Method and device for reinforcing oil bubble column floatation process of low-order coal

A flotation process, kerosene technology, applied in flotation, solid separation, etc., can solve the problems of poor selectivity, high collector consumption, etc., achieve good surface properties, good resource recovery, and increase economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

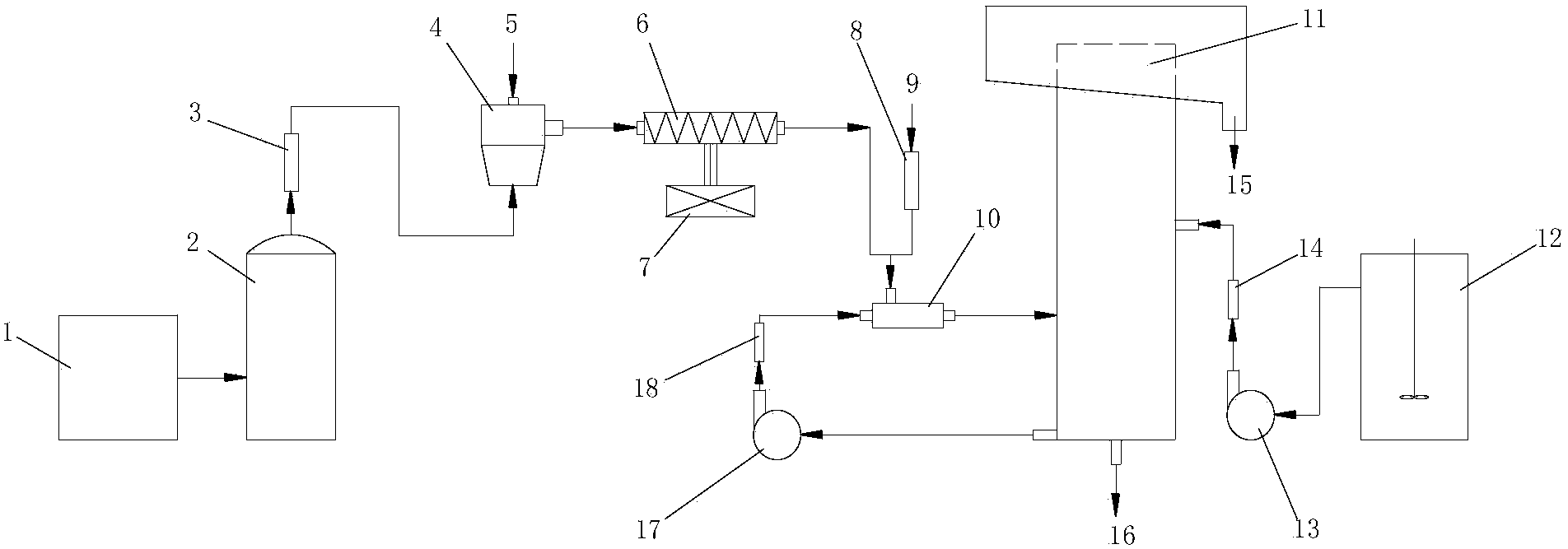

[0017] Embodiment 1: The strengthening method is as follows: the air compressor 1 compresses the dry air sucked and stores it in the air storage tank 2, and controls the output airflow flow through the gas flow meter I3; Form In the atomizer 4, the hydrocarbon oil collector 5 mixed with a certain amount of surfactant is atomized into a large number of oil mist airflows with a particle size of 1-50 μm; The inner cavity of the evaporator 6 is heated and controlled at the boiling point temperature of hydrocarbon oil; the oil-containing evaporated gas and air enter the flotation column 11 through the gas input end of the bubble generator 10, and when the gas filling amount required for column flotation is insufficient, the gas is passed through The flow meter II8 adjusts the flow rate of the air 9 required; after the low-rank coal is pre-wetted at a certain concentration in the mixing tank 12, it is pumped into the flotation column 11 through the feed pump 13, and is discharged thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com