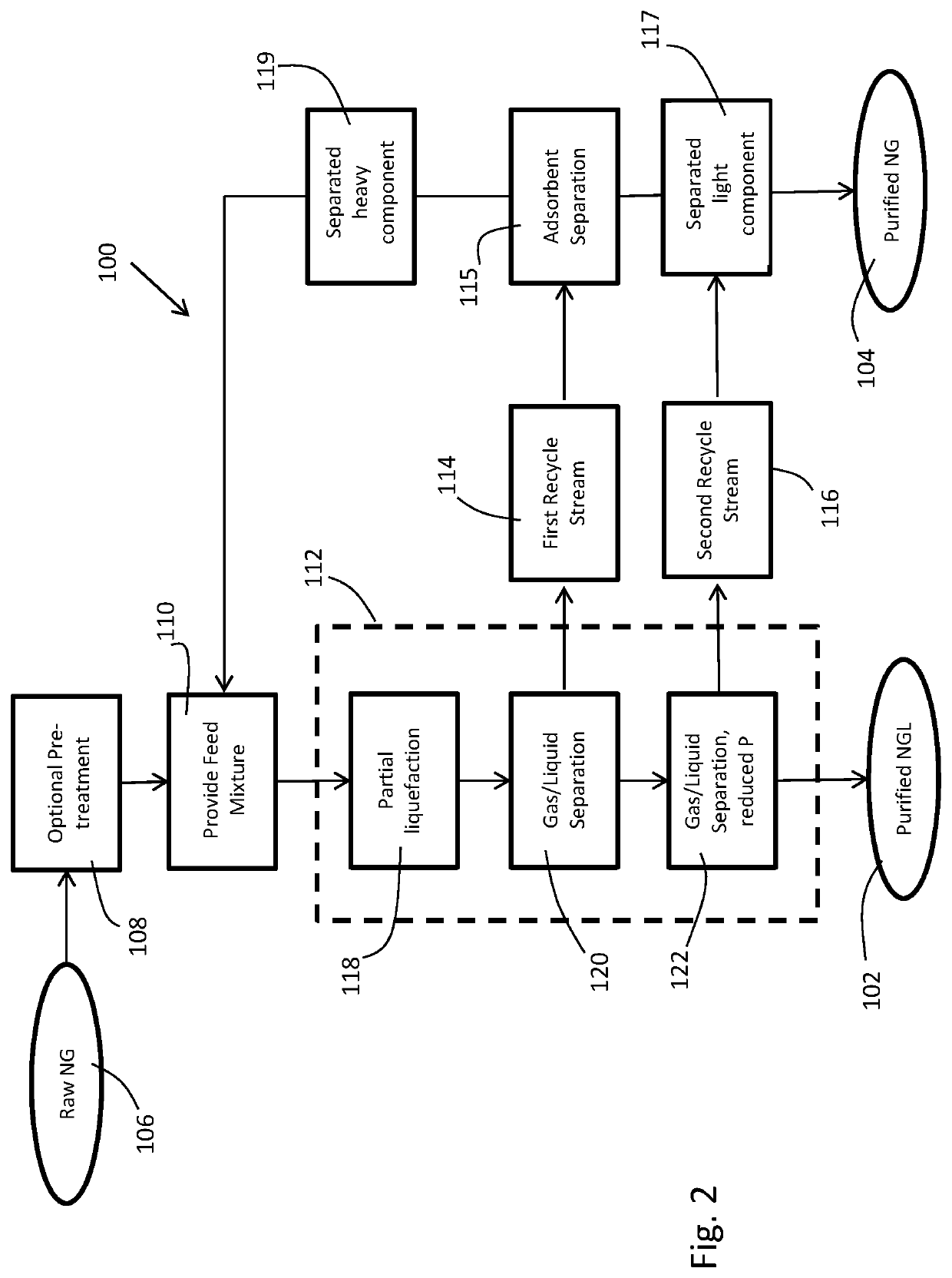

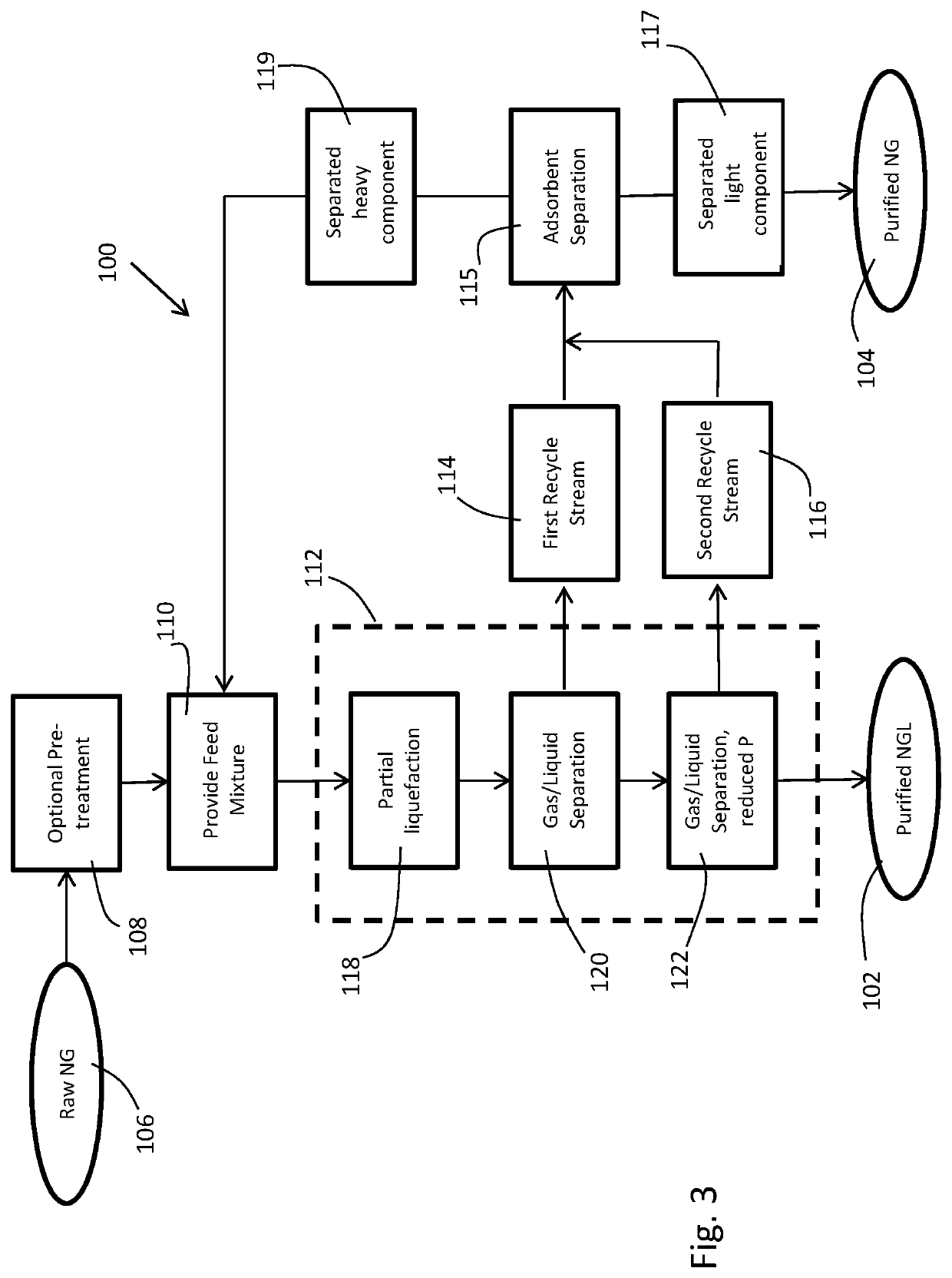

Methods and systems to separate hydrocarbon mixtures such as natural gas into light and heavy components

ActiveUS20200002628A1Improve abilitiesHigh yieldGaseous fuelsLiquid hydrocarbon mixture recoveryLiquid productHydrocarbon mixtures

The present invention integrates adsorption and liquefaction techniques to separate hydrocarbon feed mixtures into light and heavy components. A feed is partially liquefied in two or more stages. A first stage occurs at higher pressure. A second stage occurs at lower pressure. At each stage, gas and liquid components are separated. The separated heavy components resulting from liquefaction provide a purified natural gas liquid product. The separated gas components may be further processed and / or handled to provide purified natural gas. Heavy streams resulting from the further processing of the separated gas streams may be recycled and incorporated into the feed mixture. By using separate liquefaction stages at different pressures to favor C1 and then C2 separation from the heavy stream, a natural gas liquid product with high C3+ purity results.

Owner:DOW GLOBAL TECH LLC

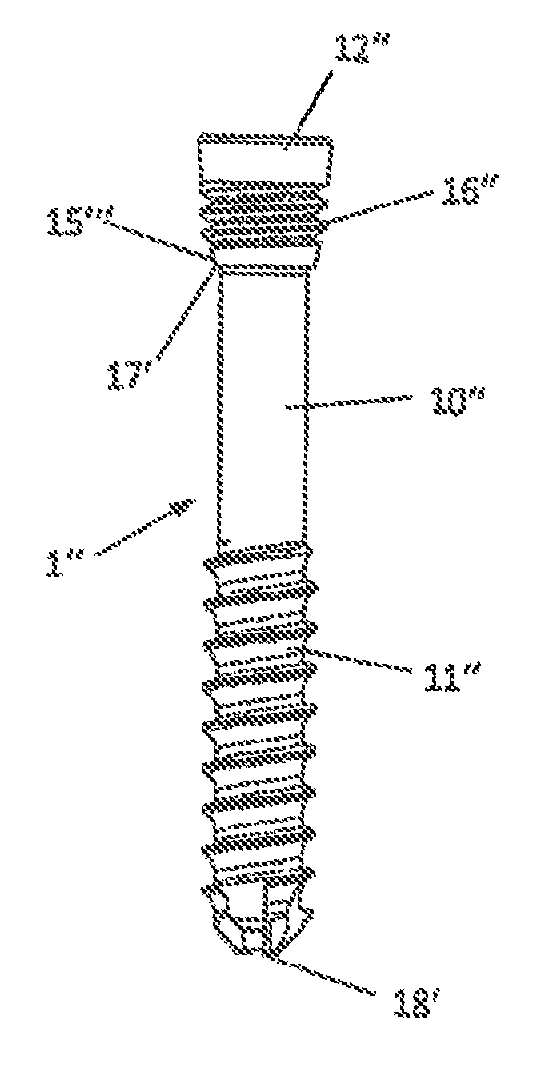

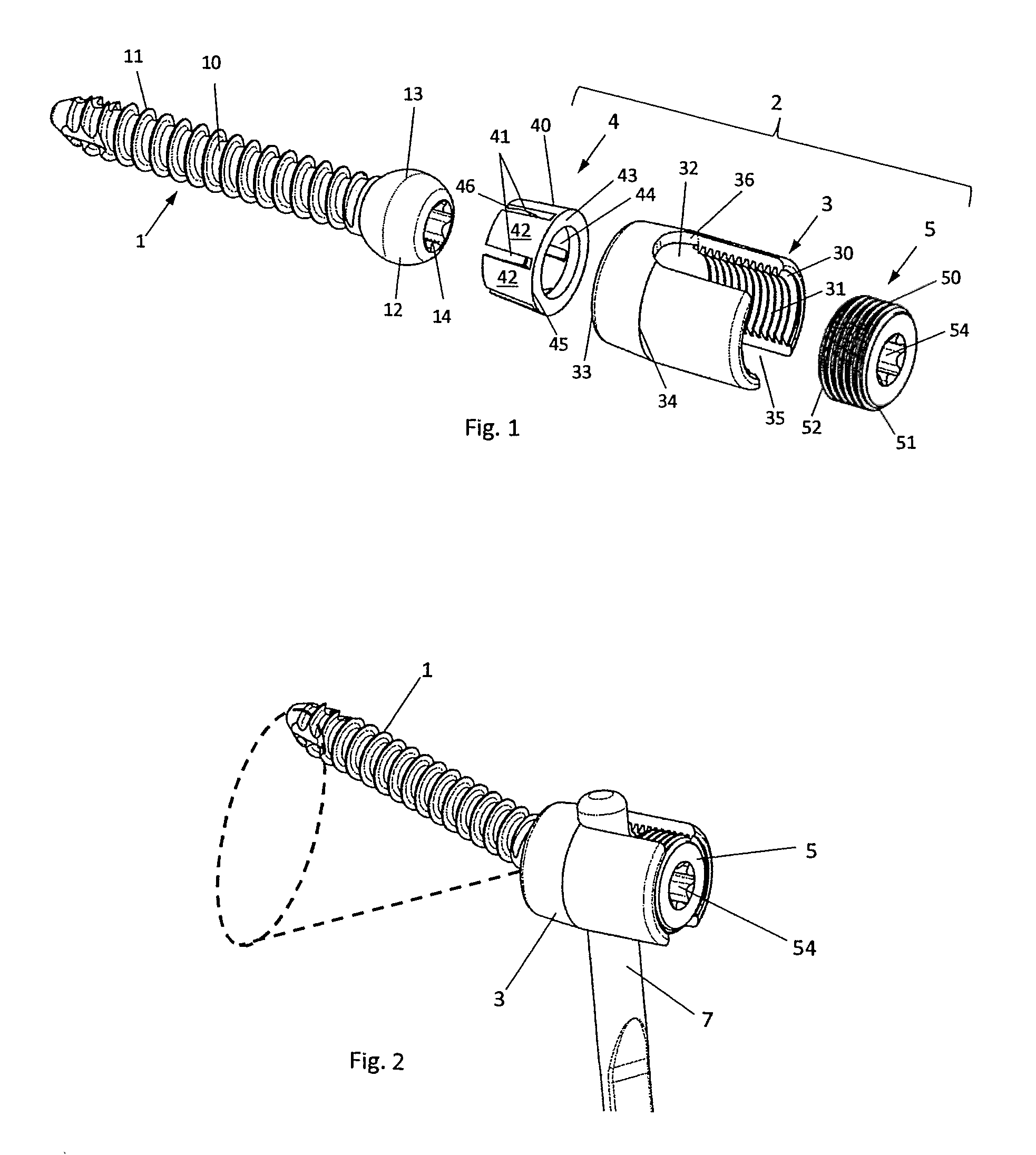

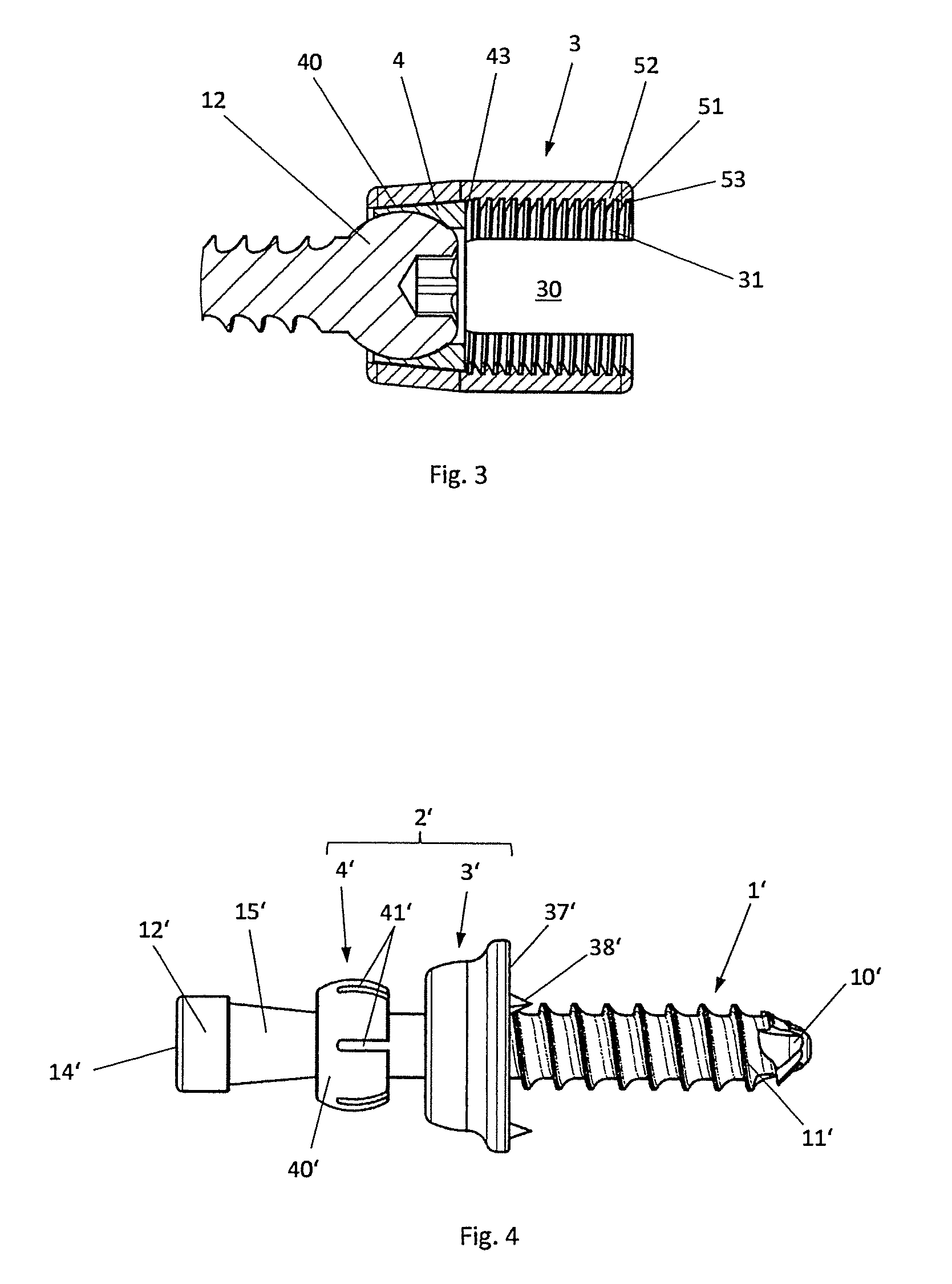

Variable angle bone screw fixation arrangement

InactiveUS9451992B2High positioning accuracyHigh strengthSuture equipmentsInternal osteosythesisScrew threadIliac screw

A fixation apparatus comprises a holder and a tension sleeve receiving a bone screw, wherein the bone screw has a shaft with a front thread and a head at the rear end, and the holder has a through borehole with a receiving seat, in which the tension sleeve is mounted and able to swivel, while the shaft has a thickening in a rear region, to the front of the head, whose width increases toward the head, and the width of the tension sleeve is larger than the width of the shaft immediately before the thickening and smaller than the greatest width of the thickening. When screwed in, the thickening widens the tension sleeve so that it is pressed by its envelope against the wall of the receiving seat. In this way, an angle-stable pressing is achieved for any given orientation of the bone screw.

Owner:FACET LINK

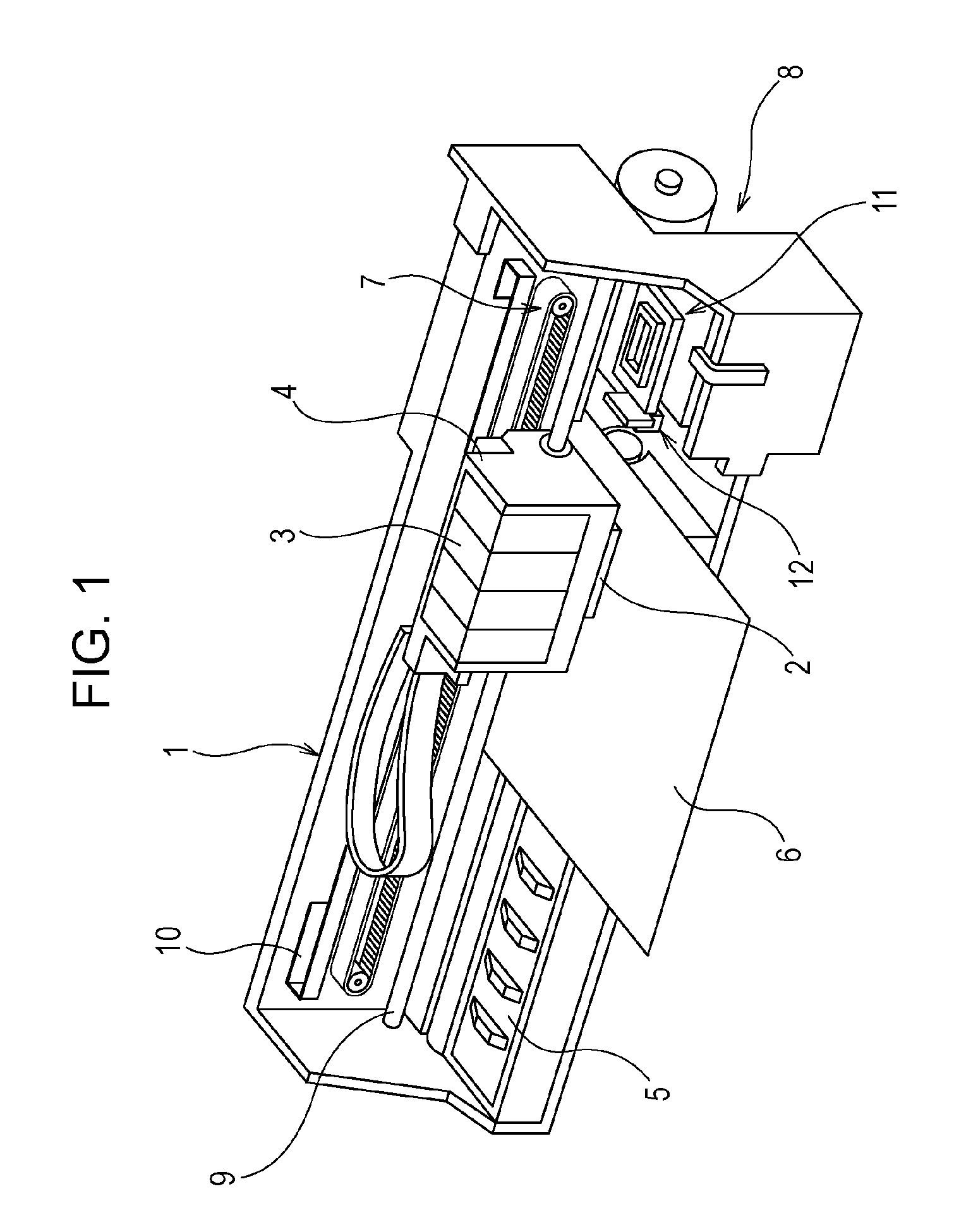

Liquid ejecting head and liquid ejecting apparatus

ActiveUS9481167B2Increase displacementImprove discharge characteristicsPrintingLiquid jetEngineering

In a liquid ejecting head, a vibration plate includes an effective displacement portion provided for each pressure chamber and an island-shaped part which is provided in the effective displacement portion at a position on the opposite side to the pressure chamber and to which one end portion of a piezoelectric vibrator is bonded; the piezoelectric vibrator has a laminate structure in which electrodes and piezoelectric material are alternately laminated; a layer at an end of one side of the piezoelectric vibrator in the laminating direction is formed of an external electrode, while a layer at an end of the other side thereof in the same direction is formed of a piezoelectric material; and the piezoelectric vibrator is disposed so as to be shifted toward the other side in the laminating direction with respect to the effective displacement portion.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com