Comprehensive treatment method for zinc hydrometallurgy high-germanium raw material and calcium sulfite residues

A technology of calcium sulfite and zinc hydrometallurgy, applied in the field of hydrometallurgy, can solve problems such as rising production costs, unrealistic economic and social benefits, and high environmental risks, and achieve the effect of large environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

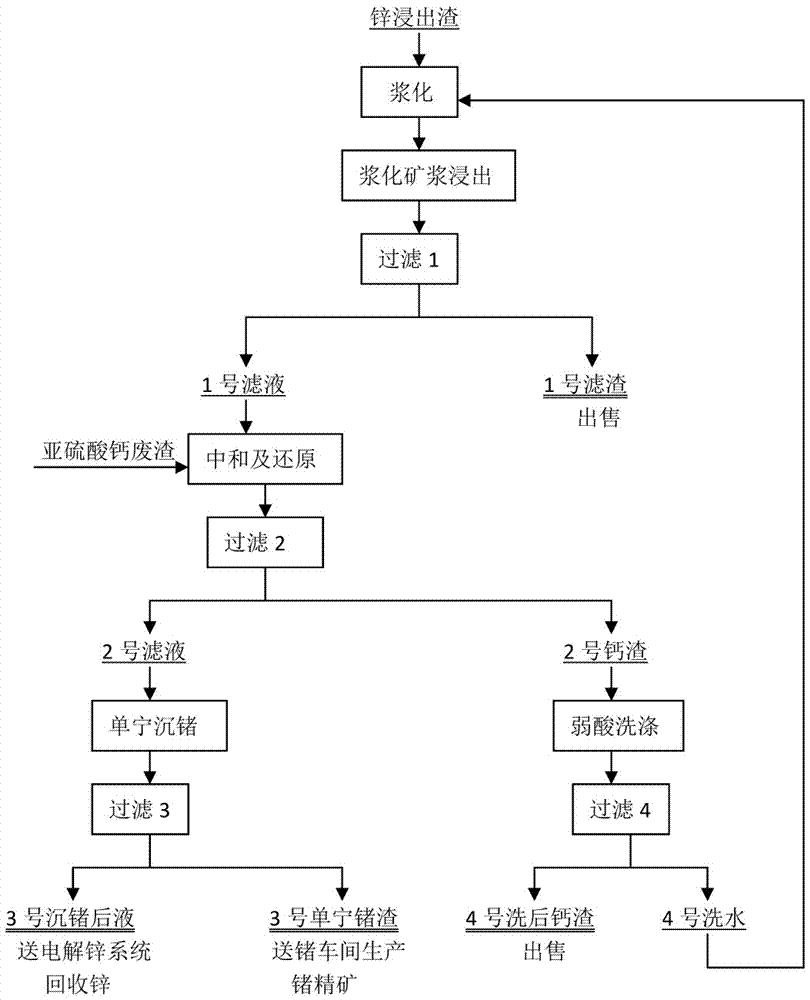

Method used

Image

Examples

Embodiment 1

[0035]Take the zinc leaching slag of high-germanium raw material zinc leached from the wet method of Zinc Electric Co., Ltd. in Yunnan Luoping and the calcium sulfite waste slag produced by the sulfur dioxide tail gas absorption workshop of the rotary kiln respectively, dry and shrink the samples to prepare 20000.00 grams each, and pass through an 80-mesh sieve for use , the main components of the high-germanium raw material zinc leaching residue are: zinc 9.66wt%, iron 13.12wt%, lead 3.25wt%, germanium 0.0216wt%, silver 0.0019wt%;

[0036] (1) Slurry of zinc leaching slag: Use industrial water as pre-liquid, take 60 liters, add 15,000.0 g of zinc leaching slag, a high-germanium raw material, for slurrying, the slurrying time is 40 minutes, stir the slurry evenly, and then proceed to the next step of slurrying chemical pulp leaching;

[0037] (2) Slurry leaching: Use concentrated sulfuric acid to adjust the initial acid 140g / l to the pulp after stirring and slurrying evenly, c...

Embodiment 2

[0047] Take the zinc leaching slag of high-germanium raw material zinc leached from the wet method of Zinc Electric Co., Ltd. in Yunnan Luoping and the calcium sulfite waste slag produced by the sulfur dioxide tail gas absorption workshop of the rotary kiln respectively, dry and shrink the samples to prepare 20000.00 grams each, and pass through an 80-mesh sieve for use , the main components of the high-germanium raw material zinc leaching residue are: zinc 14.86wt%, iron 17.89wt%, lead 4.88wt%, germanium 0.028wt%, silver 0.0047wt%;

[0048] (1) Slurry of zinc leaching slag: use industrial water as pre-liquid, take 65 liters, add 13000.0 g of high germanium raw material zinc leaching slag for slurrying, slurrying time is 45 minutes, stir and slurry evenly before proceeding to the next step of slurrying chemical pulp leaching;

[0049] (2) Slurry leaching: Use concentrated sulfuric acid to adjust the initial acidity to 150g / l for the evenly stirred pulp, control the process tem...

Embodiment 3

[0059] The zinc leaching slag of high-germanium raw material zinc from hydro-smelting of Yunnan Luoping Zinc Electric Co., Ltd. and the calcium sulfite waste slag produced by the sulfur dioxide tail gas absorption workshop of the rotary kiln were respectively taken, dried and divided to prepare samples and passed through an 80-mesh sieve for use. The main components of germanium raw material zinc leaching residue are: zinc 9.5wt%, germanium 0.020wt%, lead 3.0wt%, iron 13.0wt%, silver 0.002wt%;

[0060] (1) Slurry of zinc leaching slag: Slurry the zinc leaching slag with a slurry liquid at a liquid-solid ratio of 4:1 for 40 minutes, stir and slurry evenly before use;

[0061] (2) Slurry leaching: Use concentrated sulfuric acid to adjust the initial acid 140g / l to the evenly stirred pulp, control the process temperature at 93°C, leaching time for 4.0 hours, and filter 1 after the final acid reaches 50g / l. Output No. 1 filter residue and No. 1 filtrate, No. 1 filter residue can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com