Method for utilizing high-pressure hot air to automatically separate waste circuit board elements

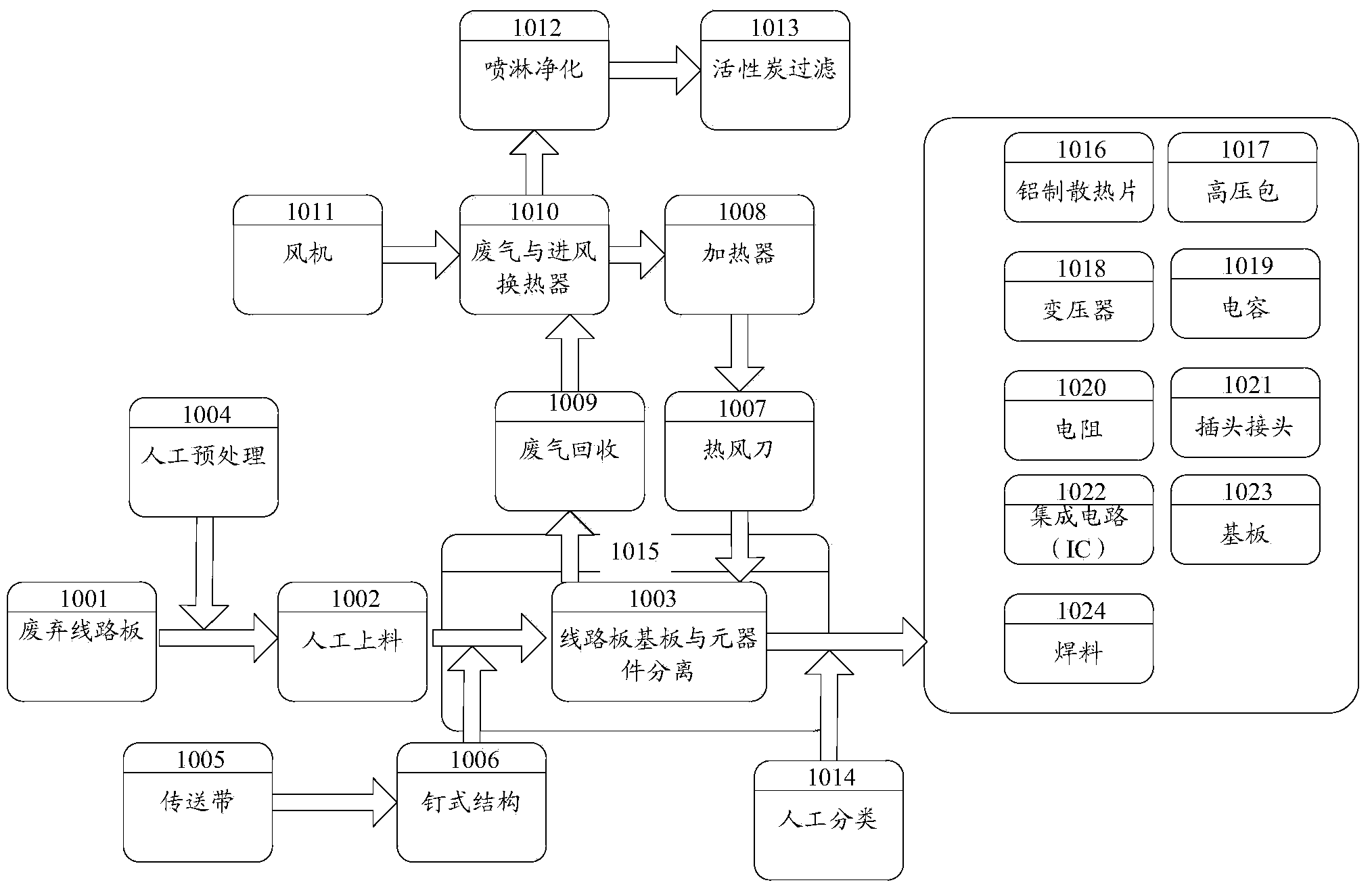

A waste circuit board, automatic separation technology, applied in chemical instruments and methods, transportation and packaging, manufacturing tools, etc., can solve the problems of working environment and human health hazards, strong toxicity, and organic pollutants with foul odor, etc., to achieve easy disposal , reduce energy consumption, increase the effect of intake air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to better understand the content of the present invention, further description will be given below in conjunction with specific embodiments.

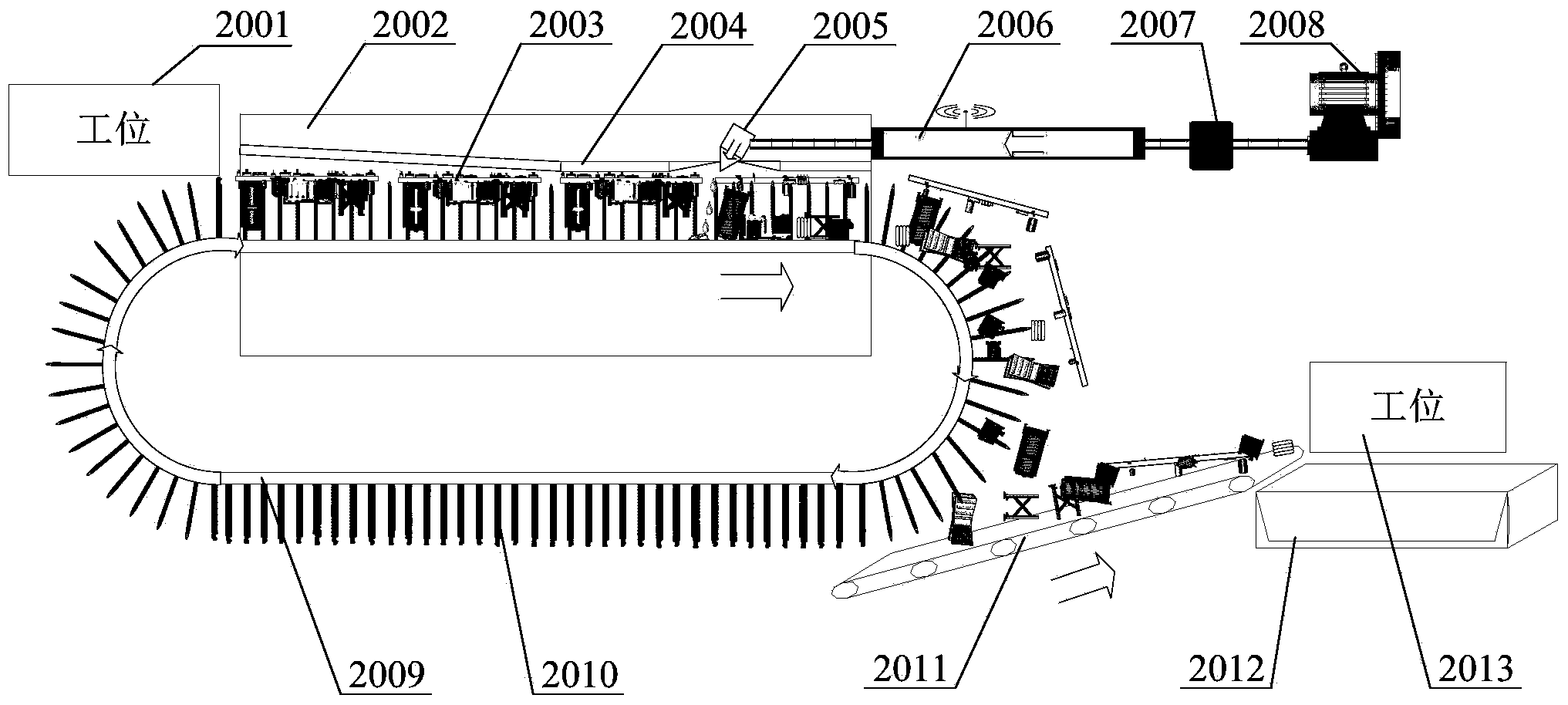

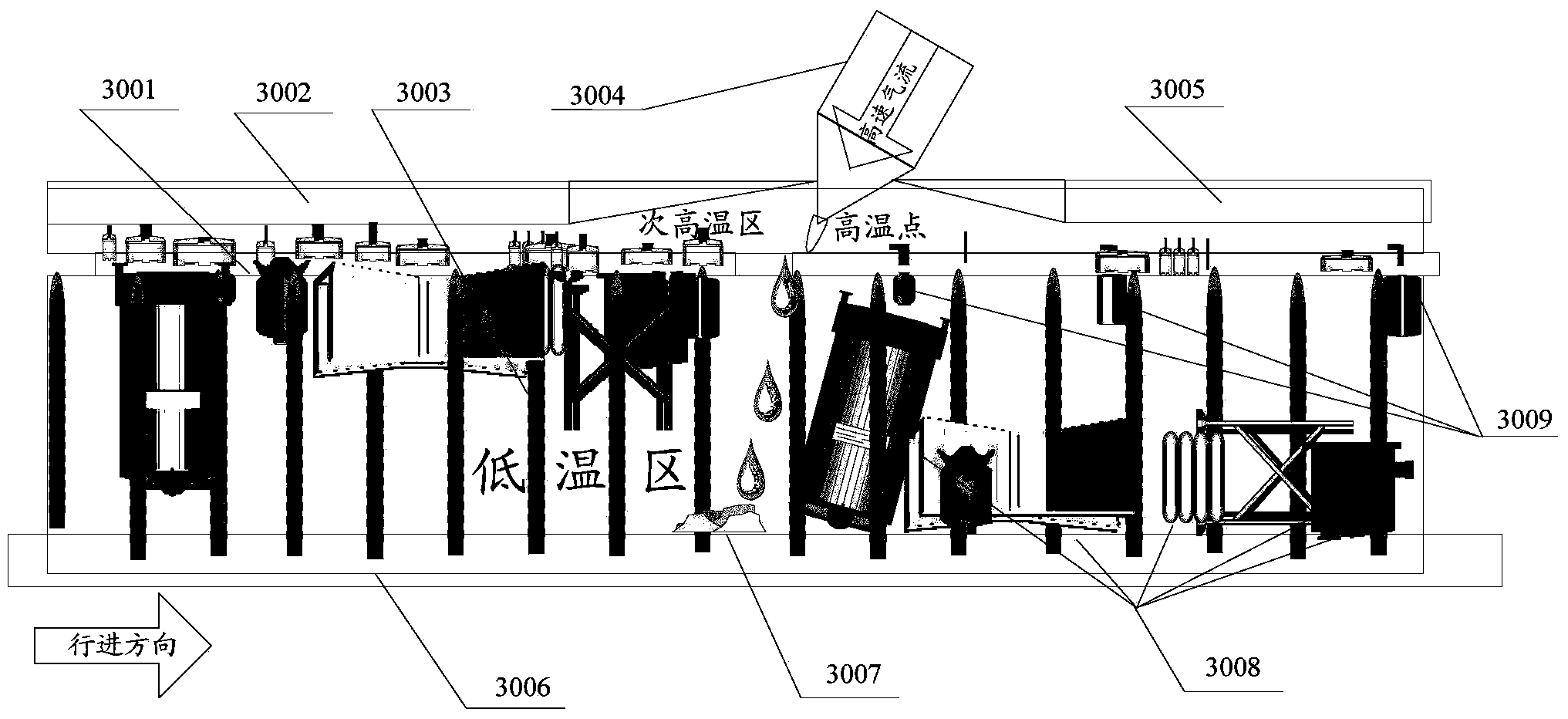

[0055] In the method for automatically separating waste circuit board components using high-pressure hot air of the present invention, such as figure 2 The schematic diagram shown: At the loading station 2001, the waste circuit board 2003 is manually pre-processed, that is, the plastic frame and related screws on the back are removed, the related iron patches are removed, and the plastic flower threads are cut off. After the pretreatment is completed, the back side of the circuit board is placed flat on the nail structure 2010, and when placing it, the space between the board and the board is guaranteed to be between 10mm and 20mm. The nail structure 2010 is conveyed by the conveyor belt 2009 into the holding room 2002. On the other hand, the high-pressure air blown by the fan 2008 is raised to 90℃~110℃ through the exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com