Method for recovering glass substrates of liquid crystal display screen

A liquid crystal display and glass substrate technology, applied in the field of waste recycling, to save time and cost, easy to industrialize, and simple to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Detachment: detach the three glass substrates of the disassembled liquid crystal display panel;

[0022] Classification: Classify glass substrates into glass substrates containing resin black matrix film, glass substrates containing chrome black matrix film and glass substrates without matrix film;

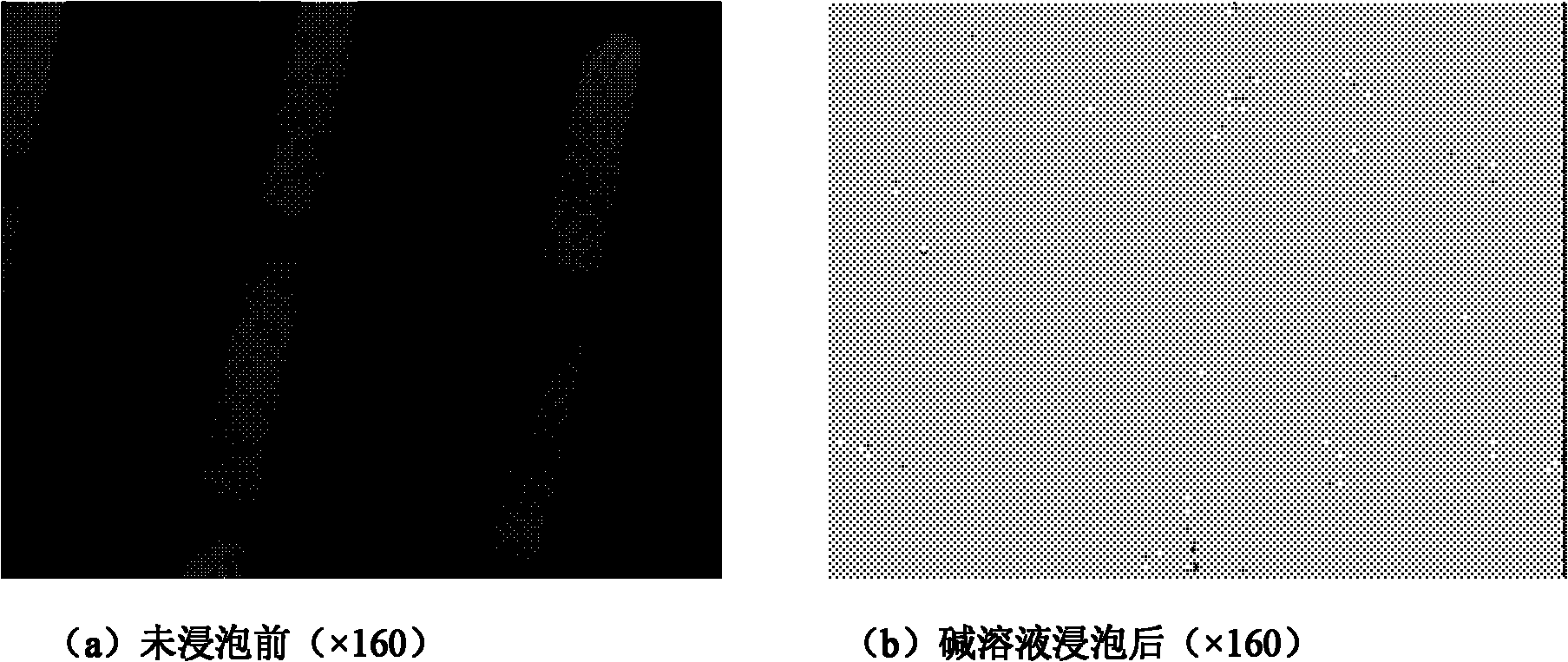

[0023] Soak the detached glass substrate containing the resin black matrix film in a 10% sodium hydroxide solution for 28 minutes, stir while heating, and control the reaction temperature to 90°C. The changes in surface morphology were observed under an optical metallographic microscope. figure 1 .

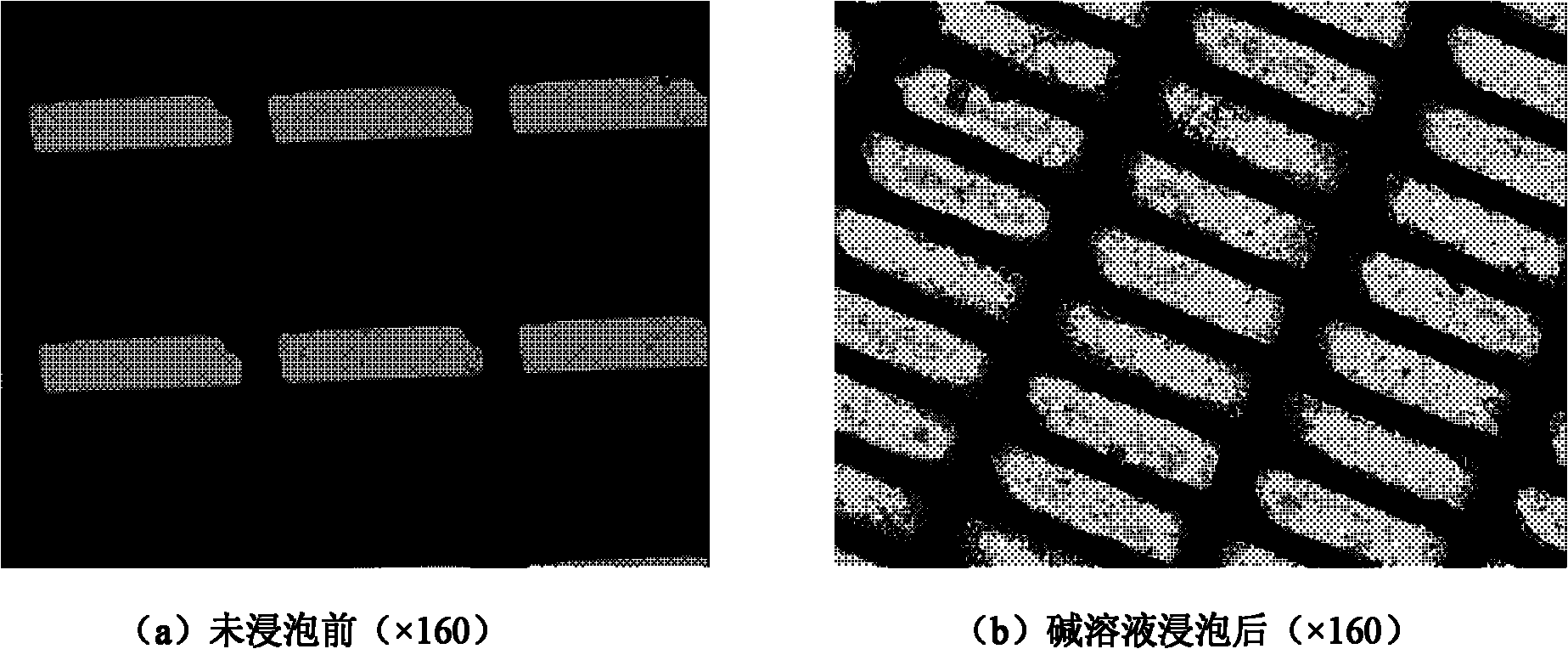

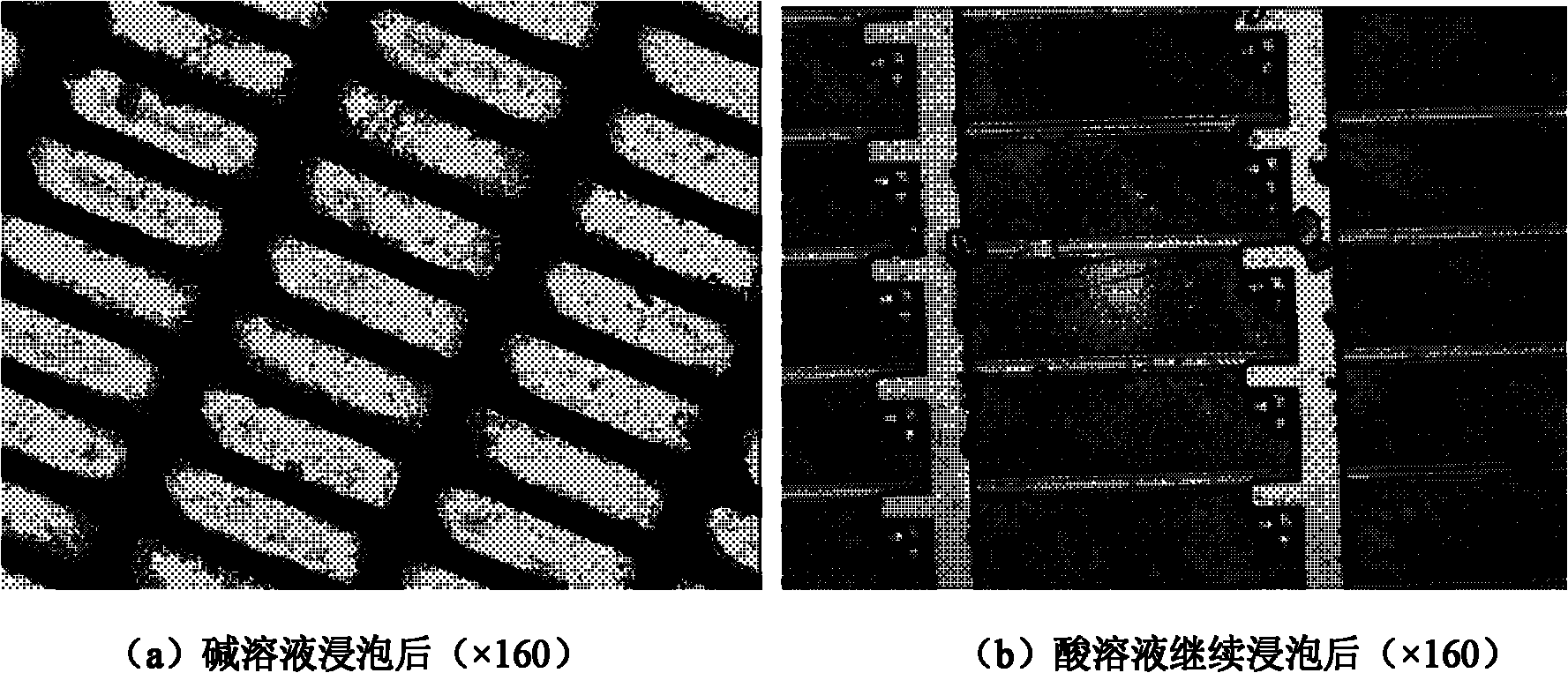

[0024] Soak the detached glass substrate containing chromium black matrix film with 15% sodium hydroxide solution, remove the polymer film for 56 minutes, stir while heating, control the reaction temperature to 90 ° C, and then use 10% concentration Continue soaking in hydrofluoric acid solution, and react for 60 minutes at room temperature to remove the metal film on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com