Patents

Literature

138results about "Chemistry apparatus and processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

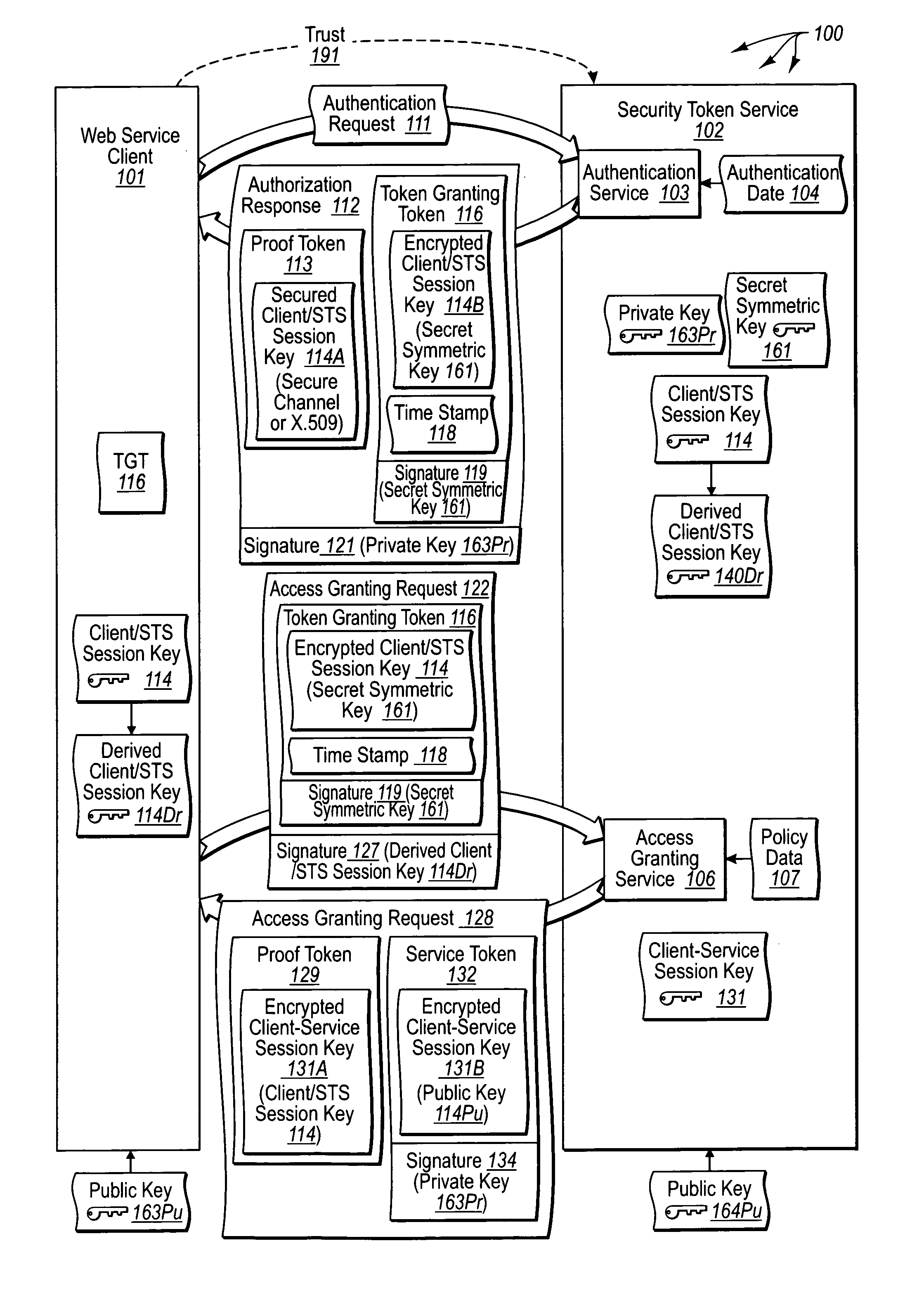

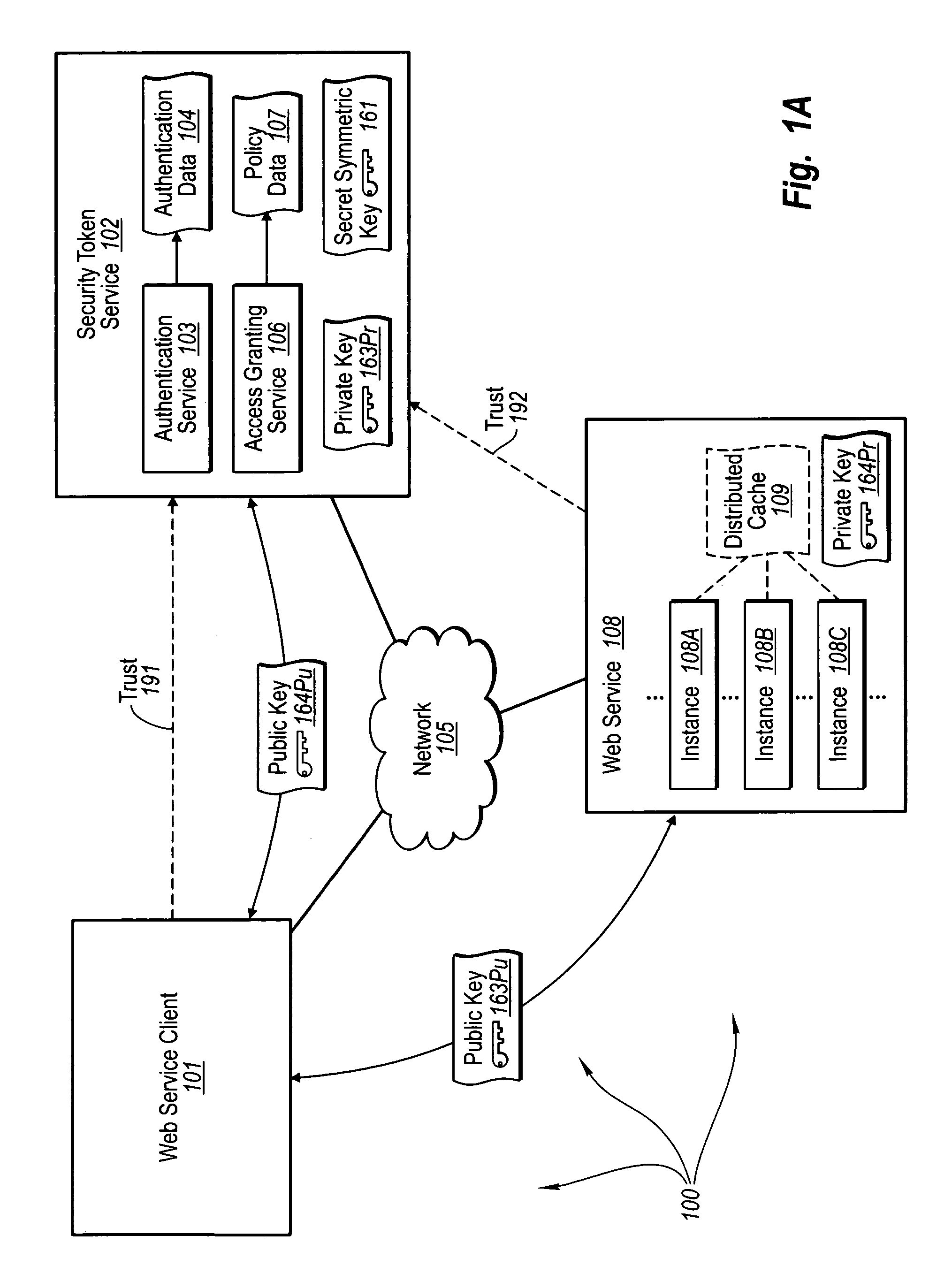

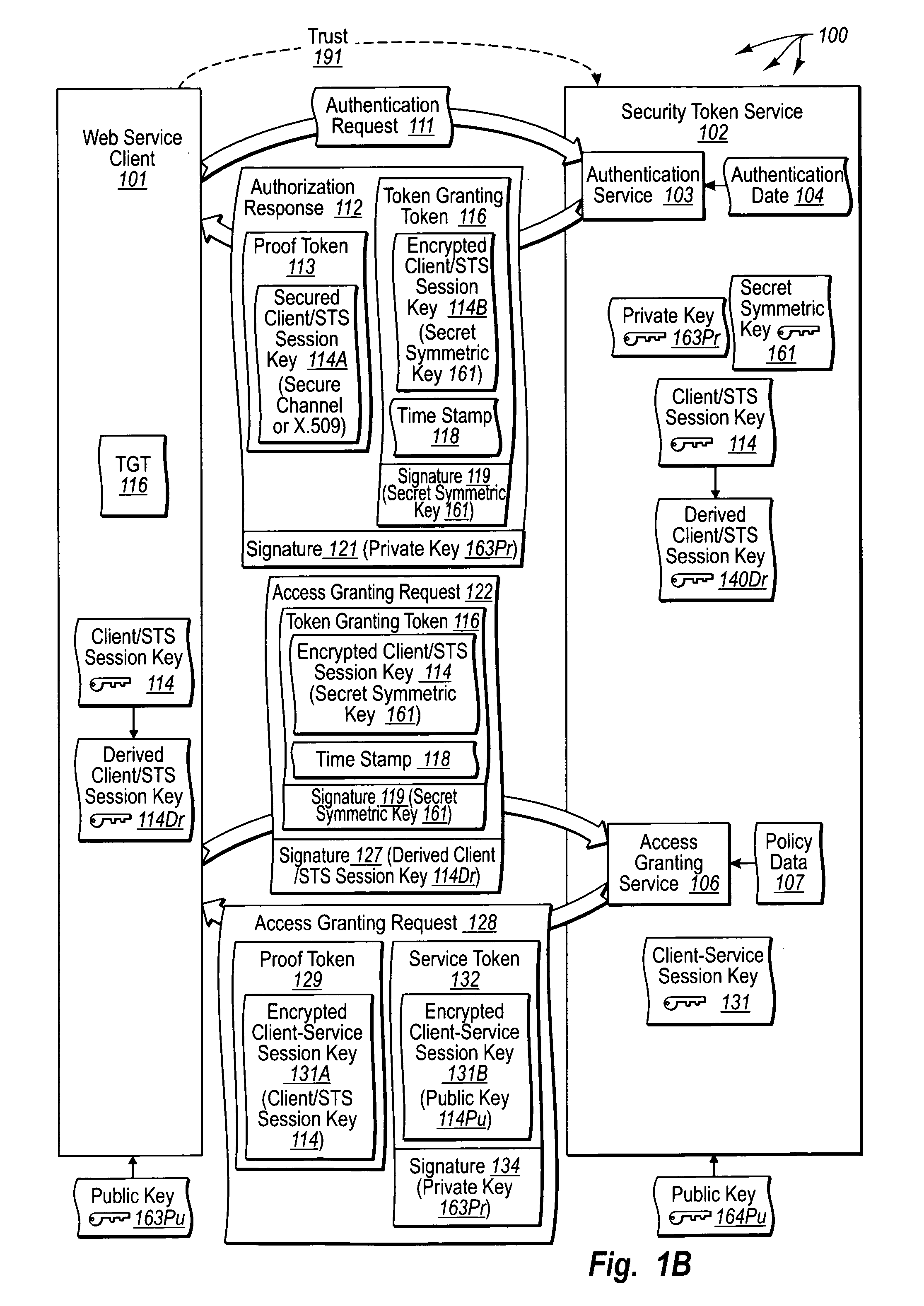

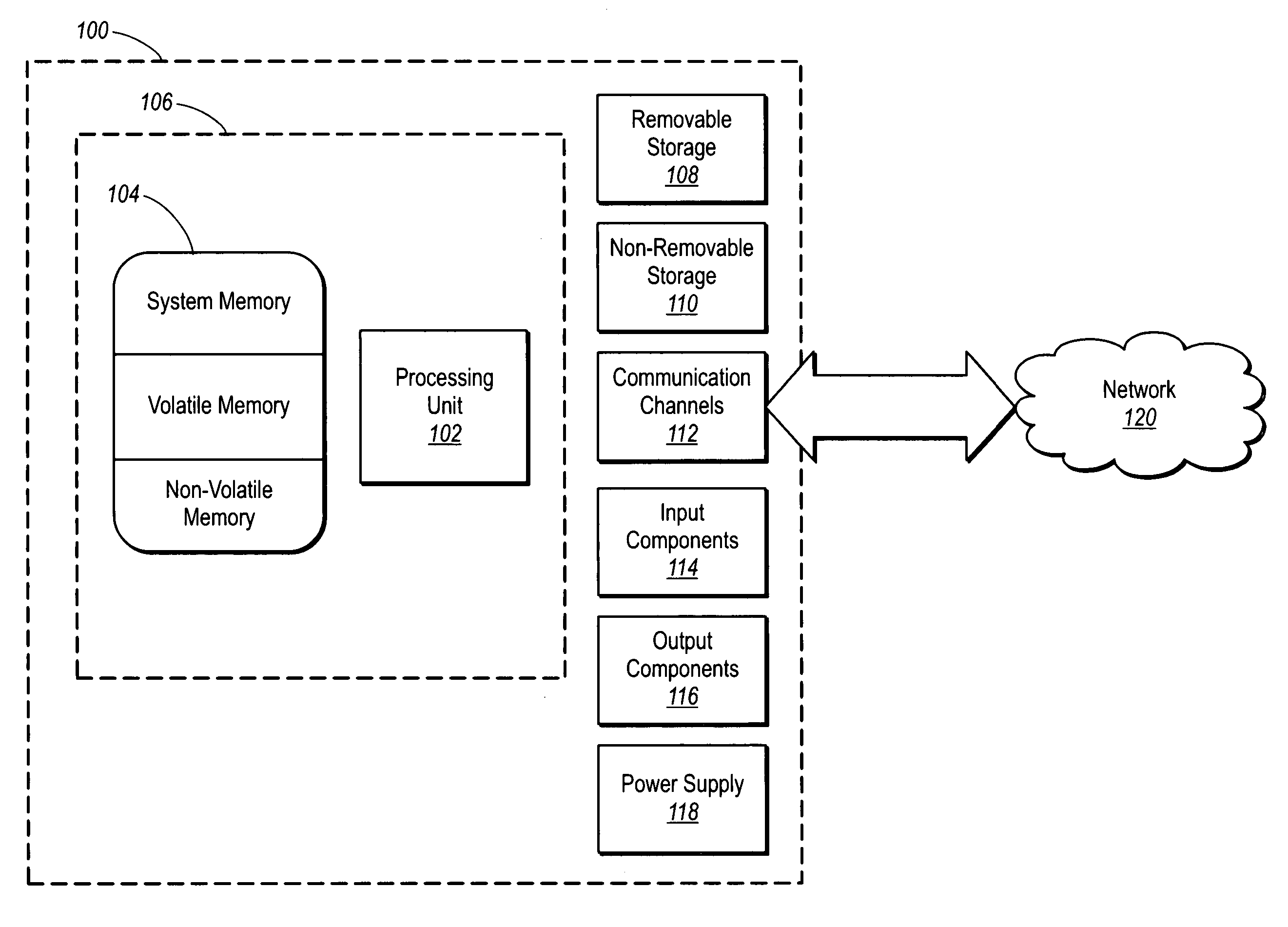

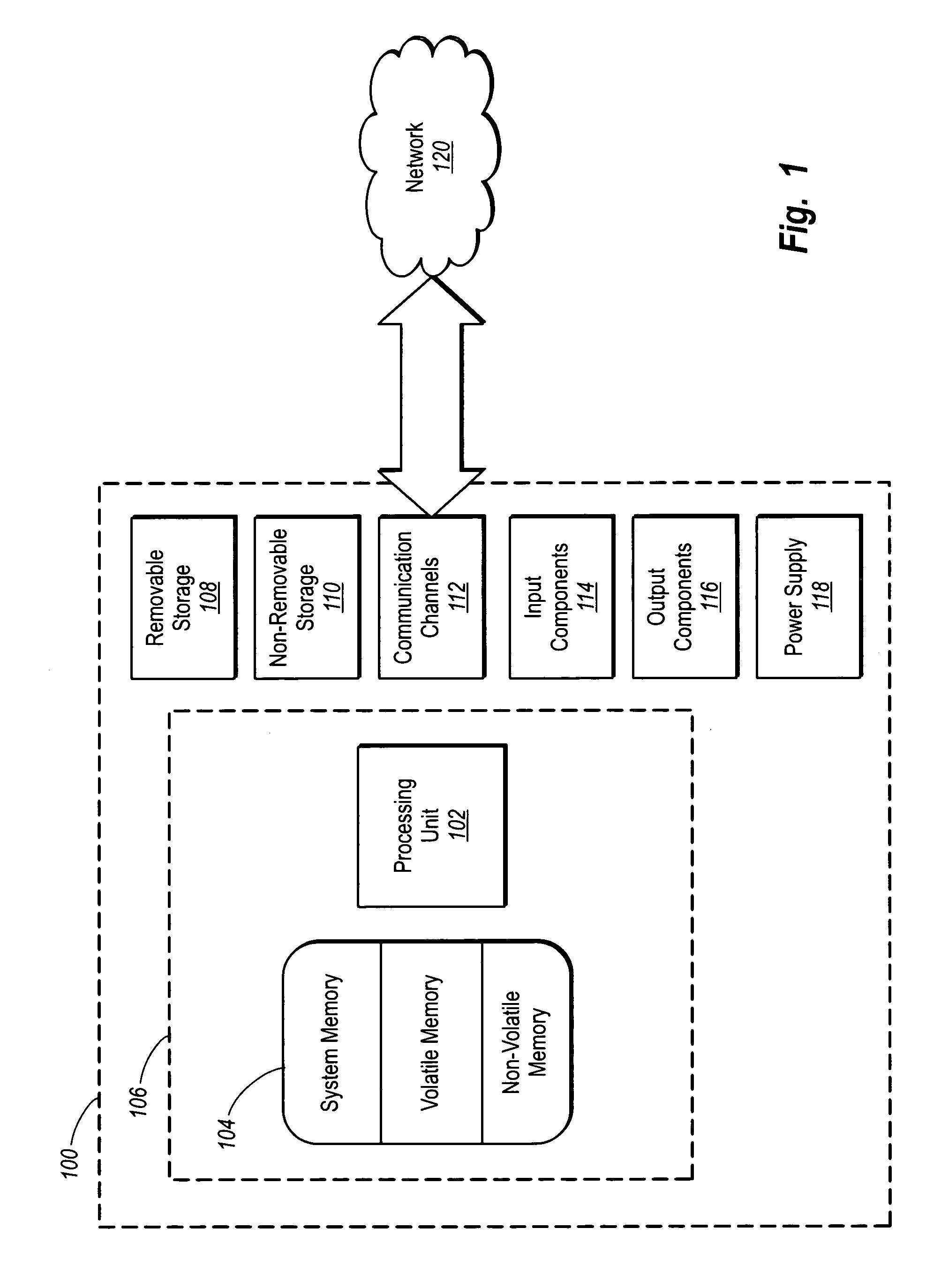

Trusted third party authentication for web services

InactiveUS20060206932A1Communication securityDigital data processing detailsUser identity/authority verificationWeb serviceInternet privacy

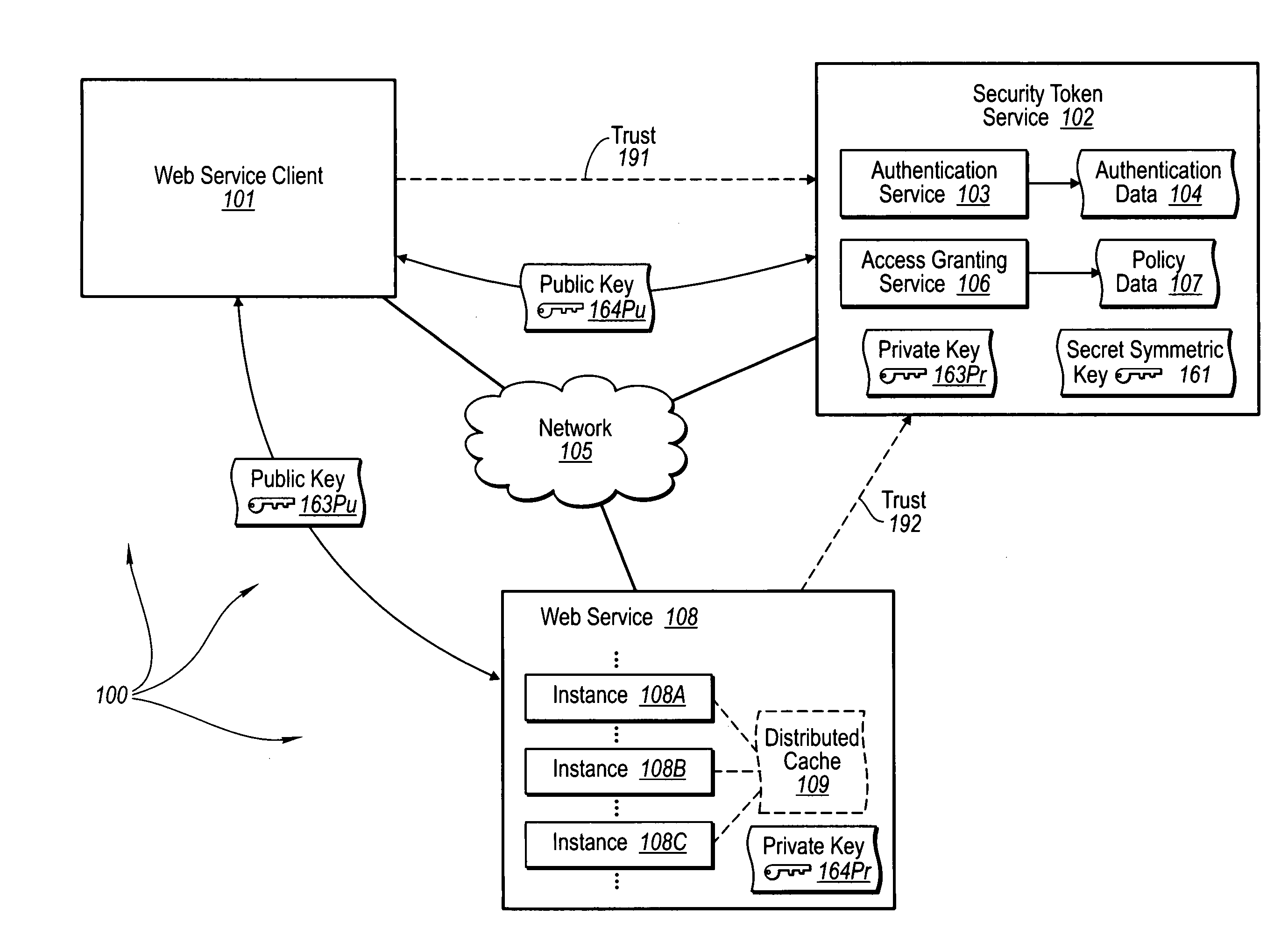

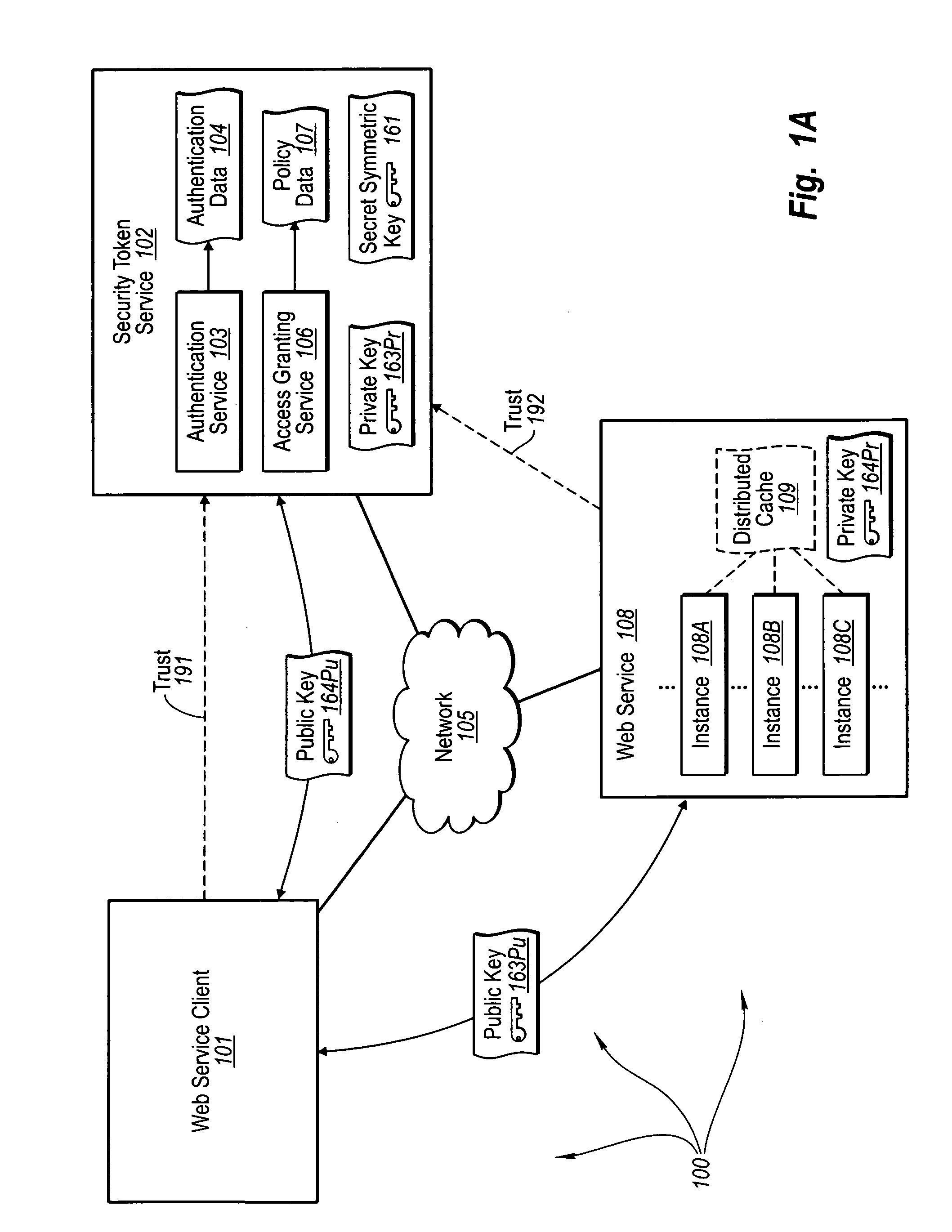

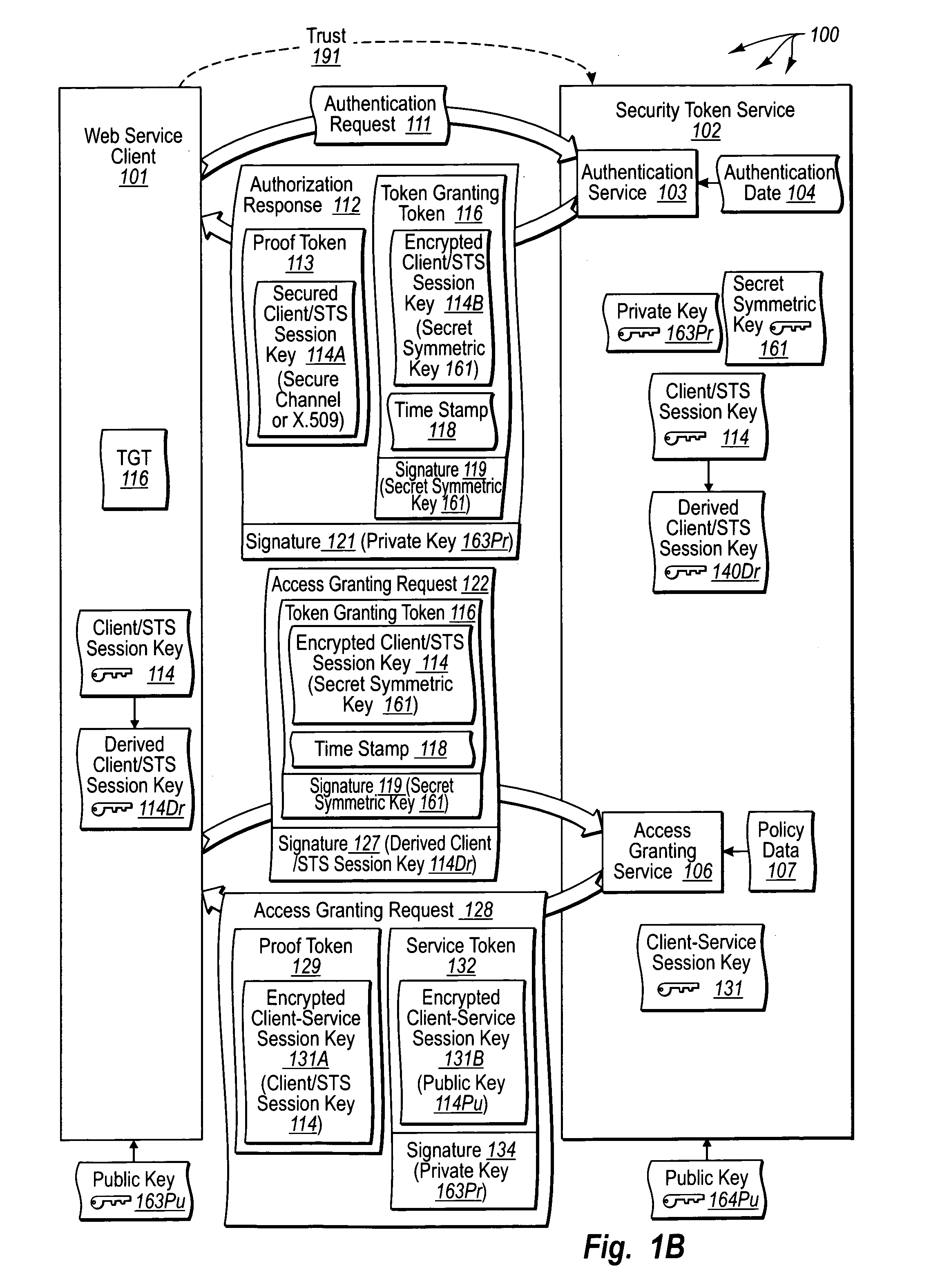

The present invention extends to trusted third party authentication for Web services. Web services trust and delegate user authentication responsibility to a trusted third party that acts as an identity provider for the trusting Web services. The trusted third party authenticates users through common authentication mechanisms, such as, for example, username / password and X.509 certificates and uses initial user authentication to bootstrap subsequent secure sessions with Web services. Web services construct user identity context using a service session token issued by the trusted third party and reconstruct security states without having to use a service-side distributed cache.

Owner:MICROSOFT TECH LICENSING LLC

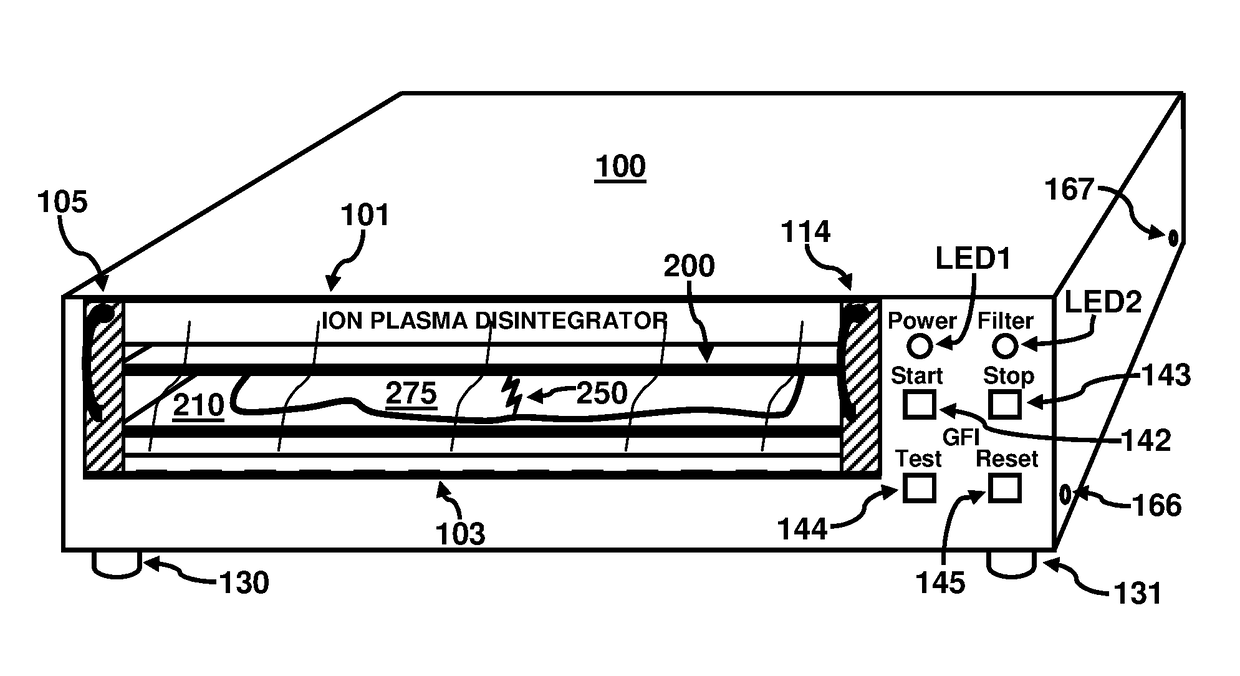

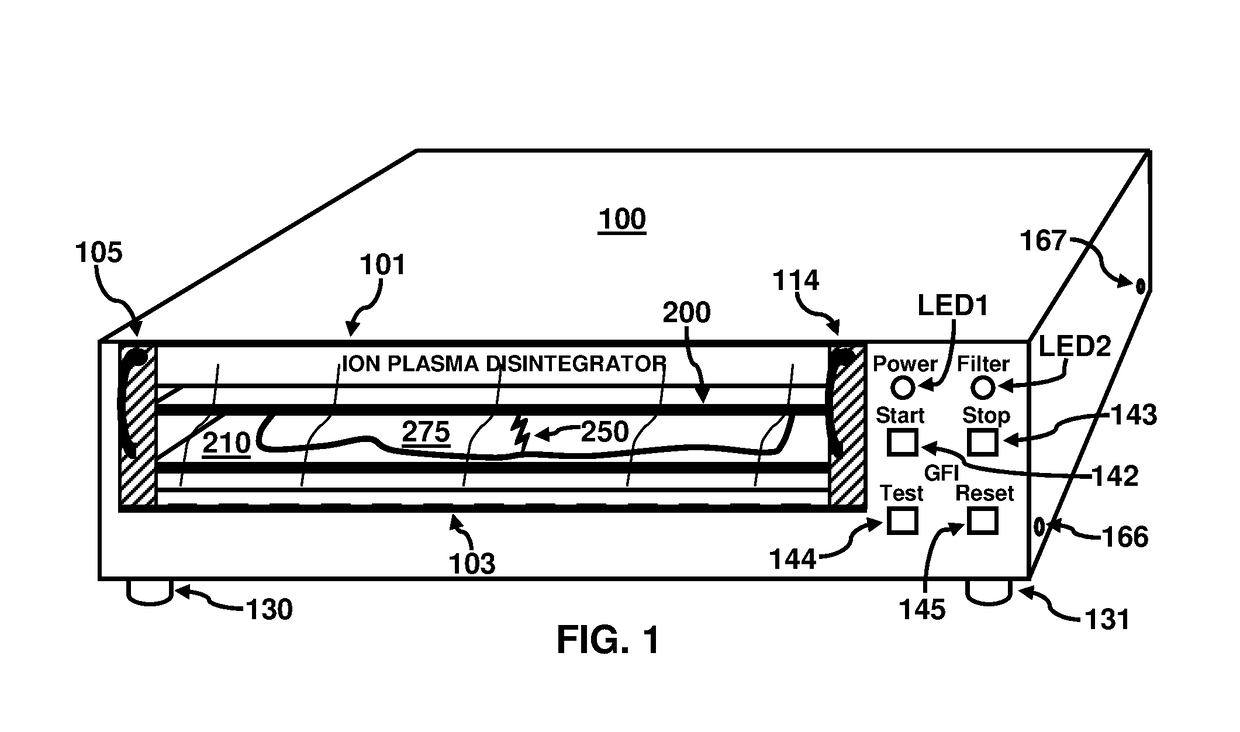

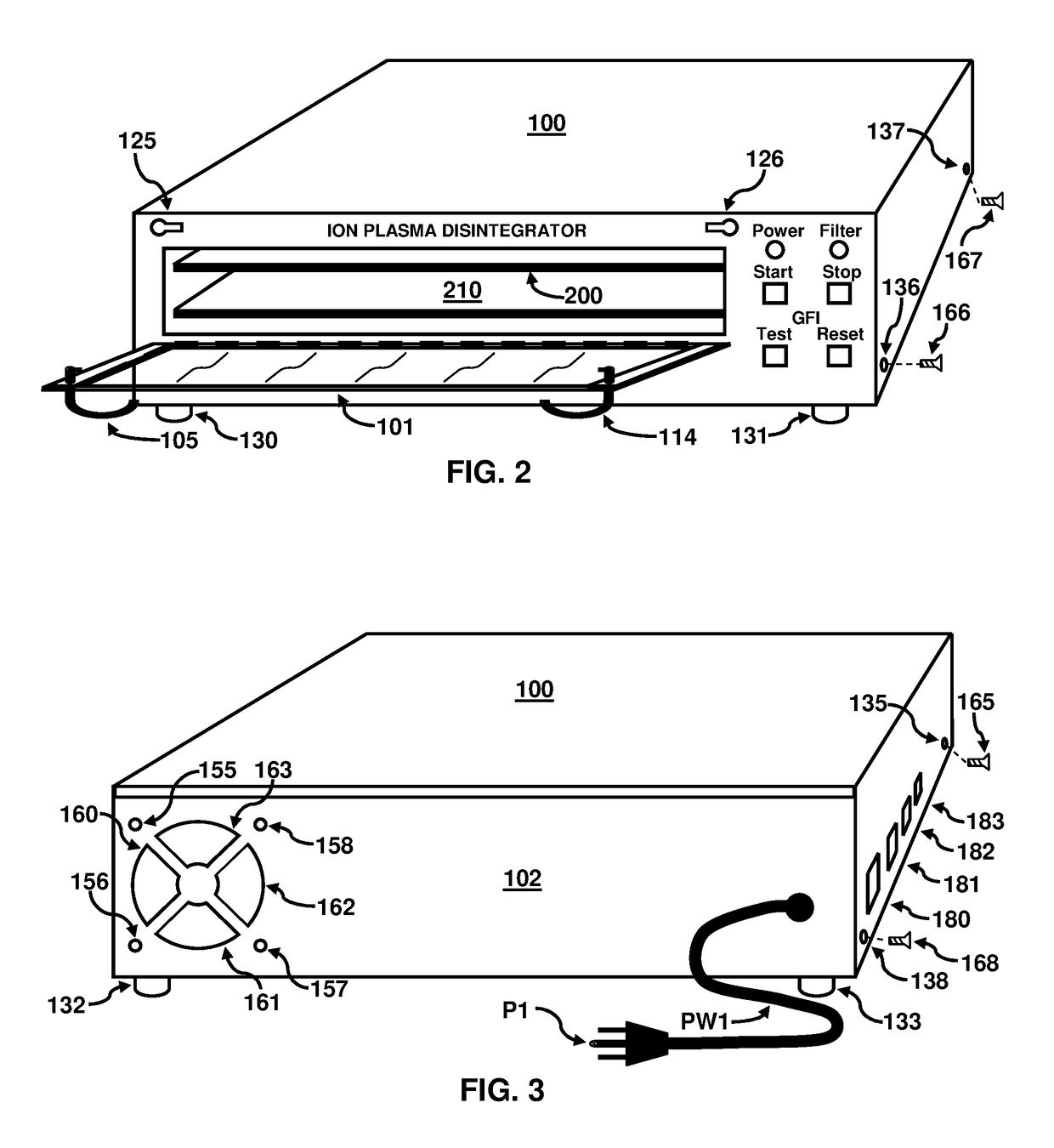

Ion plasma disintegrator

An electronic device incorporating a high voltage power supply connected to a pair of metal plates spaced to maintain a continuous high current arc of electricity creating an Ion Plasma discharge for the purpose of vaporizing documents placed between the plates. Magnetic containment coils around the outside of the metal plates are phase synchronized to the magnetic field created by the Ion Plasma arc to maintain the position of the arc between the plates and to direct the position of the arc in a predetermined pattern to search for any material between the plates that has not been disintegrated.

Owner:NELSON BRADLEY

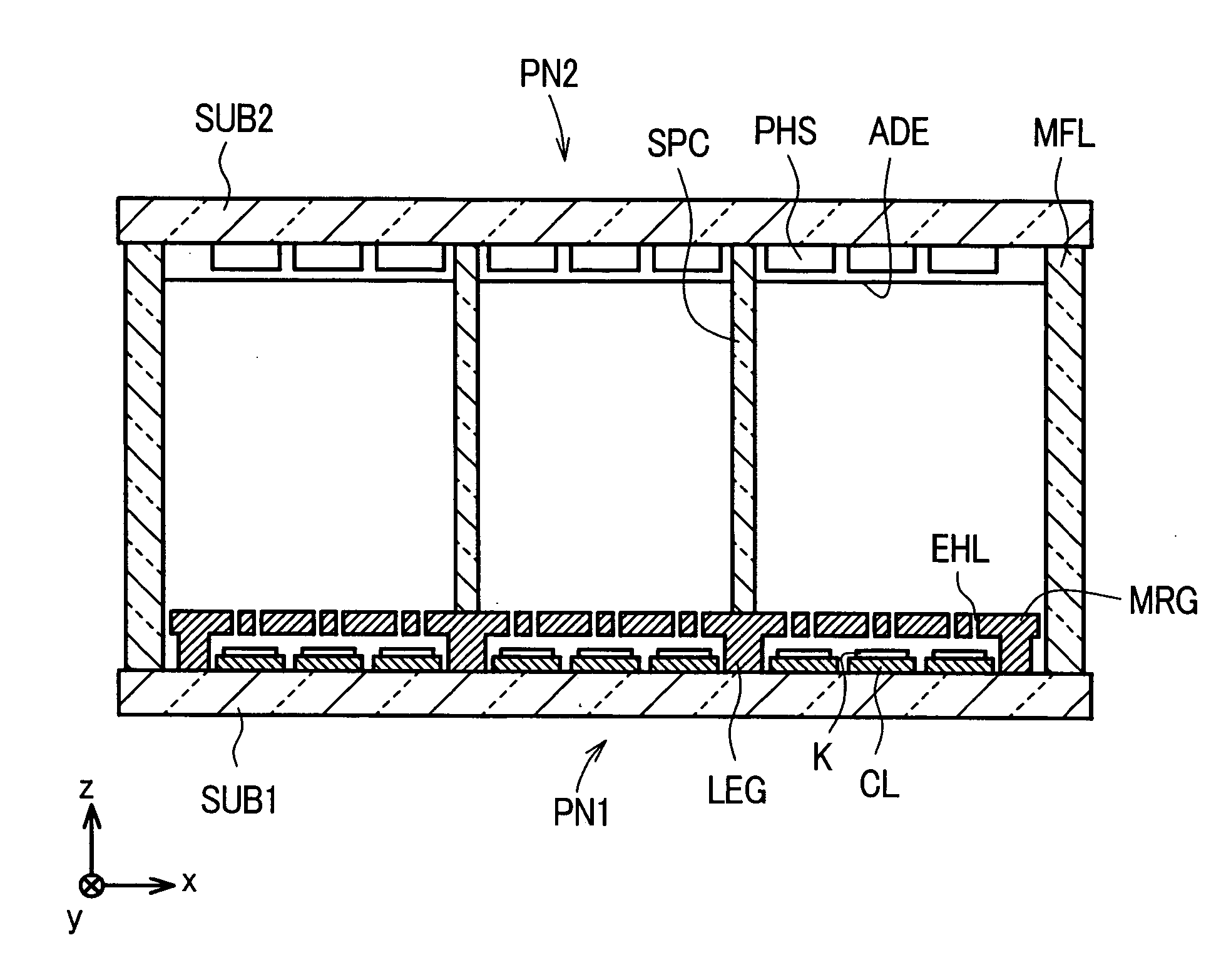

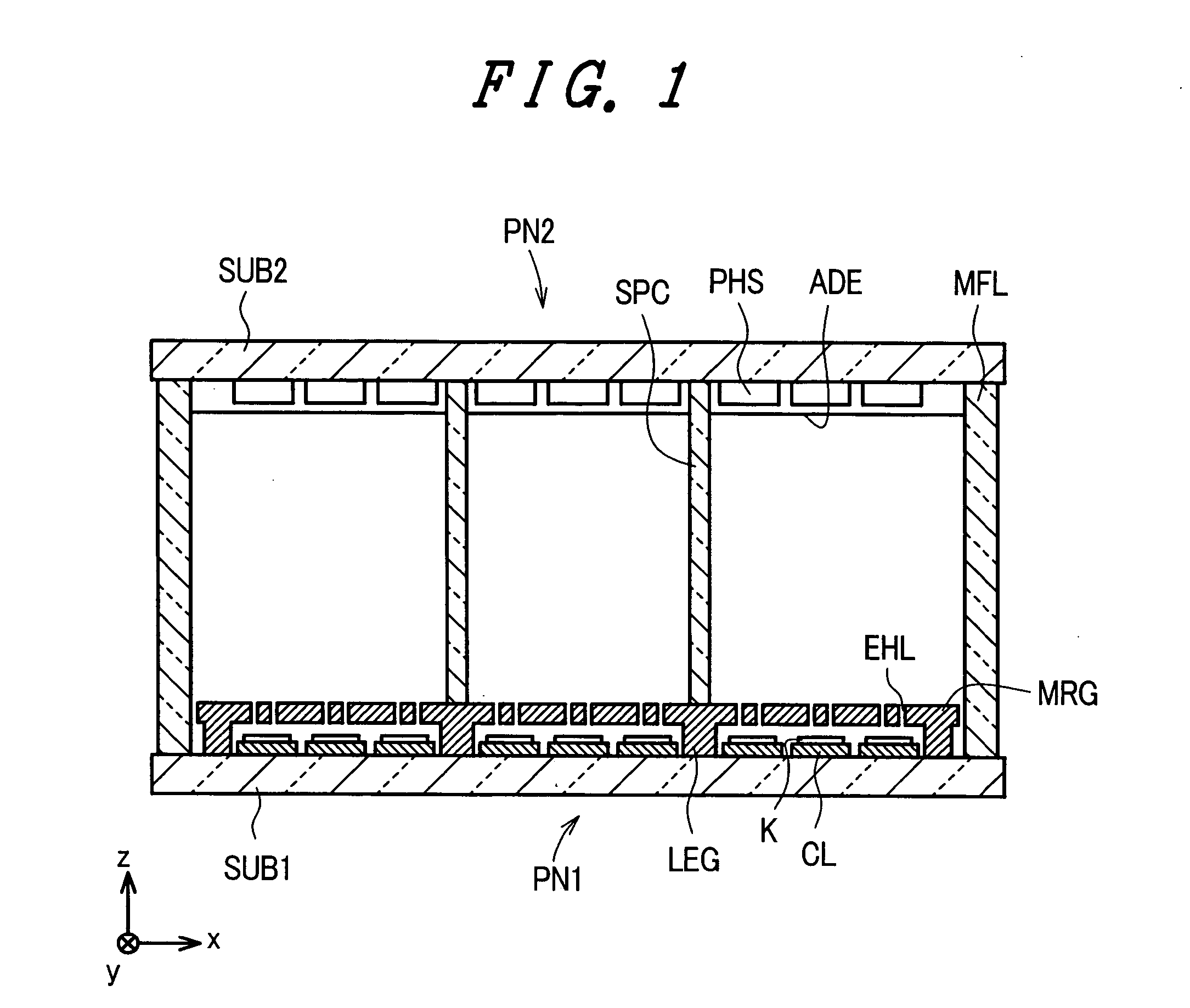

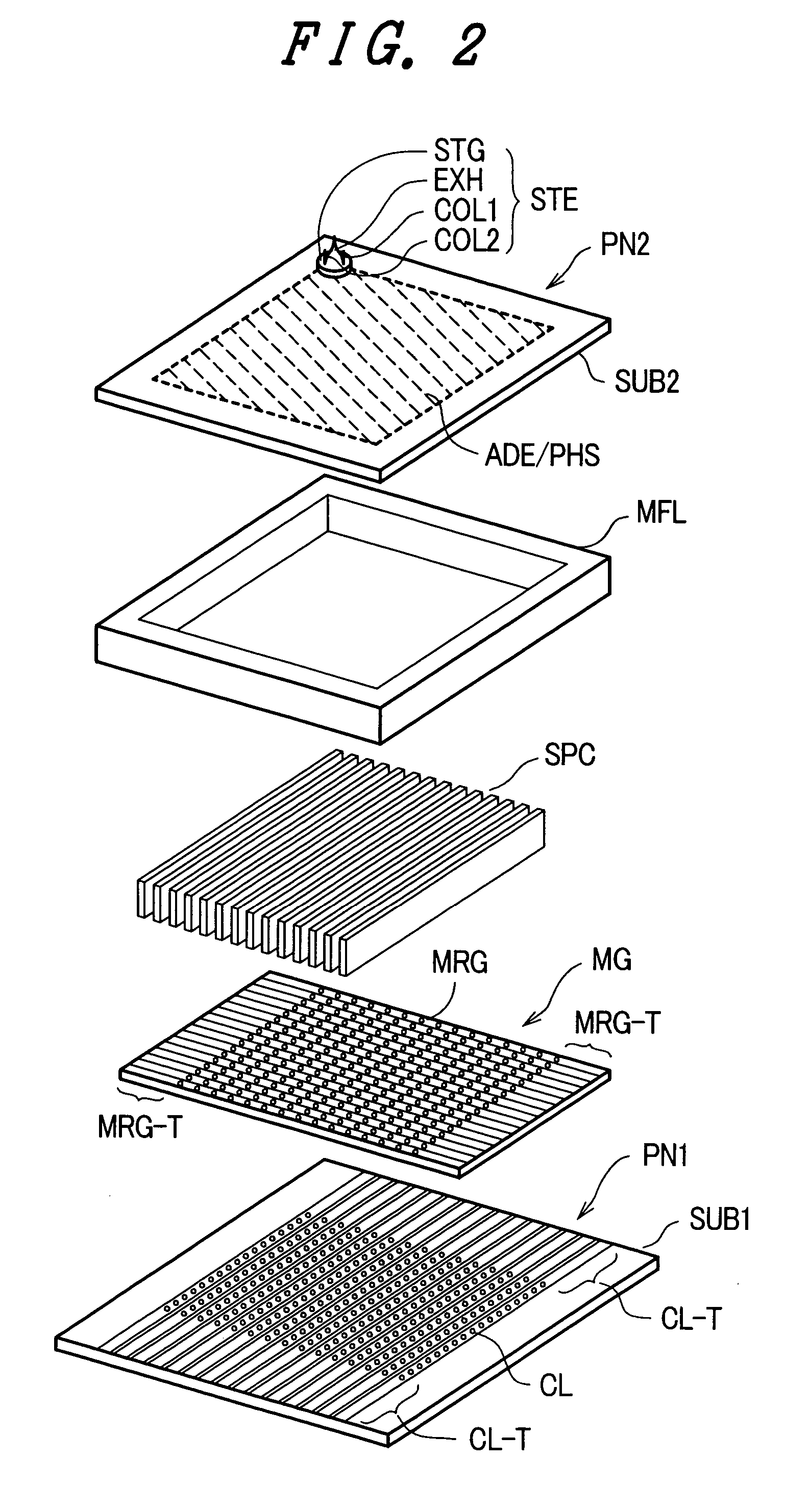

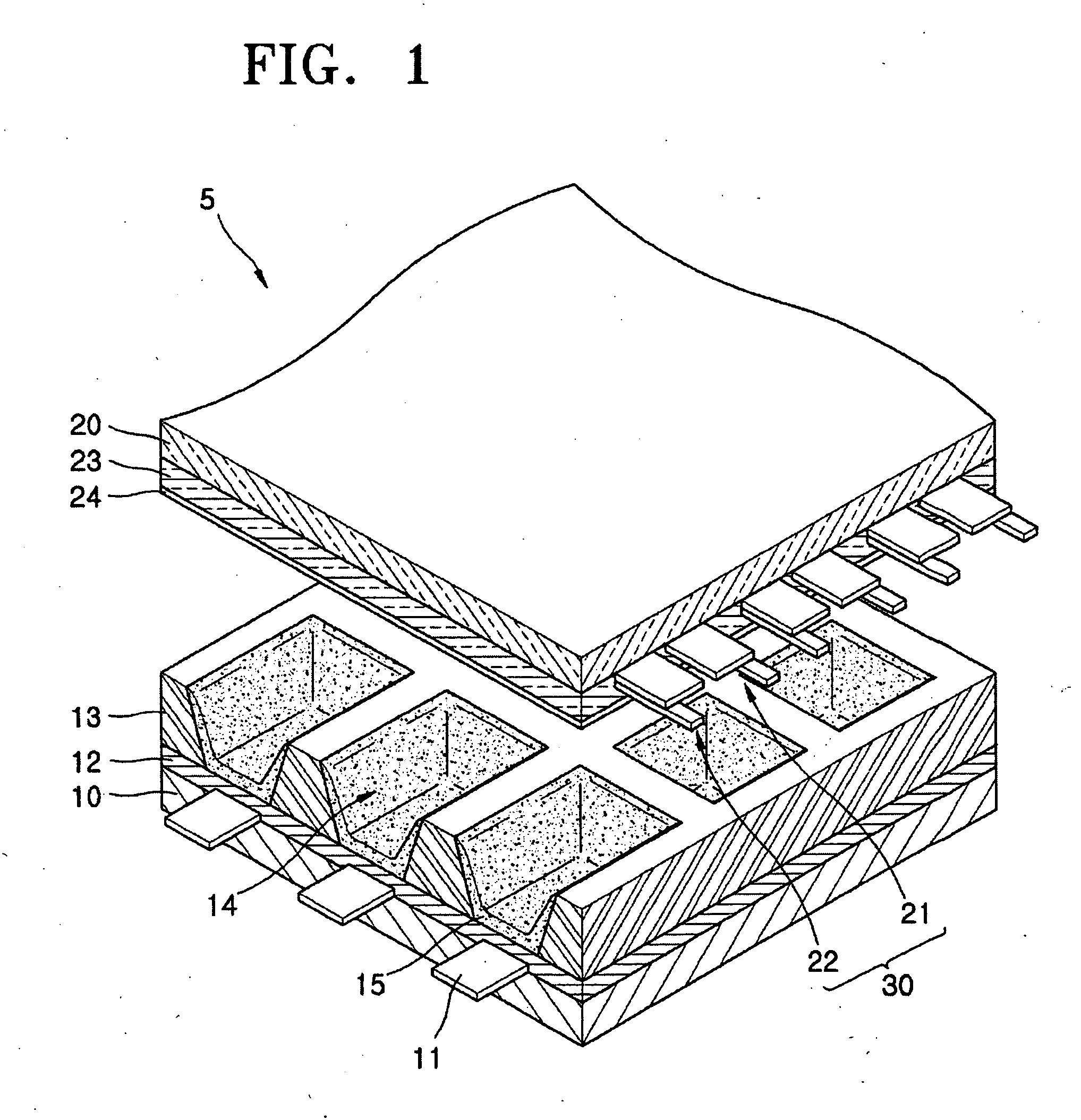

Image display device

InactiveUS20050206299A1High dielectric strengthSimple structureGas filling substance selectionGas-filled discharge tubesDisplay deviceExhaust pipe

In a corner portion outside a display region of a face substrate which constitutes a face panel of a display device, an opening is formed. In the opening, a stem glass structural body, which is configured by integrally forming an exhaust pipe on a center portion of a stem glass and by forming conductive leads in a peripheral portion thereof in an embedded manner, is fixed by welding using curing by heating. The exhaust pipe is evacuated and, thereafter, tipped off, thus realizing vacuum sealing of the inside thereof. A lead line is connected to a distal end of one conductive lead by welding and another end of the lead line is electrically connected with one end portion of the anode formed on an inner surface of the face substrate using a conductive adhesive agent. Further, a getter is mounted and fixed to another conductive lead line by welding.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

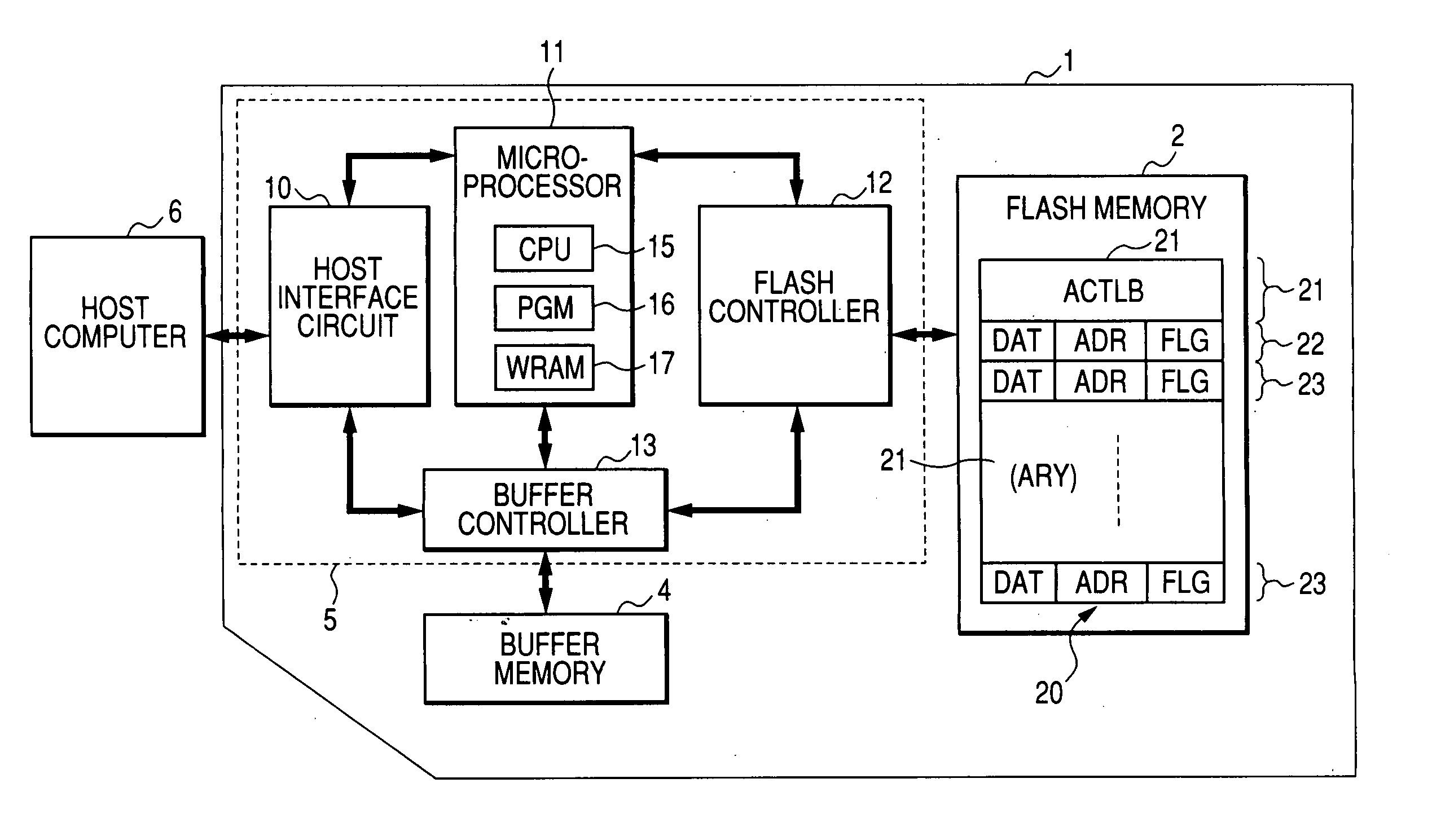

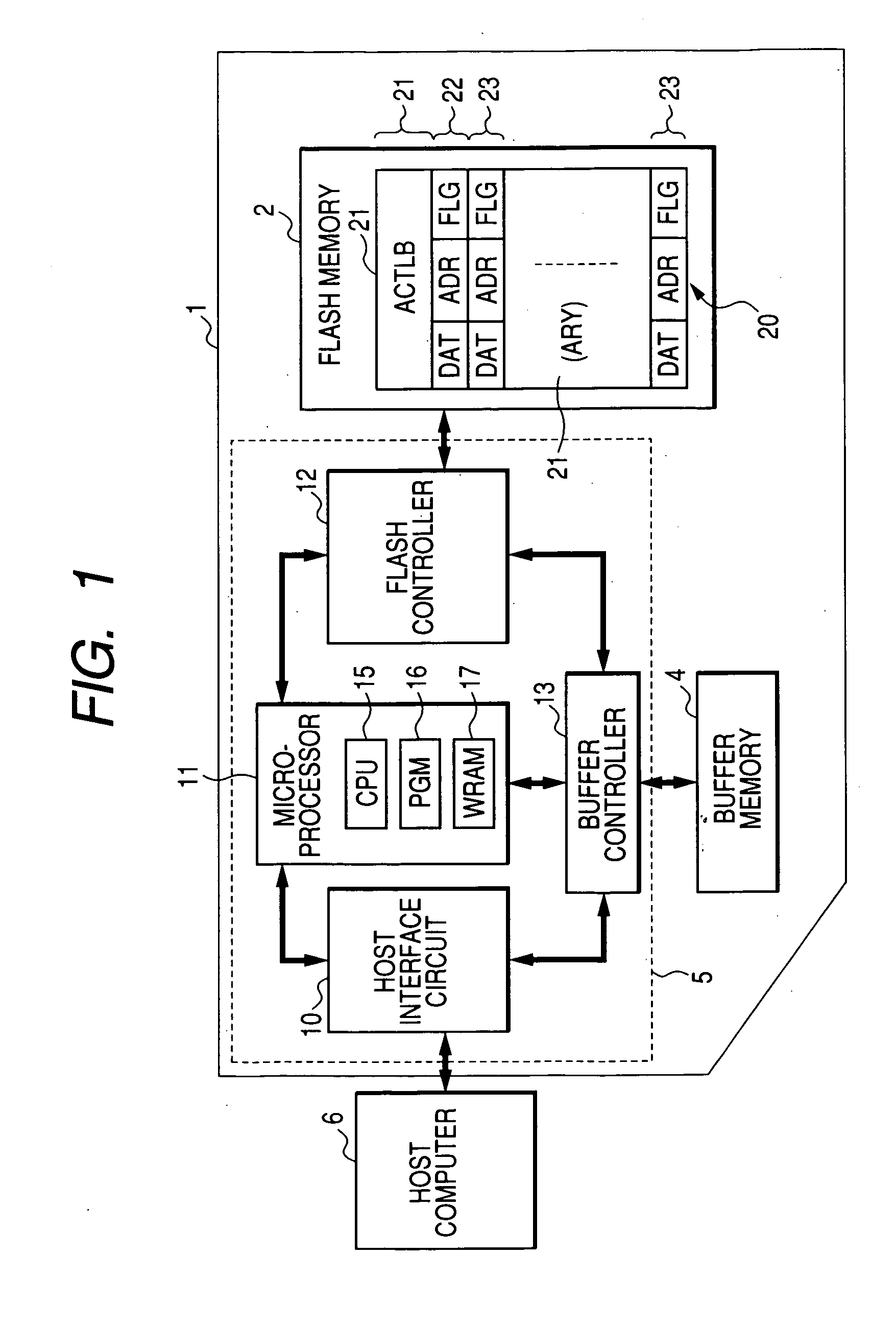

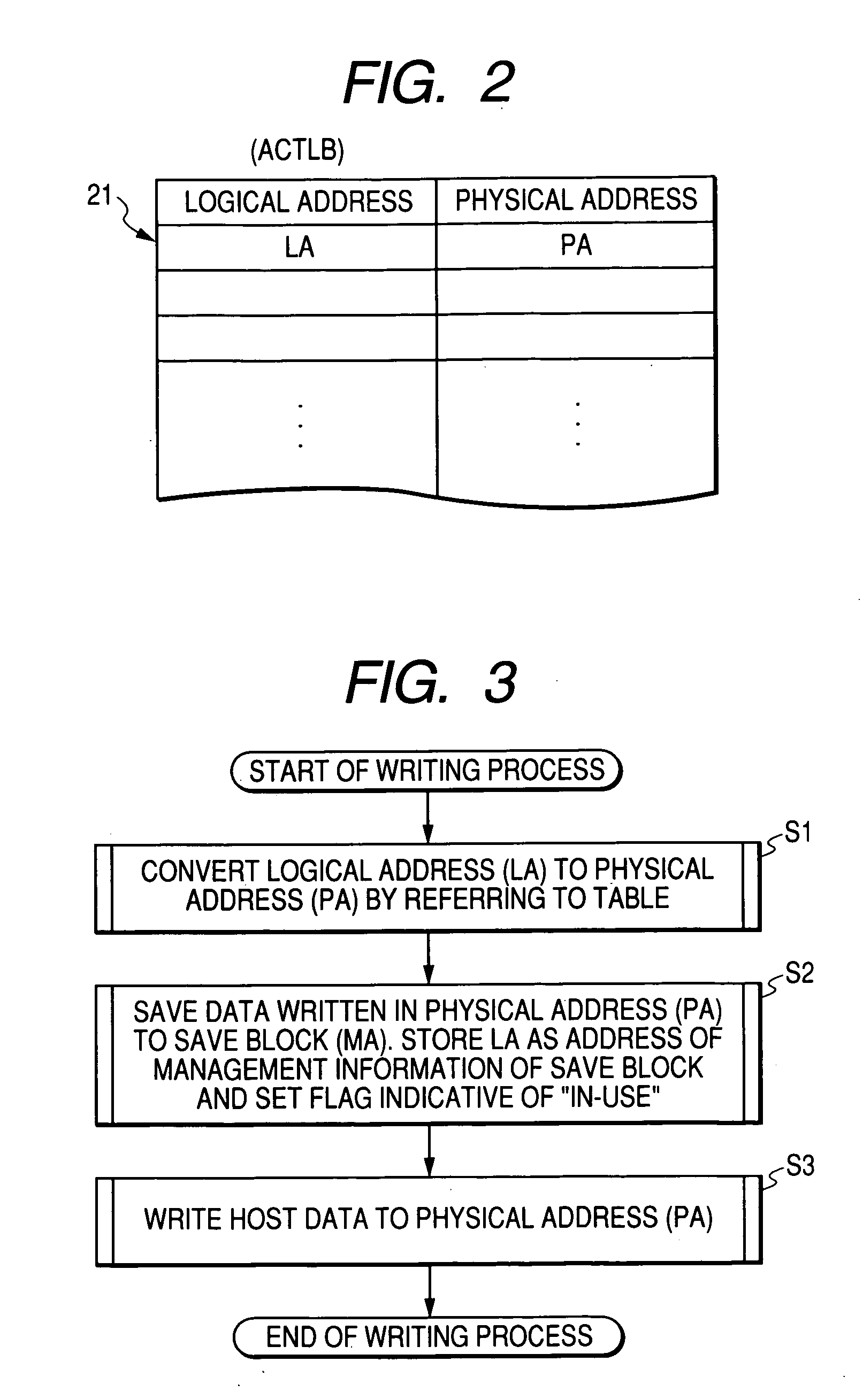

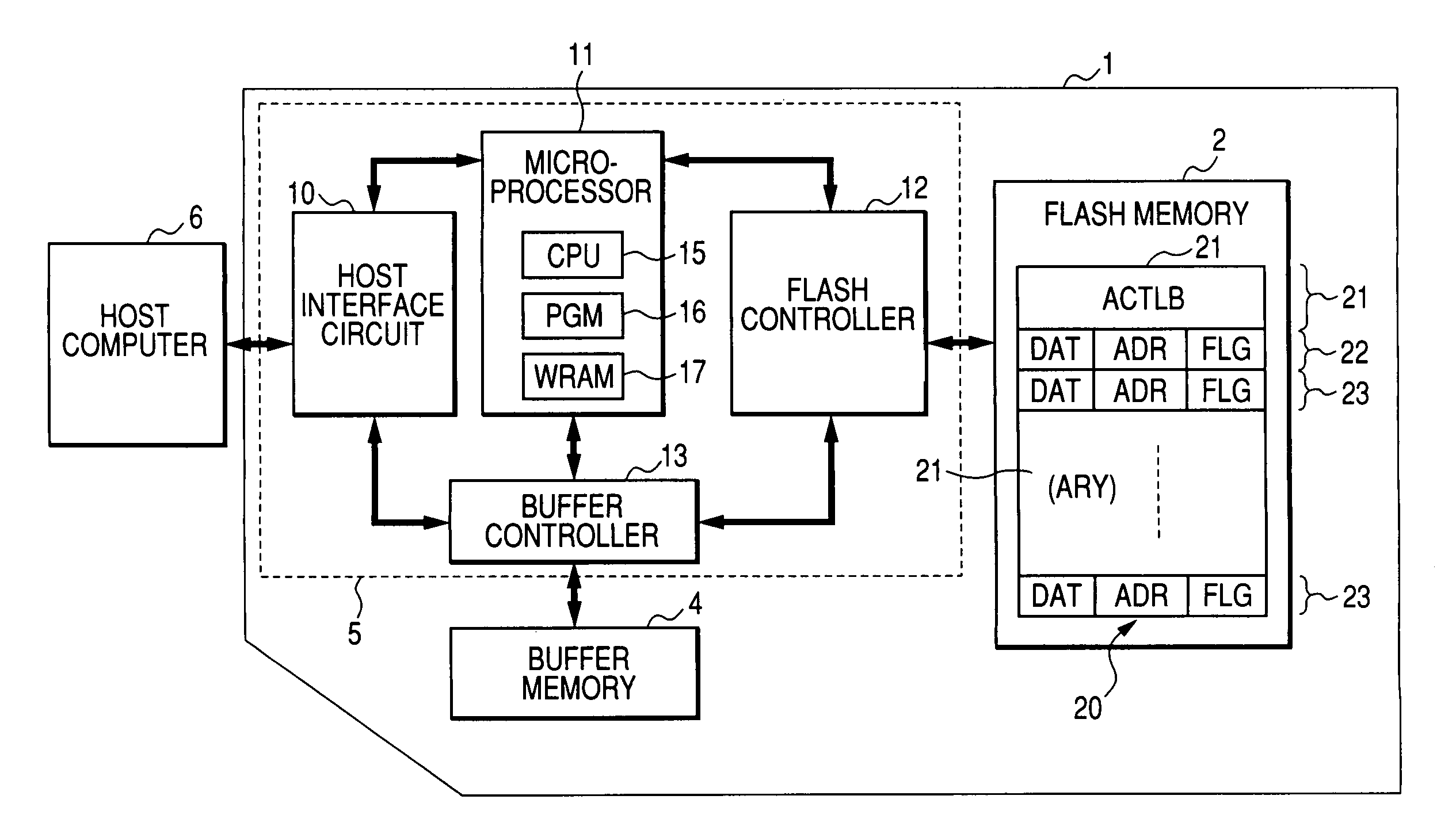

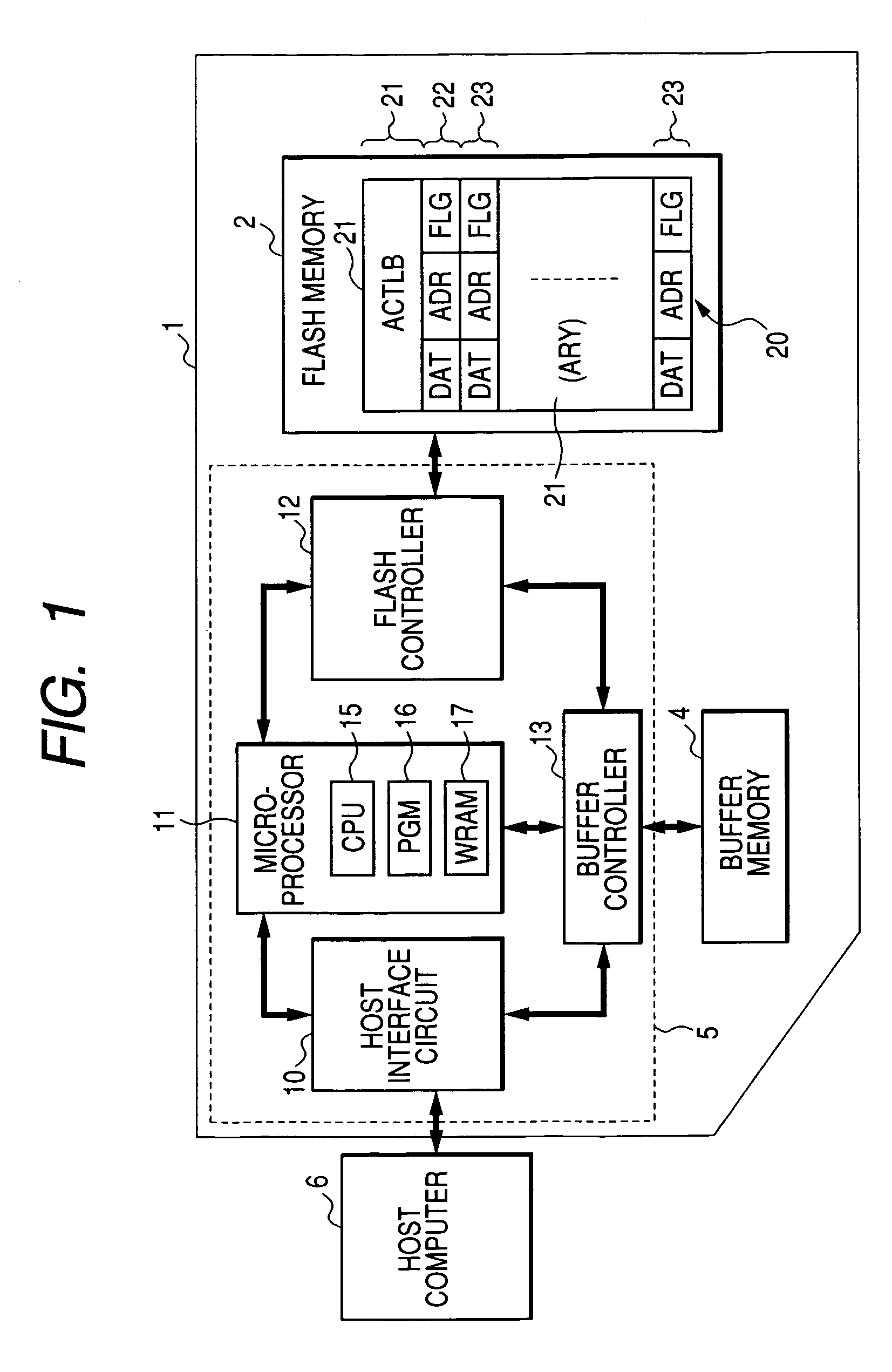

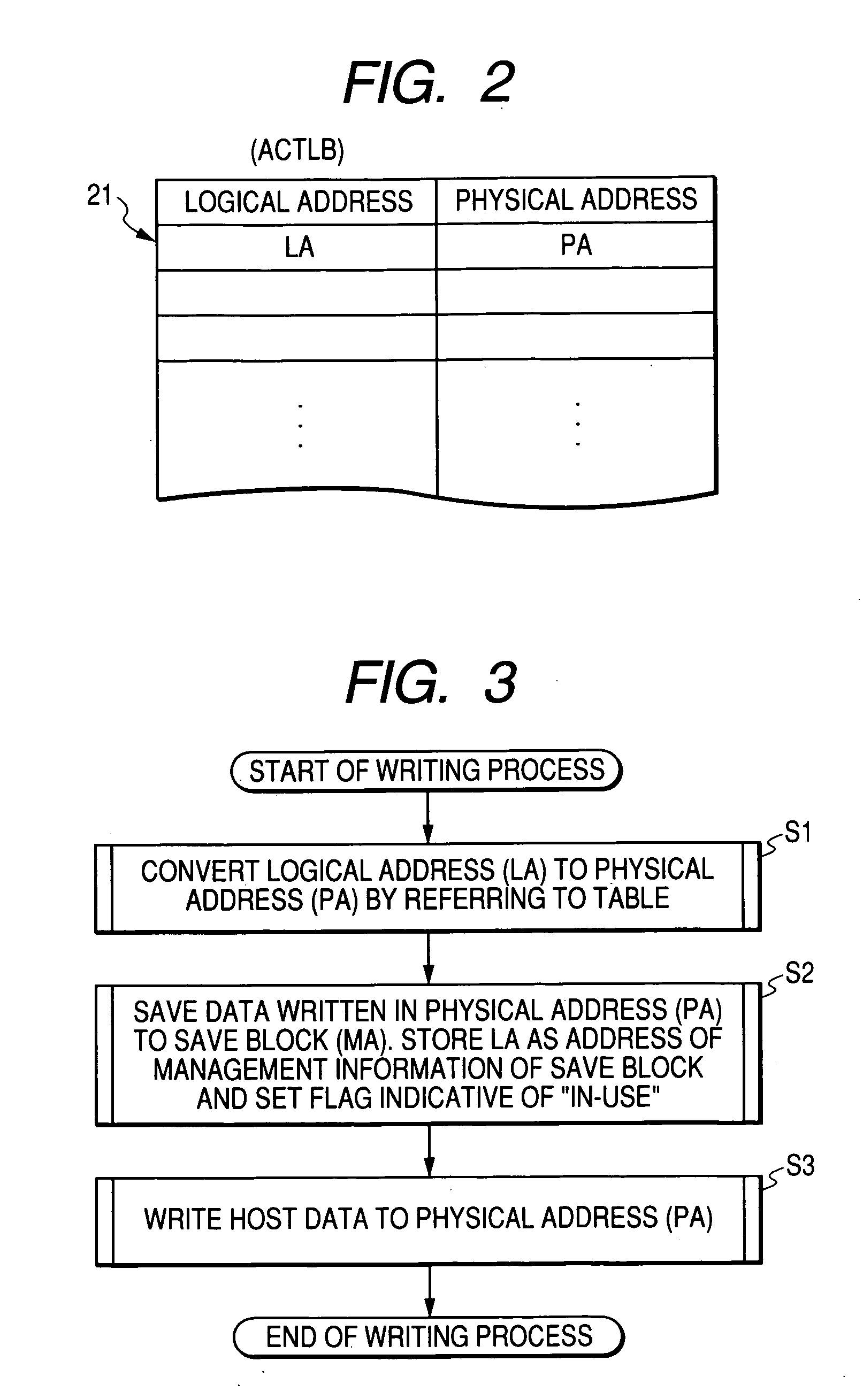

Nonvolatile memory apparatus

InactiveUS20050201177A1Shorten the timeReduce memory areaConveyorsInput/output to record carriersData lossData storing

The present invention is directed to suppress data loss caused by power shut-down during a rewriting process and to shorten time required to make a depletion check. A nonvolatile memory apparatus includes a rewritable nonvolatile memory and a card controller. The nonvolatile memory has a physical address area corresponding to a logical address and a save area. In response to a data rewrite instruction on a required logical address, the card controller stores data in a predetermined physical address area corresponding to the logical address to the save area and rewrites the data stored in the physical address area. When rewriting of the physical address area is incomplete, the card controller rewrites the data in the physical address area with the data stored in the save area. Thus, data loss caused by the power shut-down can be suppressed by data backup, and it is sufficient to make the depletion check in two places of the save area and the physical address area.

Owner:RENESAS ELECTRONICS CORP

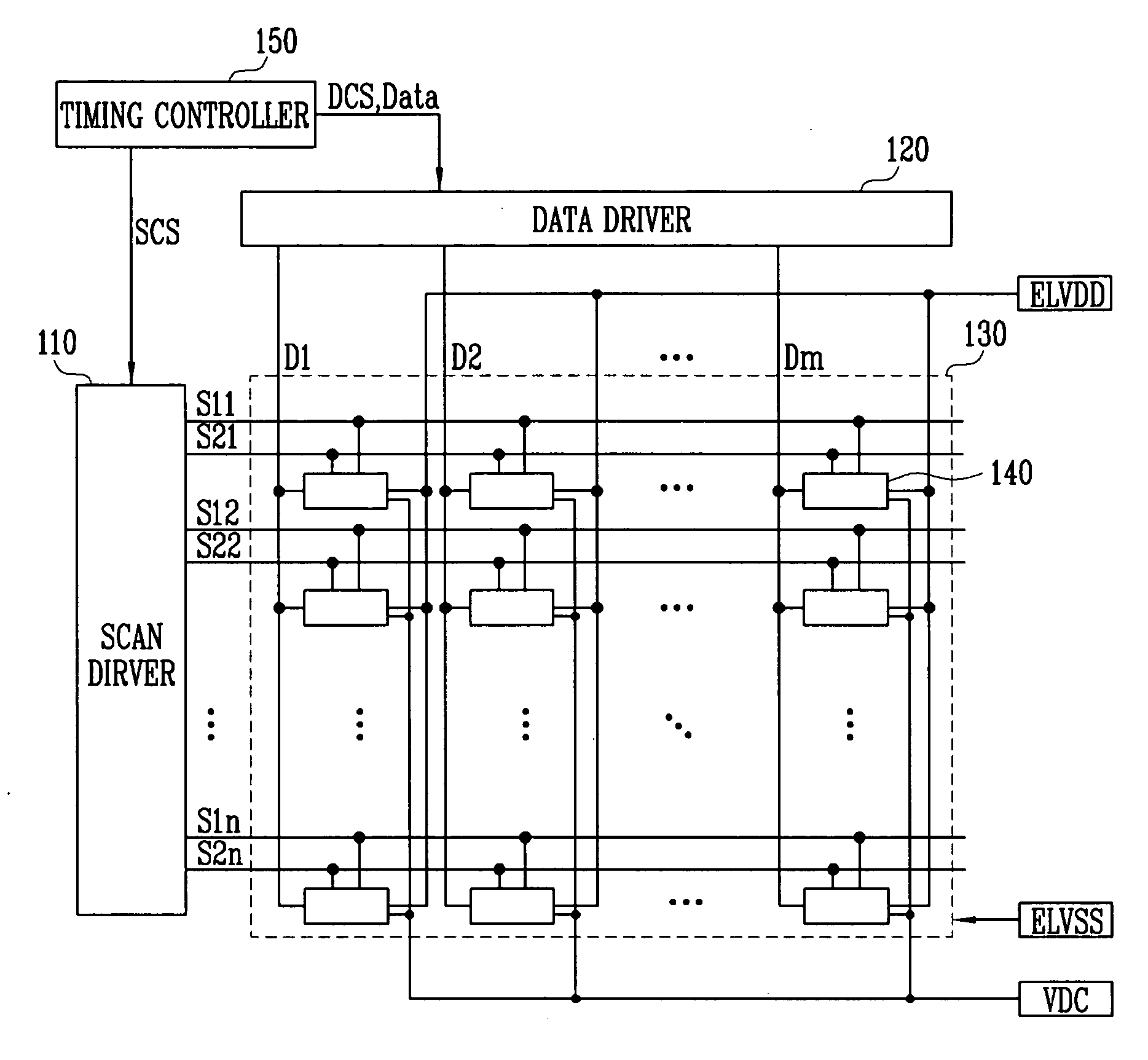

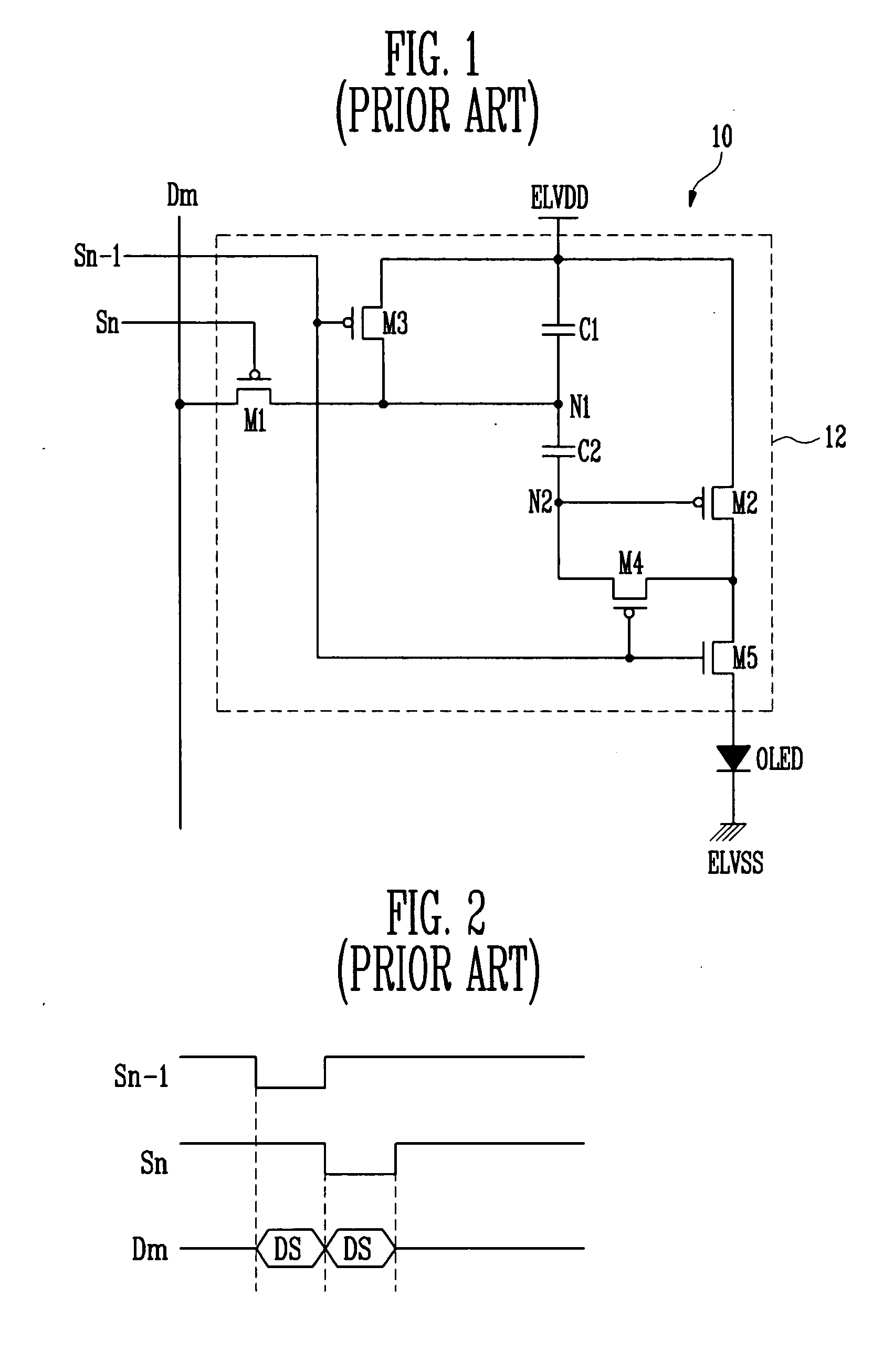

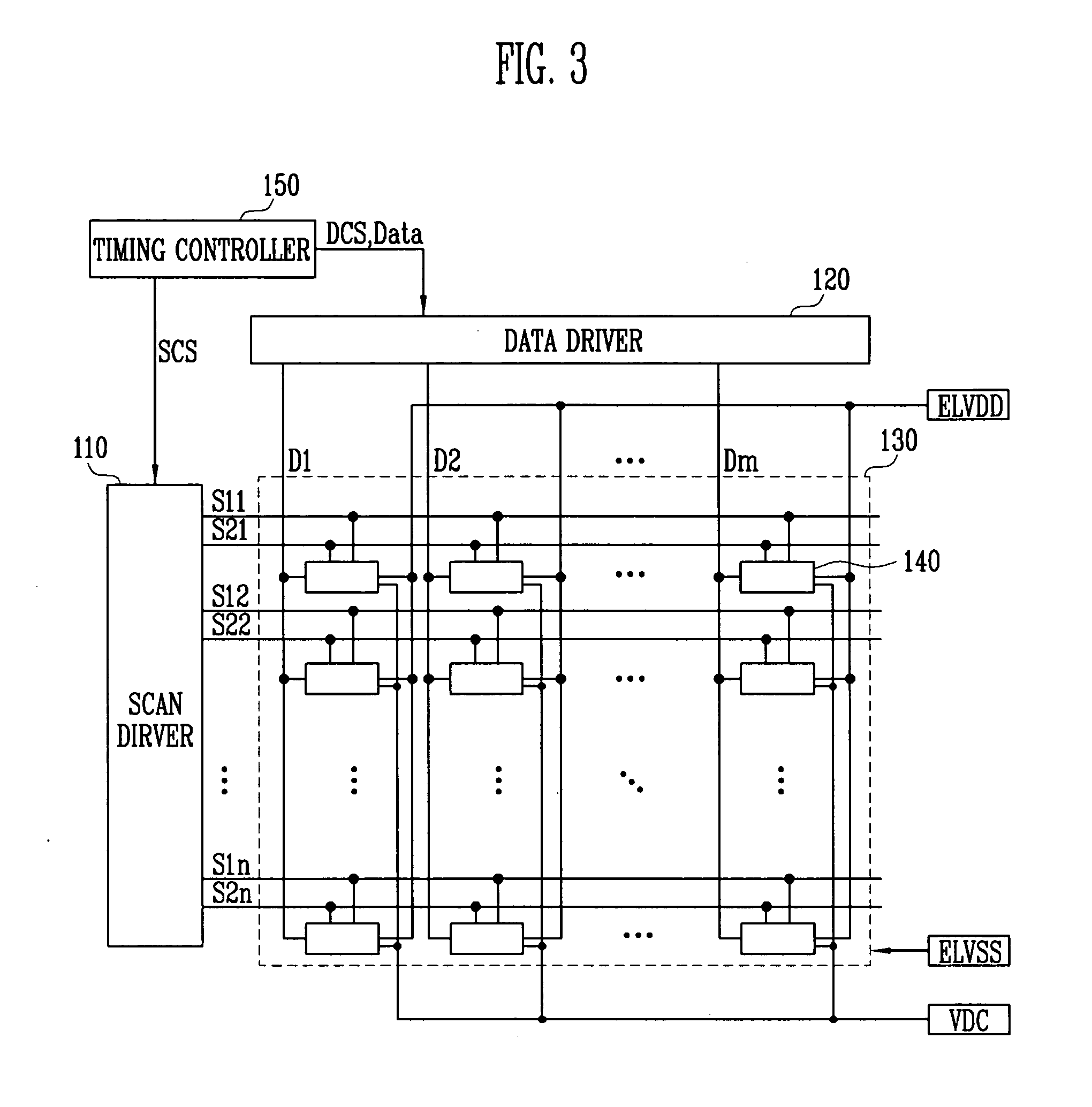

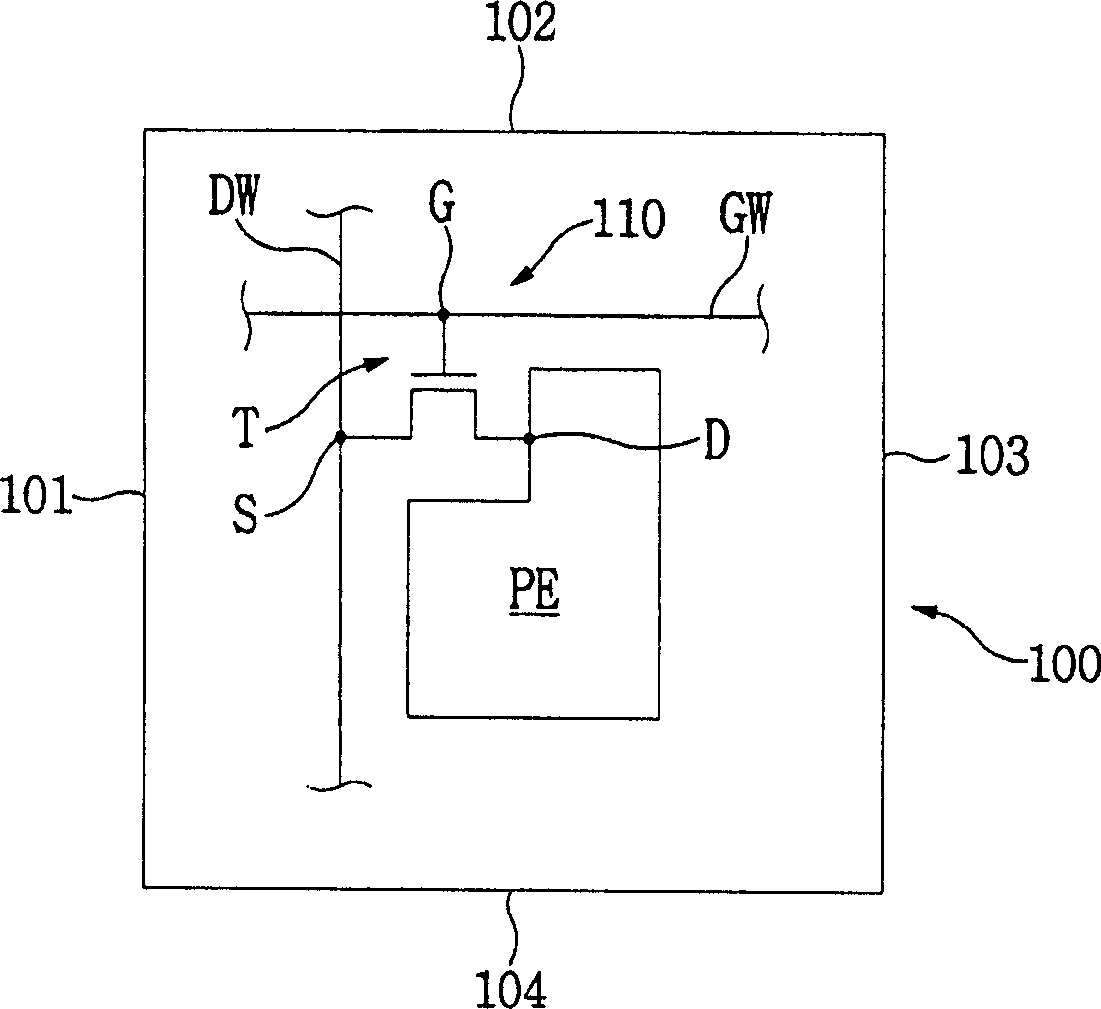

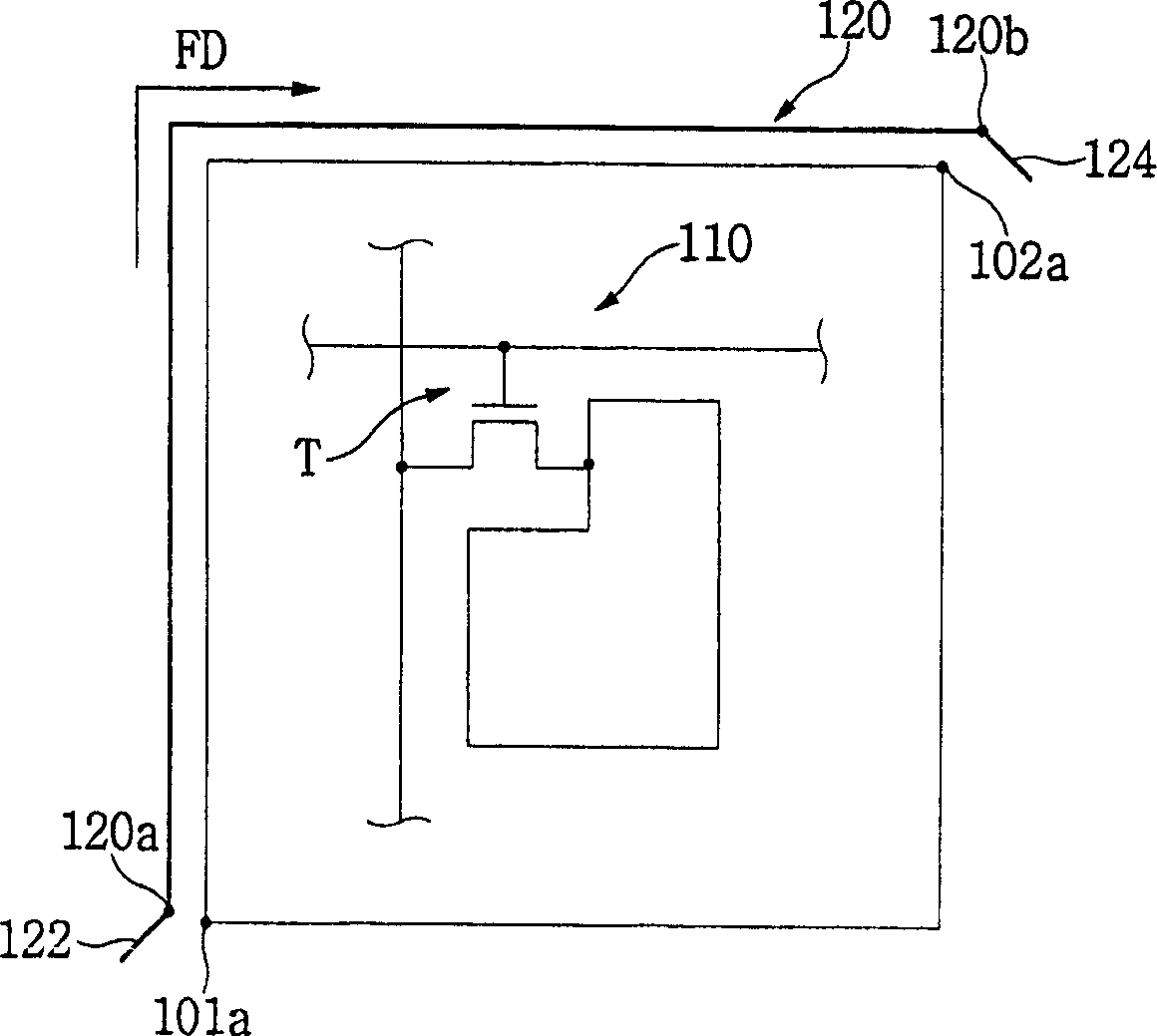

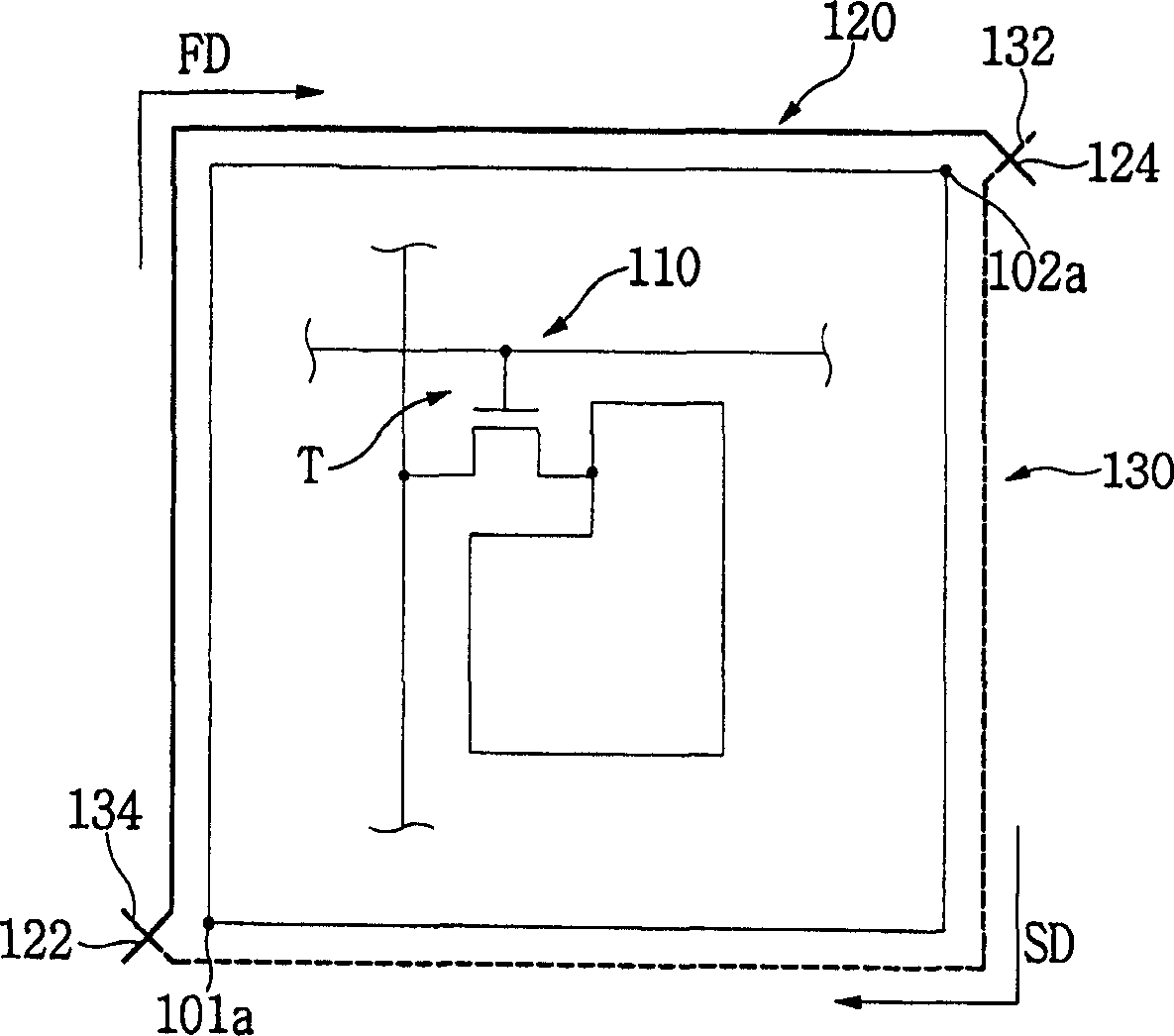

Pixel circuit, organic light emitting display using the pixel circuit and driving method for the display

InactiveUS20060248420A1Electronic circuit testingStatic indicating devicesVoltage dropLight-emitting diode

A pixel circuit and an organic light emitting display using the pixel circuit and a pixel circuit driving method capable of displaying an image of desired brightness are disclosed. The pixel provides a current for an organic light emitting diode which is not affected by a kickback voltage which occurs at the end of an initialization phase. The pixel also provides a current for an organic light emitting diode which is substantially not affected by a voltage drop in the power supply providing the current.

Owner:SAMSUNG DISPLAY CO LTD

Trusted third party authentication for web services

InactiveUS7900247B2Digital data processing detailsUser identity/authority verificationThird partyInternet privacy

Owner:MICROSOFT TECH LICENSING LLC

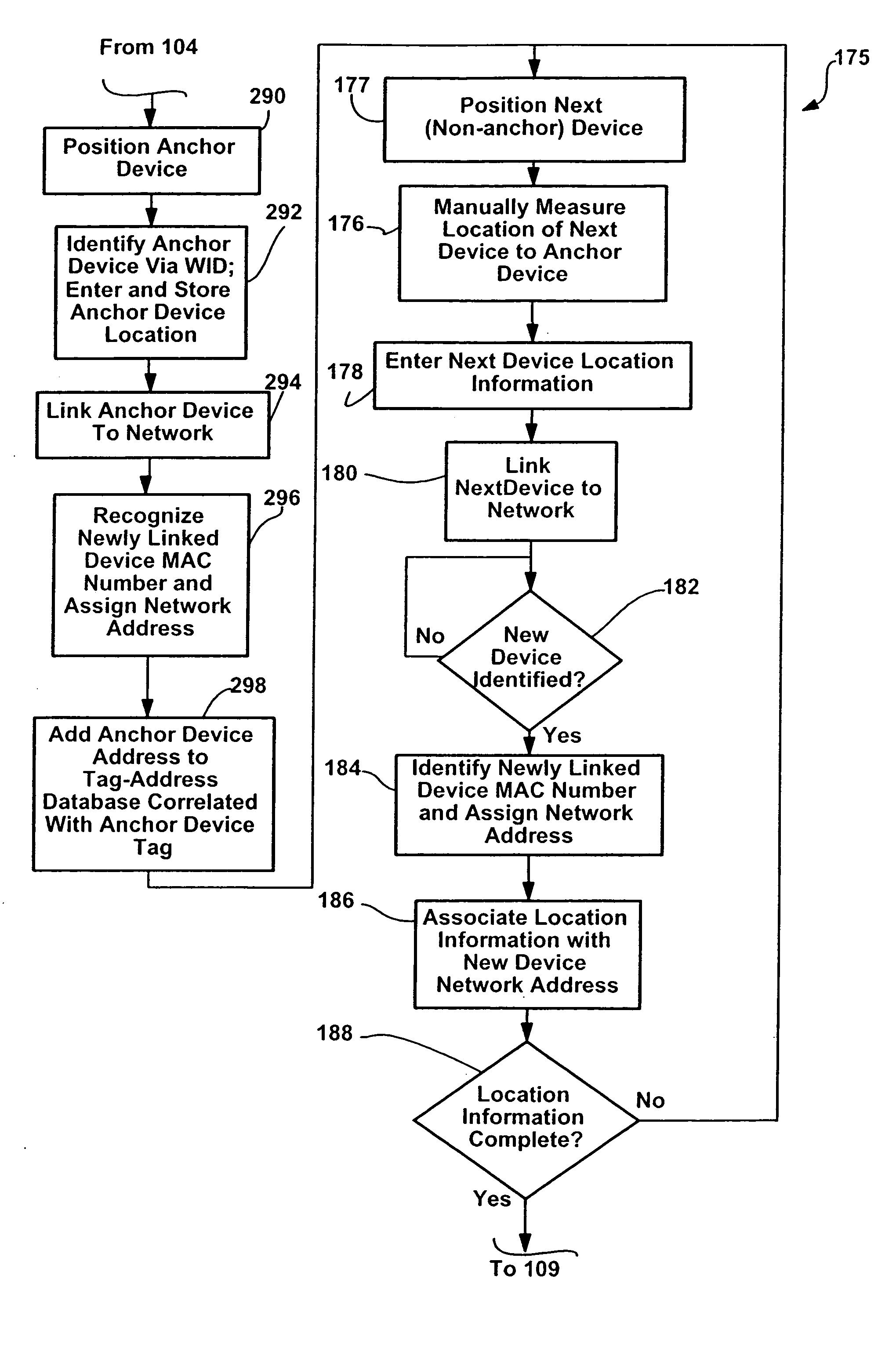

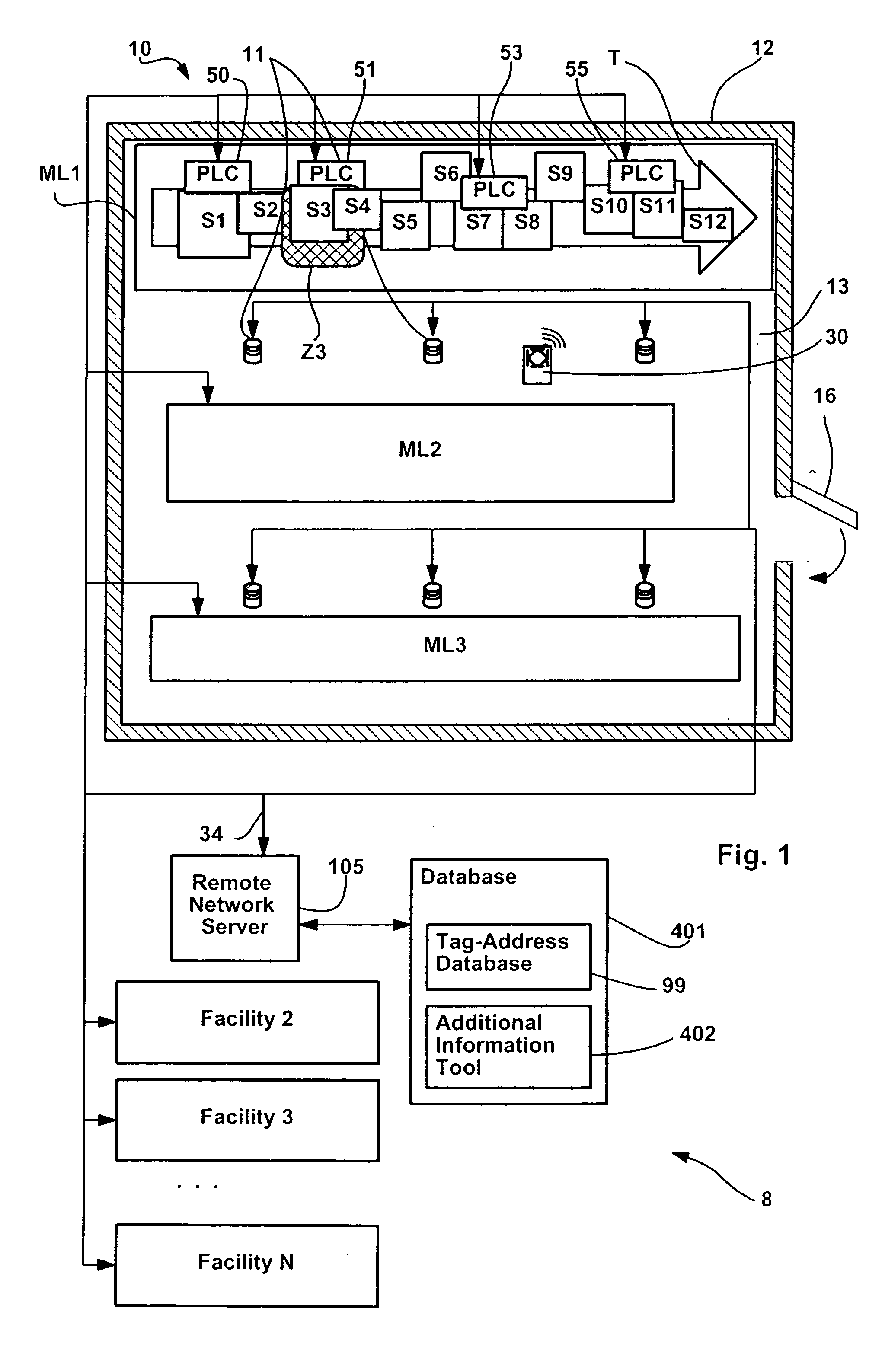

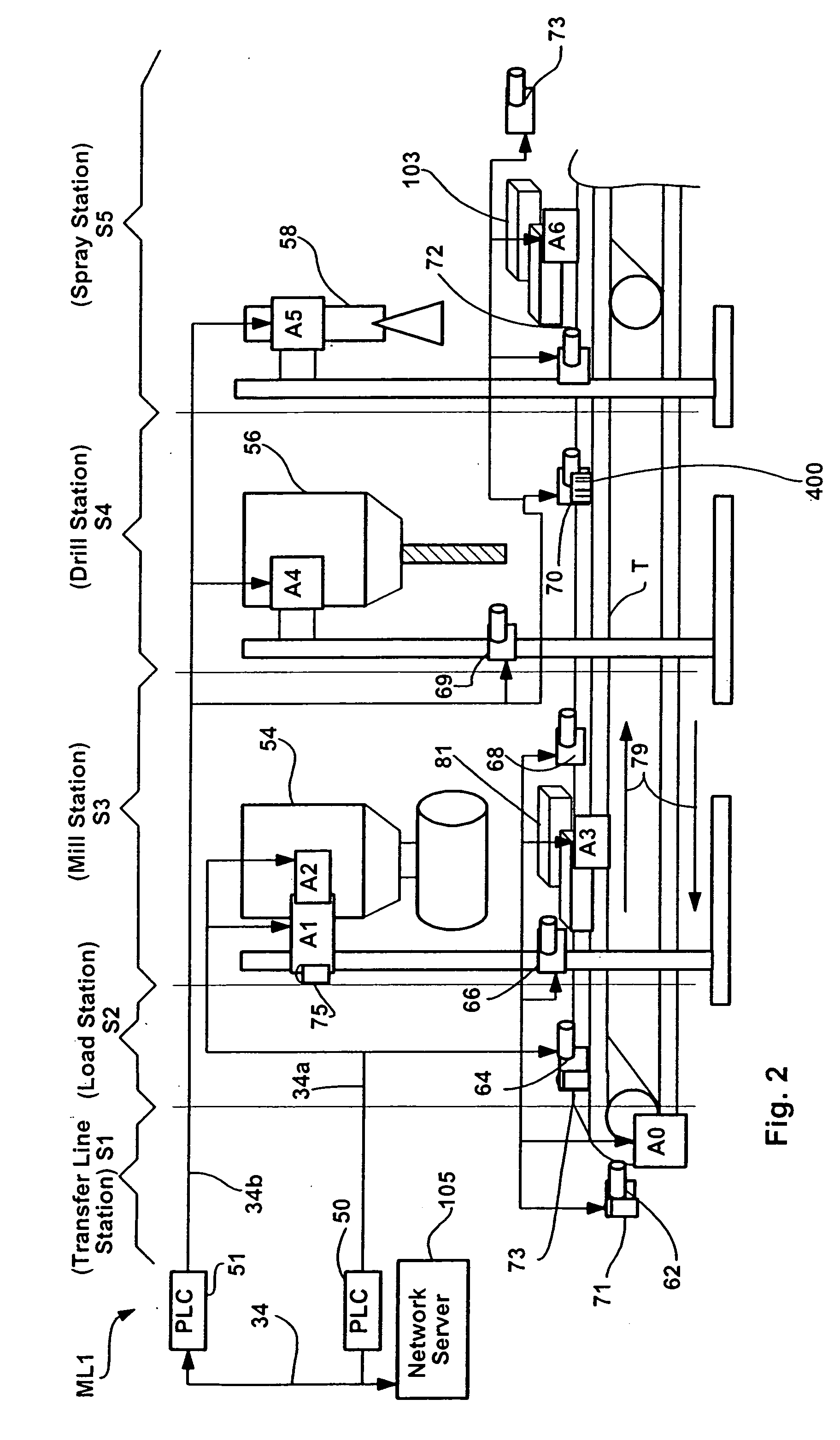

Juxtaposition based machine addressing

Owner:ROCKWELL AUTOMATION TECH

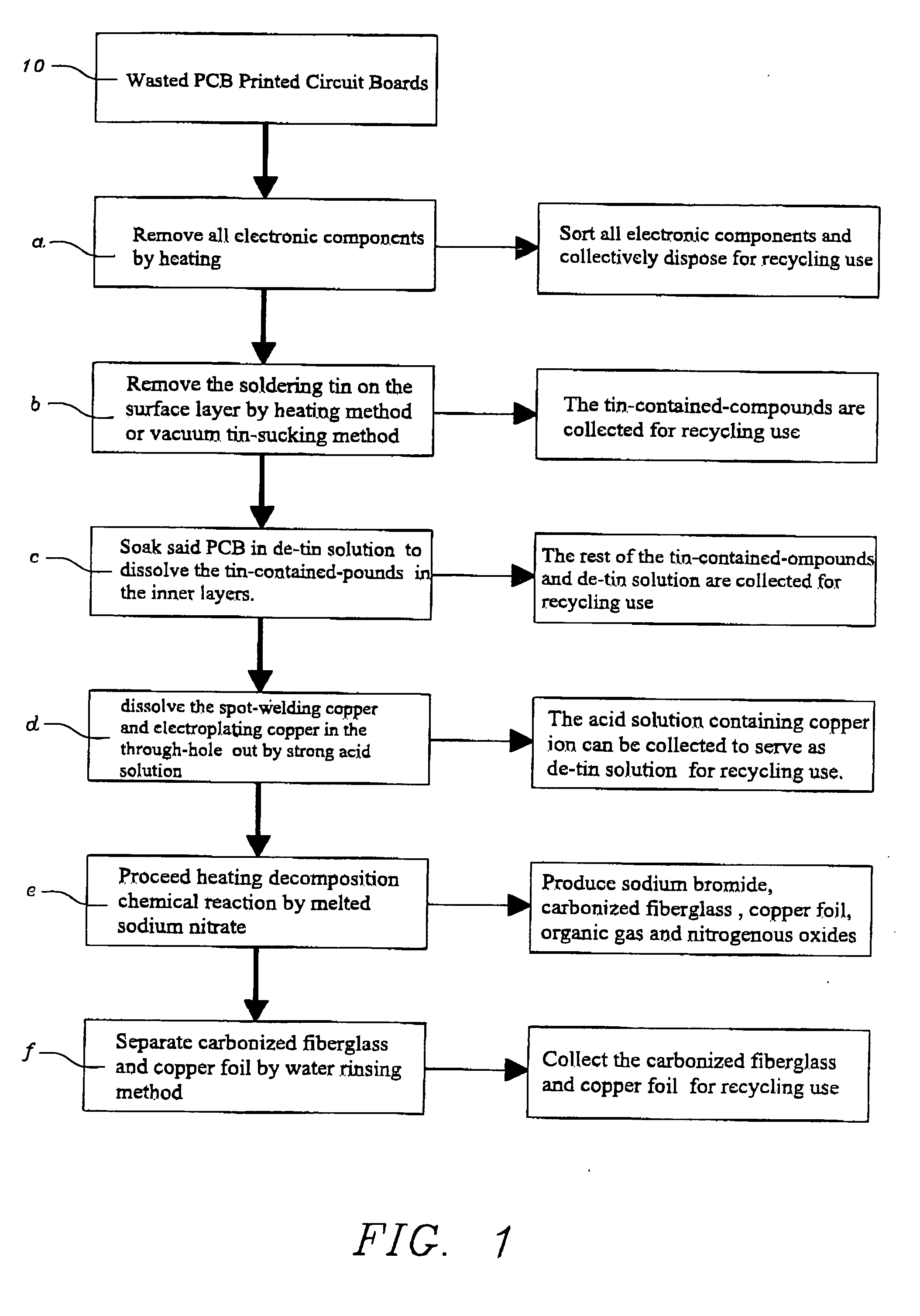

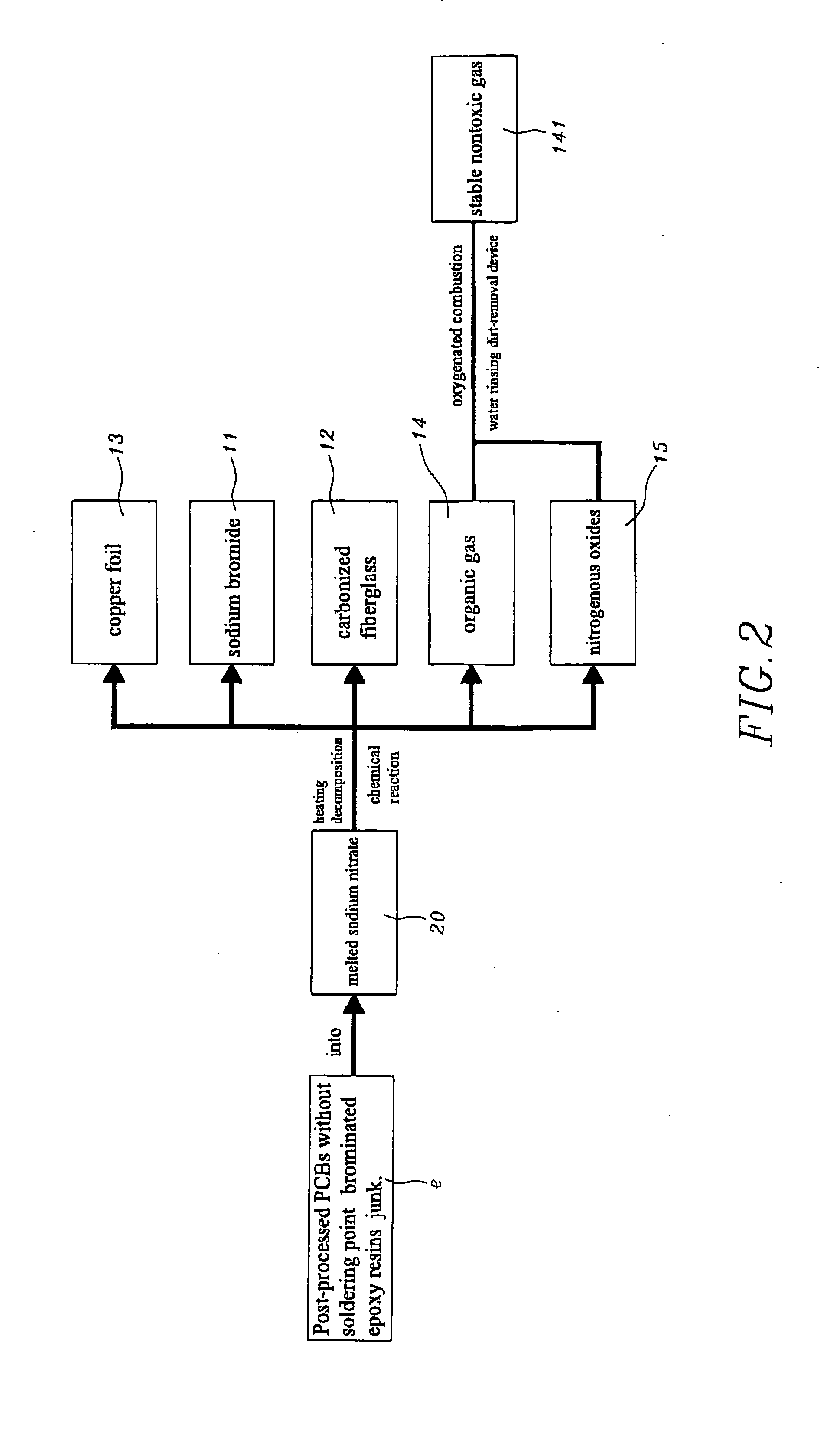

Method of recycling wasted printed-circuit-board

InactiveUS20070169330A1Final product manufactureTransportation and packagingRecovery methodGlass fiber

The present invention relates to a “method of recycling wasted printed-circuit-board”, which takes advantage of the characteristics of the PCB so as to dispose different recycling material in stage manner, so that different metals remaining on said PCB are sorted out step by step; Thereby, the bromide and the fiberglass of importance in the resins are collected and converted into variety of industrial materials as resource for recycling use in order to prevent said wasted PCB from spoiling the natural environment after recycling use.

Owner:WU HSIEH SEN

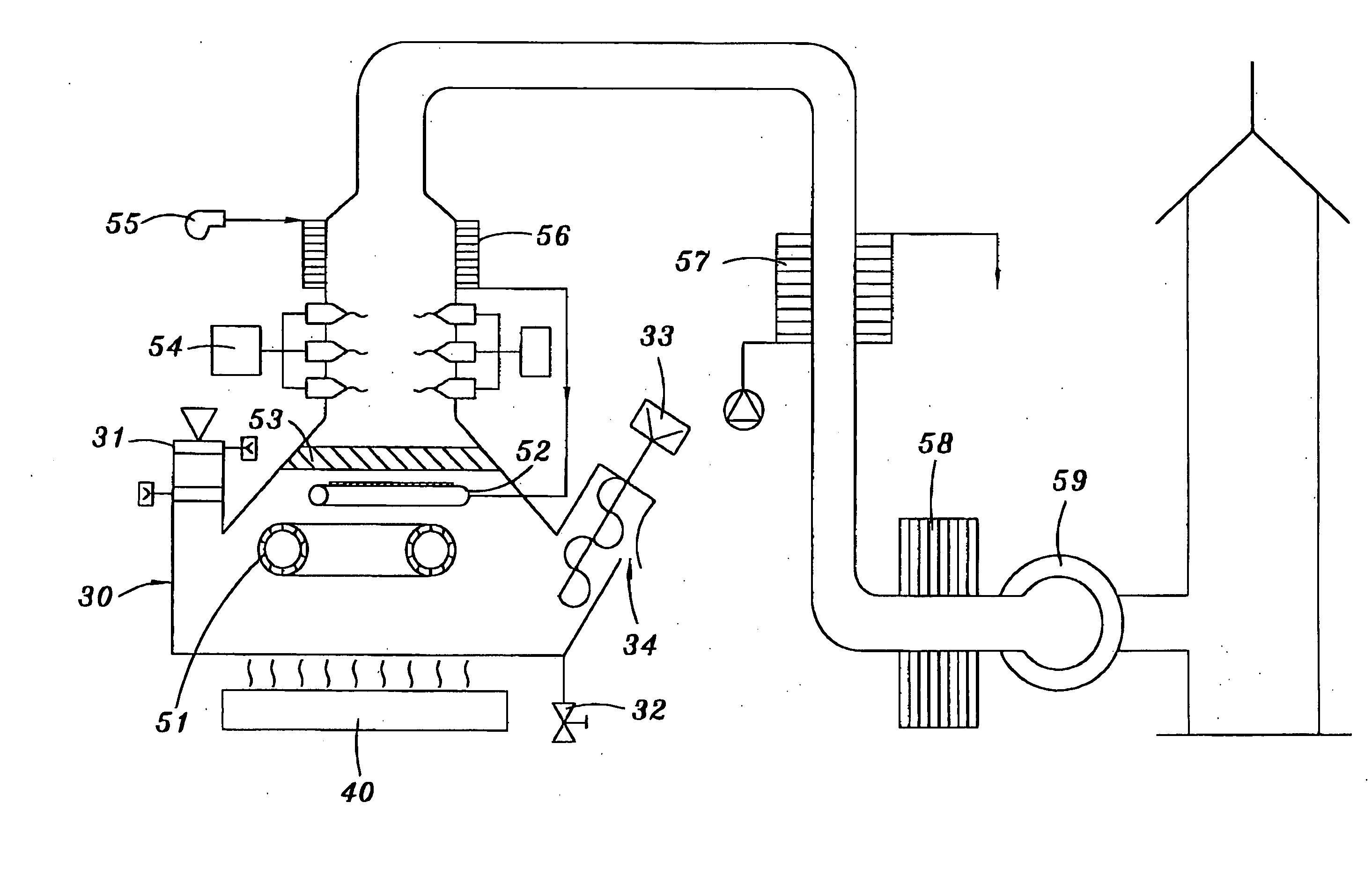

Waste treatment autoclave to provide for steam - assisted drying

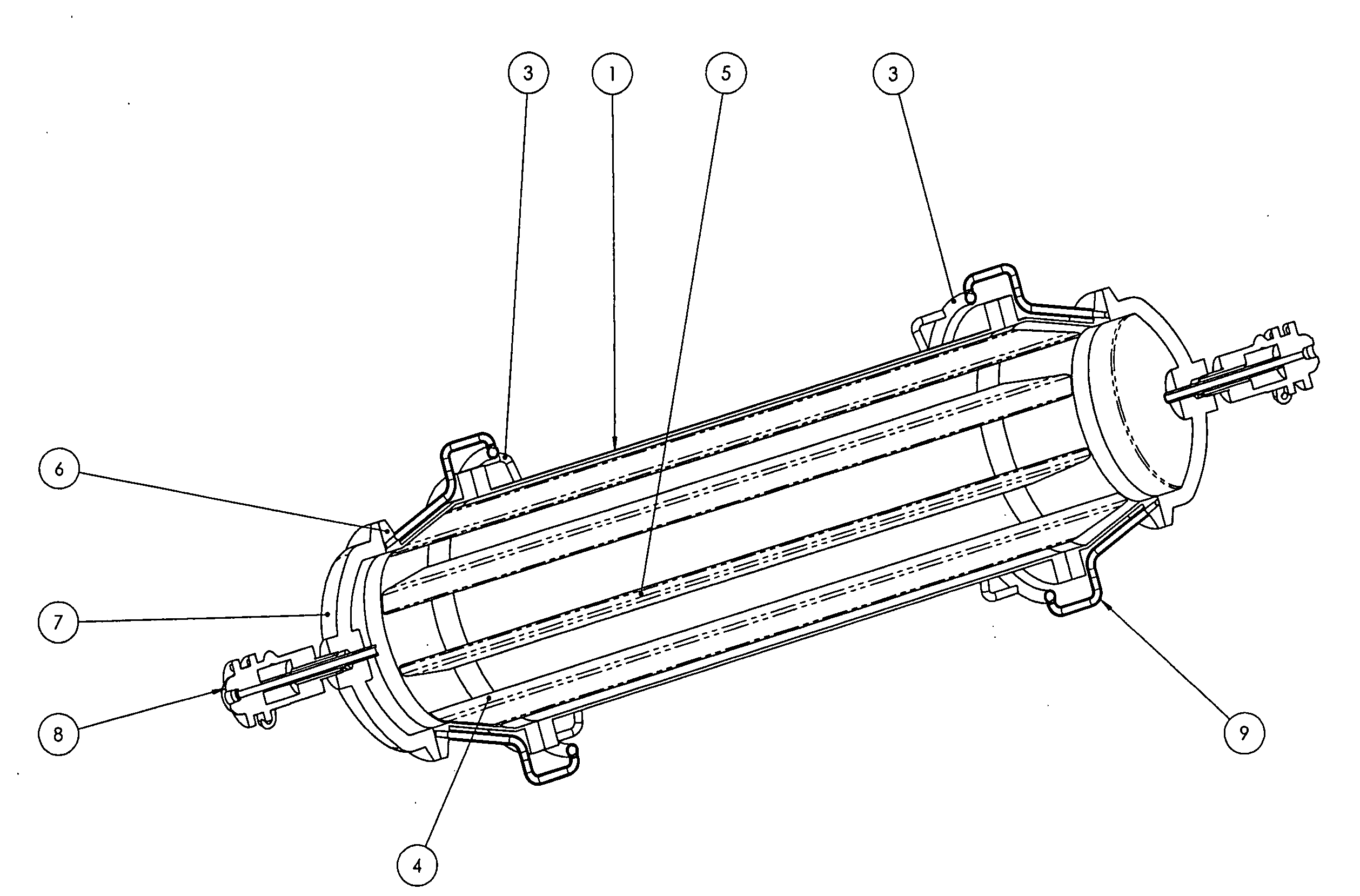

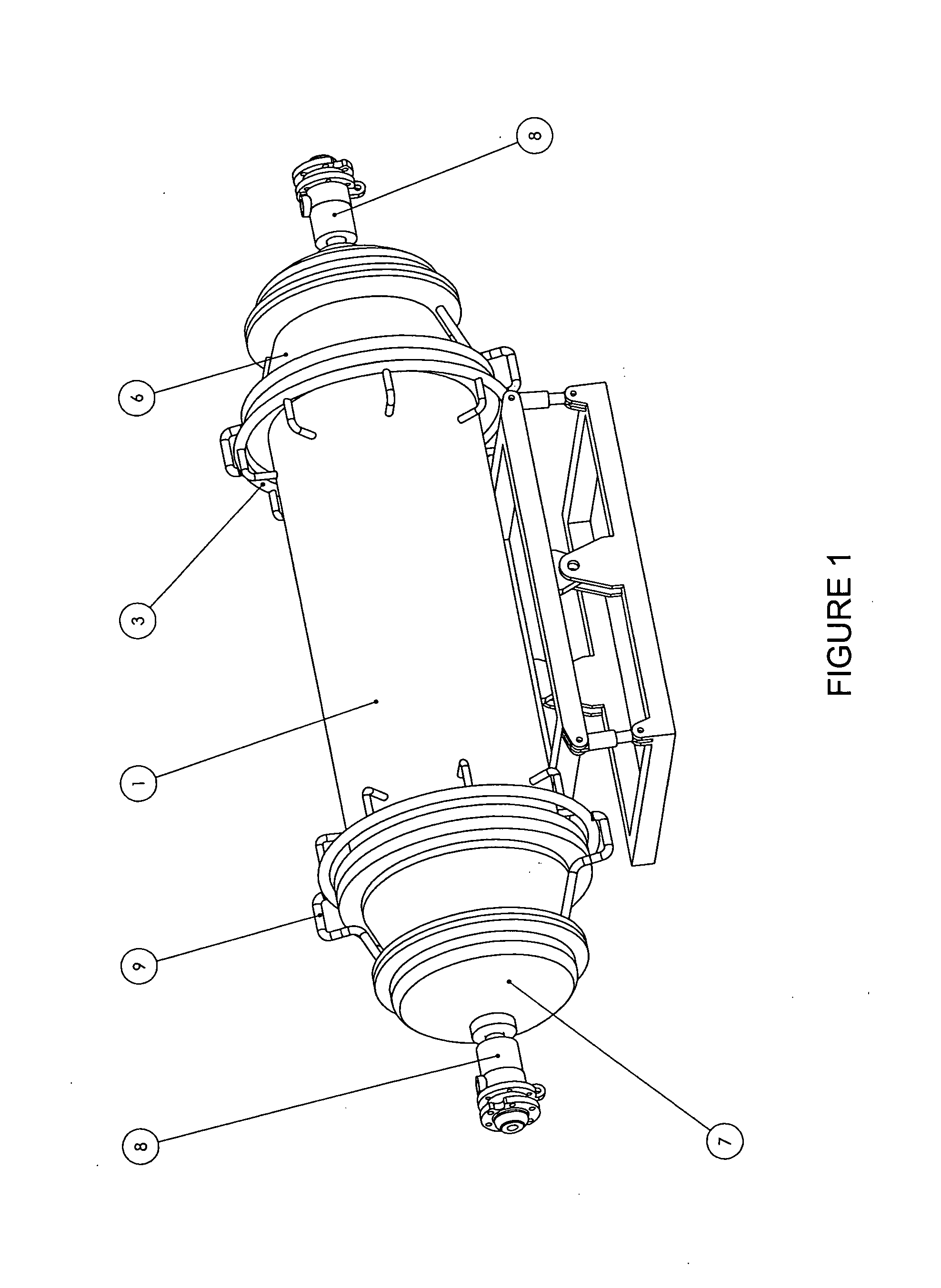

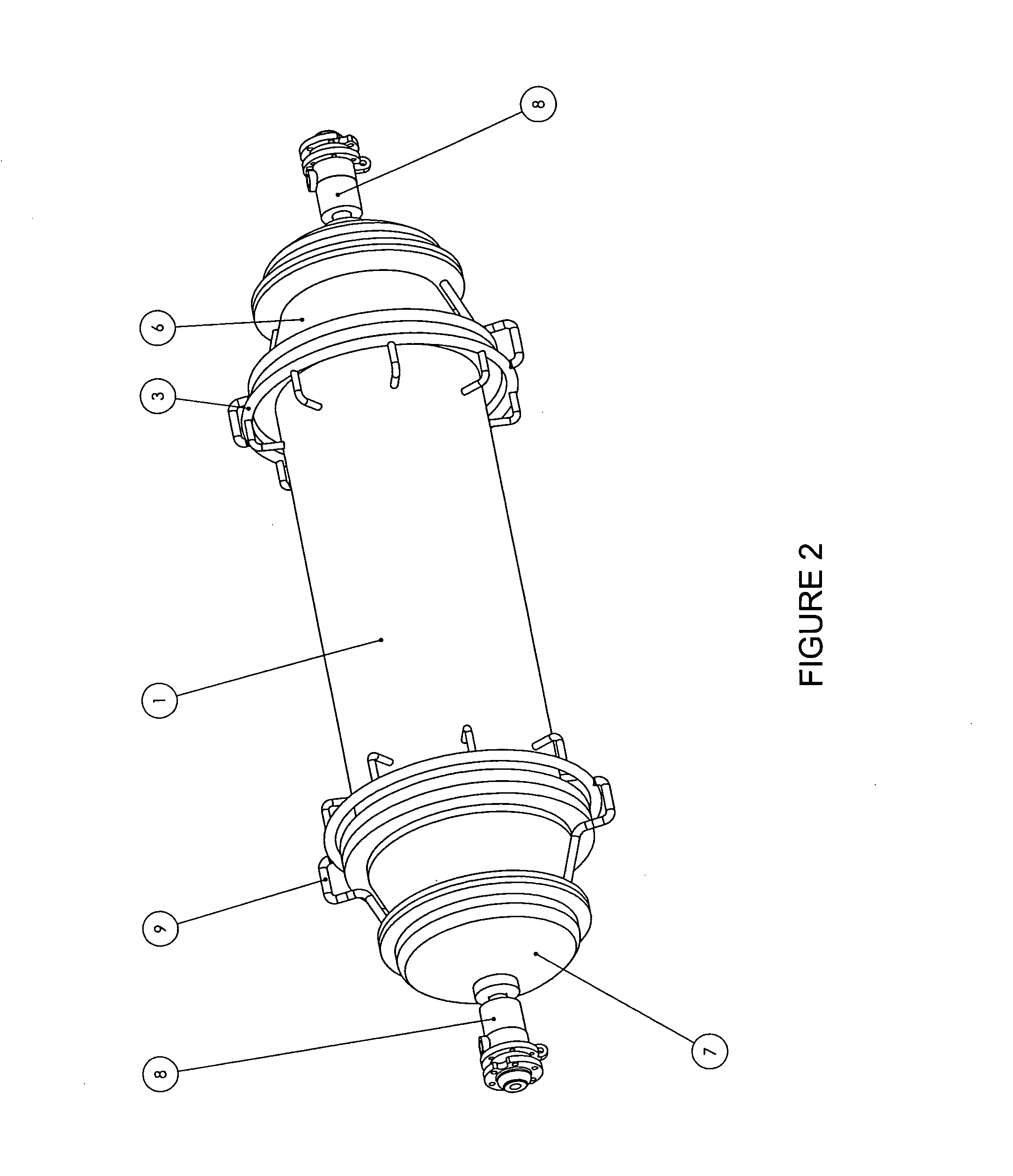

InactiveUS20100135851A1Efficient regenerationWaste processingTransportation and packagingSteam pressureSteam condensation

An autoclave system provides a means of sterilizing municipal solid waste, hydrolyzing many of its components, and preparing the material for post-autoclave automated separations. The present apparatus provides a means of drying the solid waste in the vessel, while conserving the energy used to dry the vessel. Non-contact steam is recovered through separations of steam and water, with condensate steam pressure regenerated by mechanical vapor recompression and condensate water returned to the boiler / steam generator. Heat transfer to combustion air, by heat transfer via heat pump to generate additional steam, and / or by mechanical vapor recompression recovers the latent heat of loose contact steam condensate. The process design provides for in-vessel drying while reducing the energy cost of operating a waste autoclave, as compared to the current art.

Owner:ESTECH

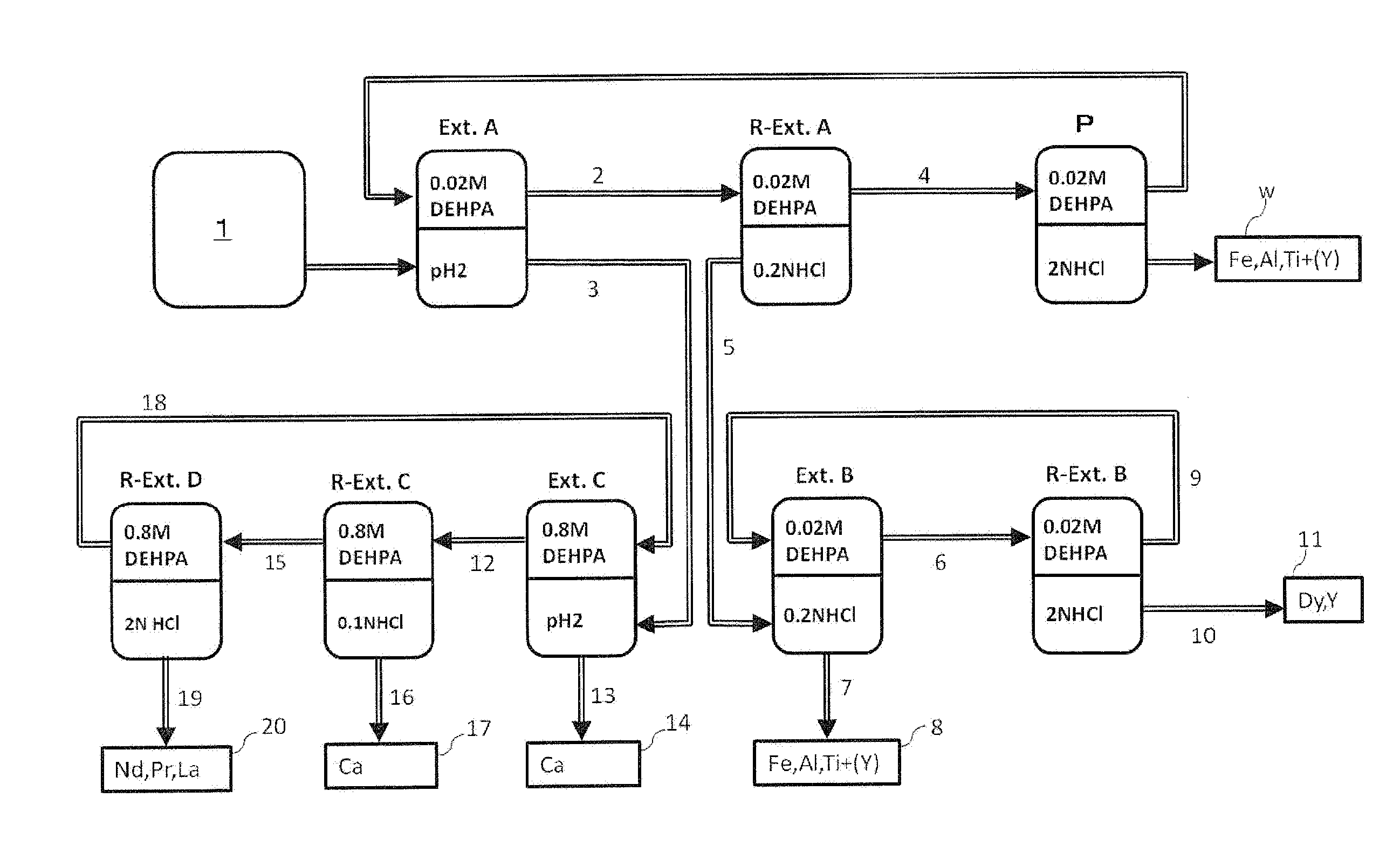

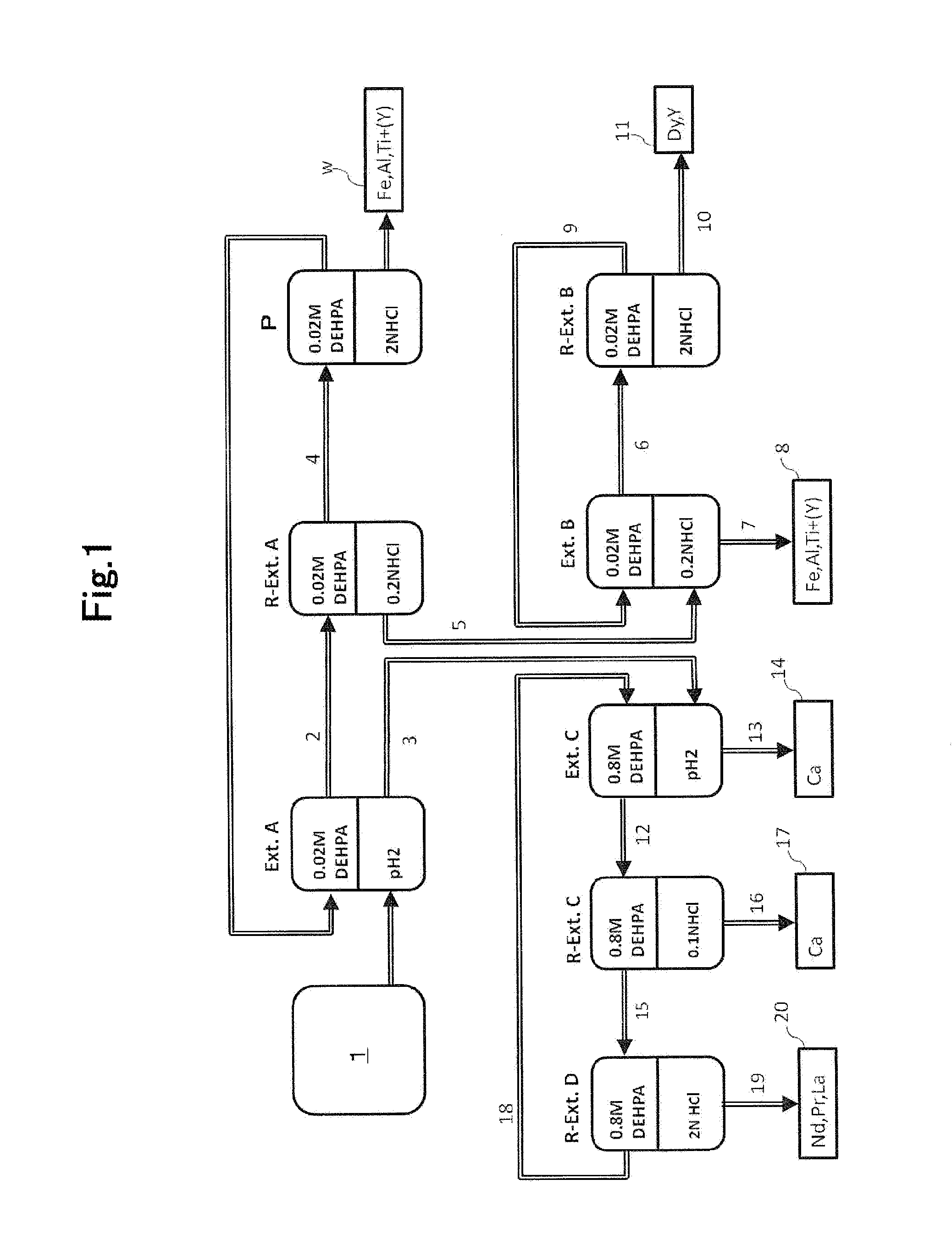

Rare earth element recovery method

ActiveUS20140283652A1Leach efficiently and easilyEfficient use ofTransportation and packagingProcess efficiency improvementSolid componentRare-earth element

Provided is a method of recovering rare-earth elements, including causing rare-earth elements particularly including Nd and Dy to leach efficiently from a raw material for leaching which contains the rare-earth elements, and separating and recovering the rare-earth elements. The method of recovering rare-earth elements includes: a leaching step including performing leaching treatment of rare-earth elements in which an acidic slurry of a raw material for leaching which contains the rare-earth elements is held under a predetermined condition, and then subjecting the slurry obtained after the leaching treatment to solid-liquid separation, yielding a leachate containing the rare-earth elements; and a separation step of separating and recovering the rare-earth elements from the yielded leachate, in which: the raw material for leaching contains Ca as CaO at a ratio of 4 to 15 mass % and Ti as TiO2 at a ratio of 2 to 13 mass % in a solid component (S); an acid aqueous solution is an acid aqueous solution of hydrochloric acid and / or nitric acid; and the leaching treatment performed in the leaching step is digestion or maceration which is performed under the heating and pressurizing conditions of a temperature of 160 to 300° C. and a pressure of 0.65 to 10 MPa, and the rare-earth elements are caused to leach together with Ca in the leaching step.

Owner:NIPPON LIGHT METAL CO LTD

Nonvolatile memory apparatus which prevents destruction of write data caused by power shutdown during a writing process

InactiveUS7330995B2Shorten the timeAvoid it happening againConveyorsInput/output to record carriersData storingData loss

Owner:RENESAS ELECTRONICS CORP

Method for separating lithium cobalt oxide and aluminum foil on scrapped lithium ion battery positive pole piece

ActiveCN103985920ALower requirementLow costTransportation and packagingWaste accumulators reclaimingState of artOrganic solvent

The invention relates to a method for separating lithium cobalt oxide and aluminum foil on a scrapped lithium ion battery positive pole piece. The method comprises the following steps: charging and dismantling a scrapped lithium ion battery, placing the waste positive pole piece into a box-type resistance furnace, roasting the waste positive pole piece in the box-type resistance furnace at the temperature of 500 to 600 DEG C, placing the roasted positive pole piece into a vessel with water, stirring the positive pole piece in the water by utilizing an electric stirrer, and screening substances in the vessel by utilizing a screen, wherein a substance on the screen is aluminum foil; washing the substance on the screen by utilizing the water, and naturally drying the substance to obtain the aluminum foil; filtering the substance below the screen (the substance below the screen is a mixed solution containing a positive active substance), placing the naturally dried filtered substance into a ceramic crucible, placing the ceramic crucible into the box-type resistance furnace to be processed at high temperature to obtain the lithium cobalt oxide. Compared with the prior art, the method has the advantages that easiness in operation is realized, the requirement on a separation device is low, the efficiency for separating the lithium cobalt oxide and the aluminum foil is high, the cost is low, no organic solvent needs to be used in the processing step, and no secondary pollution is produced in the separation process.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

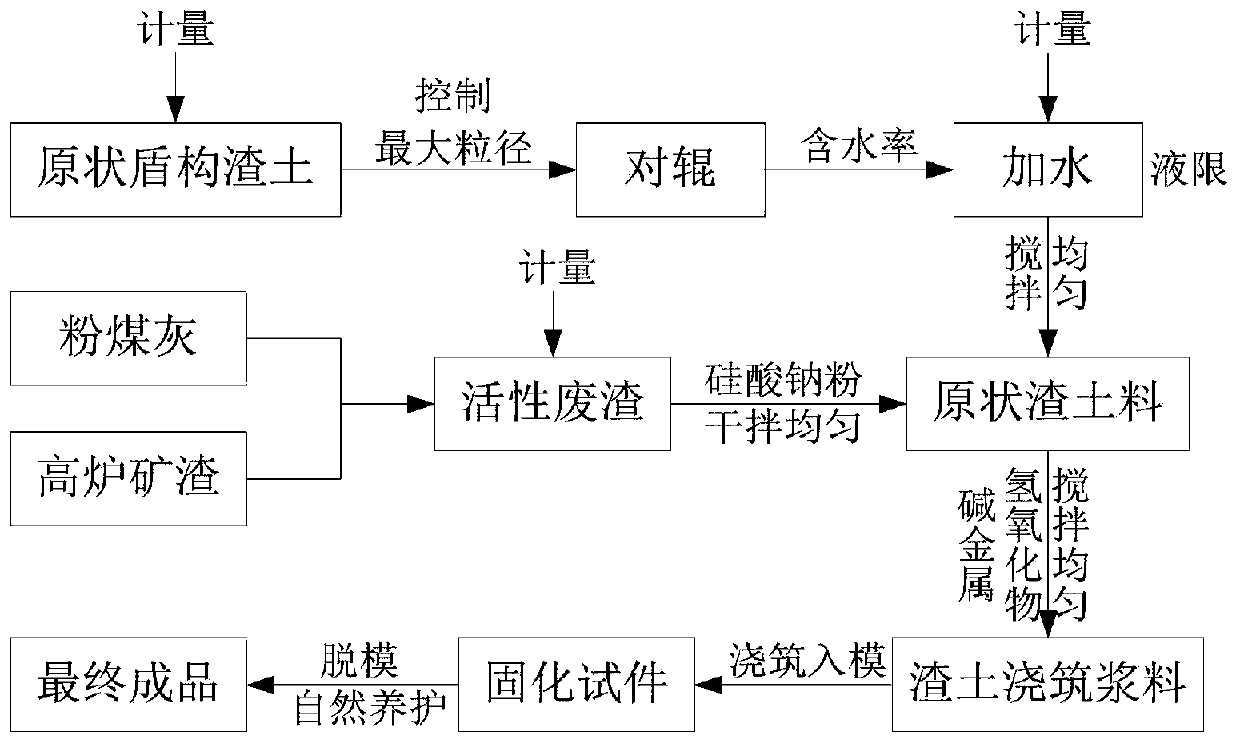

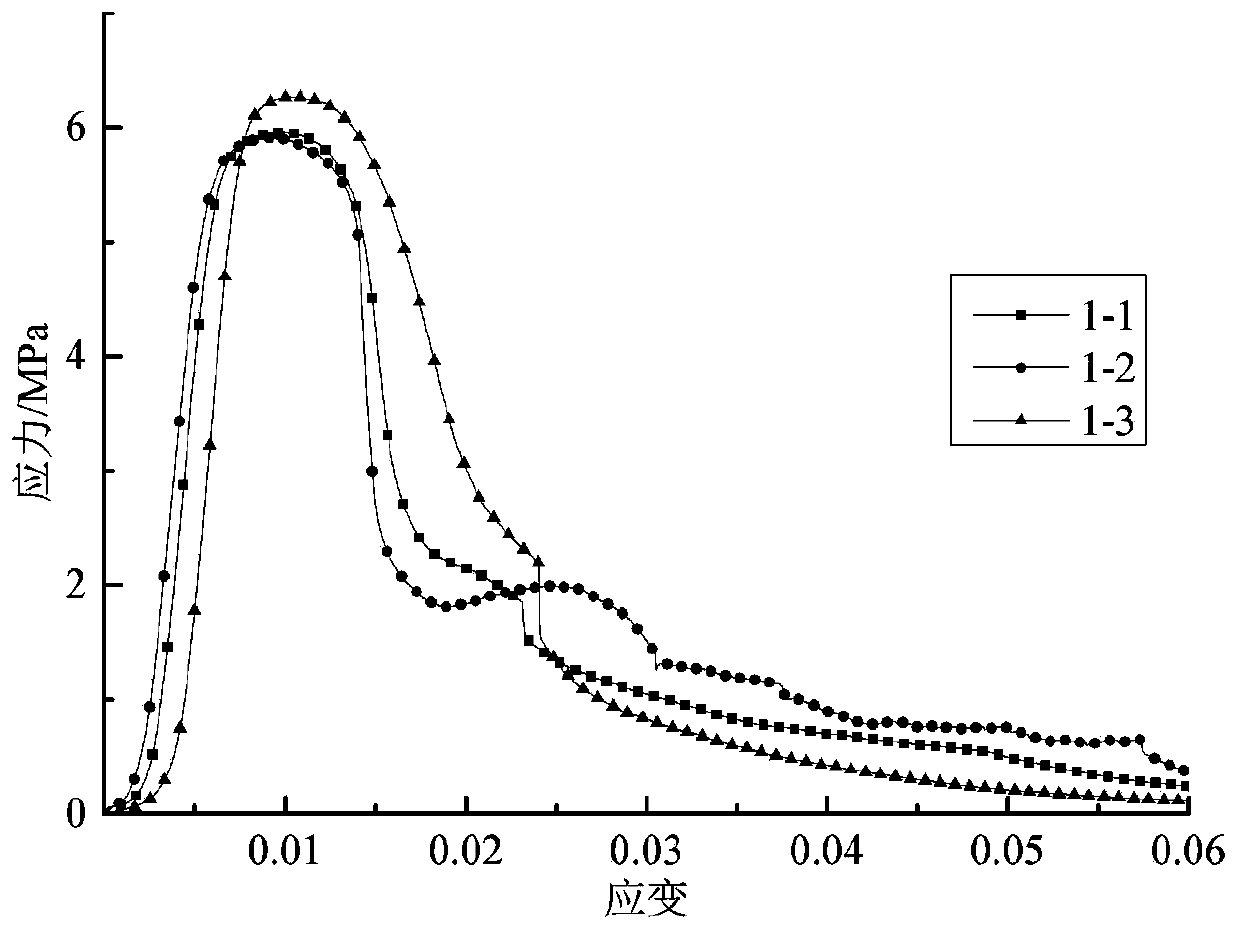

Water-containing undisturbed shield muck baking-free building material and preparation method thereof

ActiveCN111393117AUniform flow stateLittle homogeneitySolid waste managementTransportation and packagingSodium silicateMineralogy

The invention relates to a water-containing undisturbed shield muck baking-free building material and a preparation method thereof. The baking-free building material is prepared from the following rawmaterials in parts by weight: 1-80 parts of water-containing undisturbed shield muck, 1-30 parts of active waste residues, 0.1-5 parts of sodium hydroxide, 0.1-10 parts of sodium silicate and 1-20 parts of water. The method comprises the following steps: weighing the active waste residues, the sodium silicate, the water-containing undisturbed shield muck and the water, mixing, and crushing untilthe content of particles of 4.75 mm or above in the water-containing undisturbed shield muck does not exceed 10% to obtain a mixture I; adding the sodium hydroxide into the mixture I to obtain a mixture II; and pouring the mixture II into a mold to obtain the water-containing undisturbed shield muck baking-free building material. According to the method, intermediate dehydration and screening processes and links are omitted, and the production cost is greatly reduced. The invention also discloses the water-containing undisturbed shield muck unfired building material prepared by the method.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

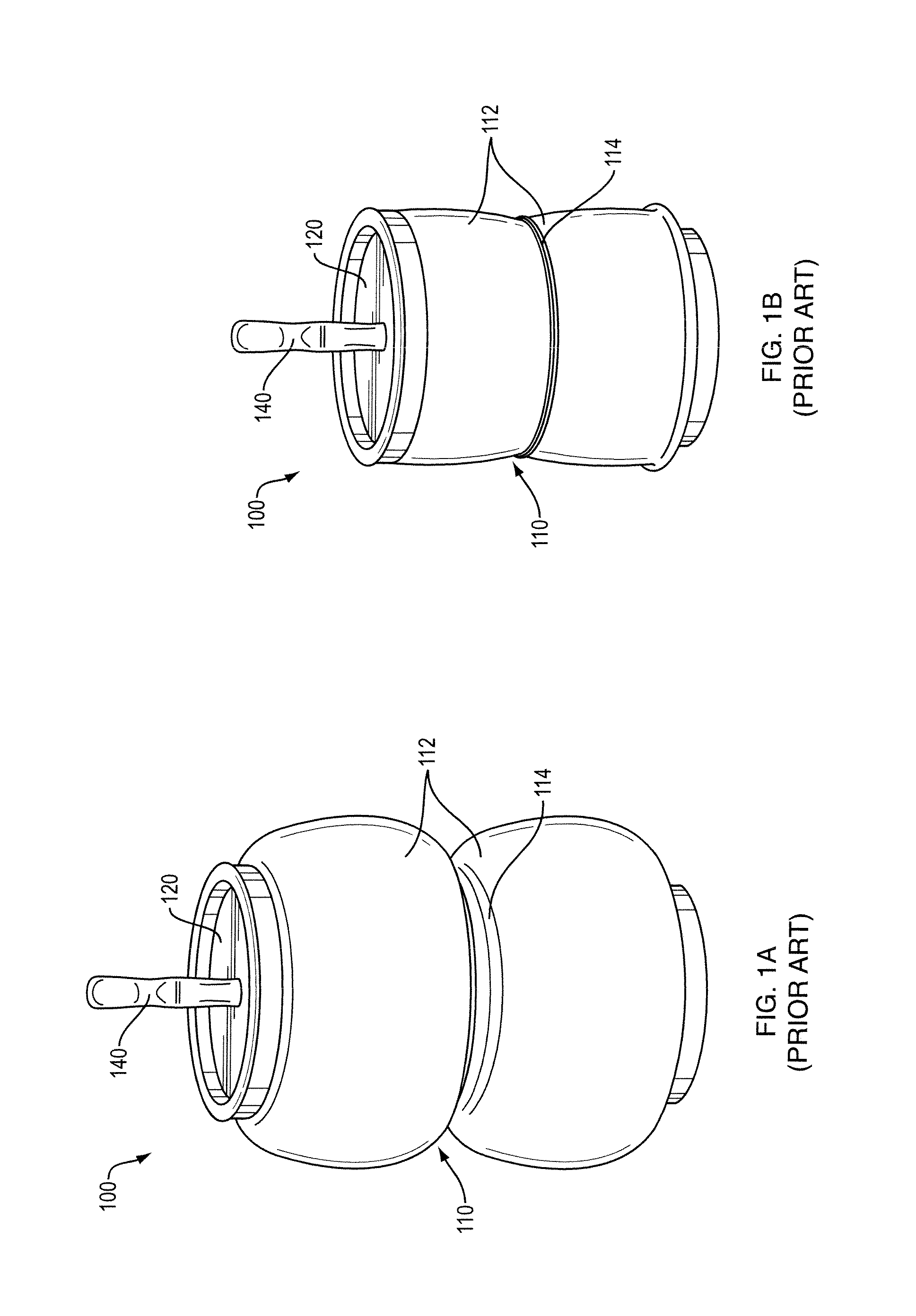

Method and apparatus for forming a sealing member for a display device

ActiveCN1673837ADrying solid materials with heatTransportation and packagingProduction rateDisplay device

A method and apparatus for forming a sealing member includes forming a first sealing part to surround one portion of a display area, the display area including a pixel, and forming a second sealing part to surround a remaining portion of the display area and to intersect ends defining the second sealing part with corresponding ends defining the first sealing part. Thus, a time needed to form the first and second sealing member may be reduced, thereby reducing an entire process time to manufacture the display apparatus. Further, an area needed to form the sealing member may be reduced, thereby enhancing productivity of the display apparatus.

Owner:SAMSUNG DISPLAY CO LTD

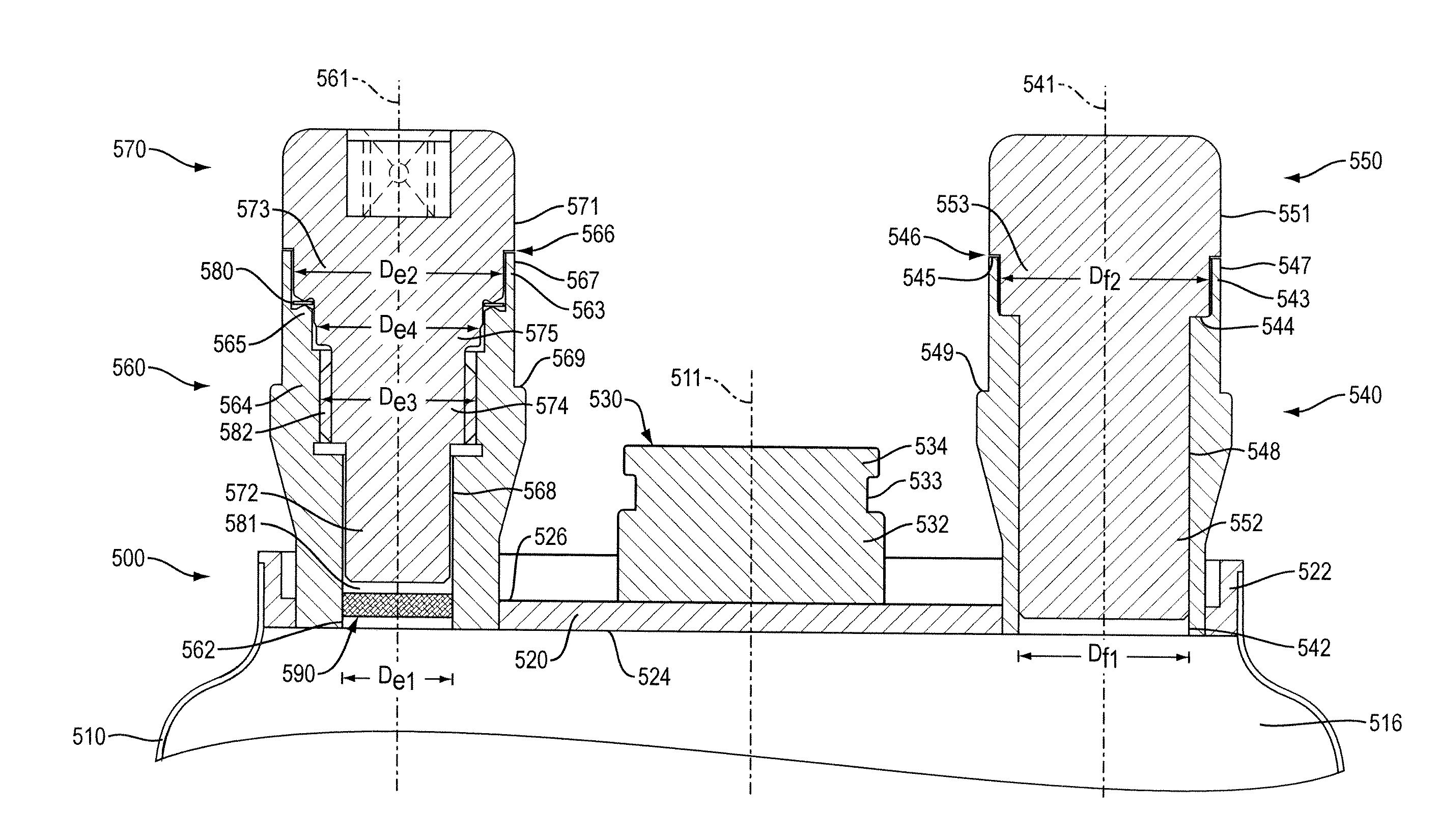

Filling Container and Method For Storing Hazardous Waste Material

ActiveUS20140221721A1Reduce the overall diameterTransportation and packagingShieldingWaste materialHazardous waste

The present invention provides systems, methods and devices for storing and / or disposing of hazardous waste material. In some embodiments, the waste material includes nuclear waste such as calcined material. In certain embodiments, the device includes a container having a container body, a filling port configured to couple with a filling nozzle and a filling plug, and an evacuation port having a filter. The evacuation port is configured to couple with an evacuation nozzle and an evacuation plug. In certain embodiments, the method includes (a) adding hazardous waste material via a filling nozzle coupled to a filling port of a container, the container including an evacuation port, (b) evacuating the container during adding of the hazardous waste material via an evacuation nozzle coupled to an evacuation port of the container, (c) sealing the filling port, (d) heating the container, and (e) sealing the evacuation port.

Owner:AUSTRALIAN NUCLEAR SCI & TECH ORGANISAT

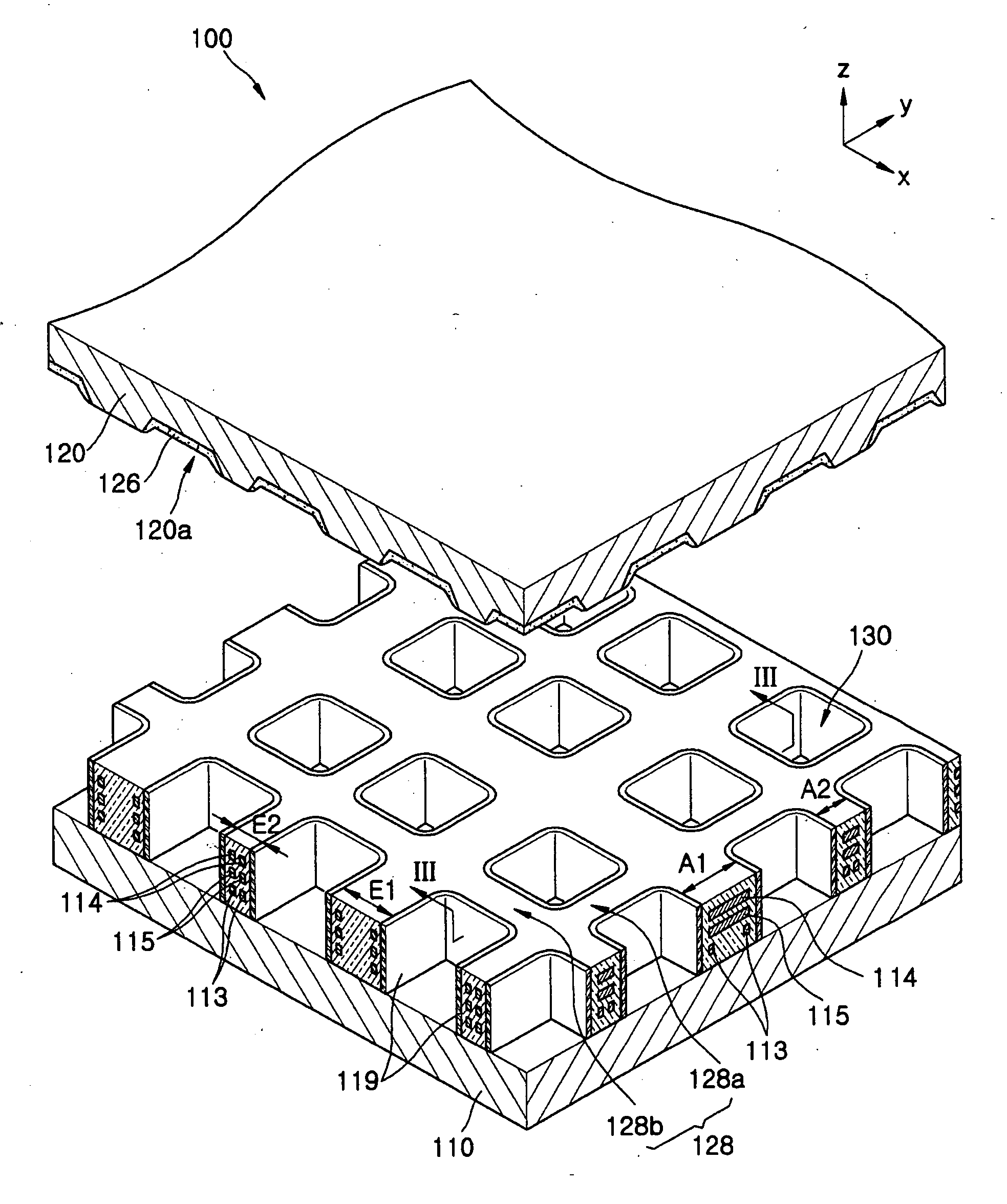

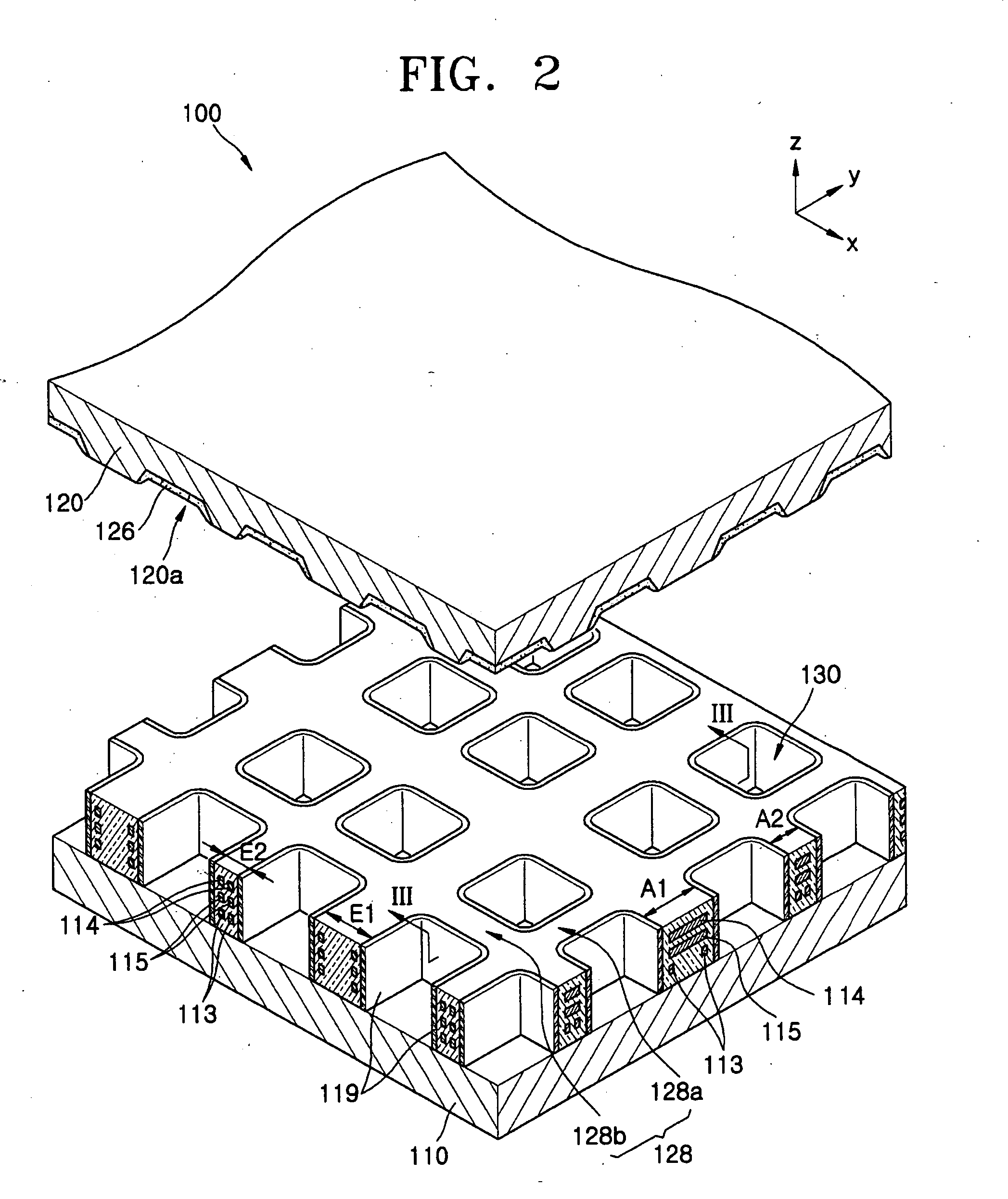

Plasma display panel

InactiveUS20060238123A1Simple designImprove luminous efficiencyAddress electrodesSustain/scan electrodesPhosphorEngineering

Provided is a plasma display panel including a rear substrate, a front substrate separated from the rear substrate, a plurality of barrier ribs arranged between the front substrate and the rear substrate and adapted to define a plurality of discharge cells corresponding to a plurality of sub-pixels, a plurality of sustain electrode pairs comprising a plurality of first discharge electrodes and a plurality of second discharge electrodes extending parallel to each other and surrounding ones of the plurality of discharge cells, the plurality of sustain electrode pairs being adapted to generate a discharge, a plurality of address electrodes extending and surrounding the plurality of discharge cells and arranged in a direction that crosses the plurality of sustain electrode pairs, a plurality of phosphor layers arranged within the plurality of discharge cells and a discharge gas arranged within the plurality of discharge cells, wherein a predetermined number of sub-pixels form a unit pixel, and unit pixels adjacent to each other in a direction are spaced apart from each other by a predetermined distance.

Owner:SAMSUNG SDI CO LTD

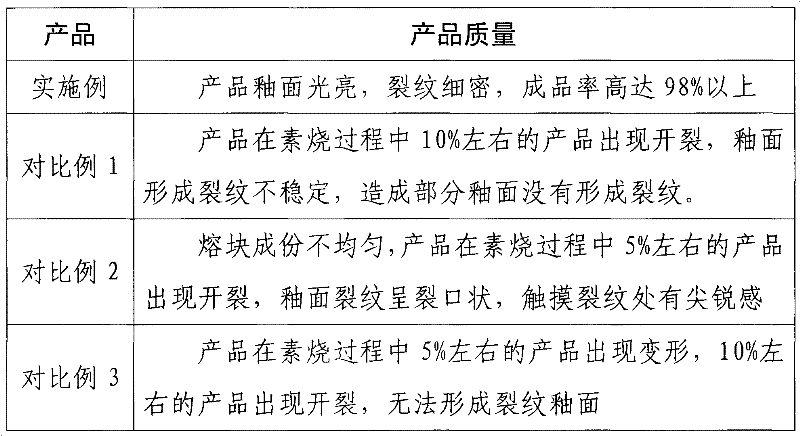

Method for producing ceramic product with crack glaze by use of waste ceramic material and waste glass

ActiveCN102503570ASmooth cracked glazeSmooth glazeTransportation and packagingCeramic materials productionStalactiteFrit

The invention discloses a method for producing ceramic products with crack glaze by use of waste ceramic material and waste glass, comprising the steps of taking waste ceramic material, waste glass, zircon sand and talc; after mixing, crushing and sieving the mixture, melting the mixture till the mixture is molten; performing water quenching and drying, and obtaining frit for later use; putting frit, feldspar, diatomite, stalactite and kaolin to a ball grinder; adding fresh water to ball-grind, and sieving; sieving, removing iron, filter pressing and pugging, and obtaining ceramic mud for later use; using the ceramic mud to produce ceramic blank, performing biscuiting; using the crack glaze to glaze the biscuited blank, and finally obtaining the product. The product manufactured by the invention has smooth glaze, fine crack and high yield; and large amounts of waste ceramic materials and waste glass can be recycled.

Owner:黄秋生

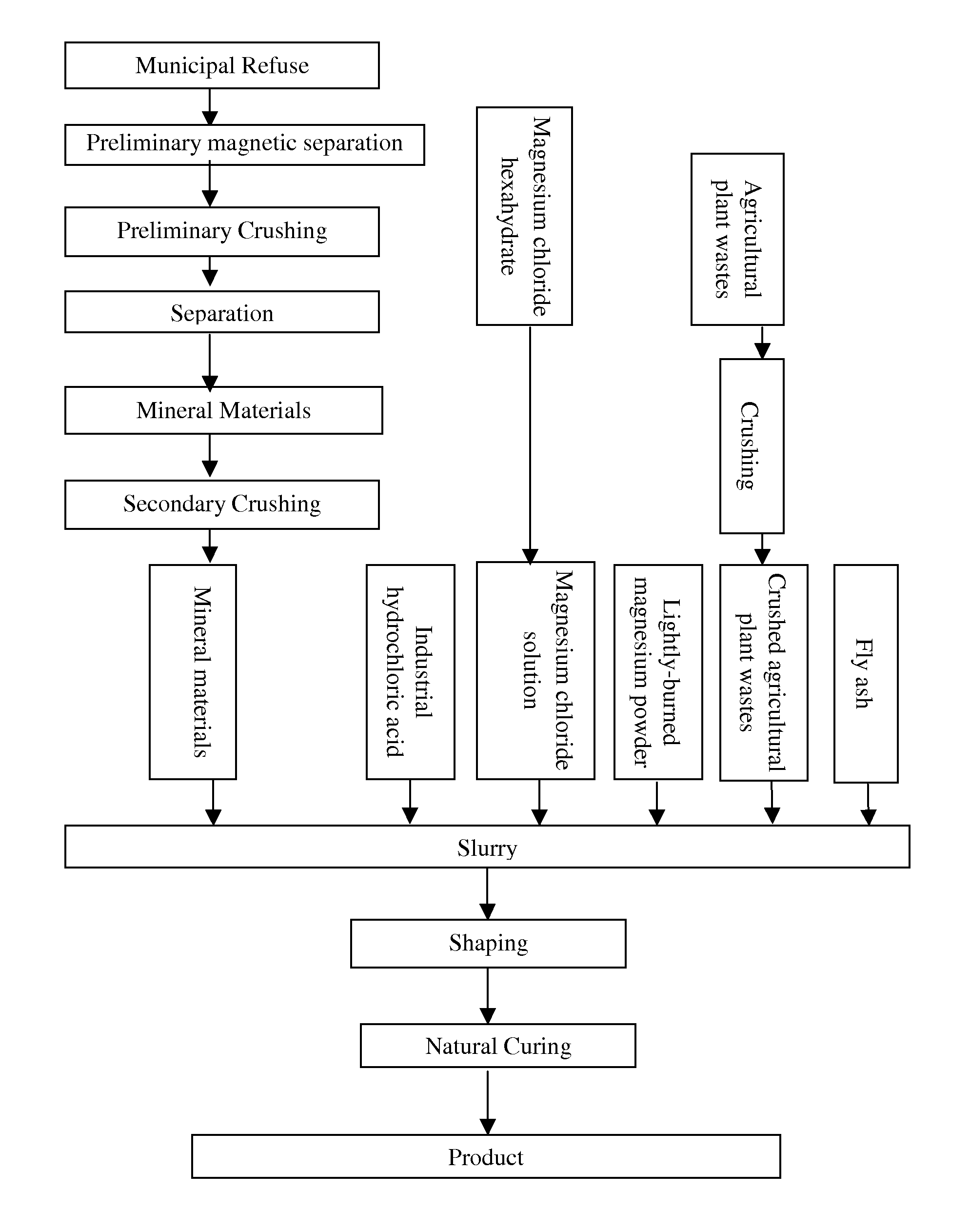

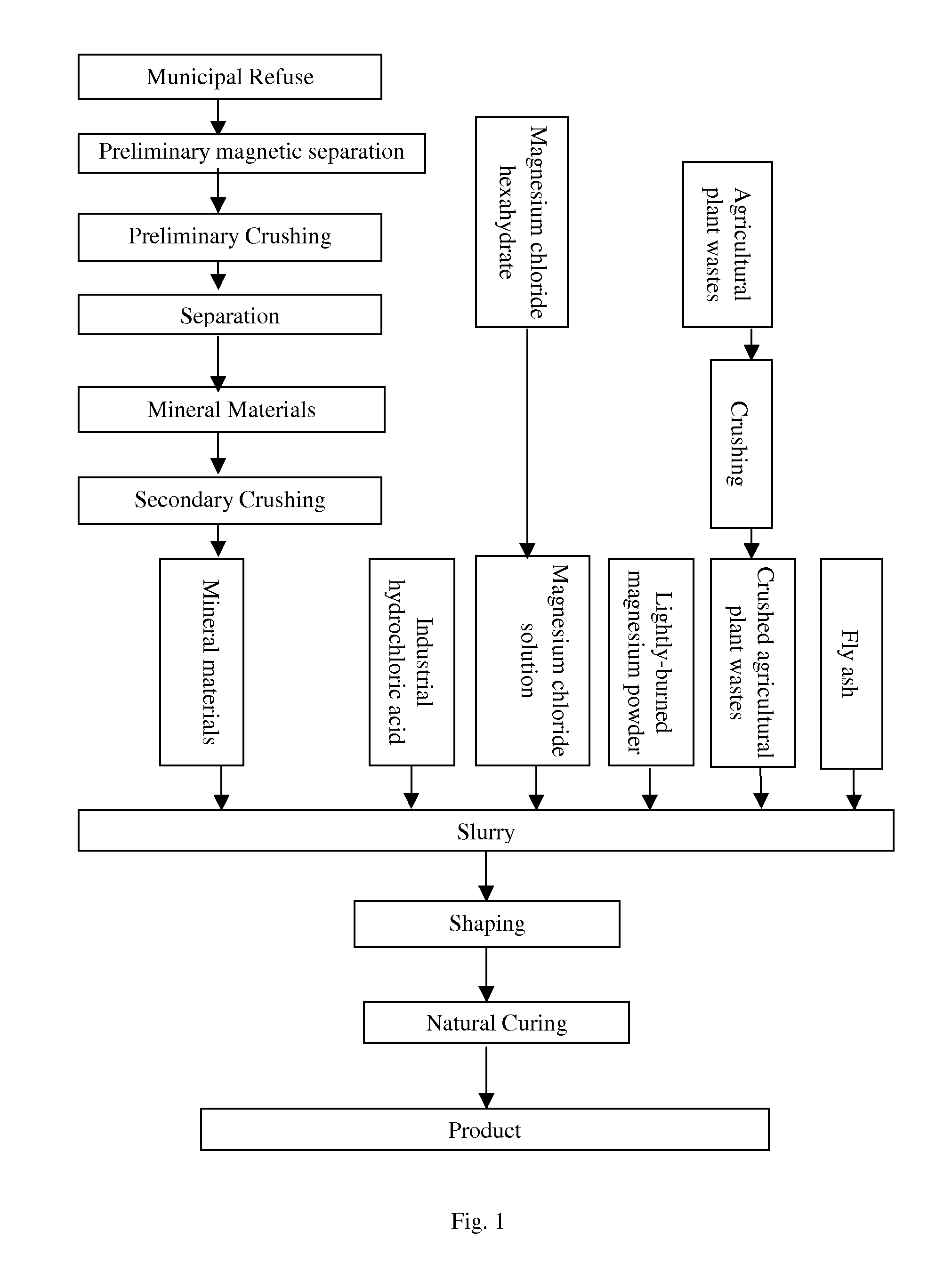

Building board made of municipal refuse and agricultural plant wastes and manufacturing method thereof

InactiveUS20090170977A1Easy dischargeReduce disposal costsSolid waste managementTransportation and packagingLitterEngineering

The invention relates to a building board made of municipal refuse and agricultural plant wastes and manufacturing method thereof. The principal raw materials of the board include 200 parts of lightly-burned magnesium powder, 40 to 75 parts of magnesium chloride solution of 28 to 32 Baume degrees, 1 to 2 parts of 36-38% industrial hydrochloric acid, 80 to 120 parts of mineral materials originated from municipal refuse, 20 to 30 parts of agricultural plant wastes, and 50 to 80 parts of fly ash. The manufacturing method of the board includes preparing raw materials, preparing slurry, shaping and curing naturally. The invention uses huge amounts of mineral materials in municipal refuse and agricultural plant wastes as raw materials to making building board, and thereby realizing a recycling of these waste materials.

Owner:BEIJING HENGYECUN S&T

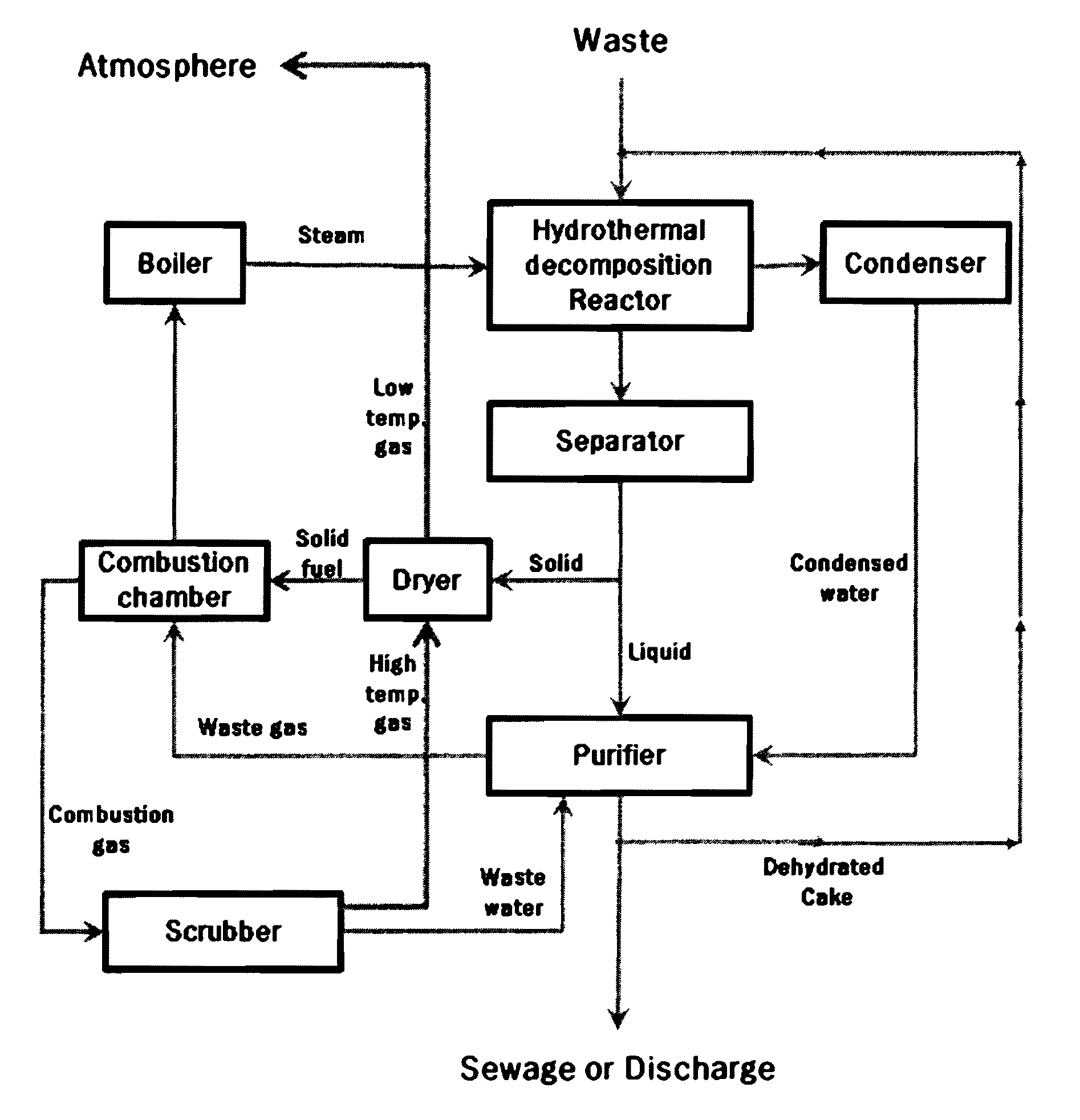

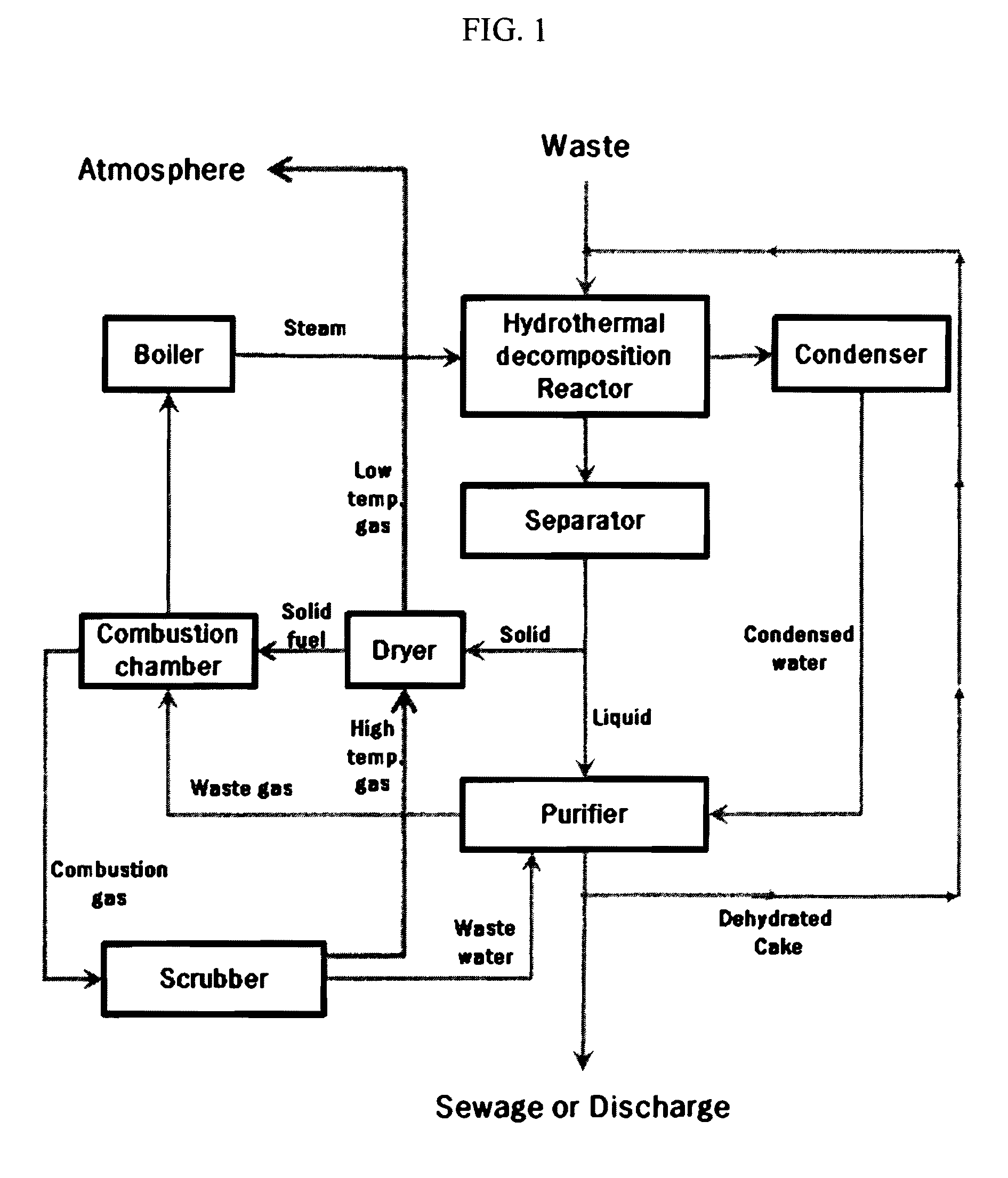

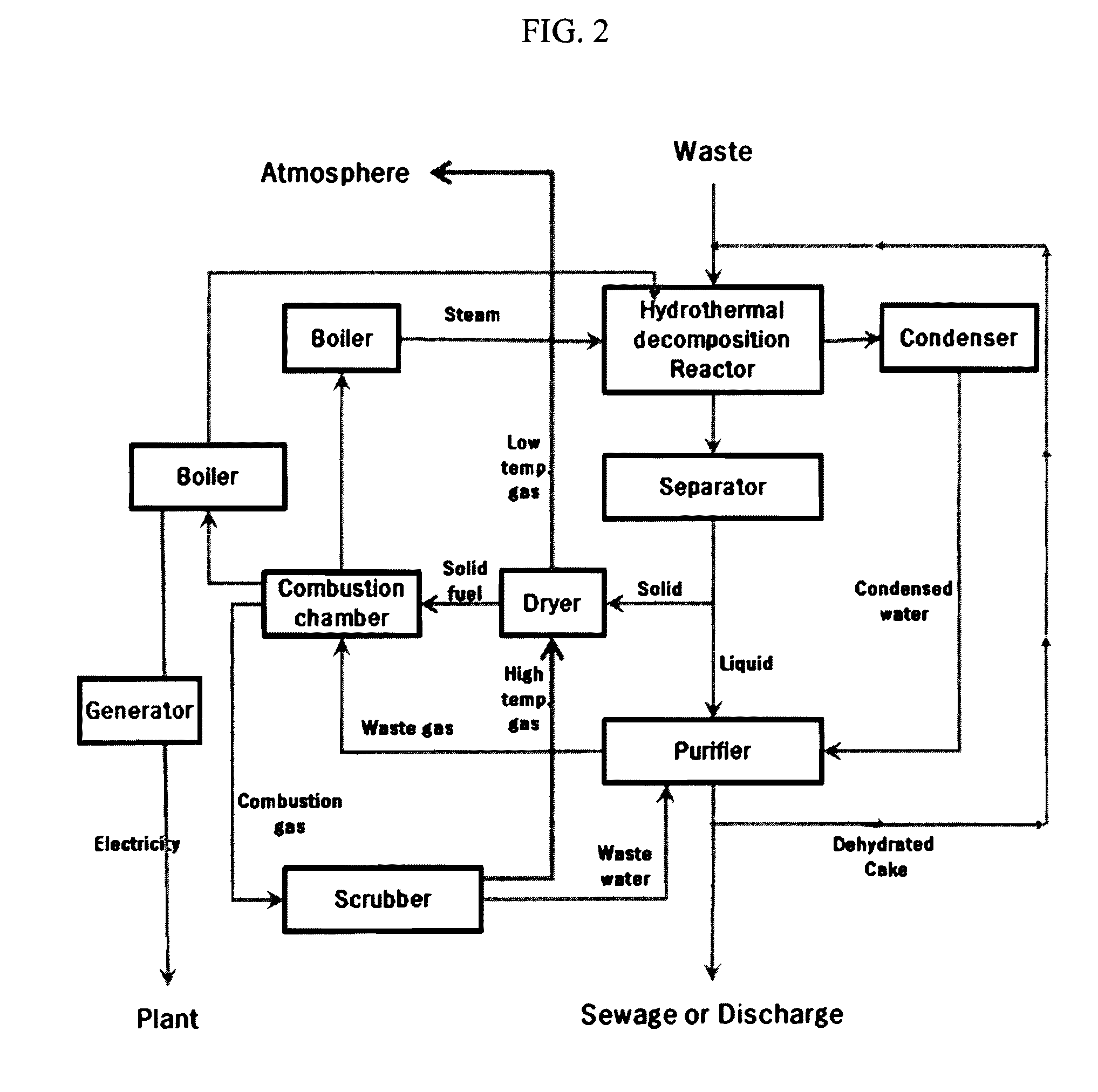

Waste to energy by way of hydrothermal decomposition and resource recycling

InactiveUS20110179981A1Improve energy efficiencyHigh removal rateTransportation and packagingBiofuelsHigh energySolid fuel

A method and an apparatus for disposing wastes comprising the steps of conducting a hydrothermal decomposition reaction of the wastes, separating the products into a solid fuel and waste water, combusting the solid fuel, scrubbing the combustion gas, generating steam using the heat generated by the combustion, and purifying the waste water, exhibit a high energy-efficiency, while exhibiting a high removal rate of the pollutants generated during the combustion.

Owner:VAN NAARDEN ROBERT +6

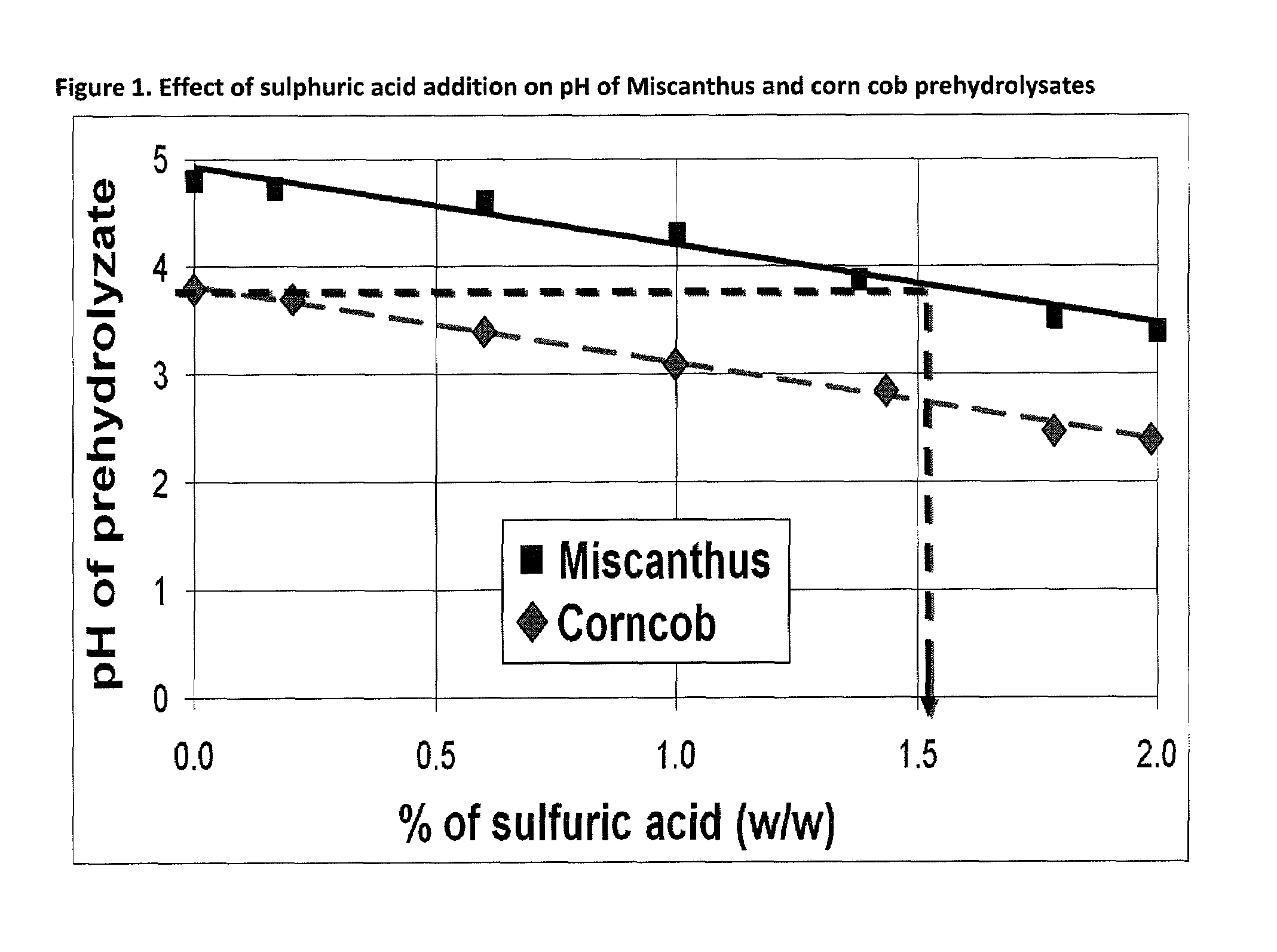

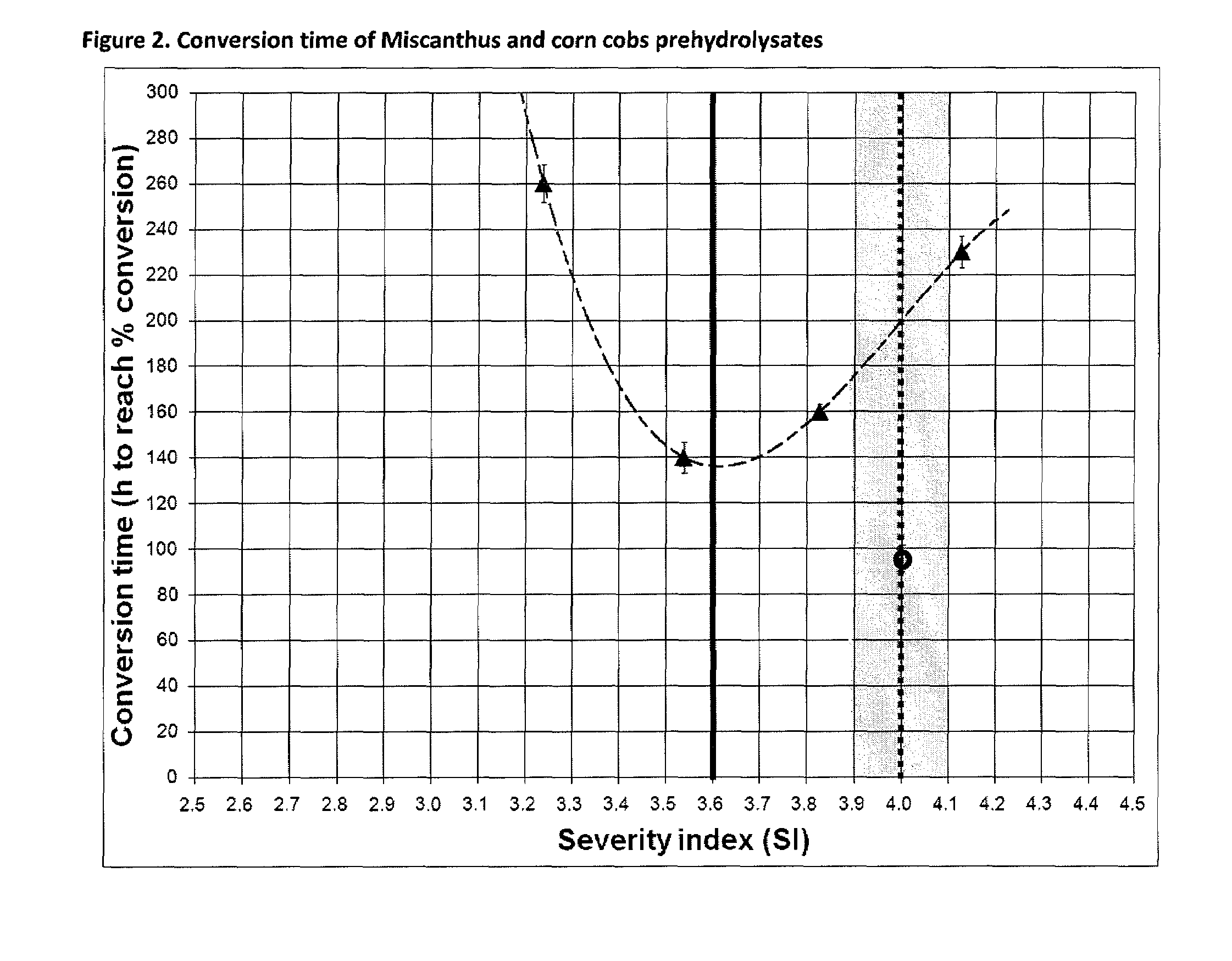

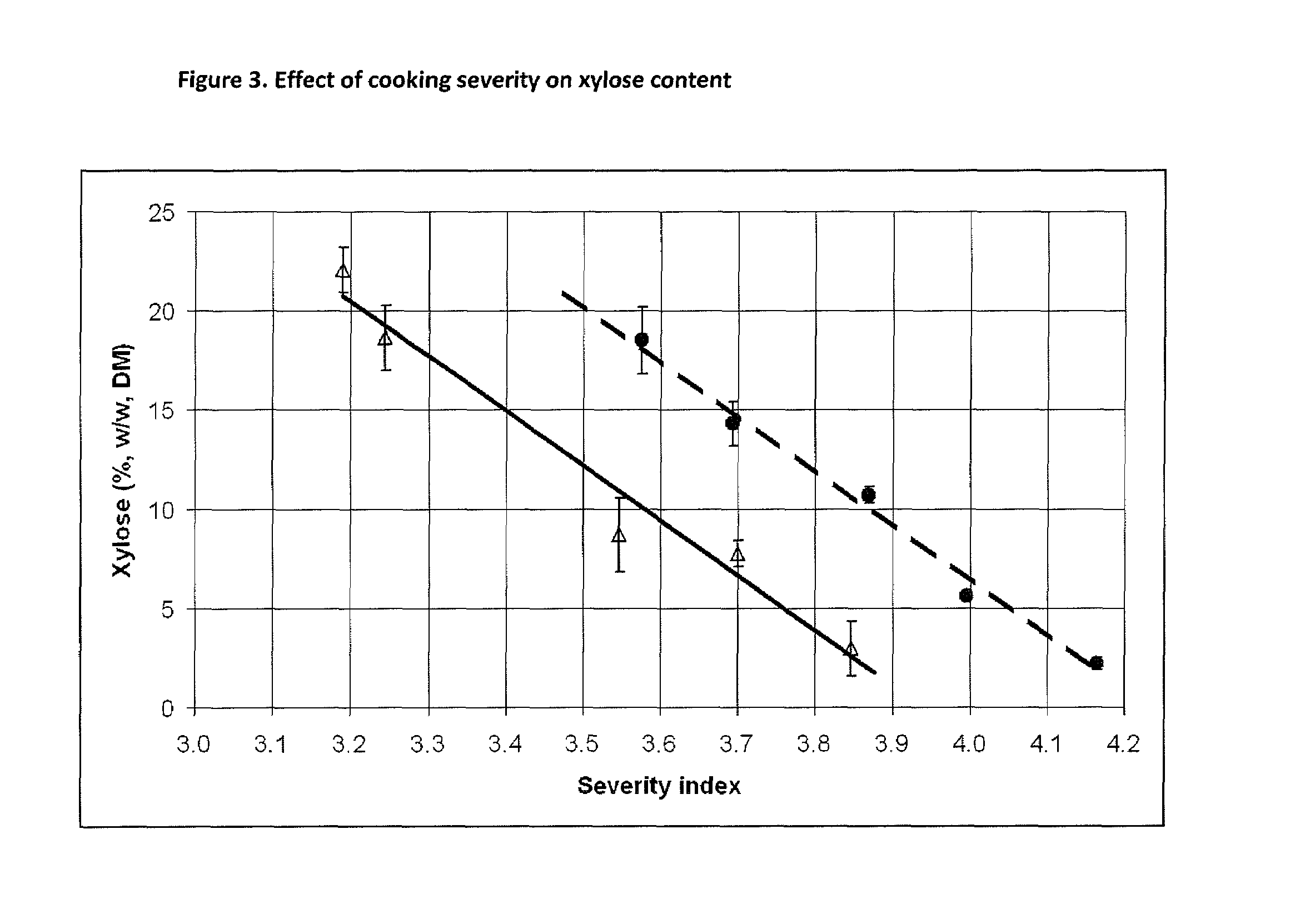

Cellulose pretreatment process

InactiveUS8287651B2Reduce the amount requiredReduce usageBiofuelsLiquid hydrocarbon mixture productionCelluloseDecomposition

A process for the production of ethanol from biomass is disclosed. The process relates to the pretreatment of corncob biomass and includes the steps of exposing corncob to steam in a reaction vessel at an elevated temperature and reaction pressure for a preselected exposure time. Volatile compounds are continuously vented during pretreatment. The reaction pressure is released for explosive decomposition of the corncob biomass into fibrous solids and condensate. The exposure is preferably carried out at a temperature of 190-210° C. and a pressure of 190 psig to 275 psig and an exposure time of 3 to 10 minutes.

Owner:GREENFIELD SPECIALTY ALCOHOLS

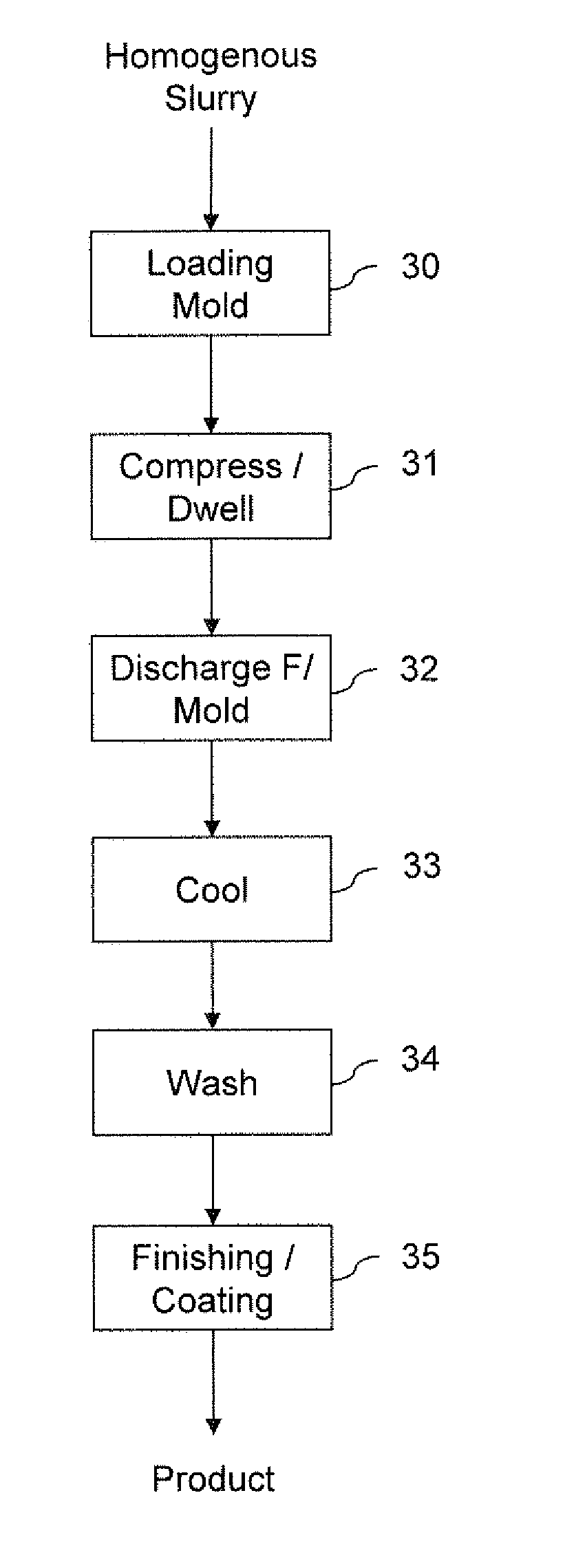

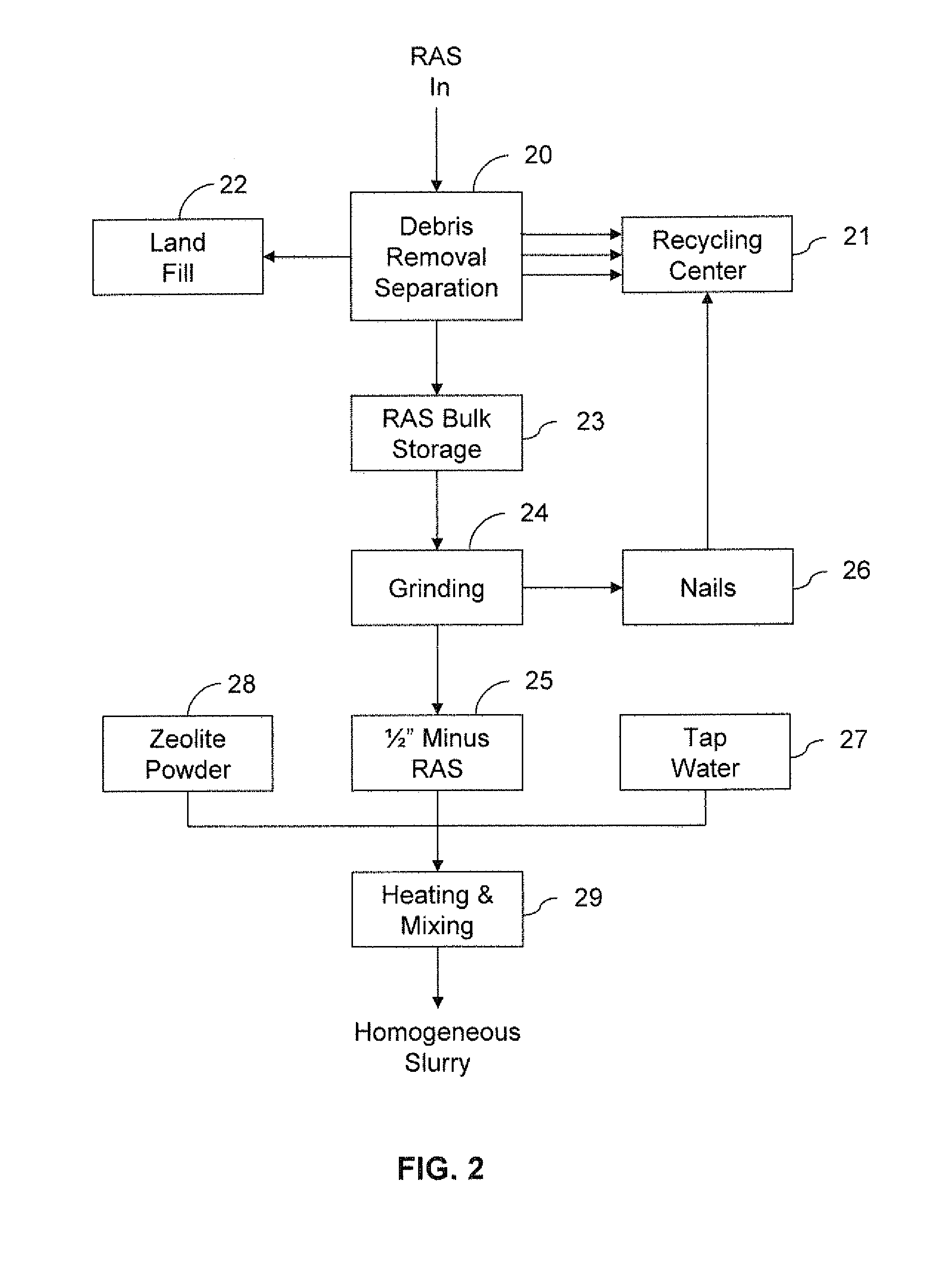

Method Of Converting Tear-Off Asphaltic Shingles To A Formed Product

A method of converting asphaltic shingles to a formed product, comprising the steps of providing a charge of recovered asphaltic shingles, comminuting the charge into small particles, adding to the charge a quantity of hydrated aluminosilicate, heating the charge while simultaneously mixing the comminuted charge to a homogeneous state, placing the mixed charge into molds to form the product, applying pressure to the charge in the mold for a determinable dwell time, ejecting the product from the mold, and cooling the product.

Owner:ASPHALT RECOVERY SPECIALISTS

Method for recycling graphite and copper foil from scrapped lithium ion battery negative pole piece

ActiveCN103985919ALow costImprove separation efficiencyTransportation and packagingWaste accumulators reclaimingCopper foilGraphite

The invention relates to a method for recycling graphite and copper foil from a scrapped lithium ion battery negative pole piece. The method comprises the following steps: charging and dismantling the scrapped lithium ion battery, placing the negative pole piece into a vessel with a water and ethanol mixed solution, then screening after stirring for a period of time, washing a substance on a sieve by utilizing water, and naturally drying the substance to obtain copper foil; heating a substance below the sieve to 70 to 90 DEG C, then filtering the substance, maintaining the temperature of the solution before the filtering at 70 to 90 DEG C in the filtering process, washing the substance on the sieve by utilizing water after the filtering is finished, and naturally drying the substance to obtain graphite. Compared with the prior art, the method has the advantages that easiness in operation is realized, the requirement on a separation device is low, the efficiency for separating the graphite and copper foil is high, the cost is low, and no secondary pollution is produced in the separation process.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

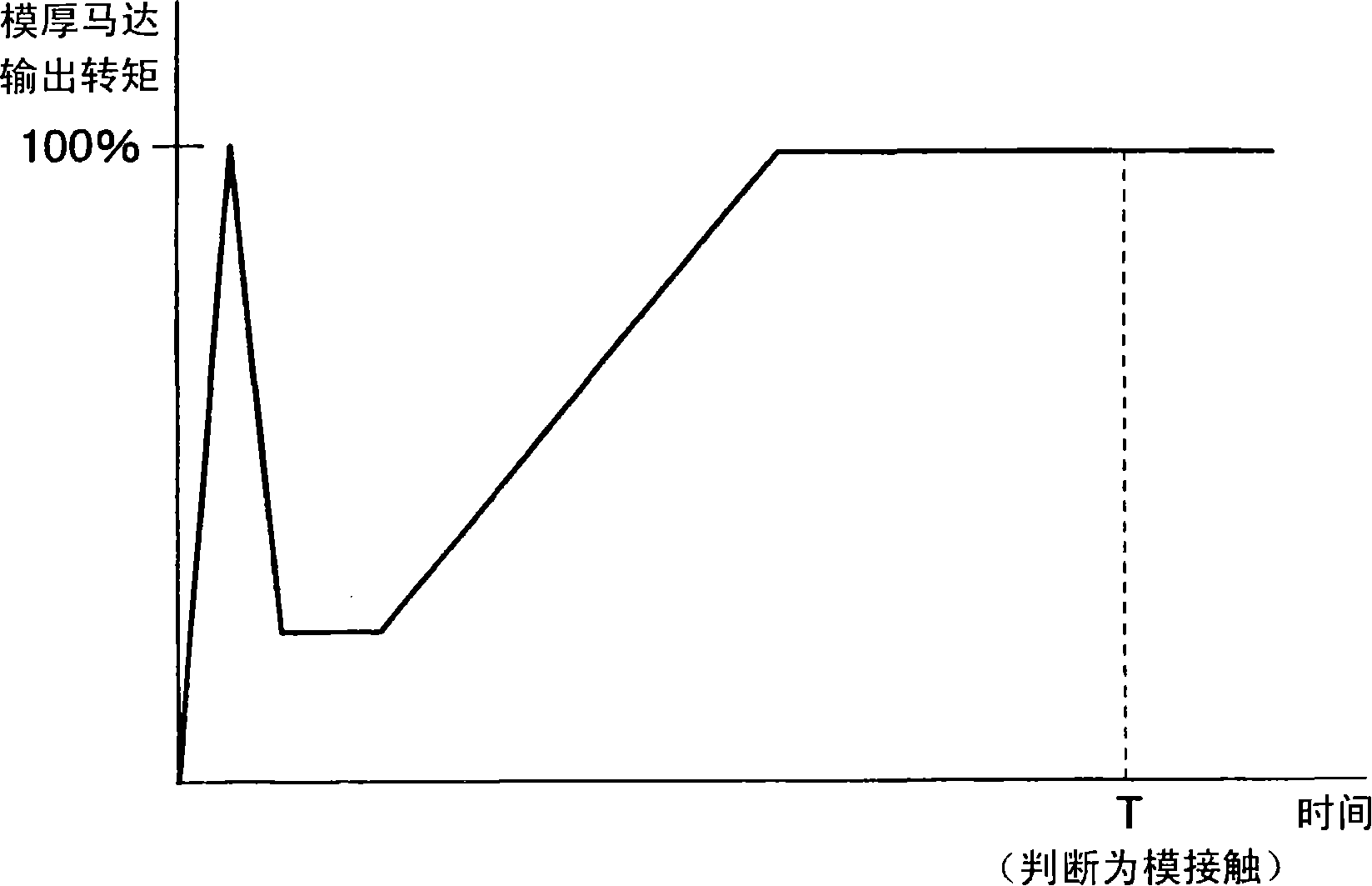

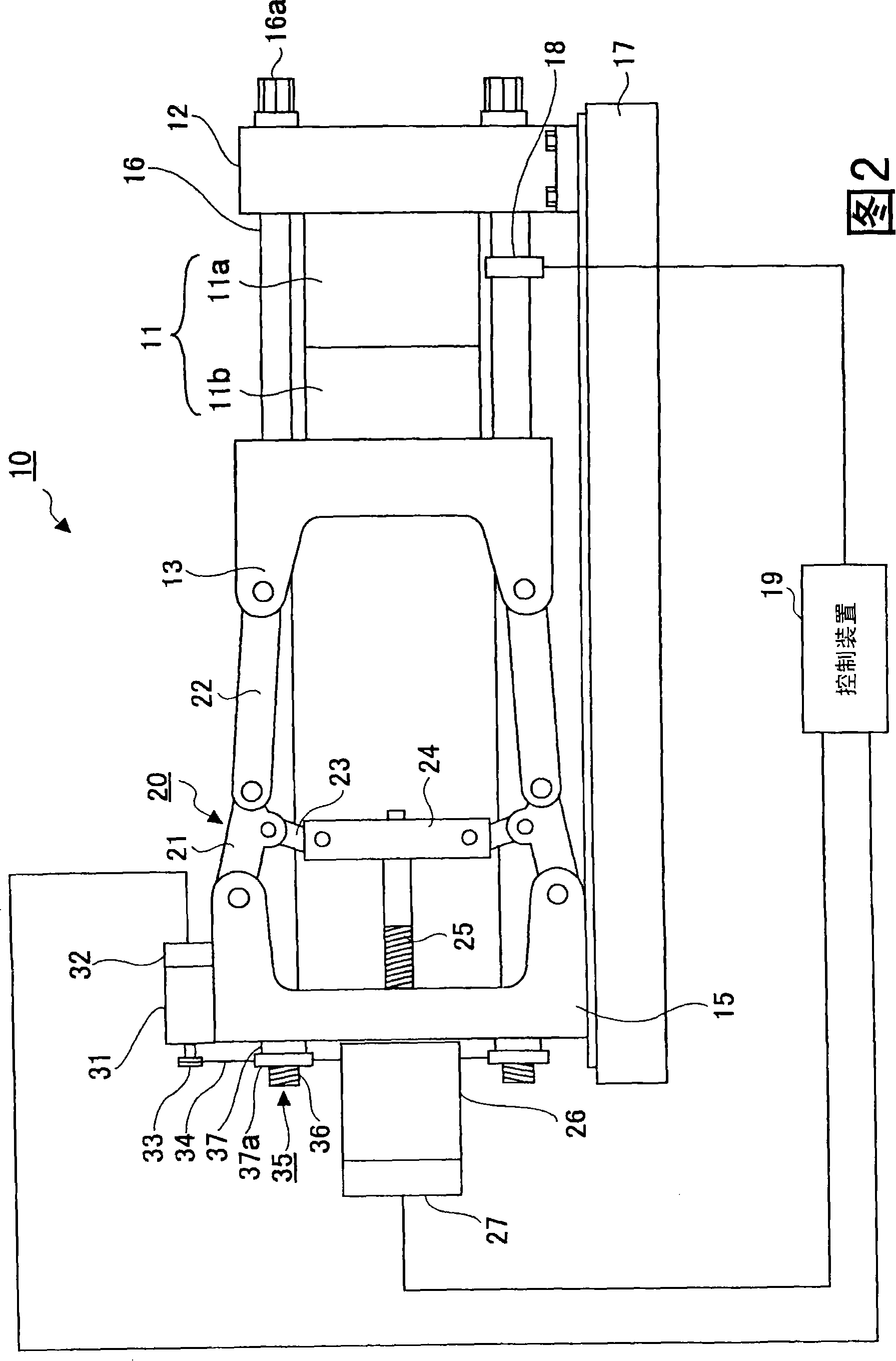

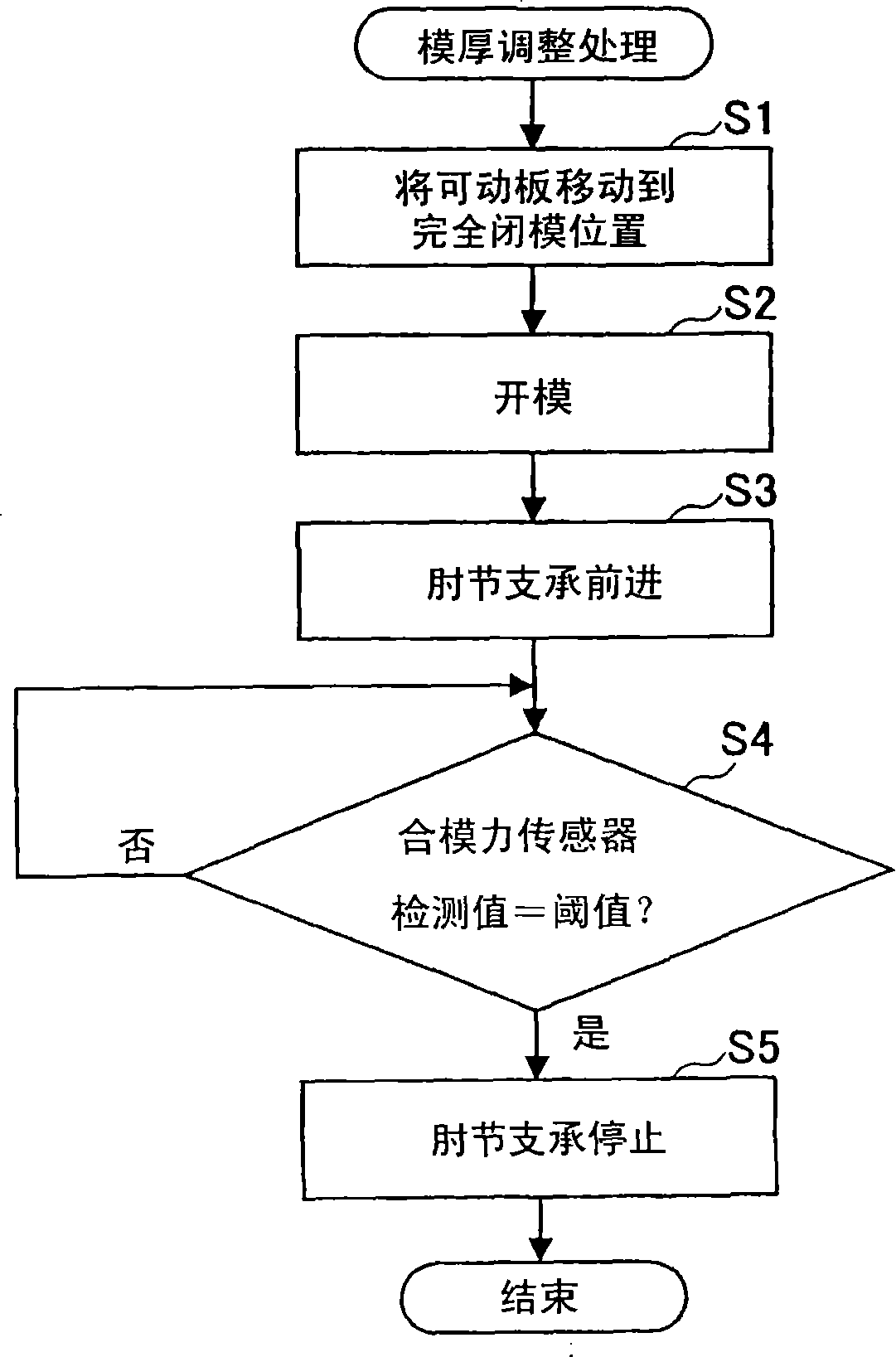

Molding condition setting method

InactiveCN101189113AJudging the circumstances of the contactTransportation and packagingPlastic recyclingStrain sensorForce sensor

A molding condition setting method capable of accurately stopping a toggle support at a specified position by accurately determining whether mold touch is performed or not in a mold thickness adjusting method. The toggle support (15) is retreated to a position where the mold touch is absent, a movable platen (13) is moved to a mold fully closed position, a mold is opened by such a distance that a prescribed mold clamping force is applied to the mold, the toggle support is advanced in a mold closing direction, and detected values from a mold clamping force sensor are monitored. When the detected values reach a threshold, the toggle support is stopped. The mold clamping force sensor comprises a tie-bar strain sensor (18) detecting the strain of a tie-bar and a pressure sensor (40) detecting a pressing force applied to the movable platen (13A) or a strain sensor (41) detecting the strain of the component of a toggle mechanism.

Owner:SUMITOMO HEAVY IND LTD

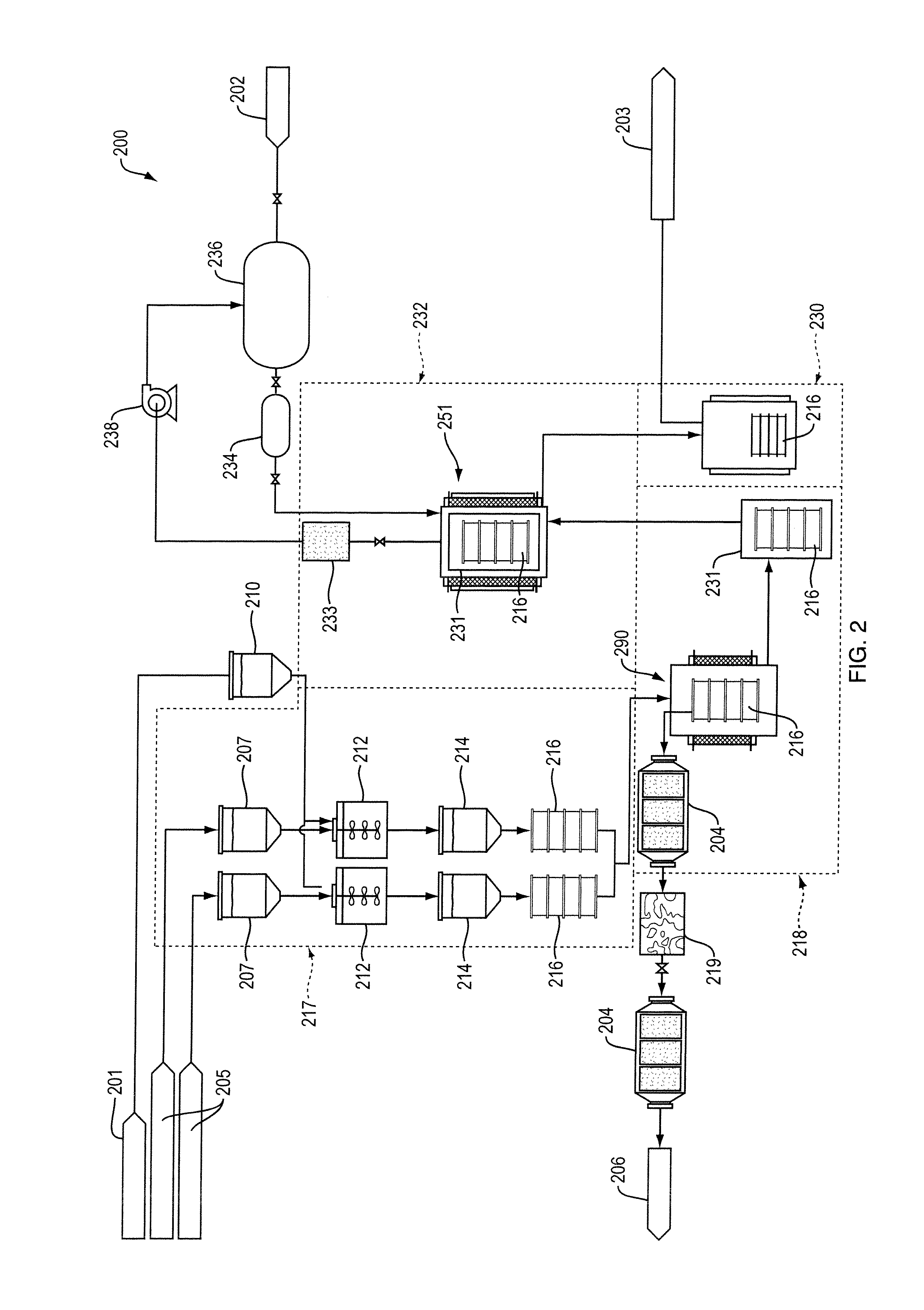

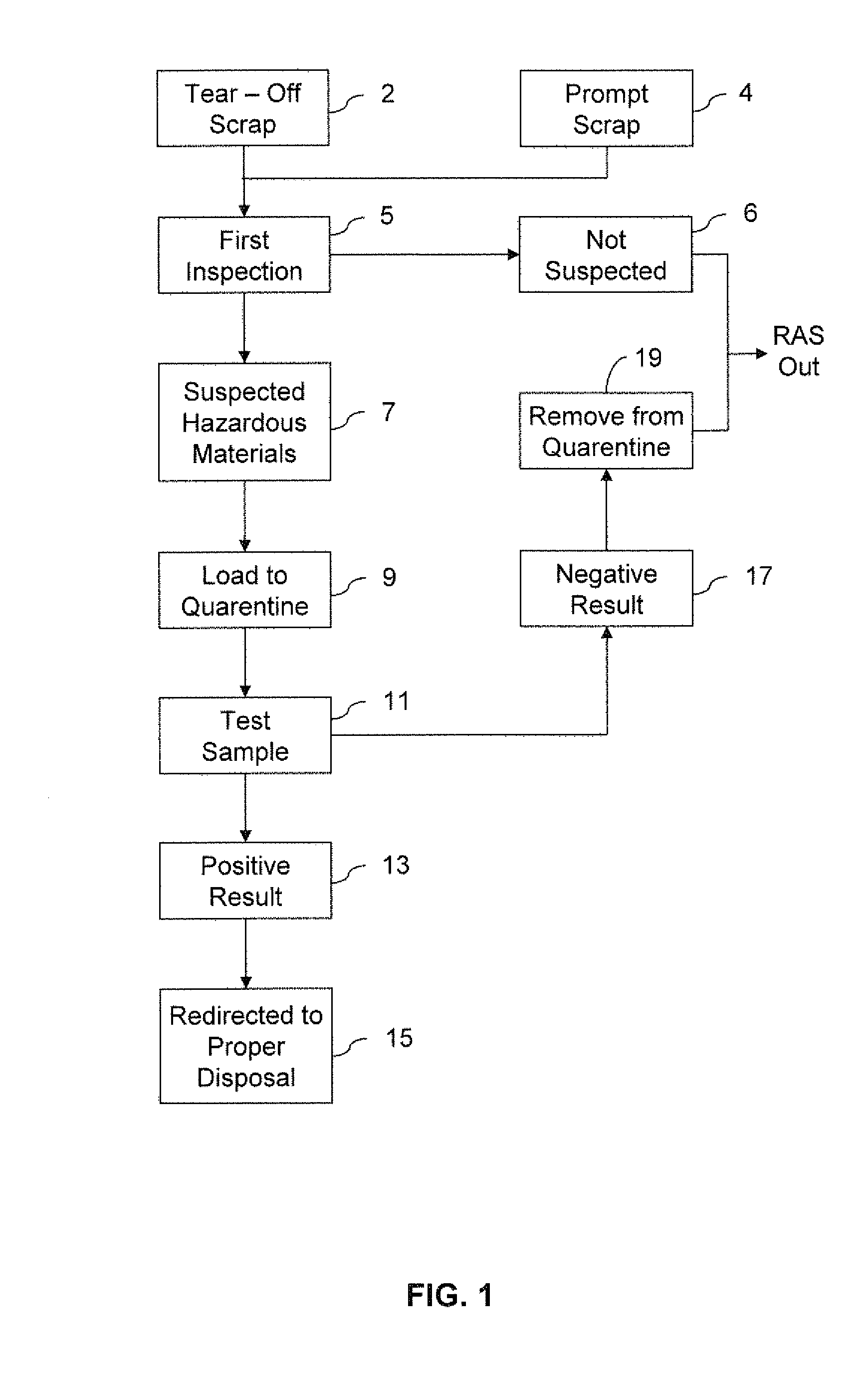

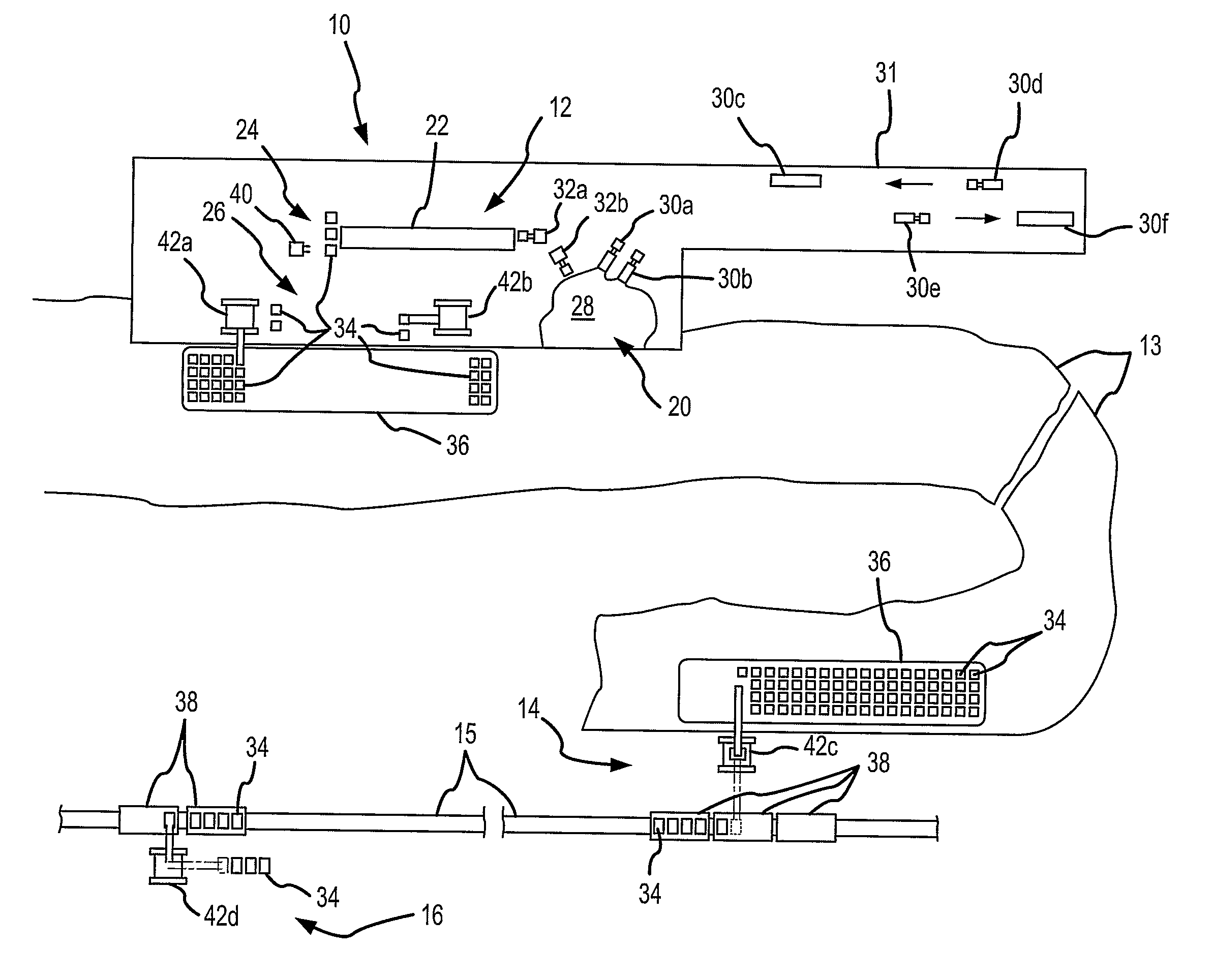

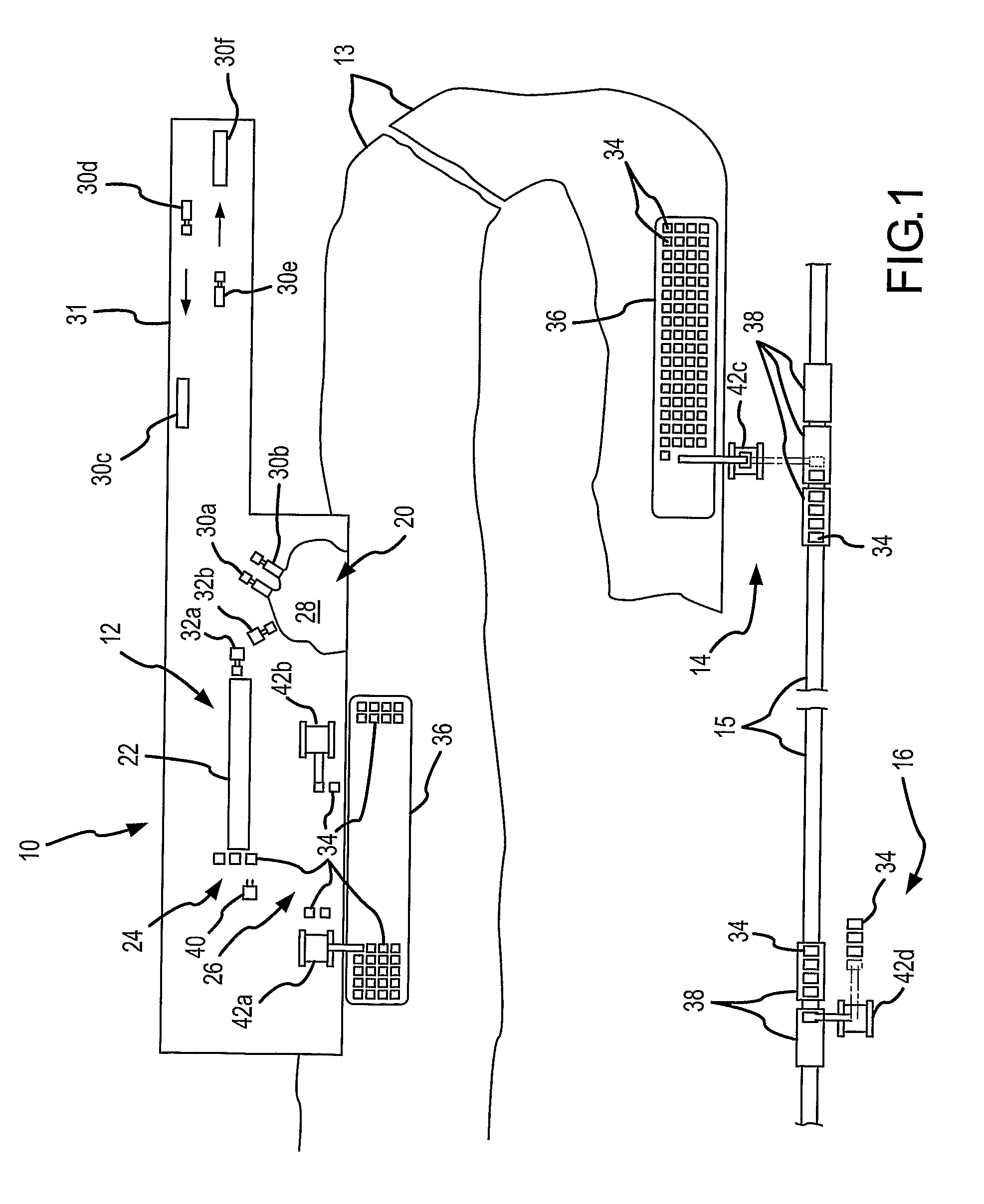

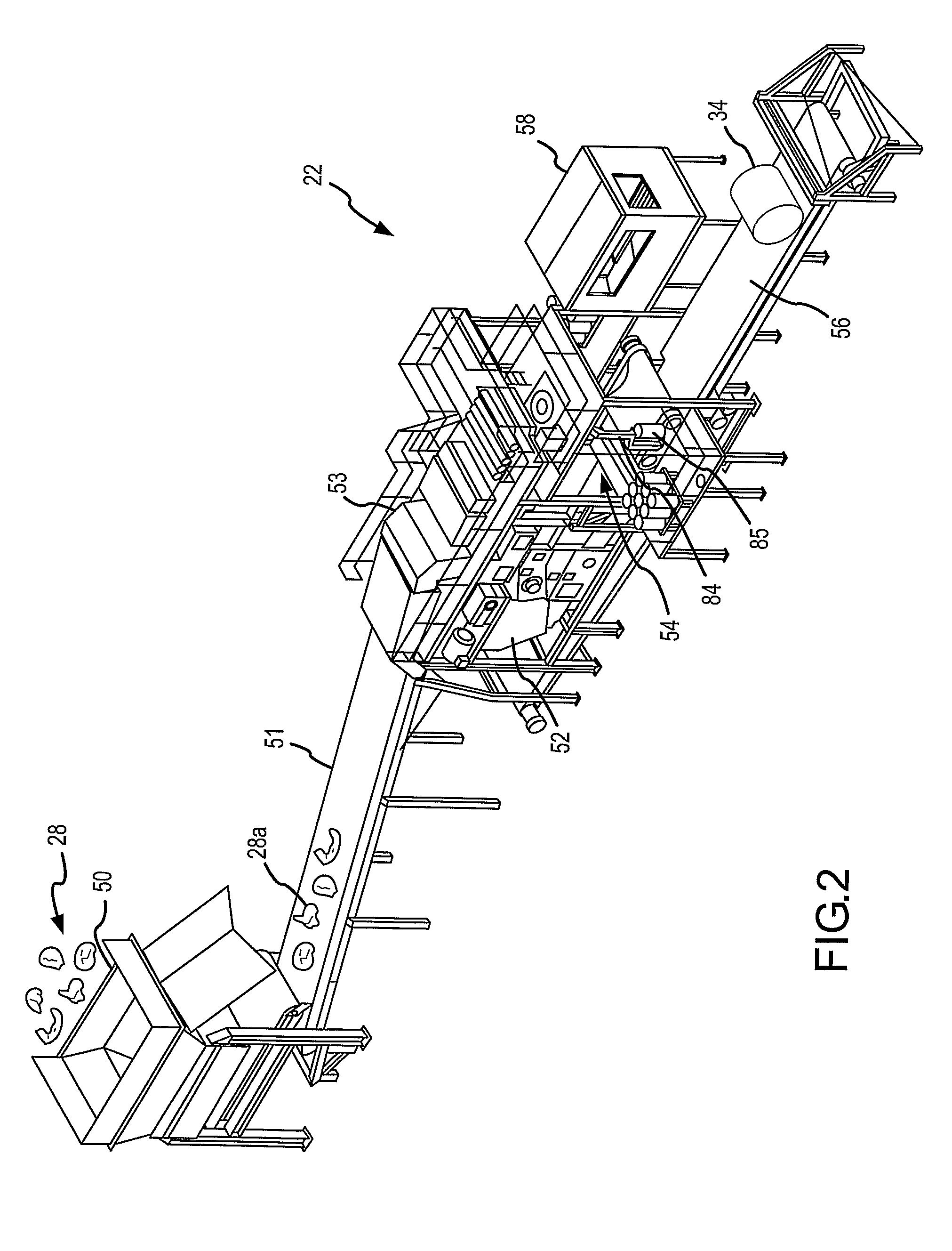

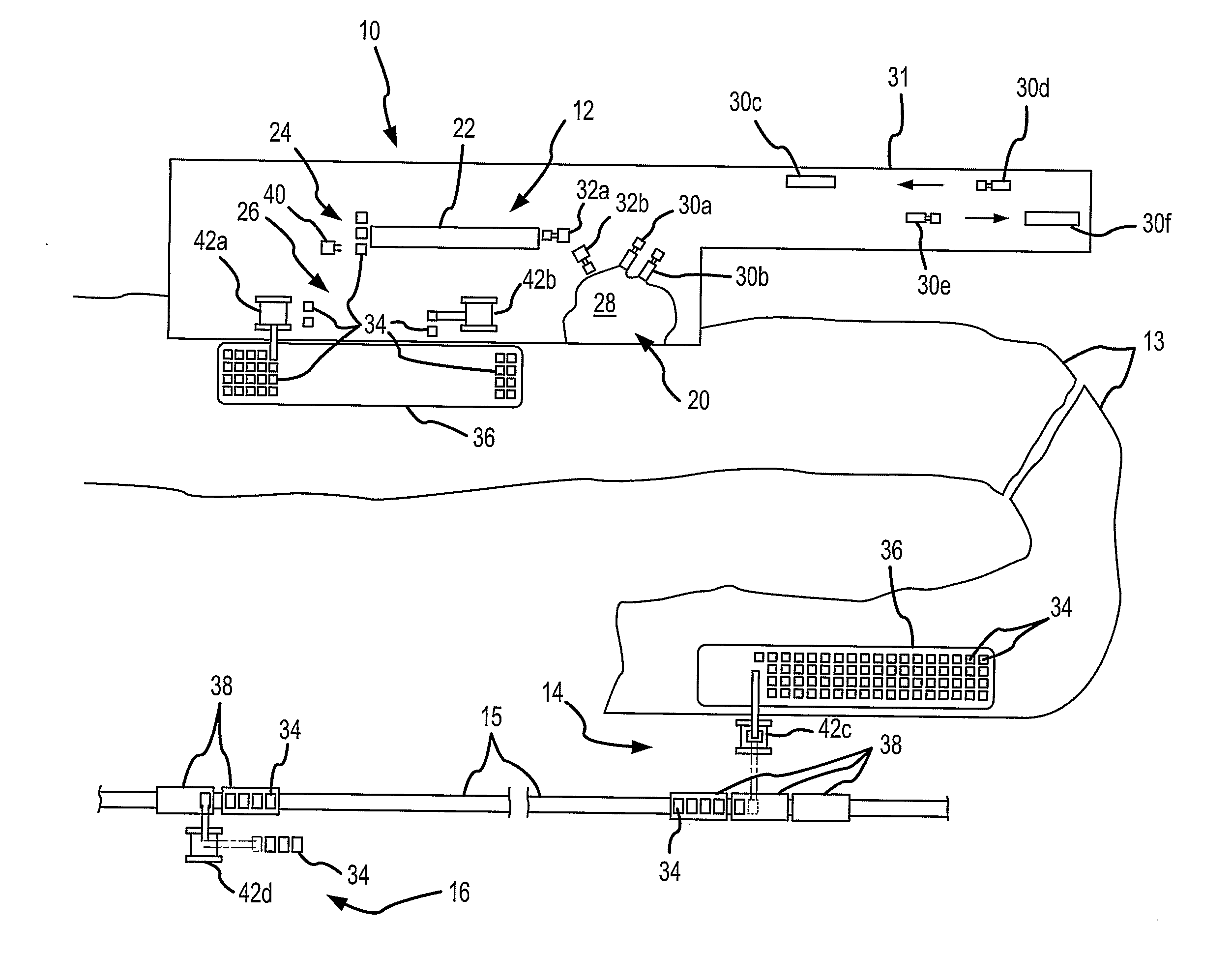

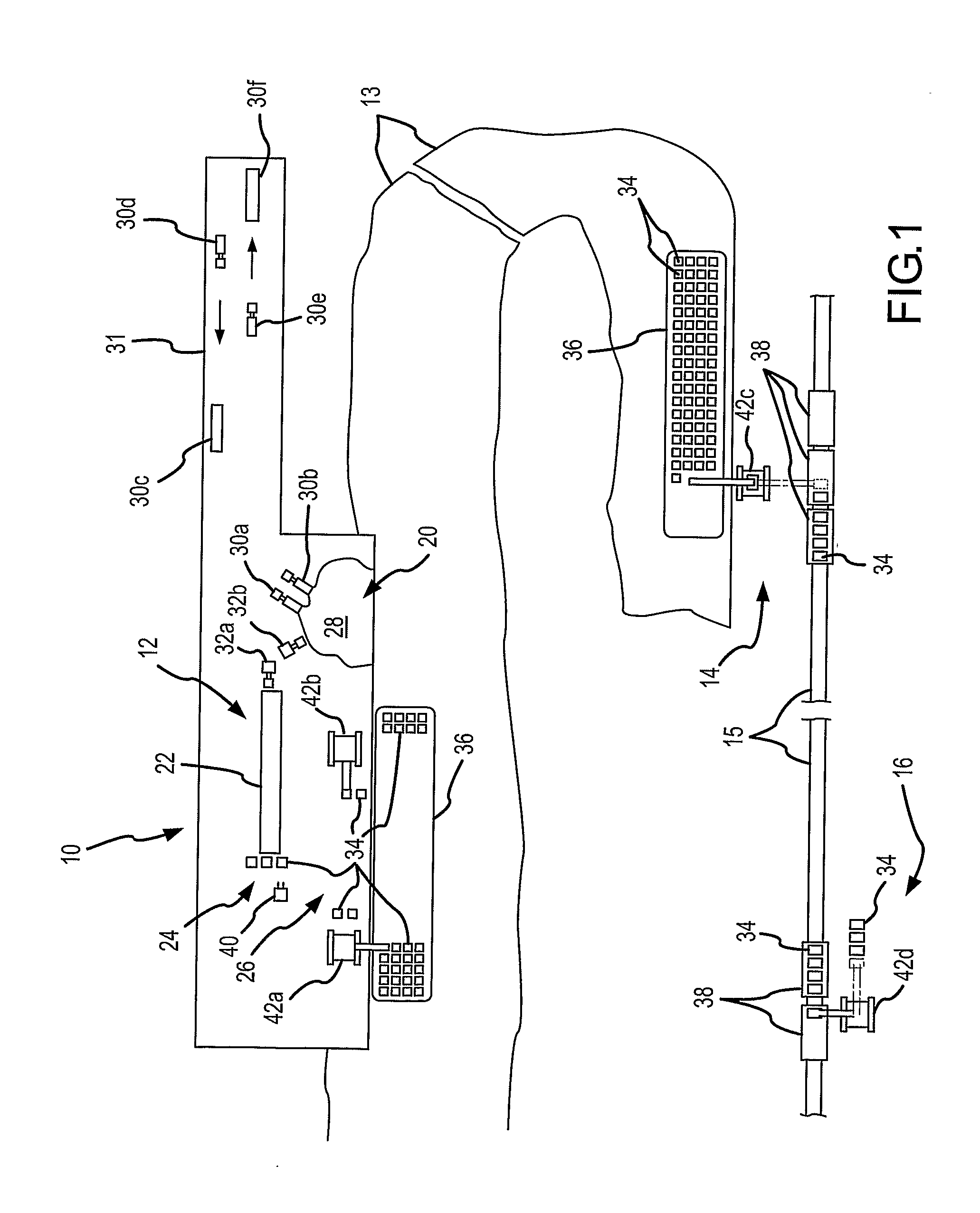

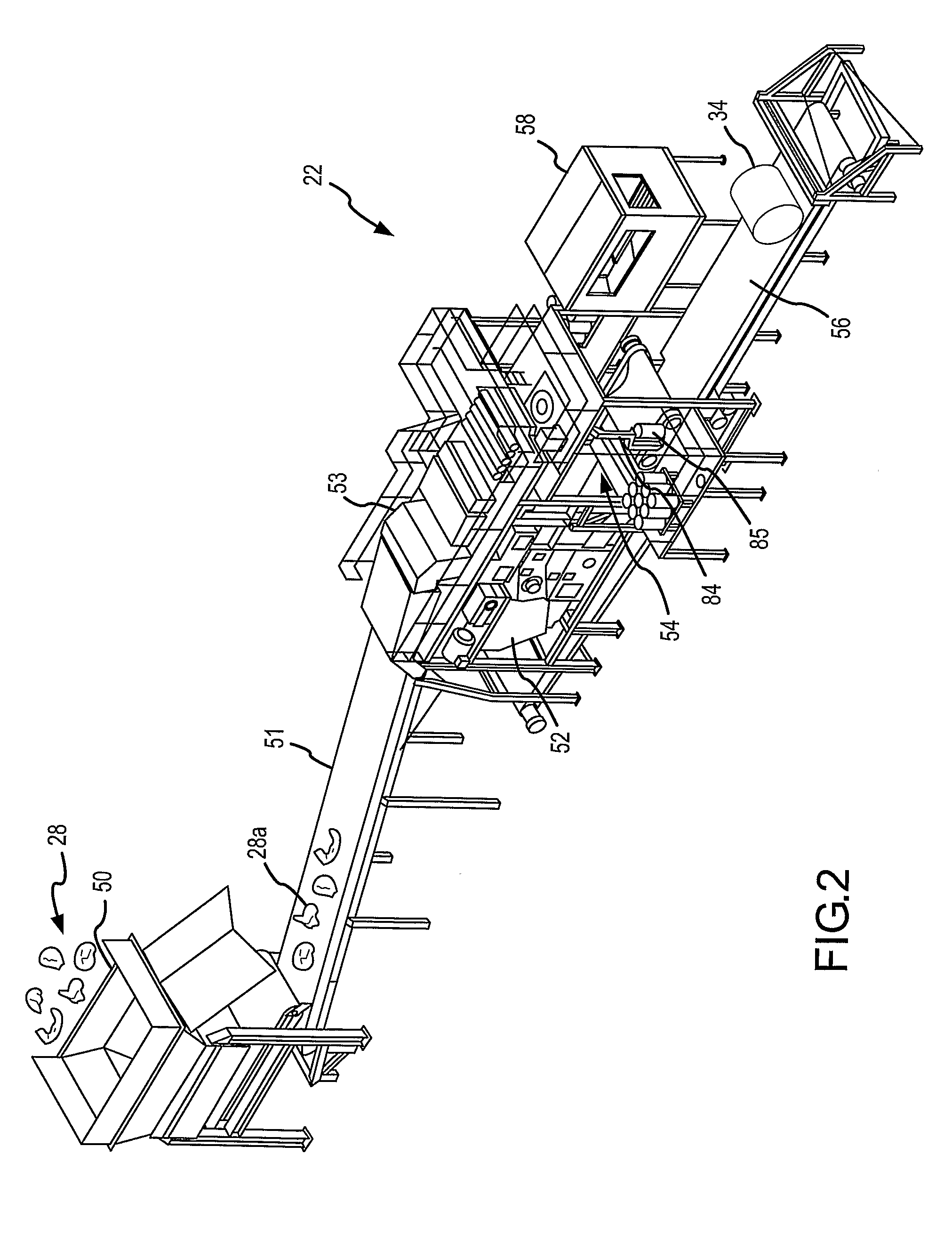

Systems and methods of processing and transporting waste

Waste-processing and transportation systems and methods are described. An exemplary waste processing and transportation system (10) comprises a receiving area (20) where loose waste (28) is delivered, a baler (22) for processing the loose waste (28) into waste bales (34), and a loading area (26) where the waste bales (34) are loaded onto a transport vehicle (e.g., a barge 36). A loader (32a) may operate in the receiving area (20) to load the loose waste (28) into the baler (22). At least one material handler (42a) may be configured to move the waste bales (34) onto the transport vehicle (36) for transport to a waste transfer facility (14). The waste bales (34) are configured such that the waste bales are unloaded from the transport vehicle (36) at the waste transfer facility (14) and loaded onto other transport vehicles (e.g., railcars 38) without further processing of the waste bales (34).

Owner:HUDSON RIVER RESOURCES LLC

Separation method of lithium cobalt oxide and aluminum foil on positive electrode sheet of scrap lithium ion battery

ActiveCN103985920BLower requirementLow costTransportation and packagingWaste accumulators reclaimingPole pieceLithium-ion battery

The separation method of lithium cobalt oxide and aluminum foil on the positive electrode sheet of the scrap lithium-ion battery, the steps are: discharge and disassemble the waste lithium-ion battery, and then put the waste positive electrode sheet into a box-type resistance furnace and bake it at 500~600°C , put the roasted positive electrode sheet into a container with water and stir it with an electric stirrer, then sieve the material in the container with a sieve, the sieve is aluminum foil, the sieve aluminum foil is washed with water, and dried naturally Aluminum foil is obtained; the undersize is a mixed solution containing positive active substances, the undersize is suction filtered, and the filtered oversize after natural drying is put into a ceramic crucible, and then placed in a box-type resistance furnace for high temperature treatment to obtain Lithium Cobalt Oxide. Compared with the prior art, the present invention has the advantages of easy operation, low requirement for separation equipment, high separation efficiency and low cost of lithium cobalt oxide and aluminum foil, no need to use any organic solvent in the treatment process, and no secondary pollution during the separation process.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

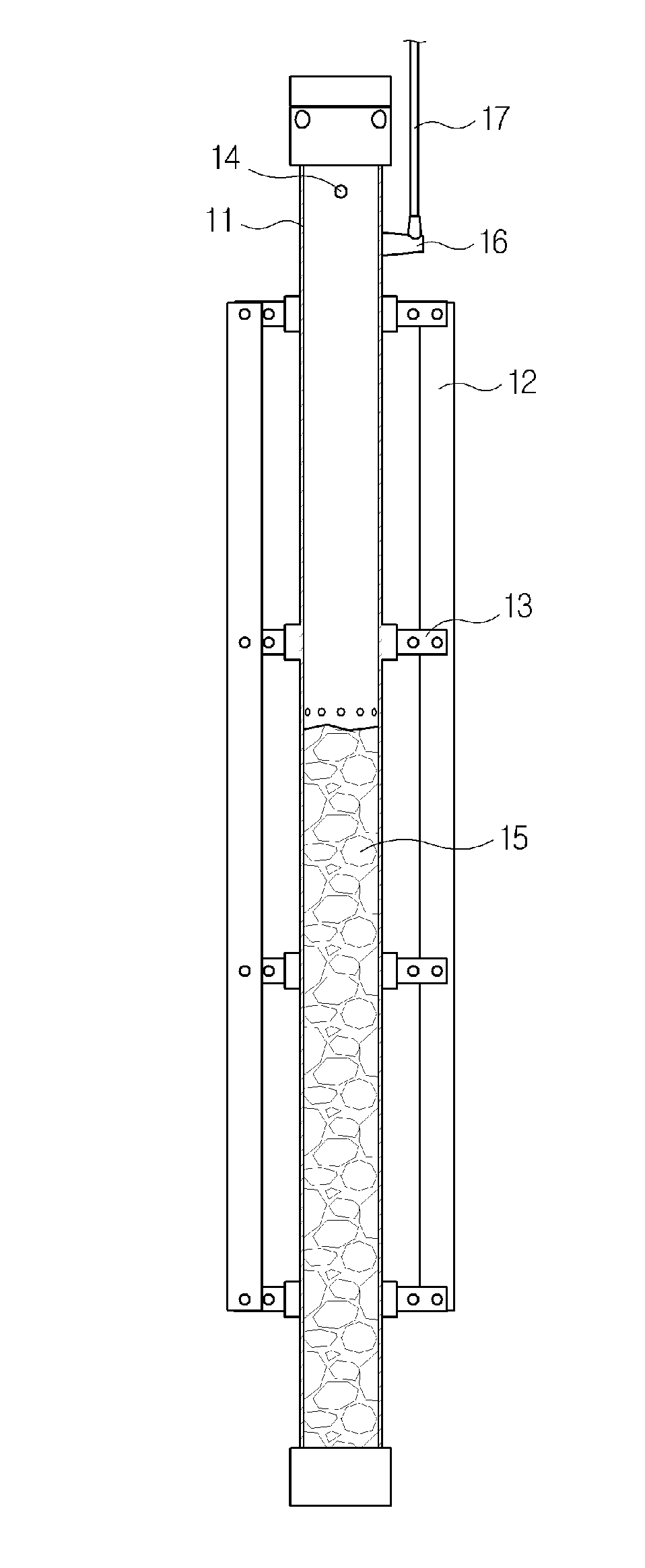

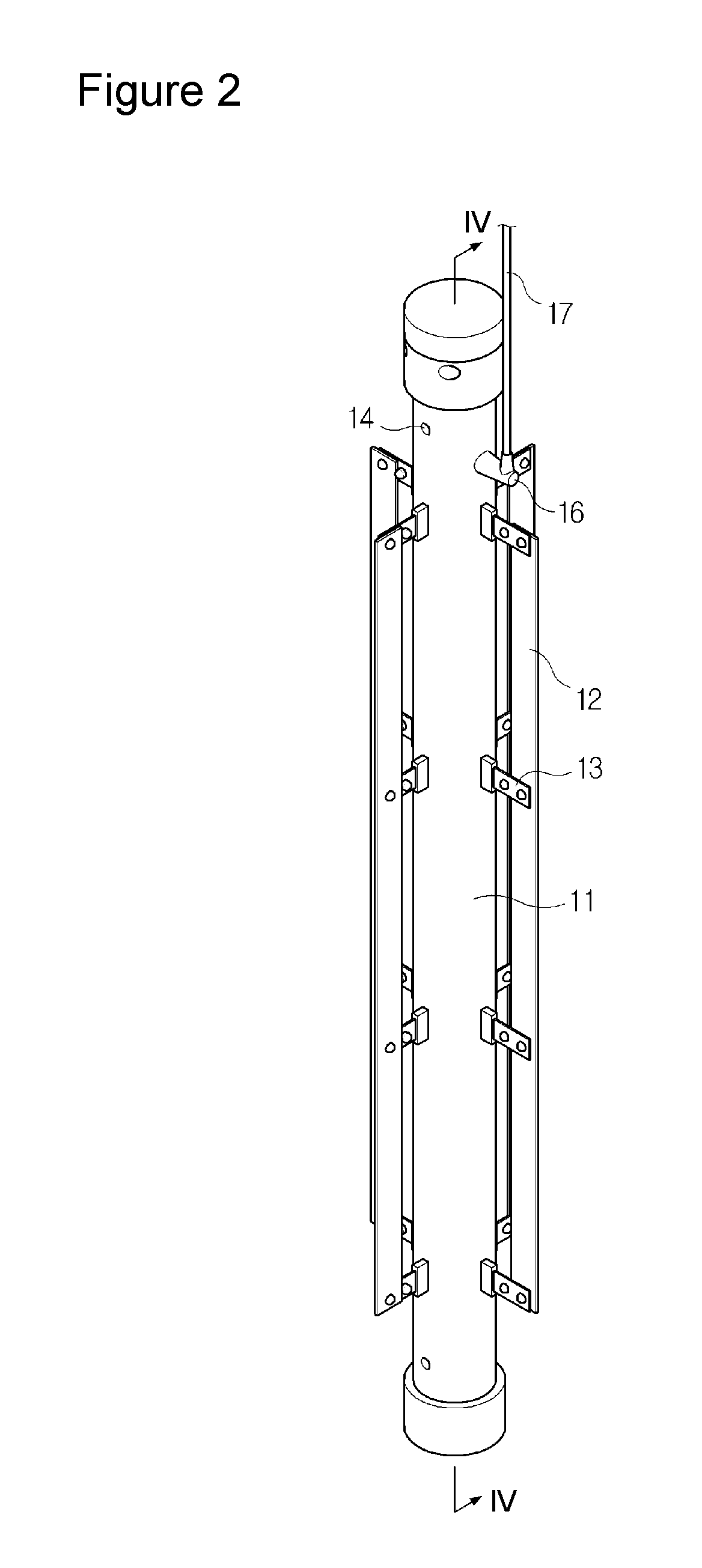

Ground rod having induction discharge skin-effect plate

InactiveUS7365267B2Easy dischargeIncrease surface areaInstallation of lighting conductorsTransportation and packagingDischarge skinElectric potential energy

A ground rod having an induction discharge skin-effect plate is disclosed, in which an electric current inputted into a ground rod can be easily discharged to the ground by forming an induction discharge skin-effect plate in parallel with a ground rod at a certain interval and increasing a critical surface area when a thunderbolt falls. In addition, an electric potential increase of the ground can be lowered by allowing an electric potential discharge to take place between the upper and lower vertical portions of a ground rod and an induction discharge skin-effect plate when a thunderbolt falls.

Owner:KIM DONG JIN

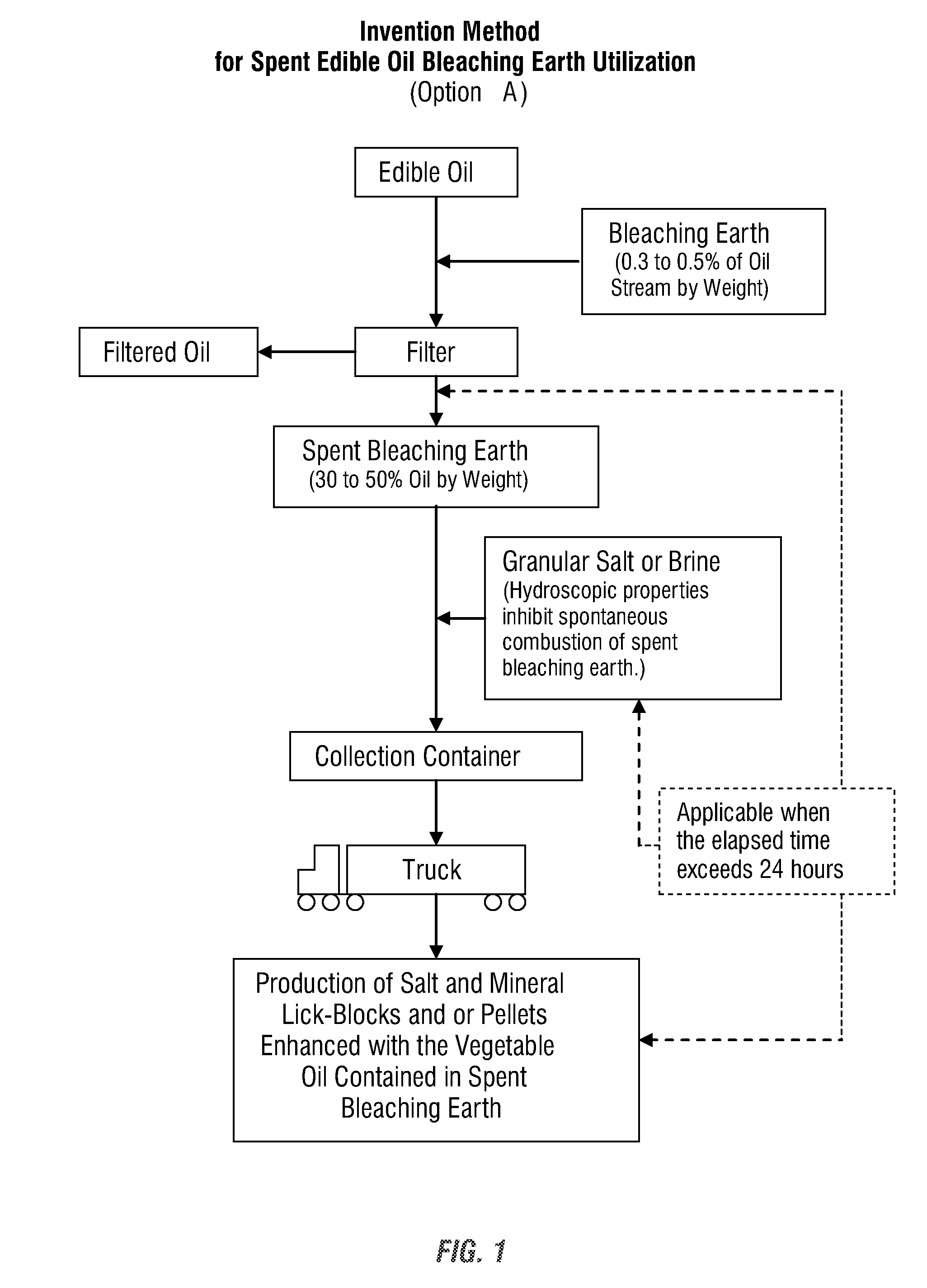

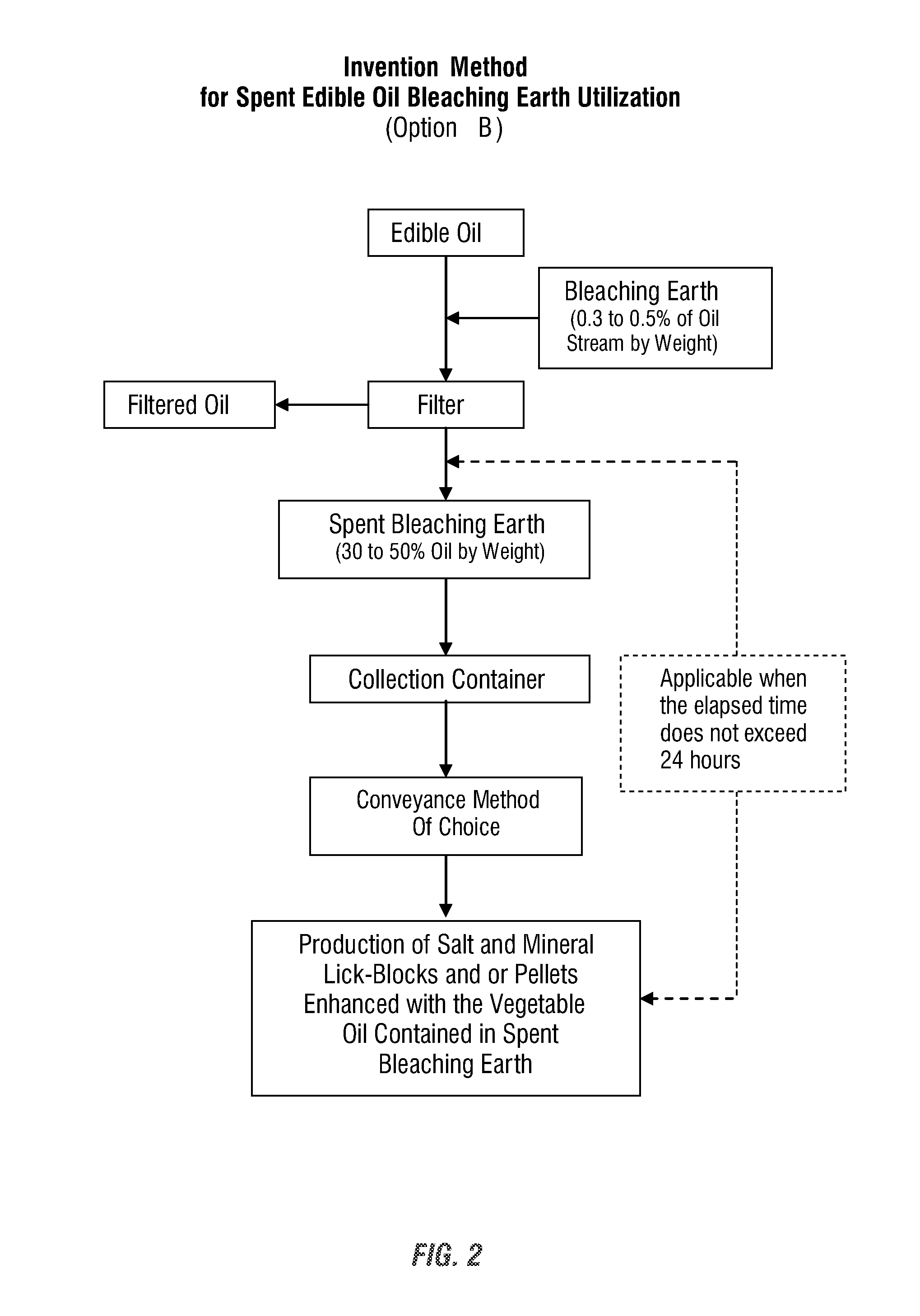

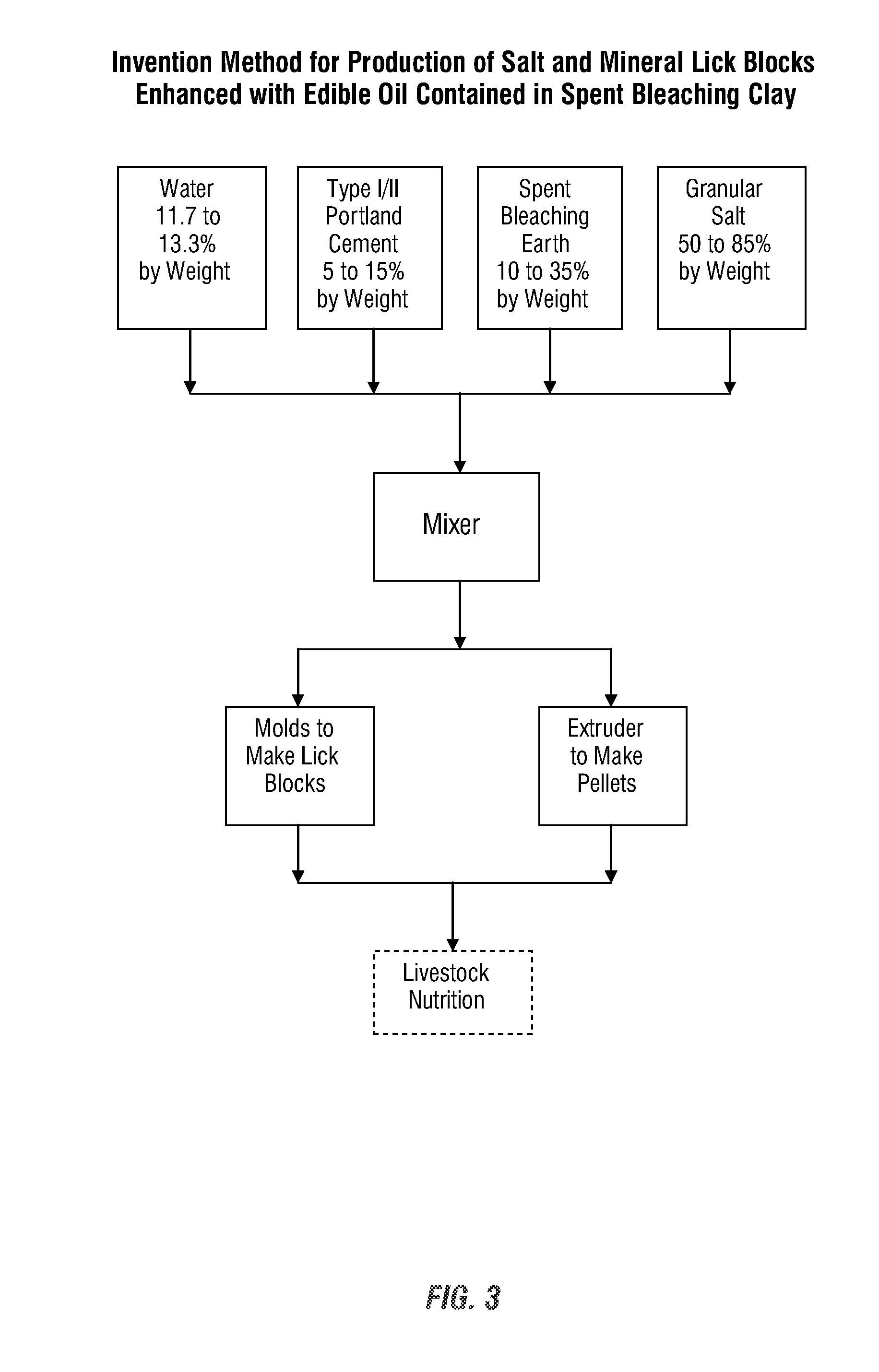

Use of spent bleaching earth from edible oil processing in the formulation of salt and mineral feed blocks or pellets for livestock

ActiveUS20140356483A1Many timesEliminate spontaneous combustionFood processingTransportation and packagingSaline waterPrill

Spent bleaching earth from edible oil processing can be used in the formulation of salt and mineral lick blocks and pellets for livestock to enhance the health and nutritional value of the feed supplements. Because of the ignition hazard inherent with spent bleaching earth, landfill has been and continues to be the dominant disposal method. By adding salt or brine to the spent bleaching earth upon discharge from the process filters, the hydroscopic property will keep the material safe for handling and economic use as described.

Owner:SMALLWOOD NORMAN J

Systems and methods of processing and transporting waste

InactiveUS20090293426A1Easy to handleGuaranteed transportation efficiencyConveyorsLoadersWaste disposal

Waste-processing and transportation systems and methods are described. An exemplary waste processing and transportation system (10) comprises a receiving area (20) where loose waste (28) is delivered, a baler (22) for processing the loose waste (28) into waste bales (34), and a loading area (26) where the waste bales (34) are loaded onto a transport vehicle (e.g., a barge 36). A loader (32a) may operate in the receiving area (20) to load the loose waste (28) into the baler (22). At least one material handler (42a) may be configured to move the waste bales (34) onto the transport vehicle (36) for transport to a waste transfer facility (14). The waste bales (34) are configured such that the waste bales are unloaded from the transport vehicle (36) at the waste transfer facility (14) and loaded onto other transport vehicles (e.g., railcars 38) without further processing of the waste bales (34).

Owner:HUDSON RIVER RESOURCES LLC

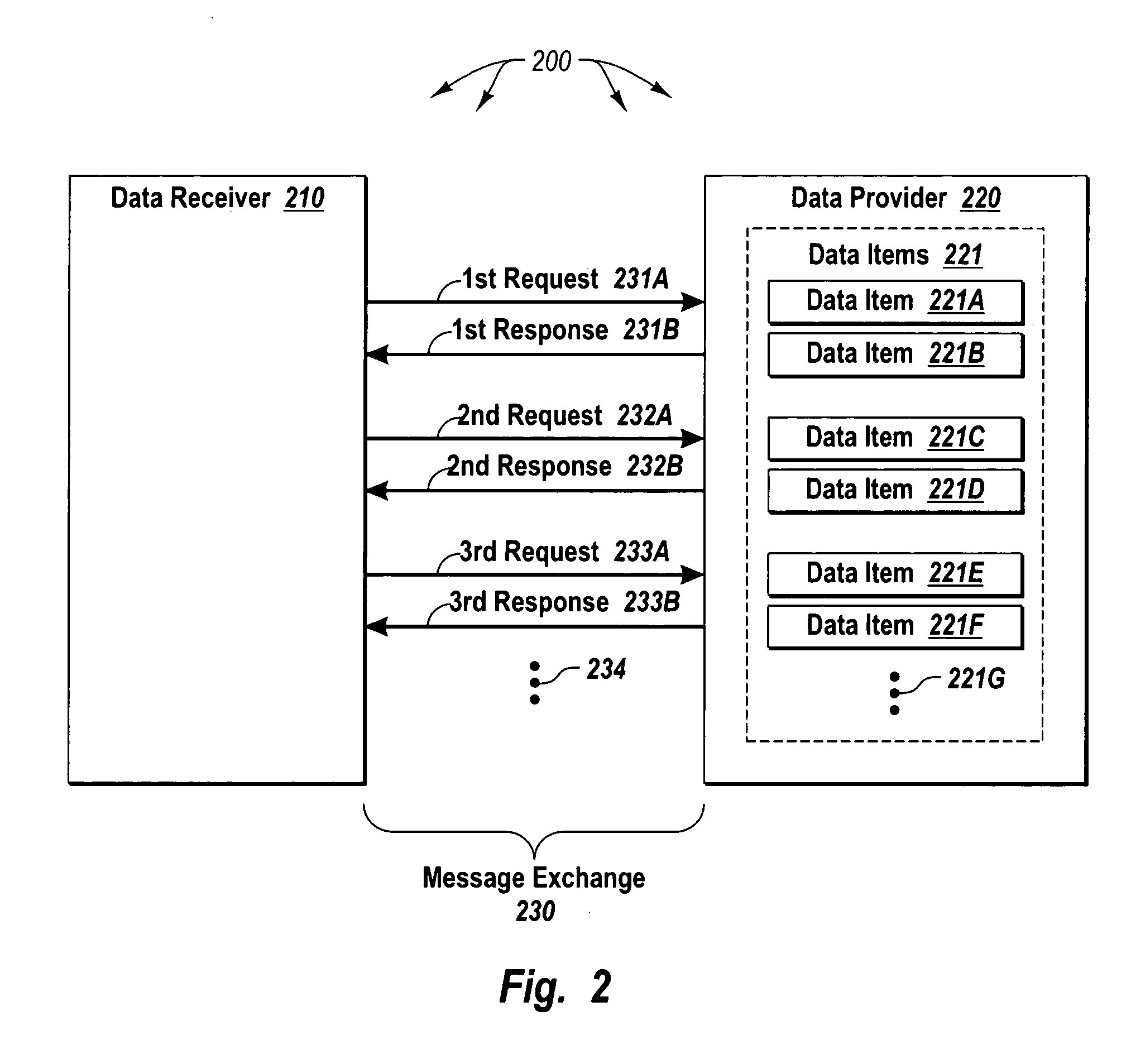

Flexible context management for enumeration sessions using context exchange

InactiveUS20060047757A1Wide flexibilitySpecial service provision for substationTransportation and packagingContext managementData provider

Mechanisms for providing requested date items in a request-driven enumeration session while retaining to control over how much inter-message context information is retained by the data provider. Upon receiving a request for the data items, the data provider identifies a portion of the data items to be provided in the first response along with context information that reflects that the first portion of information has been provided. The data provider then makes a determination of how much of the context is to be provided to the data receiver system, and then provides that appropriate context information to the data receiver. Furthermore, the data provider provides a response that includes the first portion of the data items. The data receiver includes this first provided context information in the second request for the next portion of the data items, allowing continuity in the data transfer session.

Owner:MICROSOFT TECH LICENSING LLC

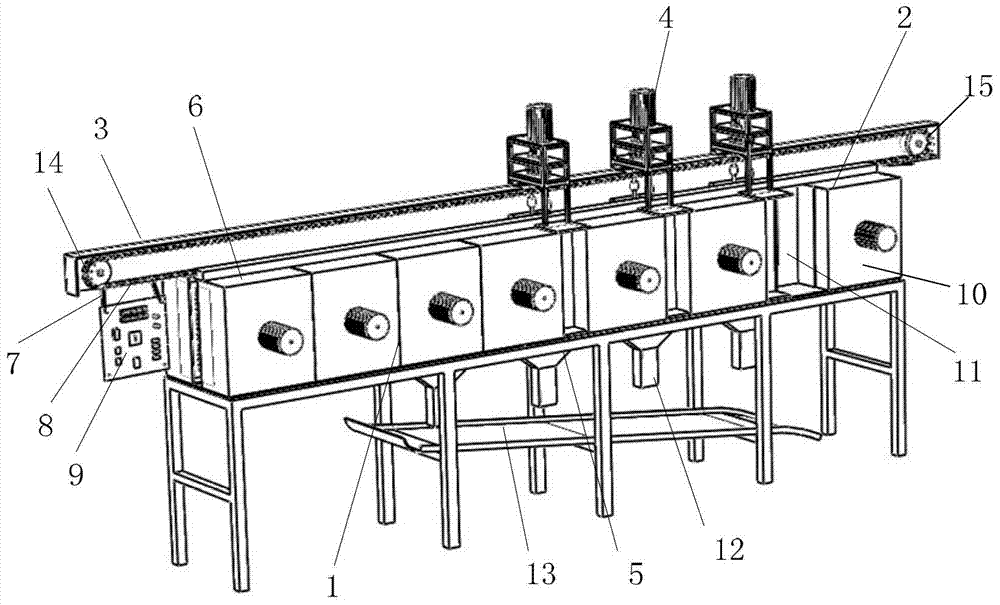

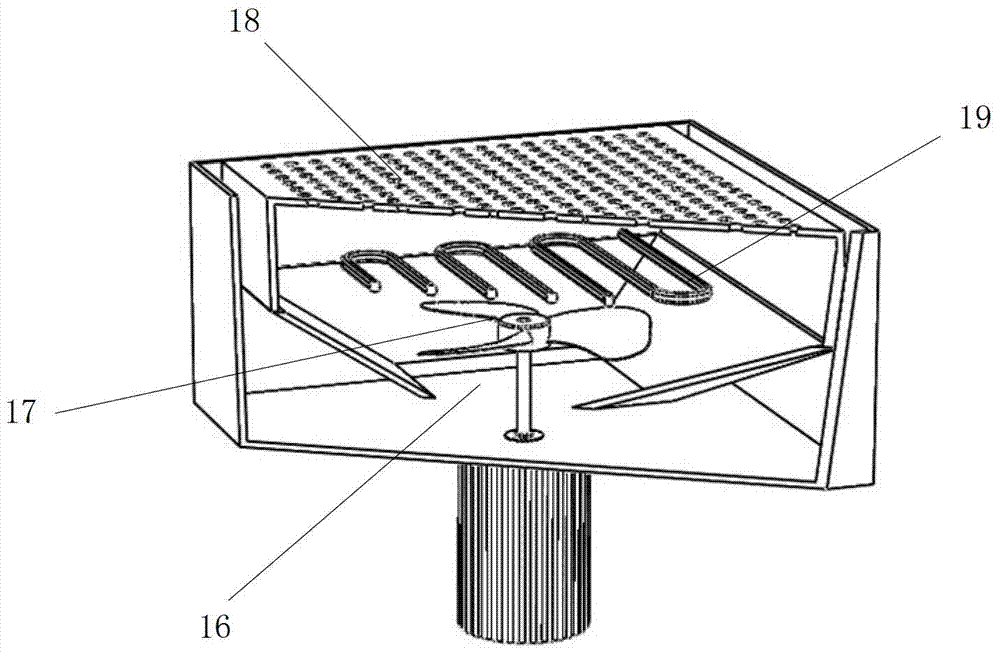

Disassembly device for reusable surface-mounted components of waste circuit board

InactiveCN103495783AReduce preprocessing timeReduce setup timeTransportation and packagingSoldering apparatusSurface mountingEngineering

The invention belongs to the field of recycling and reusing of electric product waste and discloses a disassembly device for reusable surface-mounted components of a waste circuit board. The disassembly device is composed of a heating system, a cooling system, a conveyer system, a sweeping system and a component collecting mechanism. The heating system is composed of heating areas. The cooling system is composed of a cooling area. The conveyer system is composed of a horizontally-installed conveyor chain, a driven chain wheel, a driving chain wheel, a U-shaped groove and a motor. The sweeping system is composed of sweeping mechanisms, the sweeping mechanisms on all stages are respectively provided with a left hairbrush and a right hairbrush, and the hairbrushes can be arranged in a rotating mode or a reciprocating mode. A hot air box is composed of a rectifying plate, a heater and a fan. The disassembly device for the reusable surface-mounted components of the waste circuit board has the advantages that the circuit board is conveyed through a retaining ring with a simple structure, thus, time is saved, and manufacturing cost is lowered; because the rectifying plate is vertically placed, the problem that the tiny surface-mounted components and solder enter small holes of the rectifying plate easily after the circuit board is heated and de-soldered is solved, line production can be realized, and efficiency can be improved.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com