Zircon sand rapid alkali-fusion decomposition device

A zircon sand, rapid technology, applied in the direction of solid separation, zirconium compound, filter and sieve, etc., can solve the problems of low fusion degree of zircon sand and lye, incomplete decomposition, etc., achieve better heating effect, improve product quality The effect of low quality and energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

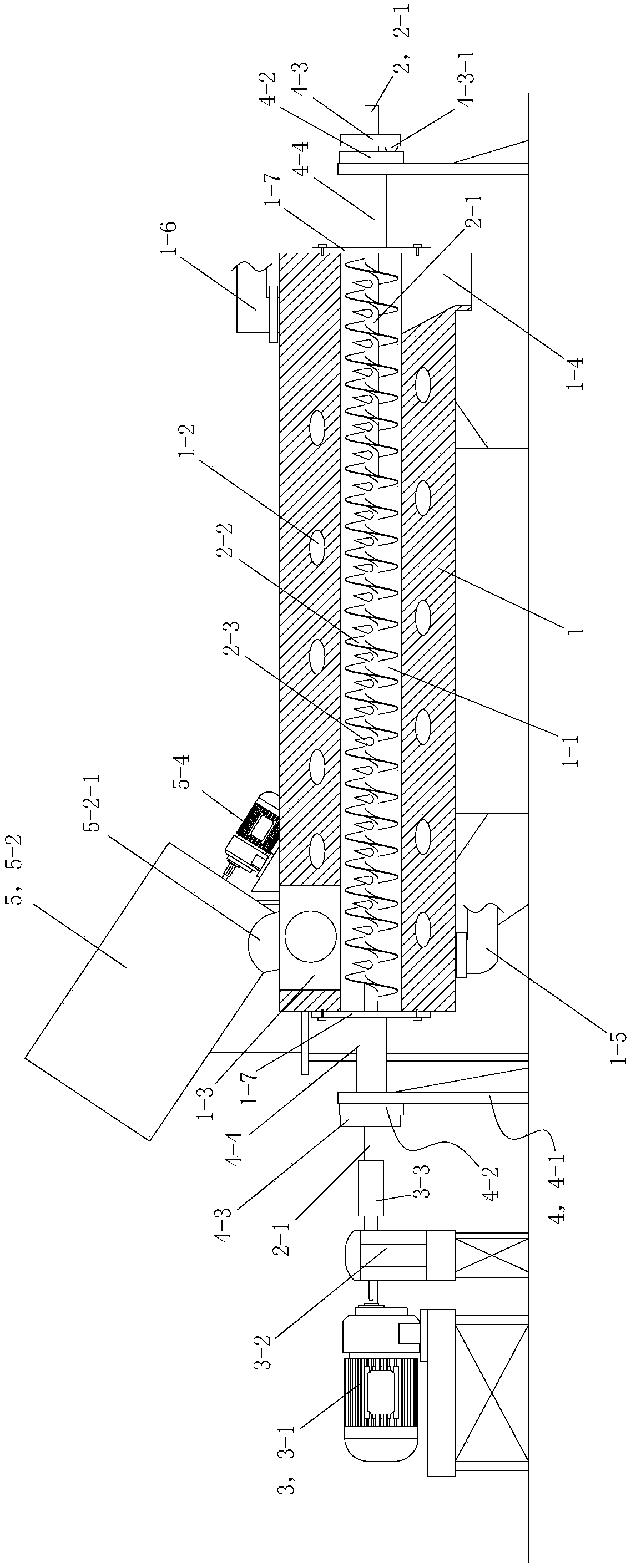

[0054] See Figure 1 to Figure 9 , the zircon sand rapid alkali fusion decomposition device of the present embodiment comprises:

[0055] Stirring chamber 1 has a stirring chamber 1-1 inside, and an oil passage 1-2 for heating the stirring chamber 1-1 is arranged on the inner wall;

[0056] The spiral stirring roller 2 is arranged in the stirring chamber 1-1 of the stirring chamber 1;

[0057] The driving mechanism 3 is used to drive the spiral stirring roller 2 to rotate for stirring;

[0058] The vibration generating mechanism 4 is used to reciprocate the axial displacement of the spiral stirring roller 2 to vibrate the material in the stirring chamber 1-1 when the spiral stirring roller 2 rotates;

[0059] The zircon sand screening mechanism 5 is used to screen the particle size of the material, and the output end of the zircon sand screening mechanism 5 communicates with the mixing chamber 1-1 of the mixing chamber 1 .

[0060] The mixing chamber 1 is provided with a ma...

Embodiment 2

[0075] This embodiment is basically the same as Embodiment 1, the difference is:

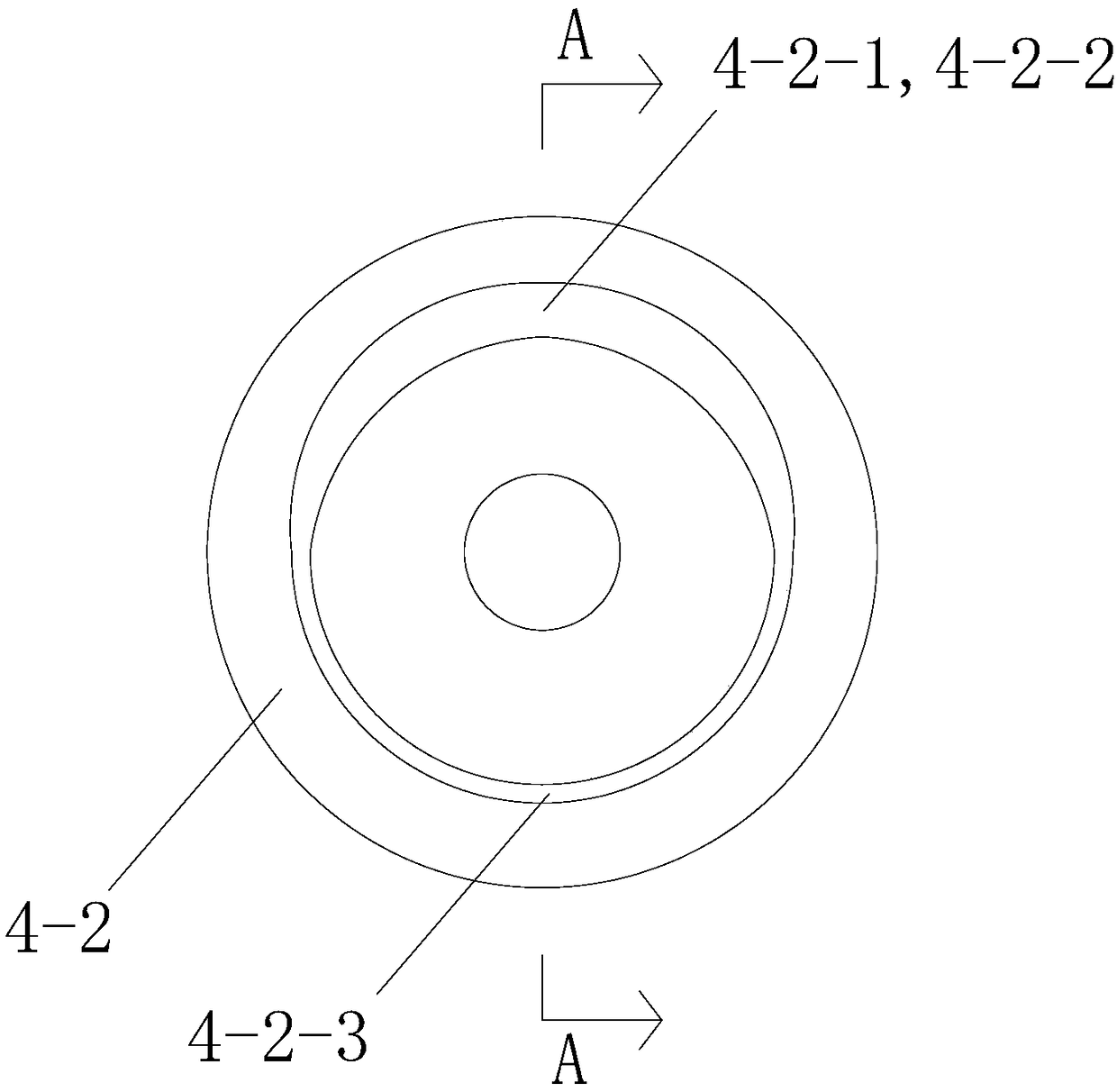

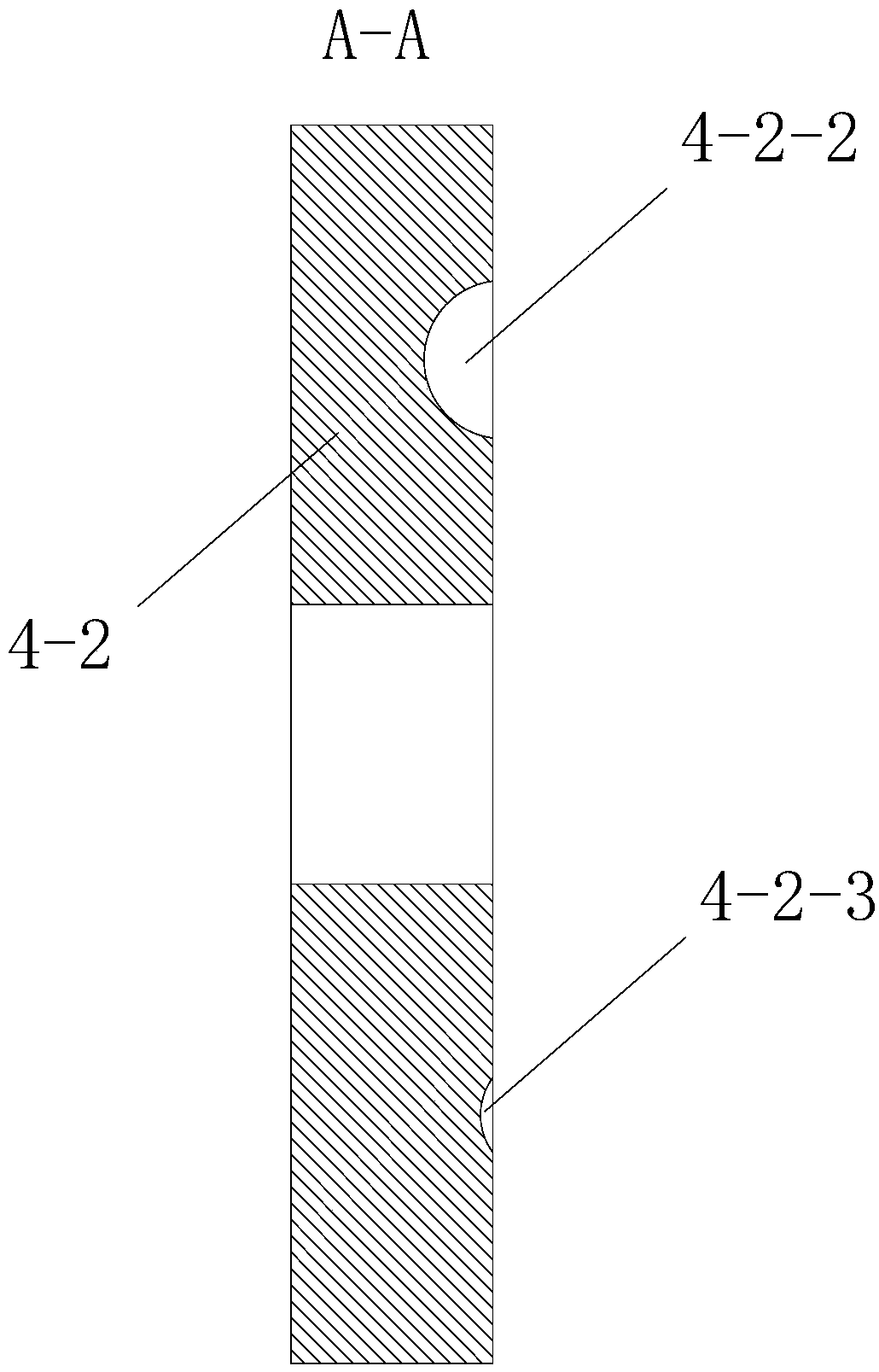

[0076] See Figure 10 with Figure 11 A hemispherical groove 4-3-2 is provided on one end surface of the driving piece 4-3 of the vibration generating mechanism 4 facing the fixed piece 4-2. The driving part is steel ball 4-3-3. The steel ball 4-3-3 is located on the hemispherical groove 4-3-2, and cooperates with the annular chute 4-2-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com