Vacuum transmission processing equipment and method

A technology of vacuum transmission and process equipment, which is applied in the direction of conveyor objects, transportation and packaging, and final product manufacturing. It can solve problems such as reduced operational reliability, complex overall structure of equipment, and complex operational control, and achieve the effect of improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

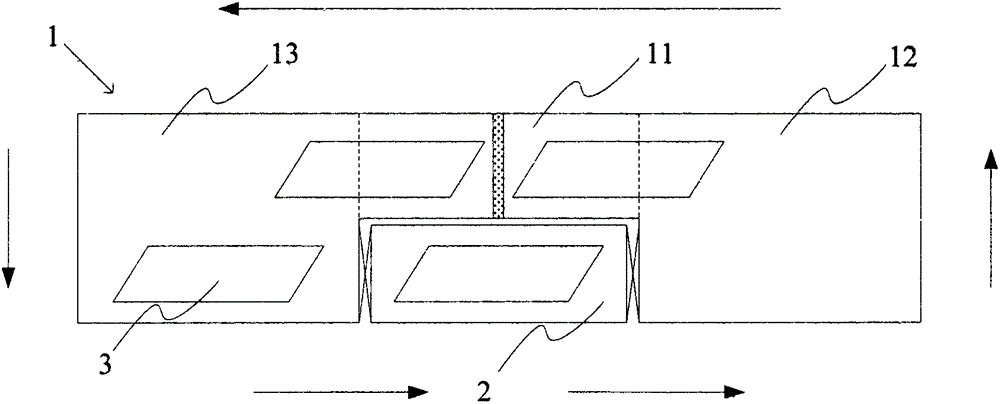

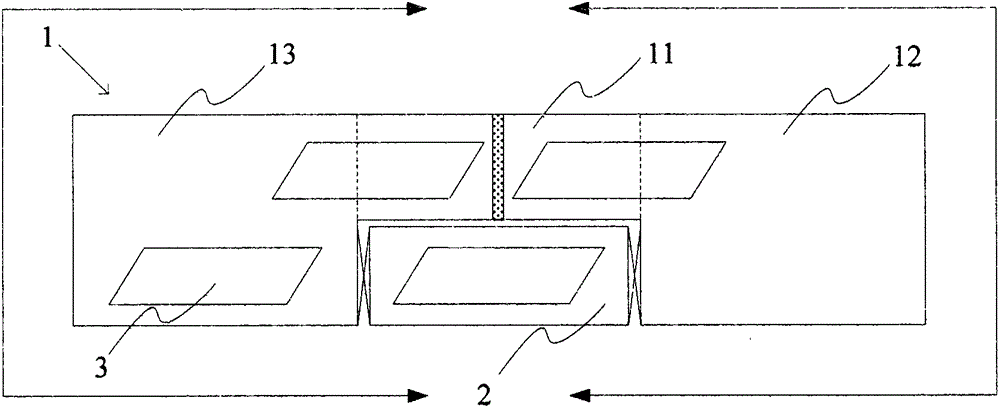

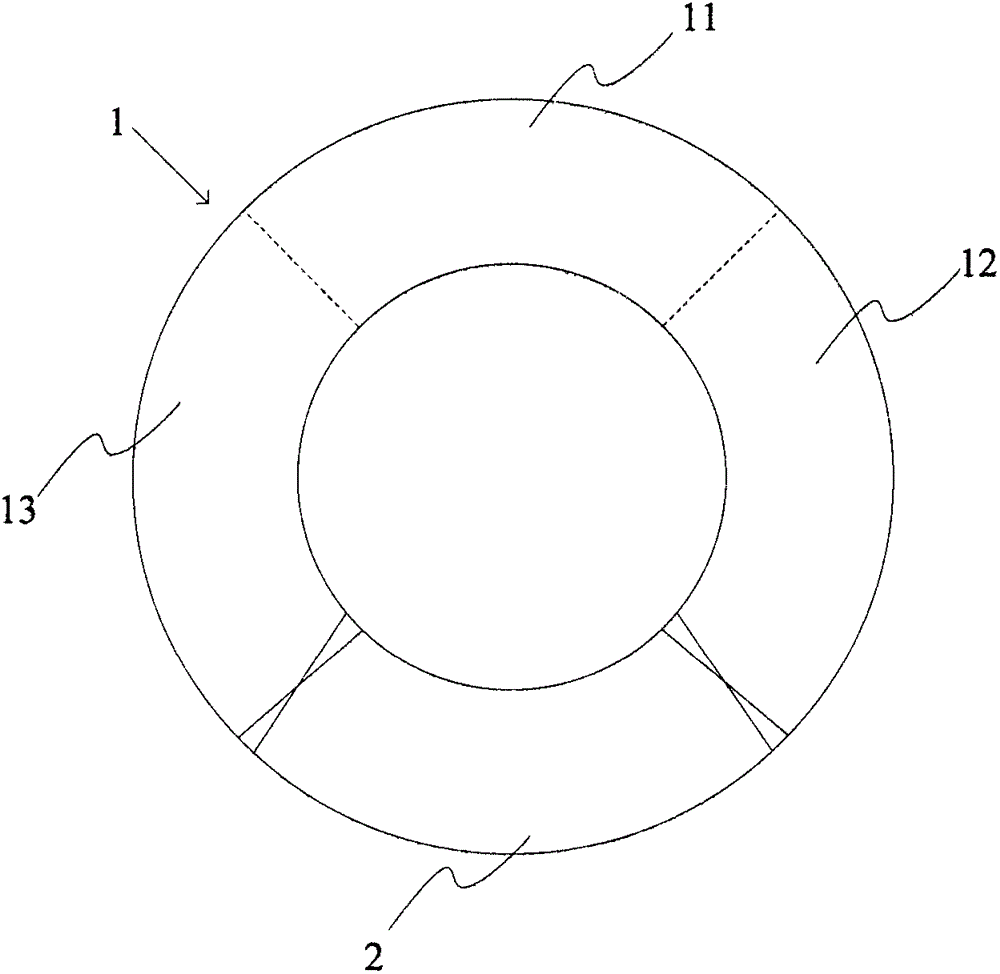

[0042] refer to figure 1 and figure 2 As shown, the vacuum transfer process equipment of the present invention mainly includes a vacuum process chamber 1 , an access chamber 2 and a plurality of transfer platforms 3 .

[0043] The vacuum process chamber 1 includes a processing area 11 ( figure 1 and figure 2 The area enclosed by the dotted line), a first waiting area 12 located on one side of the processing area 11 and a second waiting area 13 located on the other side of the processing area 11 .

[0044] One or more than two processing devices are arranged in the processing area 11, and each processing device can generate a processing medium. When the workpiece enters the effective range of the processing medium ( Figure 1-12 When the effective action range of the processing medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com