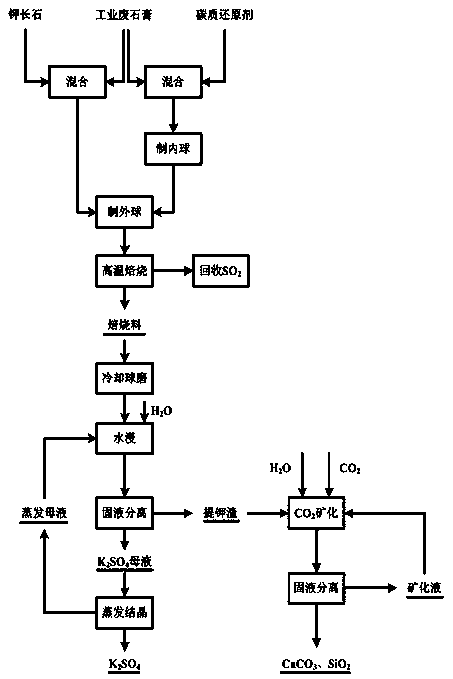

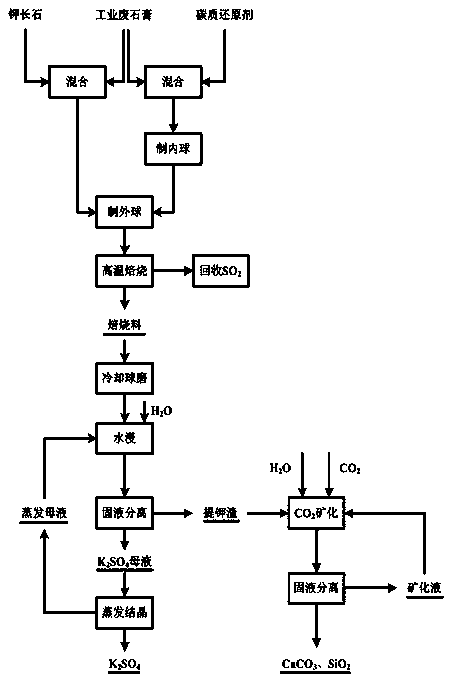

A method of mineralizing co by using potassium feldspar-waste gypsum 2 Industrial process for the co-production of potassium sulfate and sulfur dioxide

A sulfur dioxide, industrial method technology, applied in chemical instruments and methods, alkali metal sulfite/sulfite, solid waste removal and other directions, can solve problems such as burning loss, achieve simple process operation, reduce temperature, and be easy to popularize effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Put titanium gypsum with a calcium sulfate content of 70 wt.% and a particle size of 75 μm and pulverized coal with a fixed carbon content of 60 wt.% and a particle size of 200 μm into a planetary wheel mixer to control the calcium sulfate and carbon. The molar ratio is 1:1, and the uniformly mixed material is fed into 1 through the screw propeller. # silo;

[0029] (2) The potassium feldspar with a potassium oxide content of 8 wt.% was crushed and ground to 75um, and the titanium gypsum was put into a planetary wheel mixer, and the mass ratio of potassium feldspar to calcium sulfate was controlled to be 1:1. The uniformly mixed material is fed into 2 by the screw propeller # silo;

[0030] (3) put the mixed material obtained in step (1) into the inner spherical disc pelletizing machine, and simultaneously spray water to make pellets;

[0031] (4) Screen the inner ball obtained in step (3), screen out the inner ball with a diameter of 4mm and put it into the oute...

Embodiment 2

[0040] (1) The calcium sulfate content of 83 wt.%, the particle size of 35 μm phosphogypsum and the fixed carbon content of 65 wt.% and the particle size of 100 μm are put into the planetary wheel mixer, and the molar ratio of calcium sulfate to carbon is controlled to be 1:2, the evenly mixed material is fed into 1 through the screw propeller. # silo;

[0041] (2) The potassium feldspar with a potassium oxide content of 10 wt.% was crushed and ground to 150um and the desulfurized gypsum was put into the planetary wheel mill mixer, and the mass ratio of potassium feldspar to calcium sulfate was controlled to be 1:2. The uniformly mixed material is fed into 2 by the screw propeller # silo;

[0042] (3) put the mixed material obtained in step (1) into the inner spherical disc pelletizing machine, and simultaneously spray water to make pellets;

[0043] (4) Screen the inner ball obtained in step (3), screen out the inner ball with a diameter of 6 mm and put it into the outer b...

Embodiment 3

[0052] (1) Desulfurized gypsum with a calcium sulfate content of 95 wt.% and a particle size of 75 μm and coke with a fixed carbon content of 80 wt.% and a particle size of 150 μm were put into a planetary wheel mixer, and the molar ratio of calcium sulfate to carbon was controlled to be 1. :3, the mixed material is fed into 1 through the screw propeller # silo;

[0053] (2) The potassium feldspar with a potassium oxide content of 13 wt.% was crushed and ground to 150um and the desulfurized gypsum was put into the planetary wheel mixer, and the mass ratio of potassium feldspar to calcium sulfate was controlled to be 1:3. The uniformly mixed material is fed into 2 by the screw propeller # silo;

[0054] (3) put the mixed material obtained in step (1) into the inner spherical disc pelletizing machine, and simultaneously spray water to make pellets;

[0055] (4) Screen the inner ball obtained in step (3), screen out the inner ball with a diameter of 5mm and put it into the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com