Aerobic fermentation device and method for organic waste

A technology of organic waste and aerobic fermentation, applied in the direction of solid waste removal, etc., can solve the problems of low fermentation efficiency, low sludge production, small land occupation, infrastructure investment, operating cost, etc., to improve fermentation efficiency, reduce The effect of odor emission and shortening of fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

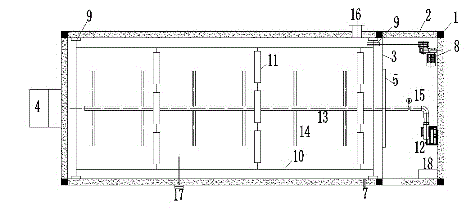

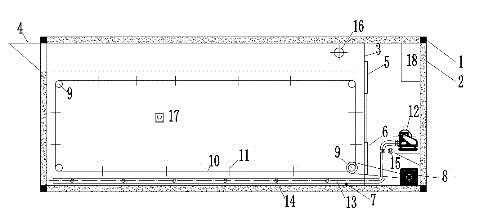

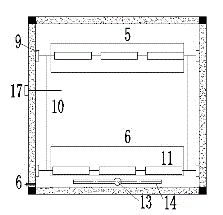

[0050] This embodiment provides a box-type aerobic fermentation equipment for organic waste, which can treat the dewatered sludge produced by the urban domestic sewage treatment plant, so that the treated sludge can meet the stabilization requirements.

[0051] Such as figure 1 As shown, the system includes: box body 1, insulation layer 2, partition plate 3, feed port 4, discharge valve plate 5, vent port 6, waste liquid port 7, drive motor 8, movable gear set 9, chain 10 , scraper 11, fan 12, main pipe 13, branch pipe 14, control valve 15, exhaust pipe 16, monitoring instrument 17, control unit 18;

[0052] in,

[0053] The box body 1 is a cuboid box body with an insulation layer 2 inside, and the side wall is equipped with a material inlet 4, a discharge valve plate 5, a vent port 6, and a waste liquid port 7; the partition 3 divides the box body 1 according to the function. Area and operation area; drive motor 8, fan 13, control valve 15, control unit 18, etc. are install...

Embodiment 2

[0063] This embodiment provides a box-type aerobic fermentation equipment for organic waste, which can process pretreated domestic waste so that the processed product meets the stabilization requirements.

[0064] The system structure and figure 1 Basically the same, the difference is that the form and height of the scraper 11, the model of the fan 12, the number of the branch pipe 14, the model of the waste gas pipe 16 and the waste liquid port 7 should be increased by one level, and the thickness of the insulation layer is not less than 100mm.

[0065] Utilize the above aerobic fermentation equipment to ferment the pretreated domestic waste, and the domestic waste is added to the front end of the aerobic fermentation equipment box 1 through the feed port 4, and aerobic fermentation is carried out in the fermentation area of the box body 1; the drive motor 8. With the cooperation of the movable gear set 9, the scraper 11 is dragged by the chain 10, and the materials continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com