Technology for continuously producing denitrifying bacteria agent

A nitrifying bacteria agent and denitrification technology, applied in the direction of biochemical equipment and methods, microorganisms, microorganisms, etc., can solve the problem that the best logarithmic growth period of bacteria cannot be guaranteed, and achieve easy promotion and application, improve cultivation efficiency, Ease of large-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A process for continuously producing denitrifying bacteria agent, comprising the following steps:

[0030] S1 preparation medium:

[0031] Select carbon source: choose sodium acetate as the carbon source, and its dosage is 2.0g / L;

[0032] Select the nitrate nitrogen source: select sodium nitrate as the nitrogen source, and the dosage is 6.0g / L;

[0033] Choose an organic nitrogen source: choose yeast extract as the nitrogen source, and the dosage is 0.5g / L;

[0034] Select inorganic nutrient salt, choose manganese chloride as inorganic nutrient salt, and its consumption is 0.1g / L;

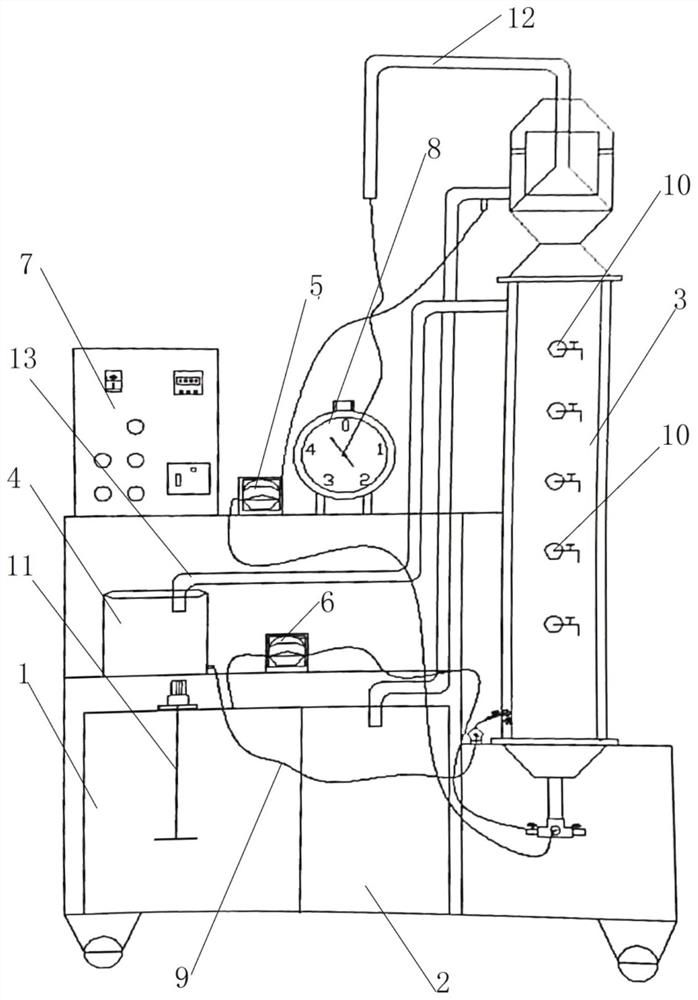

[0035] S2: Inoculate the denitrifying bacteria, the inoculation amount is 800mg / L, enter the culture medium from the water distributor at the bottom, and after the culture medium enters the reaction column 3 from the original water tank 1, denitrify the bacterial agent; the clip of the reaction column 3 The sleeve realizes the continuous circulation of hot water to heat the interior of t...

Embodiment 2

[0055] A kind of technique for continuously producing denitrifying bacteria agent, comprising the steps of:

[0056] S1 preparation medium:

[0057] Select carbon source: select citric acid as the carbon source, and its dosage is 3.0g / L;

[0058] Select the nitrate nitrogen source: select potassium nitrate as the nitrogen source, and the dosage is 5.0g / L;

[0059] Select organic nitrogen source: select peptone as nitrogen source, the dosage is 0.4g / L;

[0060] Select inorganic nutrient salt, select magnesium sulfate as inorganic nutrient salt, and its consumption is 0.15g / L;

[0061] In S2, the inoculum amount was 600 mg / L, and the temperature was controlled at about 32° C. during the reaction, and the rest were the same as in Example 1.

Embodiment 3

[0063] A kind of technique for continuously producing denitrifying bacteria agent, comprising the steps of:

[0064] S1 preparation medium:

[0065] Select carbon source: select maltose as the carbon source, and its dosage is 3.0g / L;

[0066] Select the nitrate nitrogen source: choose calcium nitrate as the nitrogen source, and the dosage is 4.0g / L;

[0067] Select the organic nitrogen source: choose soybean meal as the nitrogen source, and the dosage is 0.4g / L;

[0068] Select inorganic nutrient salt, select copper sulfate as inorganic nutrient salt, and its consumption is 0.15g / L;

[0069] In S2, the inoculum amount was 600 mg / L, and the temperature was controlled at about 32° C. during the reaction, and the rest were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com