Method of treating hard-degrading high concentrated organic wastewater

A technology of organic wastewater and treatment methods, applied in the directions of oxidized water/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem that the effluent cannot truly meet the discharge standard, the efficiency of high-concentration organic wastewater is not high, and the toxic compounds are difficult to remove. and other problems, to achieve the effect of realizing environmental and social benefits, improving biodegradability, and fully reaching the standard of effluent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Fenton oxidation treatment of 2-naphthol production wastewater.

[0037] The water sample is self-prepared 2-naphthol simulated wastewater, and the water quality components are shown in Table 1

[0038] Table 1 Water quality of 2-naphthol simulated wastewater

[0039] COD (mg / L)

[0040] After 40 minutes of treatment according to the Fenton oxidation reaction conditions described in the manual, the COD concentration of the reactor effluent is 4000-5000 mg / L.

Embodiment 2

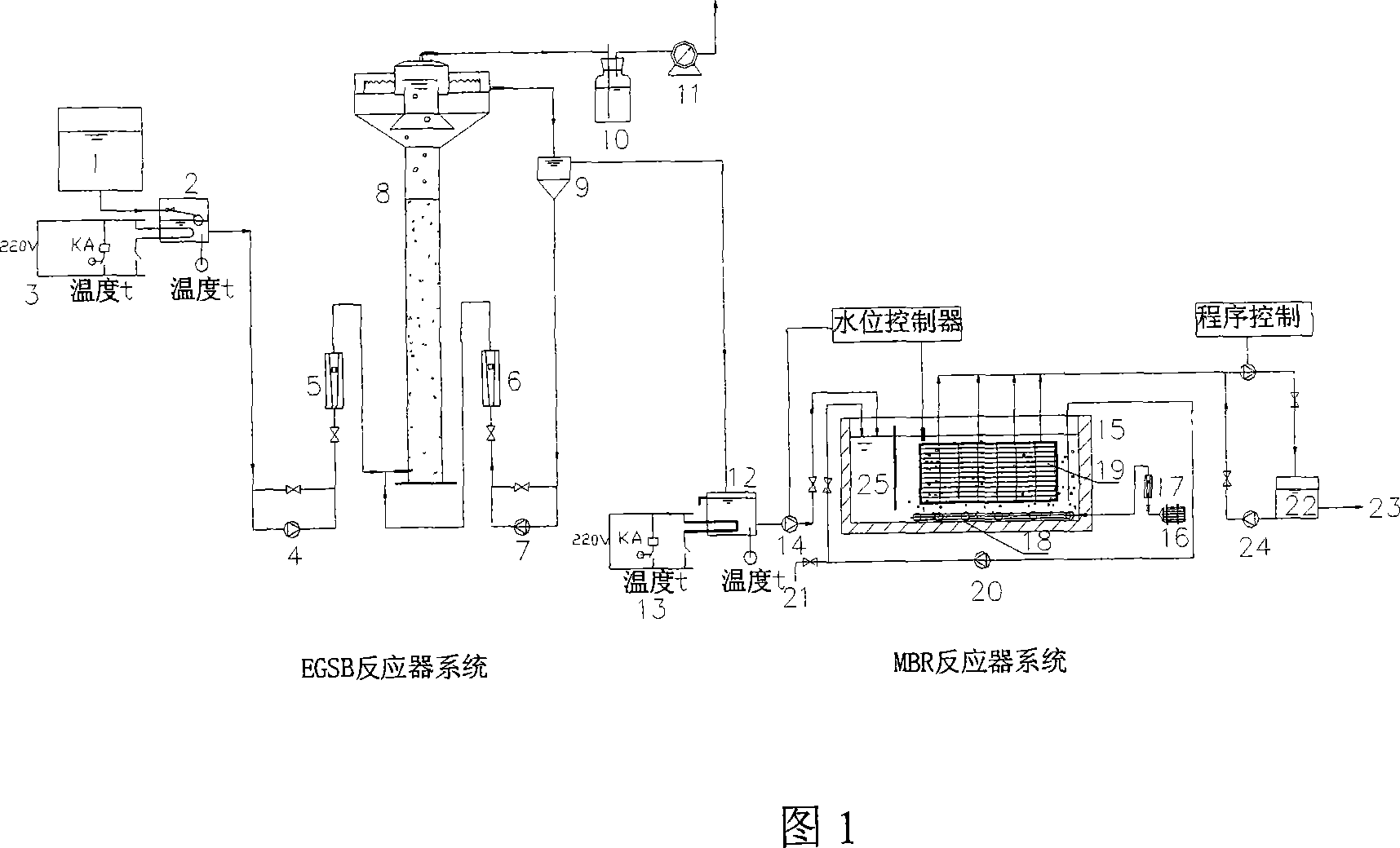

[0041] Example 2 EGSB reactor treatment of the Fenton oxidation effluent of Example 1

[0042] Table 2 Influent water quality of EGSB reactor

[0043] source of waste water

[0044] The COD concentration of the reactor effluent is 500-800mg / L.

Embodiment 3

[0045] Example 3 Integrated MBR reactor to treat the effluent of Example 2

[0046] Table 3 Influent Water Quality of Membrane Bioreactor

[0047] source of waste water

[0048] The COD concentration of the reactor effluent is 50-90mg / L.

[0049] The total COD removal of the FOP-EGSB-MBR system is shown in Table 4.

[0050] Table 4 COD removal of FOP-EGSB-MBR system and different processing units

[0051] project

[0052] Note: The unit is mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com