Comprehensive utilization method of secondary aluminum ash

A technology for secondary aluminum and aluminum ash, which is applied in the fields of aluminum compounds, chemical instruments and methods, preparation of alkali metal aluminate/aluminum oxide/aluminum hydroxide, etc., to achieve harmless treatment of secondary aluminum ash and cheap reaction agents , The effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

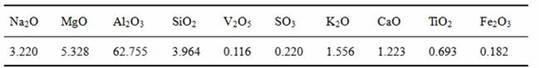

Image

Examples

Embodiment 1

[0022] A method for comprehensive utilization of secondary aluminum ash, the concrete steps are as follows:

[0023] (1) Crush and grind secondary aluminum ash to 75μm-380μm with a crusher;

[0024] (2) Mix the crushed and finely ground aluminum ash in step (1) with the additives and then roast at 800°C for 4 hours, and recover the sintering gas as nitrogen; the additives are a mixture of sodium carbonate, oxidant sodium nitrate, and calcium carbonate; The molar ratio of sodium carbonate to aluminum oxide in aluminum ash is 1.4, the molar ratio of oxidant sodium nitrate to aluminum nitride in aluminum ash is 1.2, and the total molar ratio of calcium carbonate to fluoride and silicon dioxide in aluminum ash is 2.6 ;

[0025] (3) Dissolve the roasted clinker with sodium carbonate solution, the concentration of sodium carbonate is 2g / L, the liquid-solid ratio mL:g is 2:1, the dissolution temperature is 50°C, the dissolution time is 3h, solid-liquid separation, and the filtrate ...

Embodiment 2

[0029] A method for comprehensive utilization of secondary aluminum ash, the concrete steps are as follows:

[0030] (1) Crush and grind secondary aluminum ash to 75μm-380μm with a crusher;

[0031] (2) Mix the crushed and finely ground aluminum ash in step (1) with additives, and then roast at 800°C for 2 hours, and recover the sintering gas as nitrogen; the additives are a mixture of sodium carbonate, oxidant sodium peroxide, and calcium carbonate The mol ratio of aluminum oxide in sodium carbonate and aluminum ash is 1.8, the mol ratio of oxidant sodium peroxide and aluminum nitride in aluminum ash is 1.7, the total mol ratio of fluoride and silicon dioxide in calcium carbonate and aluminum ash is 3;

[0032] (3) Dissolve the roasted clinker with sodium carbonate solution, the concentration of sodium carbonate is 10g / L, the liquid-solid ratio mL:g is 5:1, the dissolution temperature is 65°C, the dissolution time is 1.5h, and the solid-liquid separation, The filtrate is so...

Embodiment 3

[0036] A method for comprehensive utilization of secondary aluminum ash, the concrete steps are as follows:

[0037] (1) Crush and grind the secondary aluminum ash to 75μm~380μm with a crusher;

[0038] (2) Mix the crushed and finely ground aluminum ash in step (1) with additives and then roast at 1000°C for 4 hours, and recover the sintering gas as nitrogen; the additives are a mixture of sodium carbonate, oxidant sodium percarbonate, and calcium carbonate The mol ratio of aluminum oxide in sodium carbonate and aluminum ash is 2.2, the mol ratio of oxidizer sodium percarbonate and aluminum nitride in aluminum ash is 2, the total mol ratio of fluoride and silicon dioxide in calcium carbonate and aluminum ash is 3.6;

[0039] (3) Dissolve the roasted clinker with sodium carbonate solution, the concentration of sodium carbonate is 5g / L, the liquid-solid ratio mL:g is 8:1, the dissolution temperature is 80°C, the dissolution time is 2h, solid-liquid separation, and the filtrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com