Method for treating waste water containing high concentration of organosilicon

A high-concentration wastewater treatment method technology, applied in the direction of heating water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve high treatment costs, large consumption of chemicals, and sludge volume Major problems, to achieve the effect of reducing operating costs and low costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

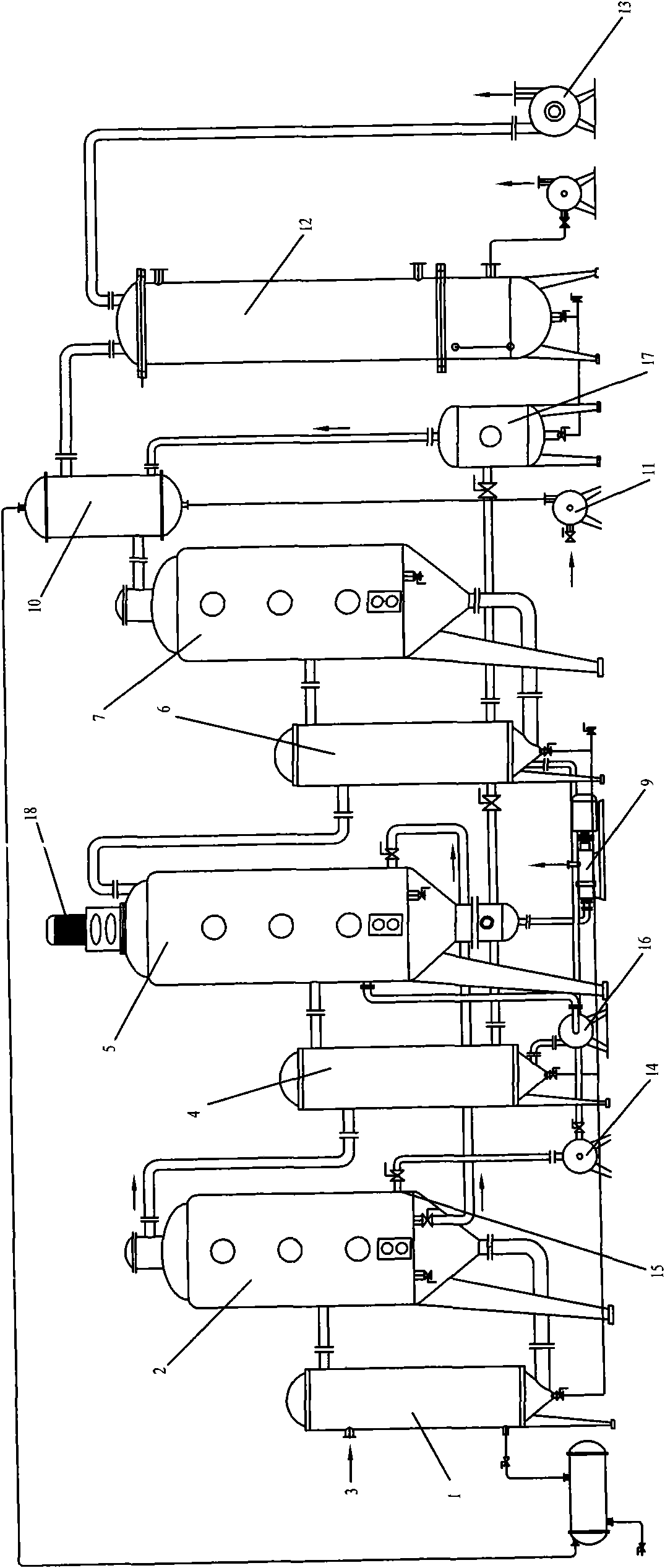

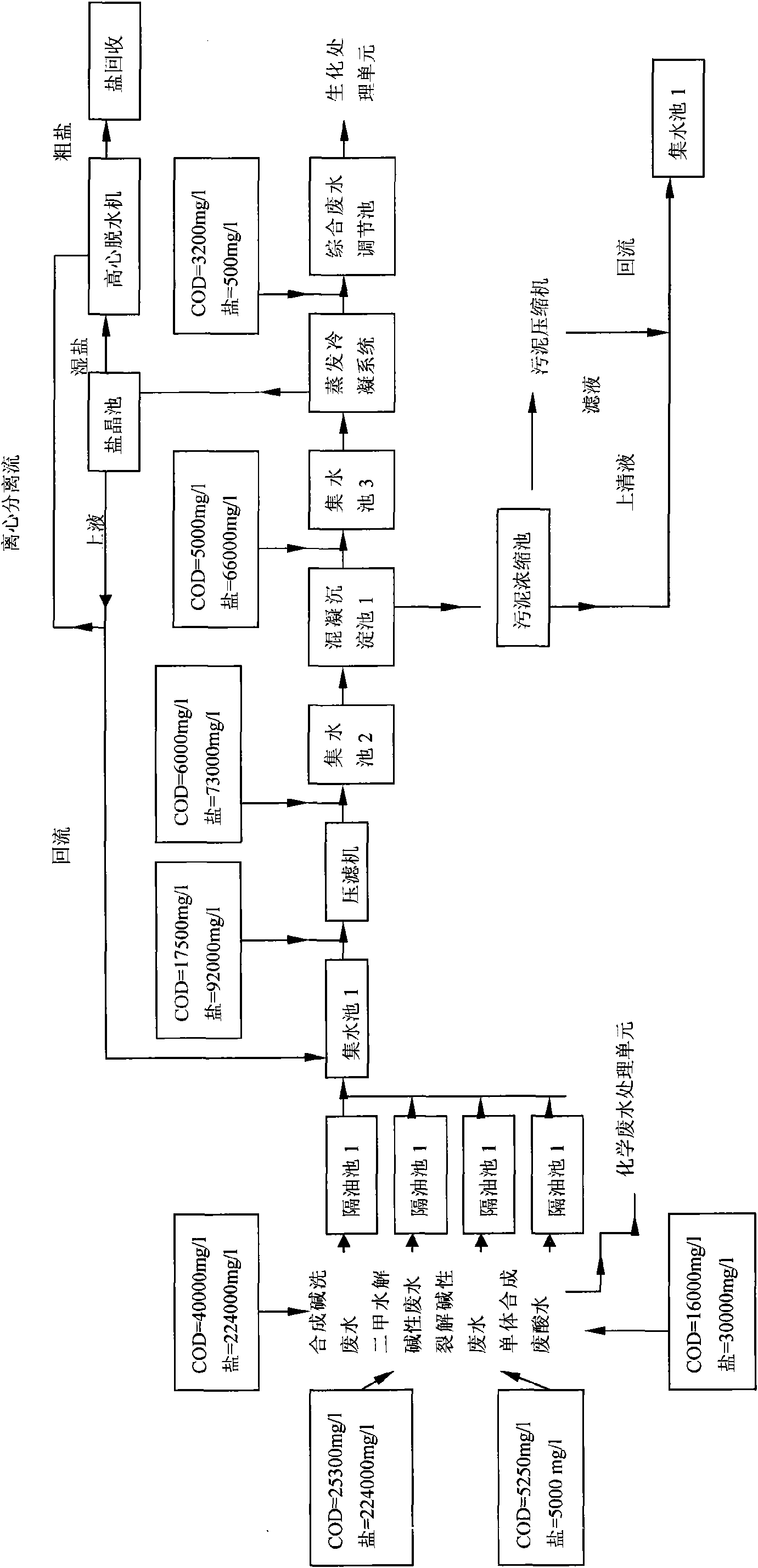

[0041] The total daily discharge of high-concentration organic silicon wastewater from an organic silicon company is 600 tons, and the highest CODcr is 30000mg / L. figure 2 The process flow is processed, and the structure of the continuous evaporative condenser used is shown in figure 1 .

[0042] A three-effect continuous evaporation condenser, including a first-effect evaporator 1 and a first-effect separation chamber 2 connected by a circulation pipeline, the first-effect evaporator 1 is provided with a raw steam inlet 3, and the raw steam inlet 3 is connected to a pressure regulator Valve, the rear of the first-effect separation chamber 2 is sequentially connected to the second-effect evaporator 4, the second-effect separation chamber 5, the third-effect evaporator 6, and the third-effect separation chamber 7, the second-effect evaporator 4 and the second-effect separation chamber 5 Connected by a circulation pipeline, the three-effect evaporator 6 is connected with the t...

Embodiment 2

[0063] The total daily discharge of high-concentration organic silicon wastewater from an organic silicon company is 1,500 tons, and the highest CODcr is 27,500 mg / L. figure 1 The process flow is processed, and the structure of the continuous evaporative condenser used is shown in figure 2 (workflow is the same as embodiment 1).

[0064] 1. Silicone high-concentration wastewater enters the sump after oil separation, and 6.1% lime is added for solidification to enhance the water permeability of the sludge filter press;

[0065] 2. Use the sludge pump to pump into the filter press for solid-liquid separation. After solid-liquid separation, the moisture content of the filter residue is 78%;

[0066] 3. Collect the filter residue and the filtrate separately, and add flocculant PAC (polyaluminum chloride) 180mg / L and coagulant PAM (polyacrylamide) 1.8mg / L to the filtrate, so that the waste water has not been removed, And the pollutants, metal cations and a small amount of silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com