Method and system for drying high-temperature waste gas aerobe in urban raw refuse

A technology of primary waste and aerobic organisms, applied in the direction of solid waste removal, etc., can solve the problems of incomplete flue gas treatment, high energy consumption, long biochemical process, etc., and achieve remarkable drying effect, large water evaporation, dryness The effect of a short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

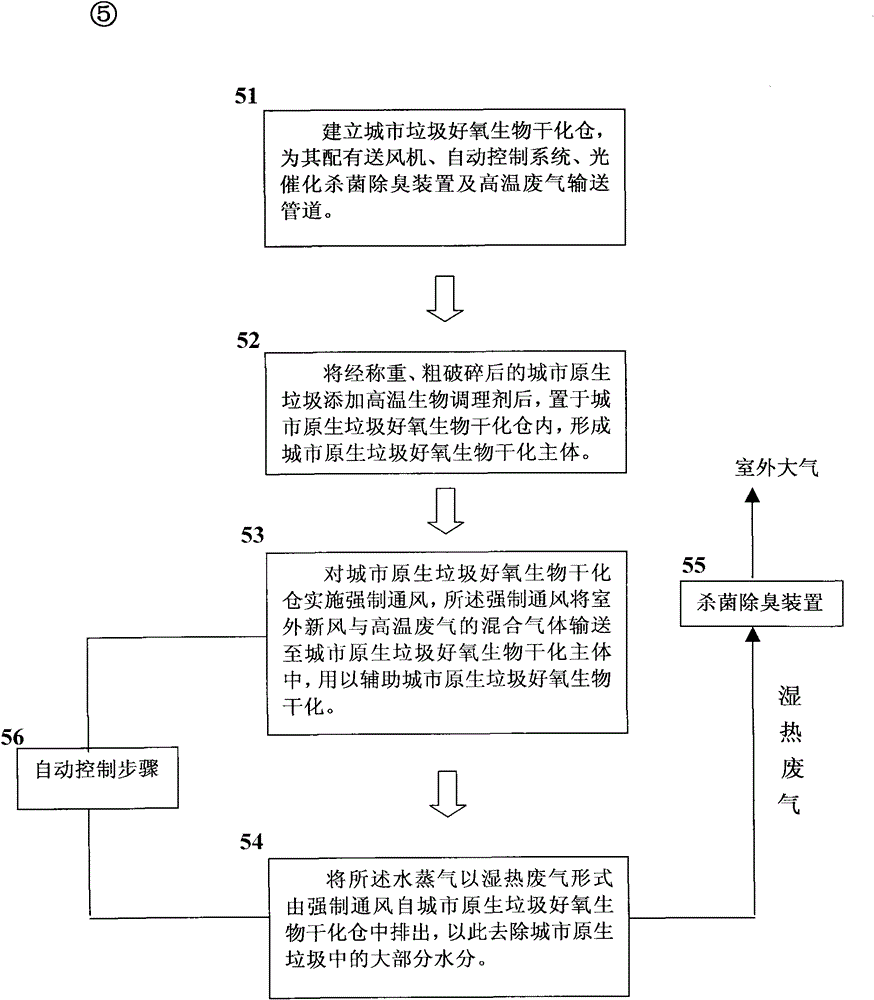

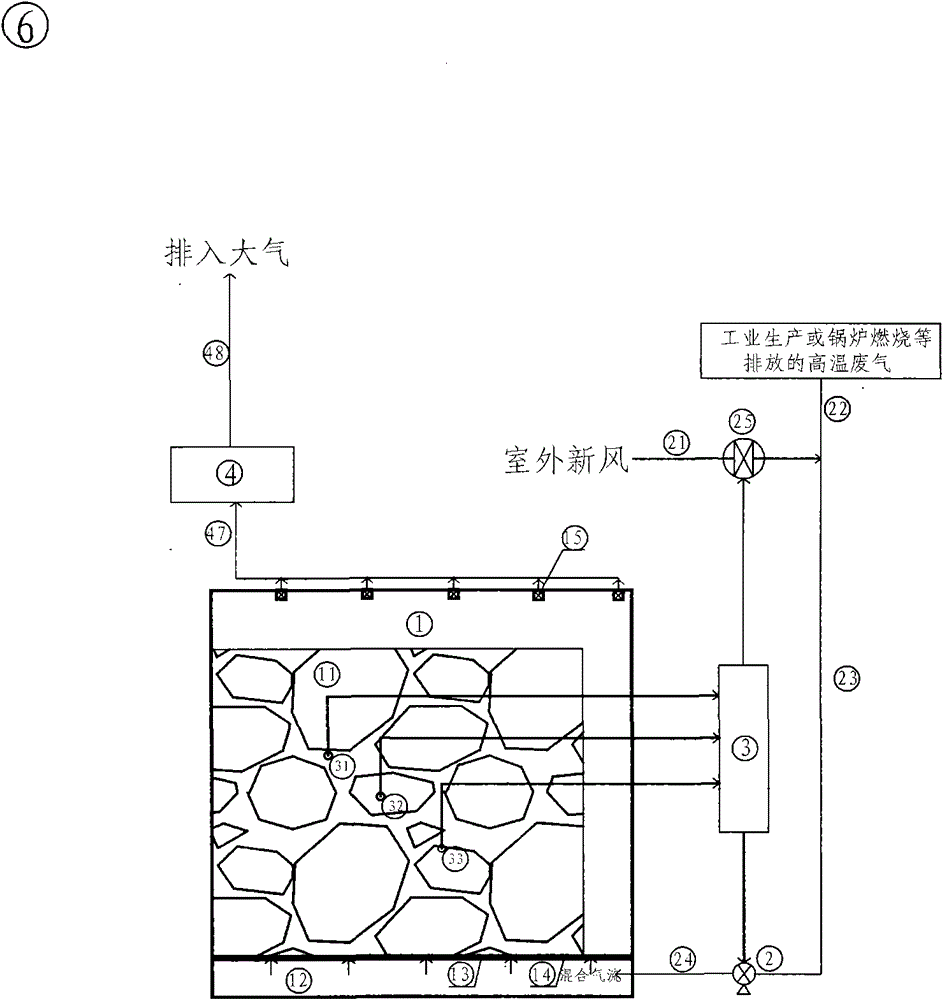

[0040] see figure 1 Shown is a schematic diagram of an embodiment of the process flow of a high-temperature waste gas aerobic biological drying method for municipal primary waste used in the present invention.

[0041] The high-temperature waste gas aerobic biological drying method 5 of urban primary garbage includes the following six steps 51-56:

[0042] Firstly, in step 51, an aerobic biological drying warehouse for urban primary garbage is established, which is equipped with a blower, an automatic control system, a photocatalytic sterilizing and deodorizing device, and a high-temperature waste gas delivery pipeline; the high-temperature waste gas refers to industrial production or boiler combustion process Exhaust gas with a temperature higher than 70°C.

[0043] Then proceed to step 52, adding the high-temperature biological conditioner to the weighed and roughly crushed urban primary waste, and then placing it in the urban primary waste aerobic biological drying bin to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com