Yarn-collecting device for compact spinning

A yarn gathering and compacting technology, which is applied in spinning machines, textiles, papermaking, drafting equipment, etc., can solve the problems of air consumption, increase negative pressure, and affect the quality of strands, so as to save energy and reduce negative pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

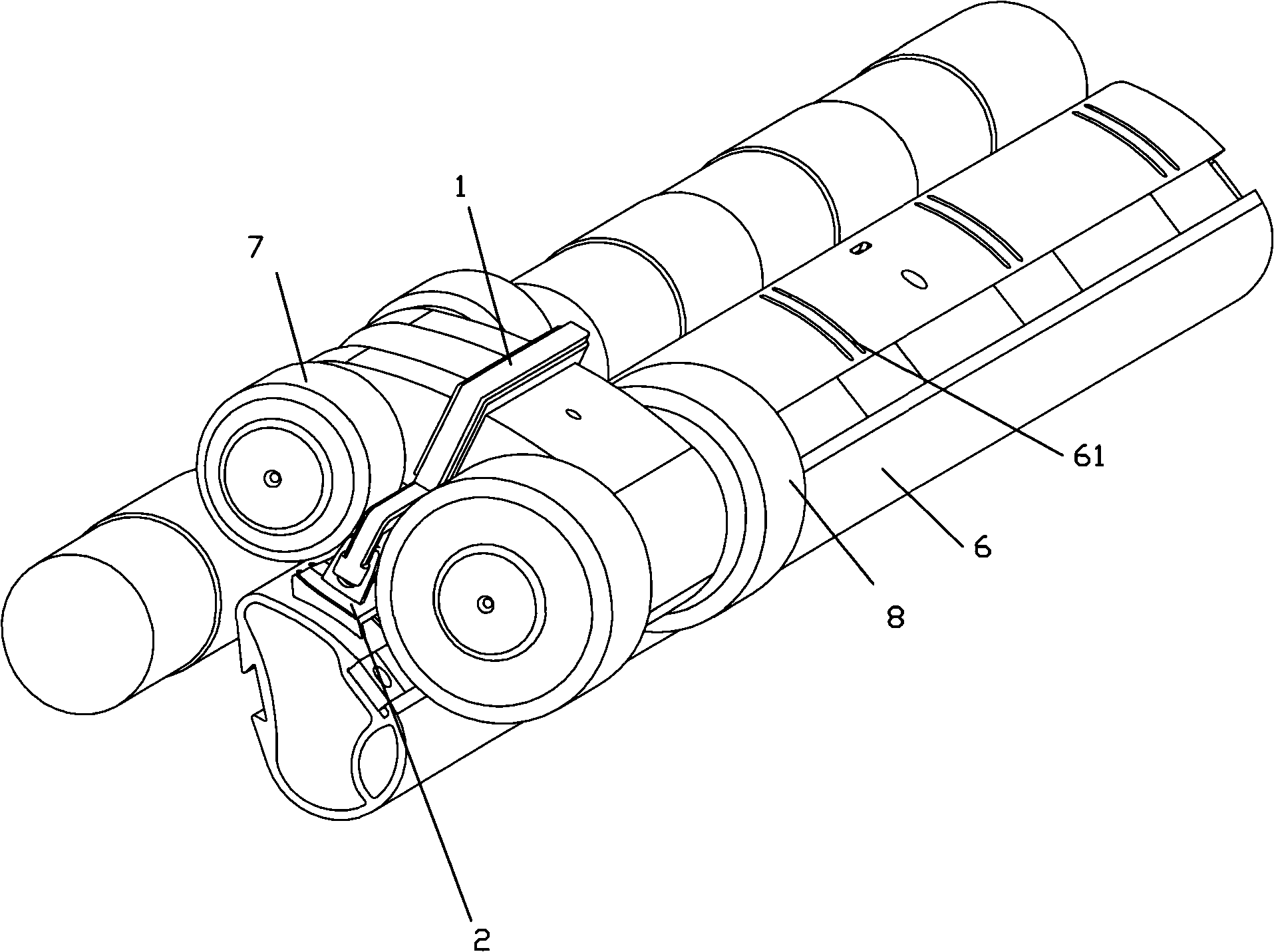

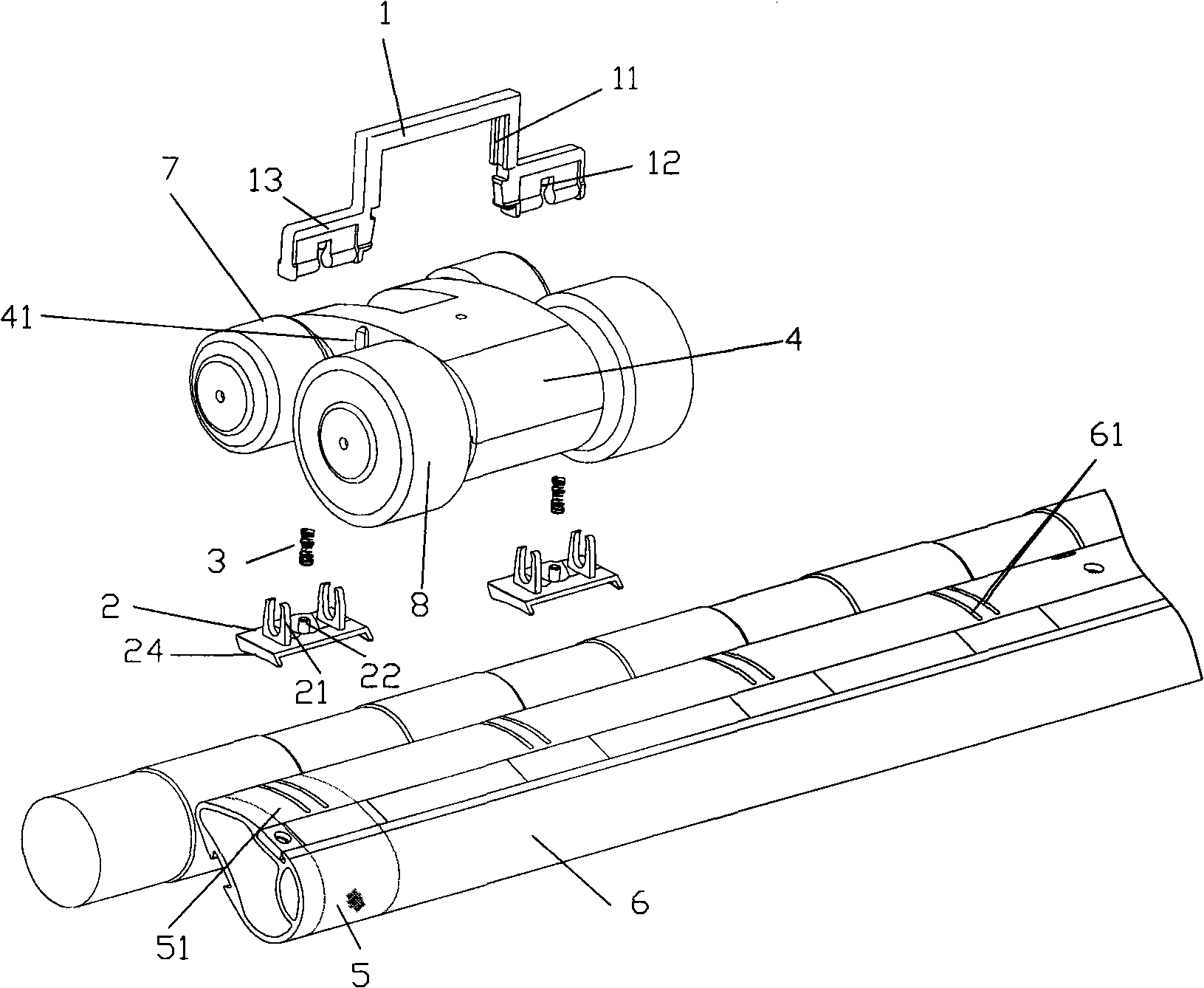

[0025] Such as figure 1 , figure 2 As shown, the yarn gathering device includes a bracket 1, a yarn gathering board 2, and a spring 3, and the bracket is provided with a groove 11 to engage with a boss 41 on the gear box.

[0026] A pair of protrusions 13 are provided on two sides of the support 1 , and the two protrusions 13 are mirror-symmetrical to the center of the support 1 .

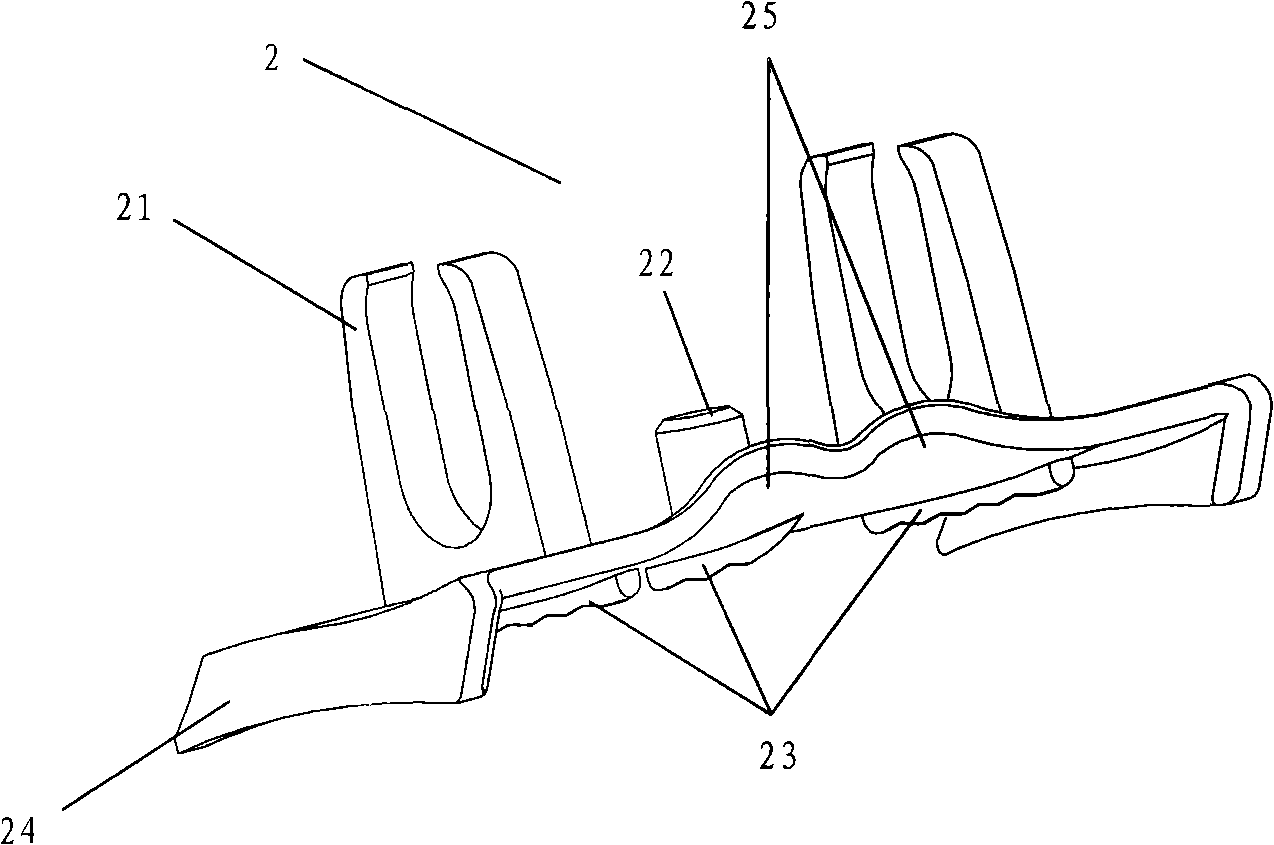

[0027] Such as image 3 with Figure 4 As shown in the yarn gathering board, a pair of grabs 21 are provided on the upper part of the yarn gathering board 2, which are buckled with the protrusions 13 of the yarn gathering board support.

[0028] A pair of legs 24 are provided on the lower part of the yarn gathering plate 2, which straddle the conveyor belt 5 and elastically rest on the conveyor belt sliding surface 51.

[0029] The yarn-gathering air-flow gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com