Method for producing ceramic product with crack glaze by use of waste ceramic material and waste glass

A production method and technology of waste glass, applied in the field of ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

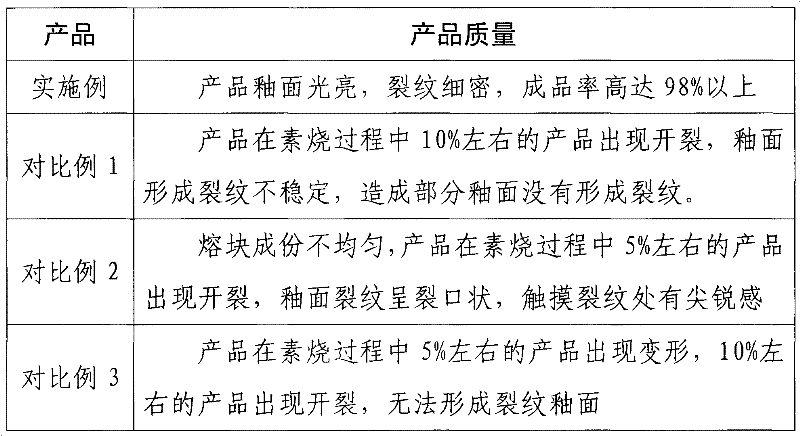

Examples

Embodiment

[0012] Example: Take 40 parts by weight of waste porcelain, 35 parts by weight of waste glass, 10 parts by weight of zircon sand, and 15 parts by weight of talc, mix them and pulverize them through a 325-mesh sieve, and put them in a crucible for melting at 1260°C to melt them Then, it is quenched with water and dried to form a frit for later use;

[0013] Take 40 parts by weight of frit, 40 parts by weight of feldspar, 10 parts by weight of diatomaceous earth, 5 parts by weight of stalactite, and 5 parts by weight of kaolin and put them into a ball mill, and then add 30 parts by weight of clear water to ball mill through a 240 mesh sieve to produce cracked enamel spare;

[0014] Take 40 parts by weight of frit, 15 parts by weight of feldspar, 30 parts by weight of silica powder, 5 parts by weight of stalactite, and 10 parts by weight of kaolin and put them into a ball mill, then add 30 parts by weight of clear water to ball mill through 240 mesh sieve, and then sieve and remove A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com