Patents

Literature

53results about How to "Pore structure high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose composite microsphere and preparation method thereof

InactiveCN102553545ALarge specific surface areaHigh porosityOther chemical processesAlkali metal oxides/hydroxidesSolventUrea

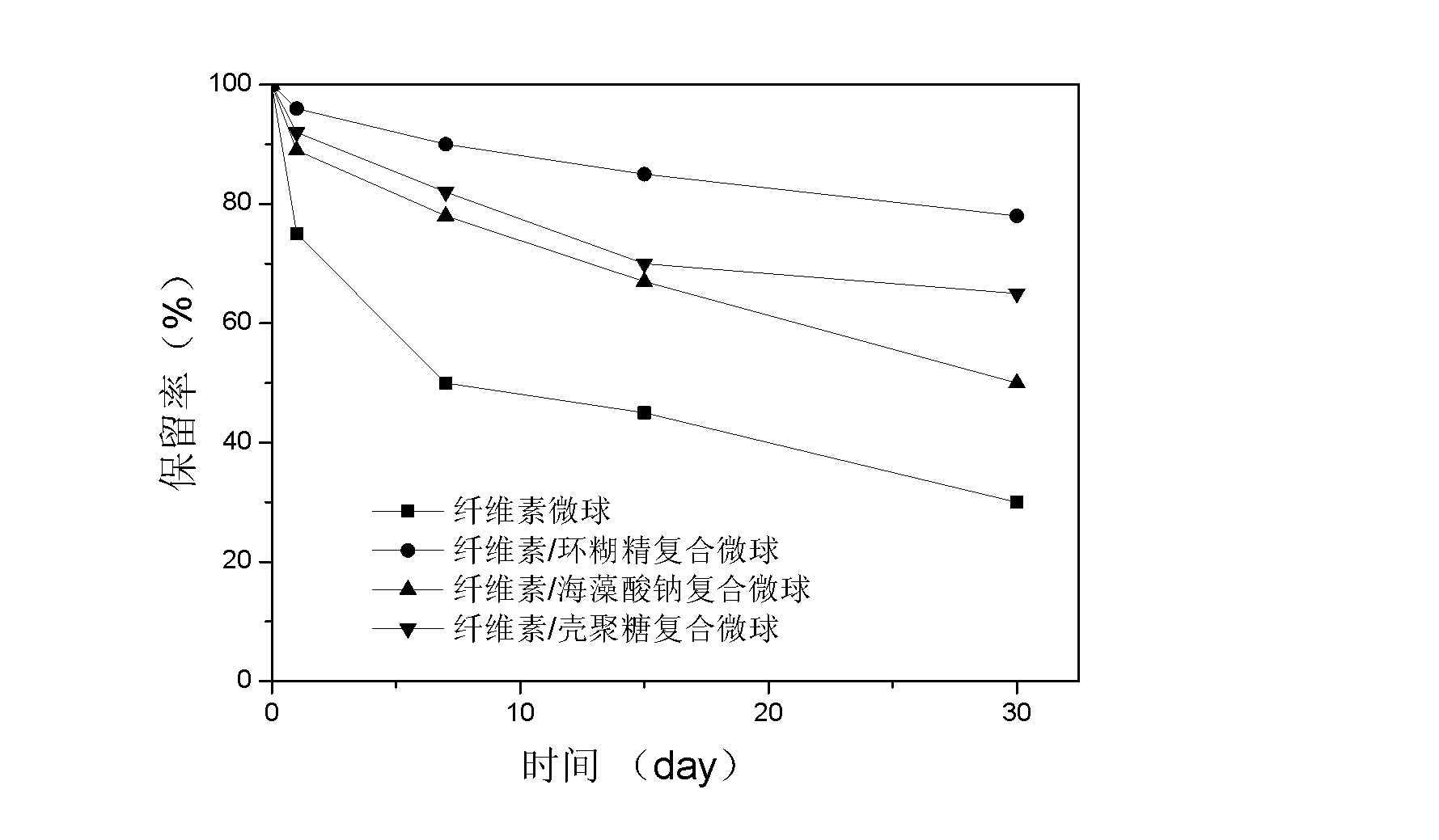

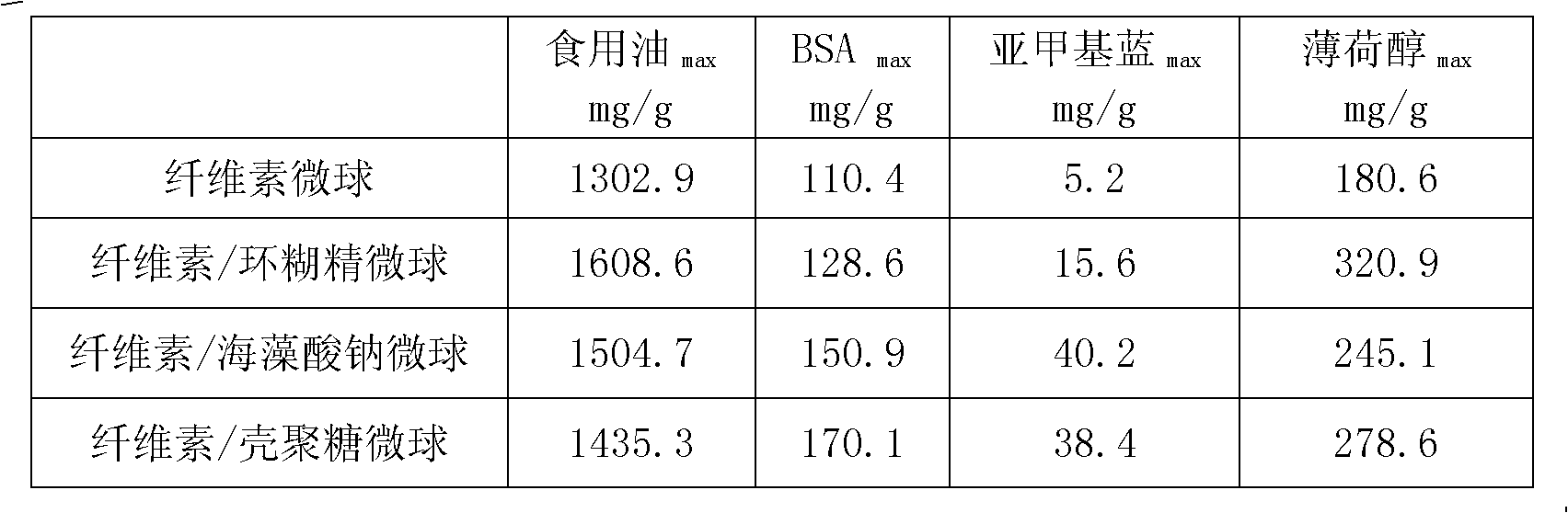

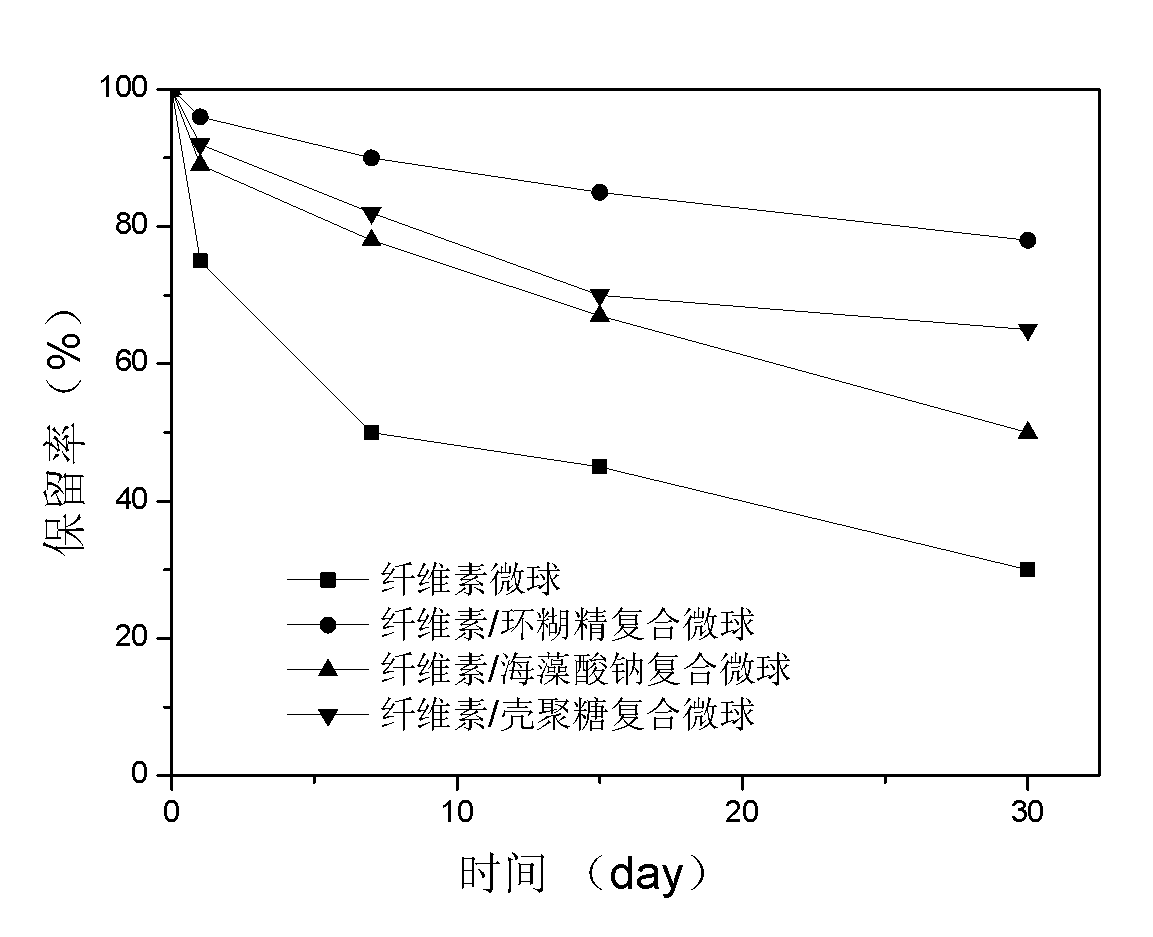

The invention discloses a cellulose composite microsphere, a preparation method thereof and application. The particle size of the cellulose composite microsphere is 1mum-1200mum, the specific surface area of the cellulose composite microsphere is 100m<2> / g-500m<2> / g, and the aperture of the cellulose composite microsphere is 200nm-900nm. The preparation method comprises the following steps of: preparing a mixture solution of cellulose and a composite material by using the cellulose as a matrix, a polymer material as composite material and a water solution of alkali / urea or alkali / thiourea as a solvent, and obtaining the cellulose composite microsphere through sol-gel phase transition and cross-linking agent cross linkage. The advantages of cellulose microsphere are reserved by the cellulose composite microsphere, and due to the adding of the composite material, new functional groups are simultaneously added for the surface of the microsphere and further decoration and modification are facilitated. An organic solvent used in the preparation method disclosed by the invention can be reused, the whole preparation technology is simple, low in time consuming, undemanding for equipment and convenient for industrial production, and the prepared cellulose composite microsphere has a good flow property and mechanical property and a wide application.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

Strong-hydrophobic porous carbon nanofiber and preparation method thereof

ActiveCN103422194AEasy to prepare and effectiveLow surface oxygen contentMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberCarbon fibers

The invention relates to strong-hydrophobic porous carbon nanofiber and a preparation method thereof, and belongs to the technical field of porous carbon fiber. The preparation method comprises the following steps: adding thermosetting phenol resin and high molecular weight linear polymers into organic solvent with two proportions to be mixed until the thermosetting phenol resin and the high molecular weight linear polymers are fully dissolved, performing electrostatic spinning on the solution to form phenolic resin fiber, and carrying out curing and carbonizing to obtain the hydrophobic porous carbon nanofiber. The porous carbon nanofiber and the preparation method have the advantages as follows: the diameter, the pore structure and the hydrophobicity of the fiber can be adjusted and controlled through the change of the proportions of the solvent, the prepared carbon nanofiber has good flexibility, a developed pore structure and strong hydrophobicity, and is more conductive to practical application.

Owner:TSINGHUA UNIV

Method for performing three-dimensional printing on biological ceramic bracket based on light-cured molding, and application

ActiveCN107296985AIncreased intensityHigh precisionAdditive manufacturing apparatusTissue regenerationThree Dimensional SizeRepair material

Owner:GUANGDONG UNIV OF TECH

Preparation method of tert-butyl peroxide

InactiveCN104557652AStrong acidPore structure highOrganic compound preparationPeroxy compound preparationPtru catalystDi-tert-butyl peroxide

The invention provides a method for preparing tert-butyl peroxide by using a heterogeneous catalyst. The method comprises the following steps: by using tert-butyl alcohol and oxydol as raw materials and an acidic ion exchange resin as a catalyst, reacting under reflux, cooling, standing, and separating to obtain an oil phase and a water phase; and washing the oil phase with alkali and water to obtain a di-tert-butyl peroxide solution (DTBP), wherein the oil phase water washing solution and water phase are the tert-butyl hydroperoxide water solution (TBHP). Since the ion exchange resin has the advantages of large pore structure, high acidity and high catalysis efficiency and the large pore structure can not be destroyed in reaction, the catalyst can be easily separated from the reaction product and can be recycled repeatedly, thereby having higher economic value. Besides, no sulfuric acid or any other strong acid is used in the production process, so the method has the advantages of low corrosion to equipment and no environment pollution, and has higher environmental benefit.

Owner:NORTHWEST NORMAL UNIVERSITY

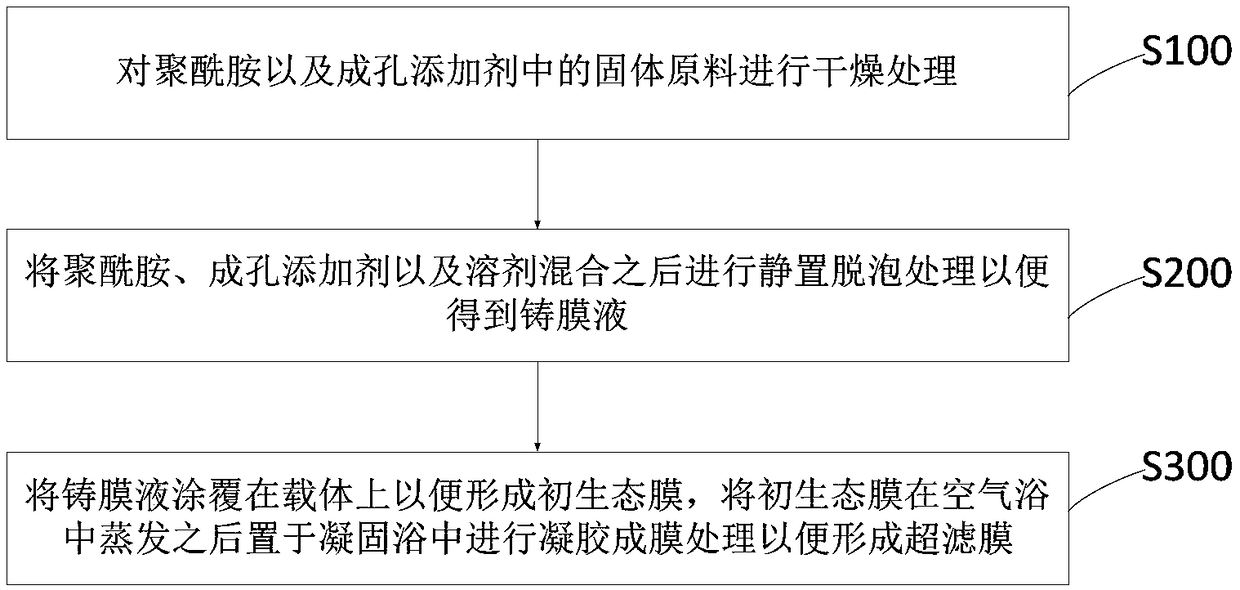

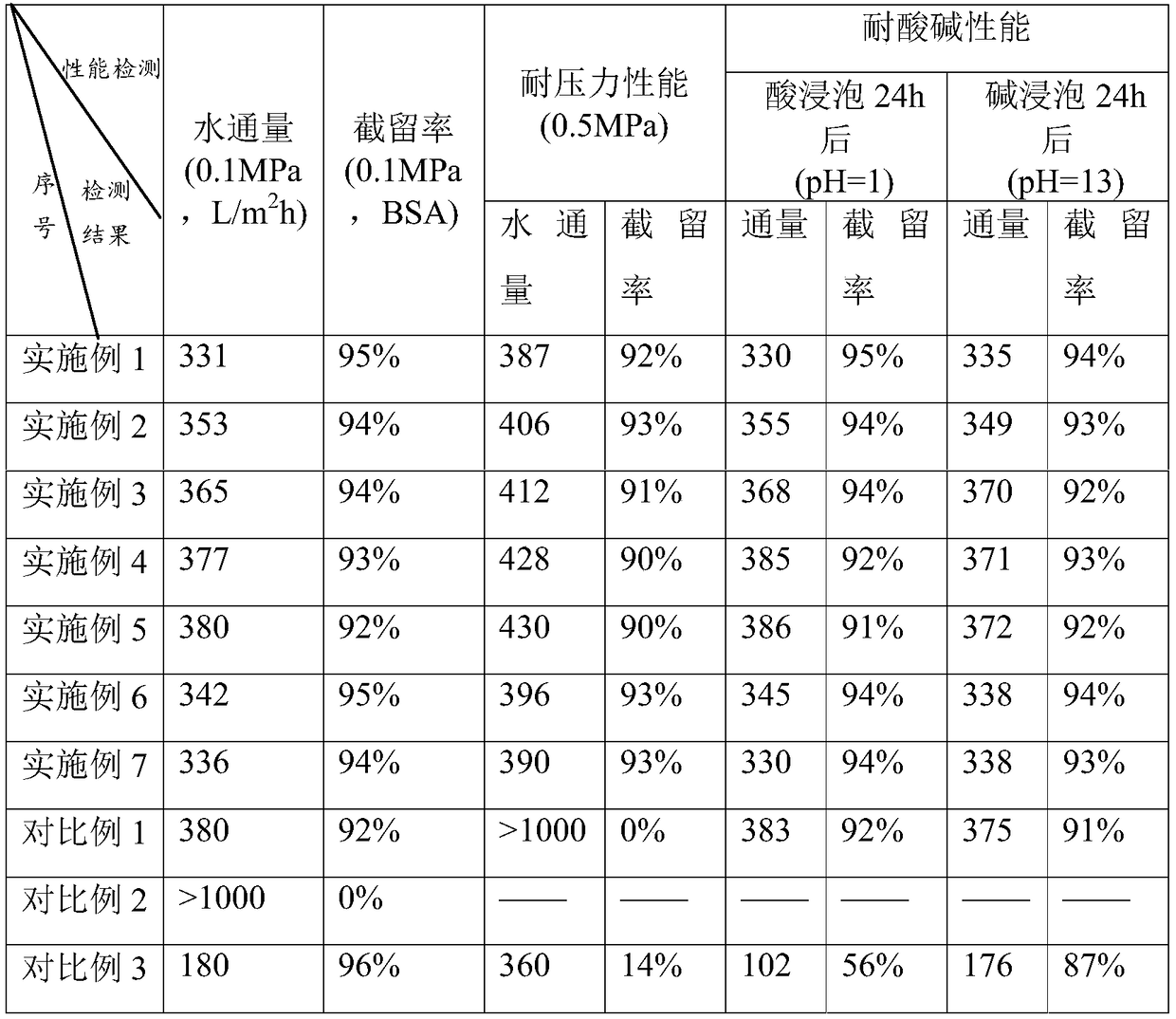

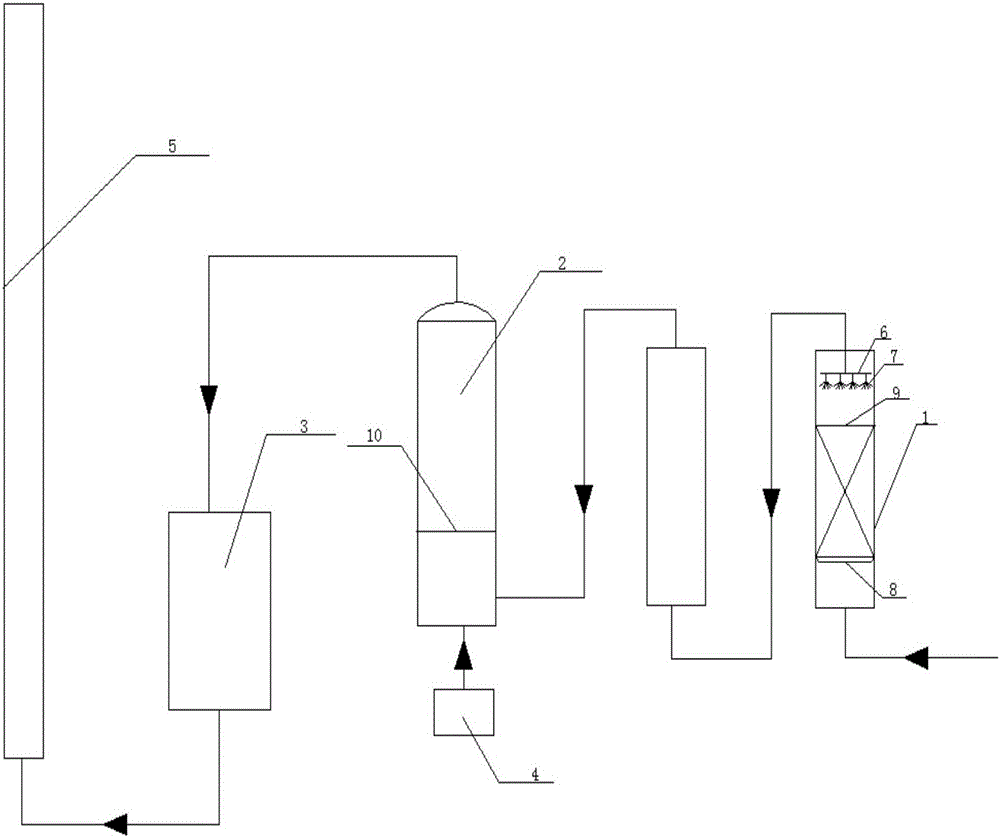

Membrane casting solution, ultrafiltration membrane and preparation method of ultrafiltration membrane

ActiveCN109012236AGood acid and alkali resistanceImprove heat resistanceUltrafiltrationWater/sewage treatment bu osmosis/dialysisUltrafiltrationPolyamide

The invention provides a membrane casting solution, an ultrafiltration membrane and a preparation method of the ultrafiltration membrane. The membrane casting solution includes: polyamide; a pore-forming additive; and a solvent, the relative molecular mass of the polyamide is 200000-300000. As a result, the viscosity of the membrane casting solution is more appropriate, and the membrane casting solution has almost no bubbles, and is conducive to film formation.

Owner:CHINA LUCKY FILM CORP

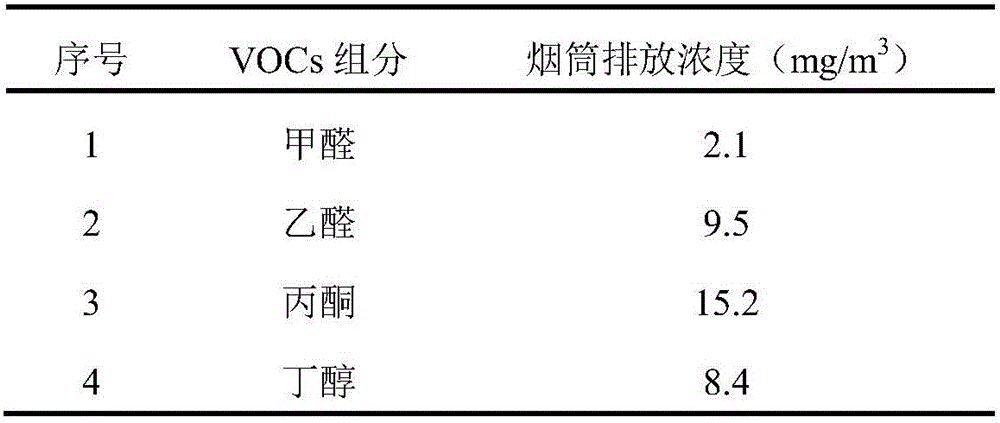

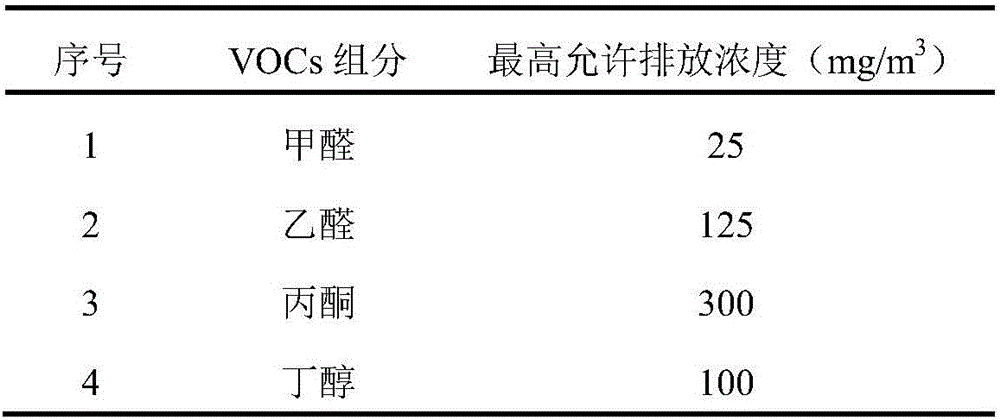

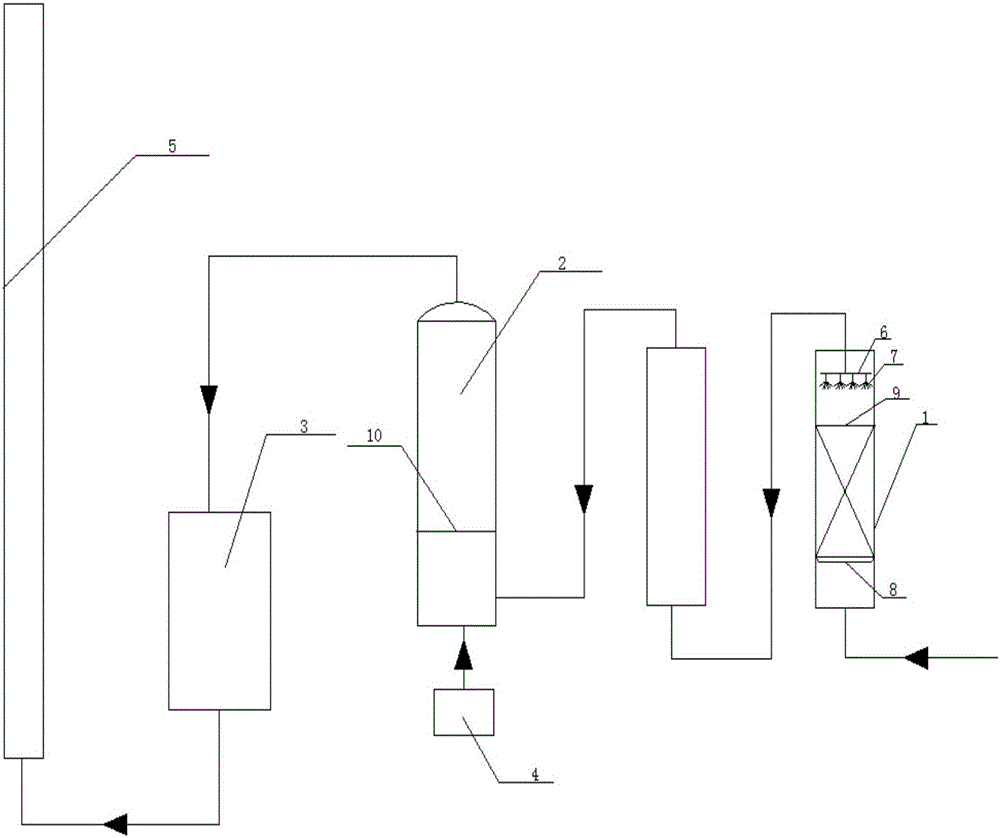

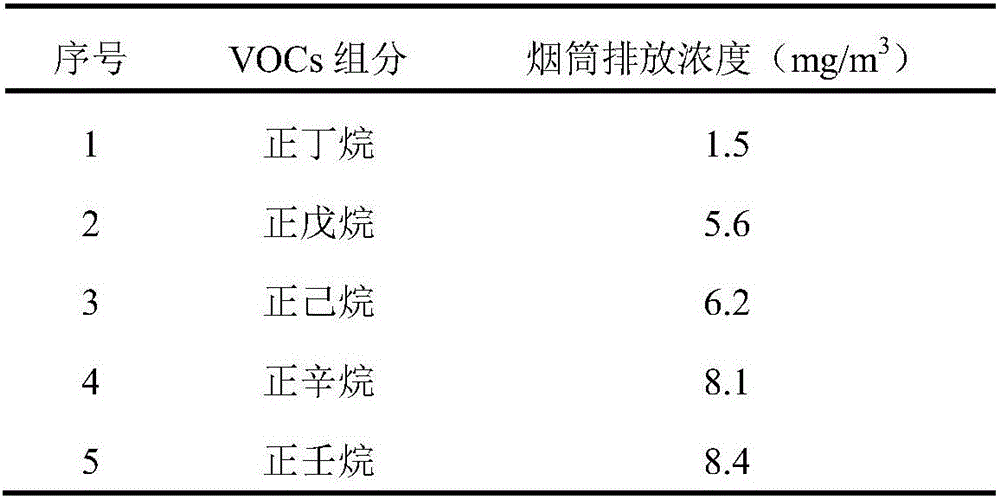

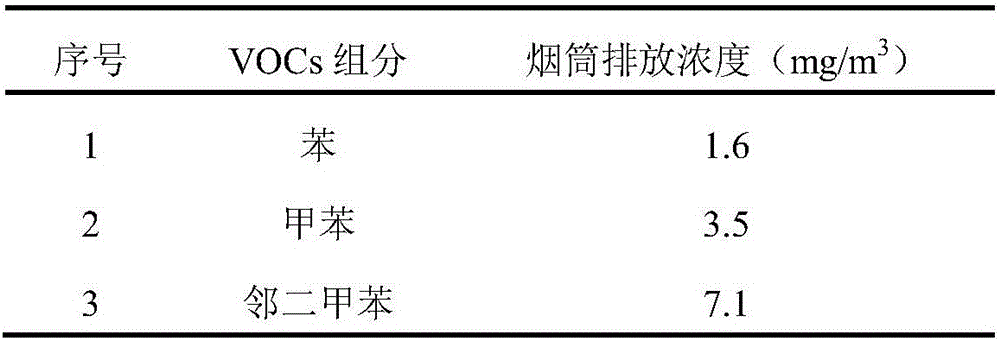

Preparation method of catalyst for catalyzing ozonization and decomposition volatile organic compounds (VOCs) at normal temperature

InactiveCN106238041AIncrease the areaPore structure highGas treatmentHeterogenous catalyst chemical elementsDecompositionRare earth

The invention discloses a preparation method of a catalyst for catalyzing ozonization and decomposition volatile organic compounds (VOCs) at normal temperature. The preparation method comprises the following steps: (1) loading nano rare earth oxide coating serving as an auxiliary agent on a catalyst carrier, coating an active component, namely nano perovskite, on the carrier, on which the rare earth oxide is loaded, calcining the catalyst carrier, on which the auxiliary agent and the active component are loaded, and forming a large amount of micropores in the surface of and inside the catalyst carrier to obtain a target catalyst with pores; and (2) fixing the prepared target catalyst on a catalytic bed layer of a catalytic oxidation tower, starting an ozone generator, introducing VOC waste gas subjected to pretreatment in the catalytic oxidation tower, and performing deep oxidation on the VOCs at normal temperature of -10 to 40 DEG C to generate non-toxic and odorless substances. By the method, the VOCs can be completely oxidized at room temperature to generate carbon dioxide and water, so the method is safe in operation and low in energy consumption.

Owner:TIANJIN UNIV

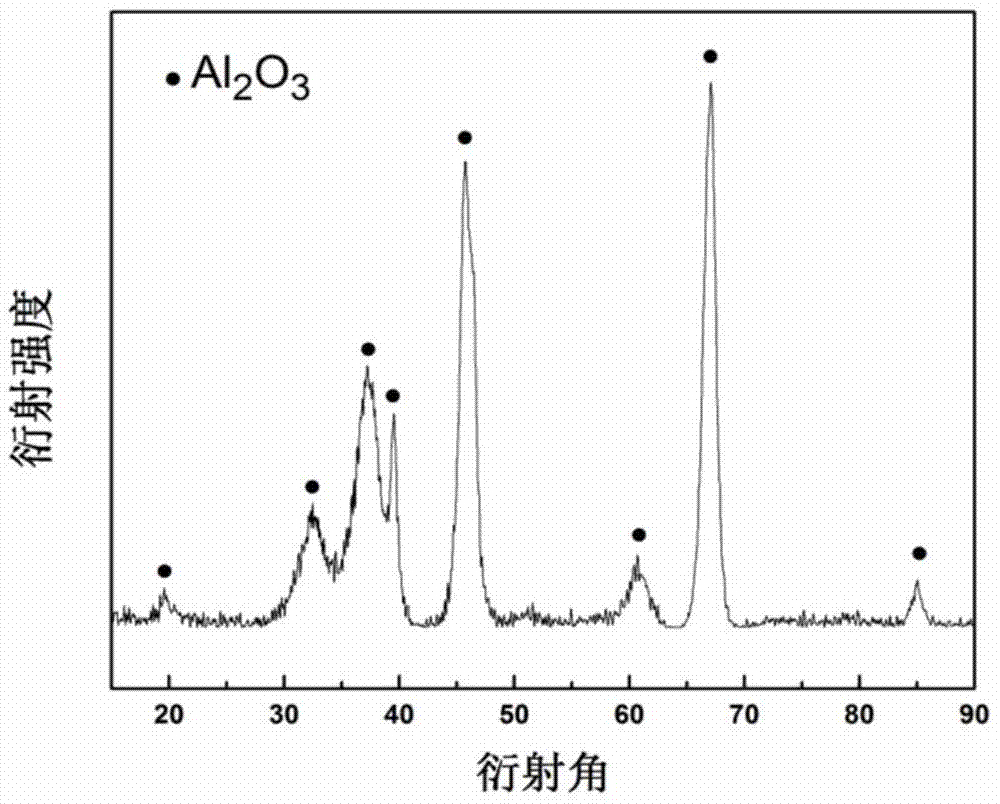

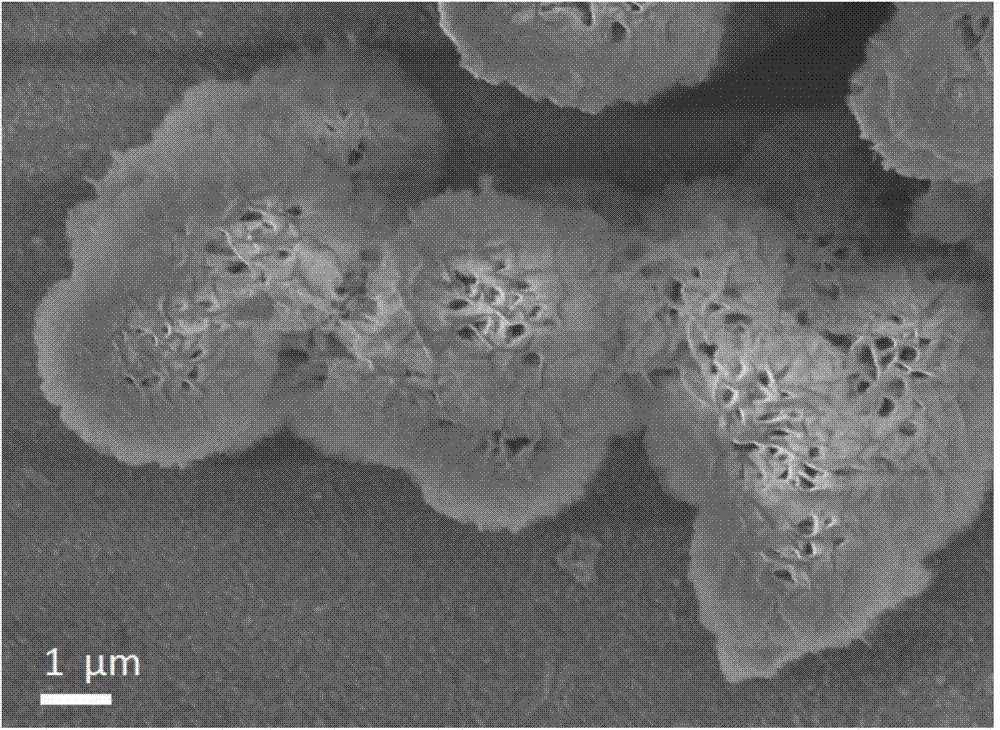

Gamma-aluminium oxide nanometer material and preparation method of nickel/gamma-aluminium oxide catalyst

ActiveCN104709932ALow equipment requirementsCheap and easy to getMetal/metal-oxides/metal-hydroxide catalystsAluminium oxides/hydroxidesNickel saltSynthesis methods

The invention discloses a synthesis method for a gamma-aluminium oxide nanometer material. The synthesis method comprises the following steps: at room temperature, adding alum and carbamide into deionized water, cooling, centrifugating and washing the sediment after the hydrothermal reaction; calcining the dried hydrothermal products to obtain the gamma-aluminium oxide nanometer material. The gamma-aluminium oxide nanometer material prepared by adopting the synthesis method has a relatively high specific surface area and a certain pore structure. The invention further provides a method for prepare a nickel / gamma-aluminium oxide catalyst by adopting the gamma-aluminium oxide nanometer material obtained by adopting the synthesis method as the raw material. The method comprises the following steps: impregnating the gamma-aluminium oxide nanometer material into a nickel salt solution in the appropriate concentration, carrying out magnetic stirring till the solvent evaporates; collecting the dried impregnating products and grinding into powders, and carrying out heating reduction in the reducing atmosphere to obtain the nickel / gamma-aluminium oxide catalyst. The catalyst can be used for catalyzing the methane dry-process reforming reaction, has a relatively high methane conversion rate, and can still maintain excellent stability and carbon formation resistance in the long-term catalytic reaction under high temperature.

Owner:SHANGHAI JIAO TONG UNIV

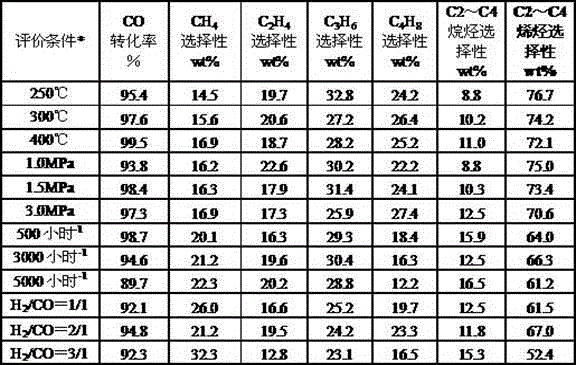

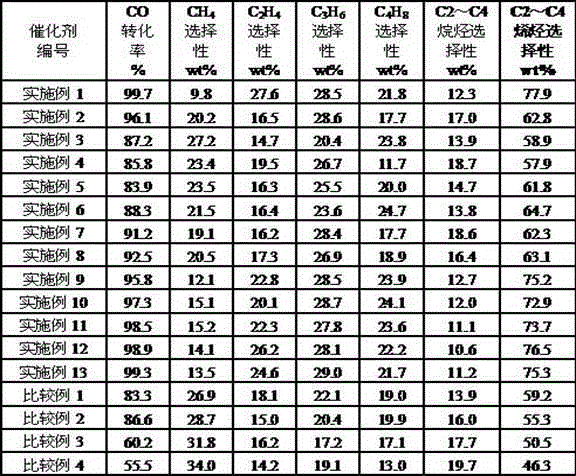

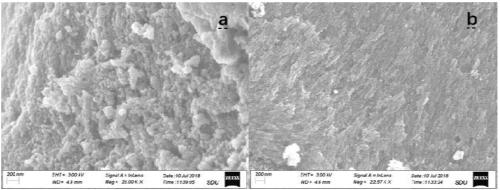

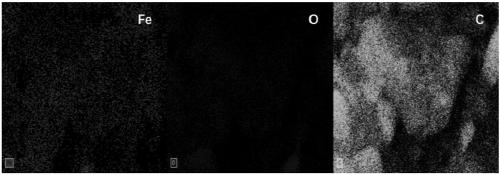

Iron-based catalyst for preparing low-carbon alkane as well as preparation method and using method of iron-based catalyst for preparing low-carbon alkane

ActiveCN104437524AHigh activityActive releaseHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsAlkanePtru catalyst

The invention relates to an iron-based catalyst for preparing low-carbon alkane as well as a preparation method and a using method of the iron-based catalyst for preparing the low-carbon alkane. The iron-based catalyst for preparing the low-carbon alkane is mainly used for solving the problems that the reaction of preparing low-carbon alkane from a synthesis gas in the prior art is low in CO conversion rate and low in low-carbon alkane selectivity, and the catalyst is poor in strength and thermal stability under a using condition. The problems are solved very well by adopting a technical scheme that the catalyst comprises the following components in parts by weight: a) 20-80 parts of an iron element or oxides thereof; b) 1-15 parts of a cobalt element and oxides thereof; c) 10-30 parts of at least one element selected from molybdenum and vanadium or oxides thereof; d) 5-20 parts of at least one element selected from magnesium and barium or oxides thereof; e) 5-20 parts of at least one element selected from tin and aluminum or oxides thereof; and f) 0.5-10 parts of a scandium element or oxides thereof. The catalyst can be used for industrial production of preparing low-carbon alkane from the synthesis gas by virtue of a one-step process.

Owner:CHINA PETROLEUM & CHEM CORP +1

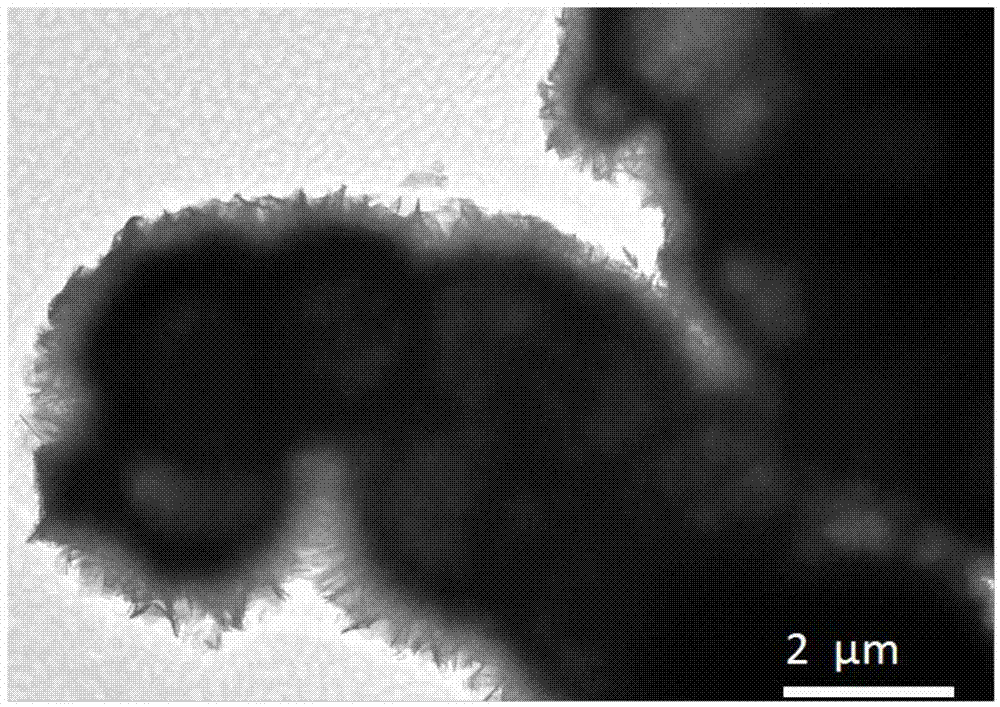

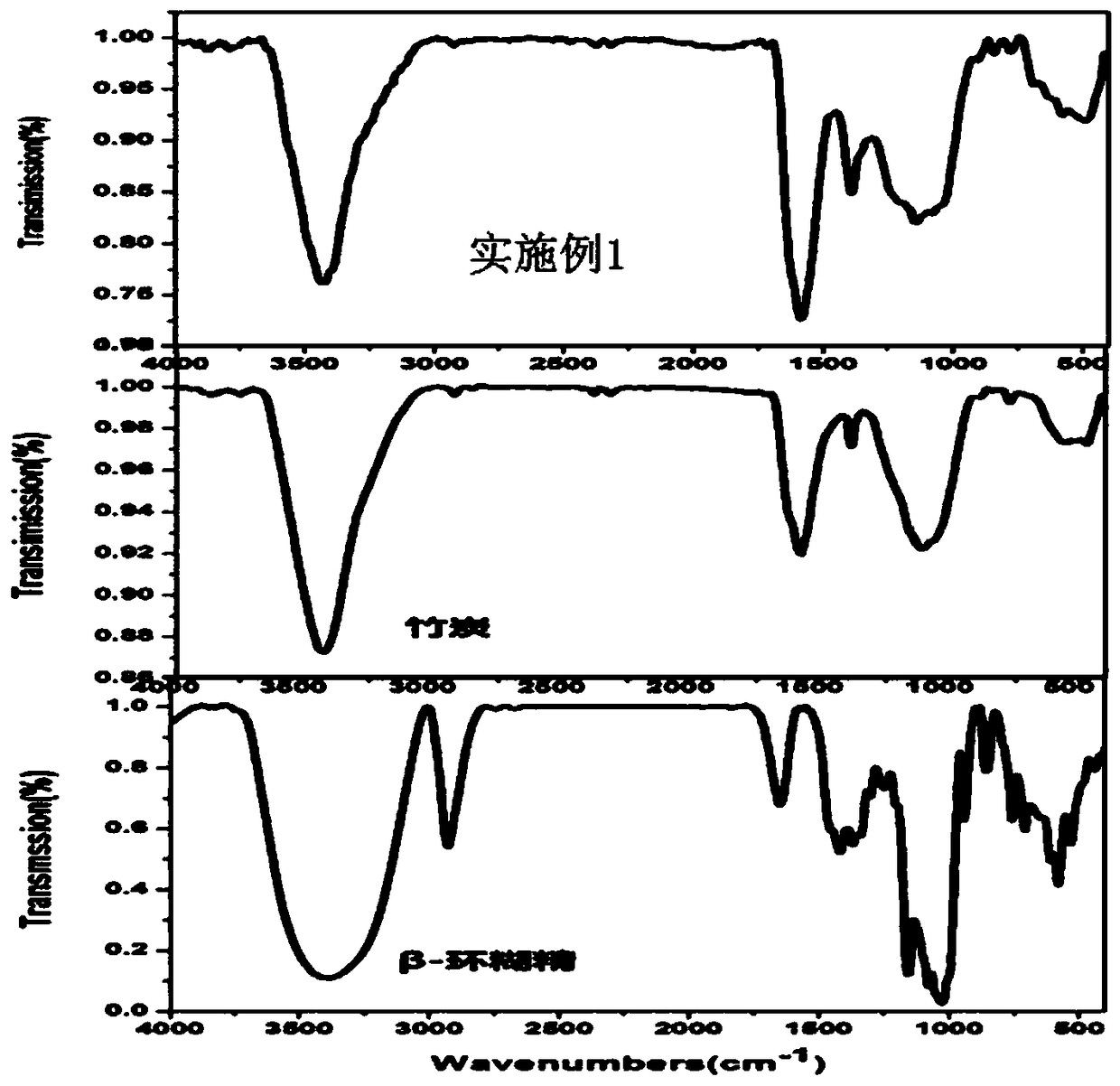

Preparation method of iron and cyclodextrin co-modified biochar composite material

InactiveCN109289787AHigh specific surface areaStrong combinationOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsPollutantSolubility

The invention relates to a preparation method of an iron and cyclodextrin co-modified biochar composite material. According to the invention, beta-cyclodextrin and iron are introduced to the biochar surface to obtain the iron and beta-cyclodextrin co-modified biochar composite material. The material has good adsorption and catalytic degradation performance, and has adsorption and catalytic degradation performance on organic pollutants and heavy metals at the same time. The iron and beta-cyclodextrin co-modified biochar on the one hand enhances the water solubility of the material, and on the other hand increases the active sites of the material, thus greatly improving the adsorption and catalytic degradation performance.

Owner:SHANDONG UNIV

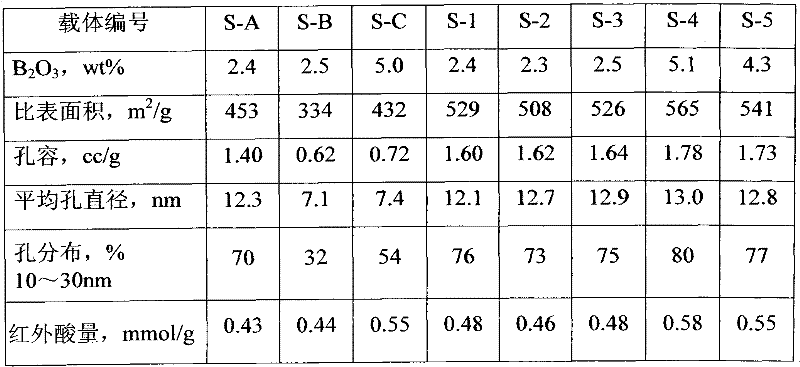

Boron-containing alumina carrier and preparation method thereof

ActiveCN102451771AEffectively regulates acidityImprove anti-cokingCatalyst carriersAdhesiveAluminium hydroxide

The invention discloses a preparation method of a boron-containing alumina carrier. The method comprises the following steps of: gelling the conventional aluminum hydroxide; adding into a stable boron-containing organic compound solution; aging, filtering, washing and drying to obtain dry boron-containing aluminum hydroxide gel; mixing and molding with an adhesive; and heating and performing gradual programmed heating and baking to obtain the boron-containing alumina carrier. Boron-containing alumina is a high-performance carrier component, which can be used for providing a large pore volume and a large specific surface area, has an appropriate pore structure and acidity, and is particularly suitable for a catalyst material needed by a heavy hydrocarbon catalytic processing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

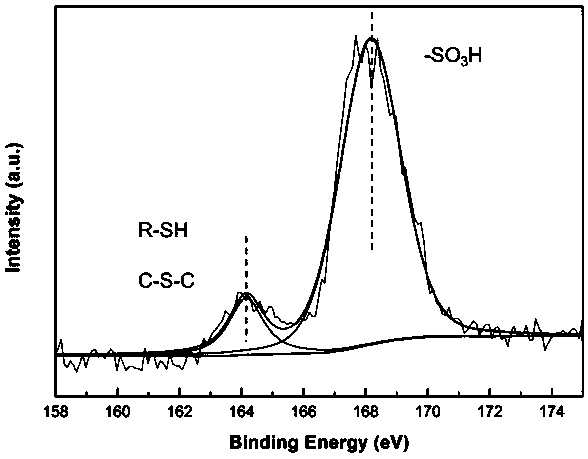

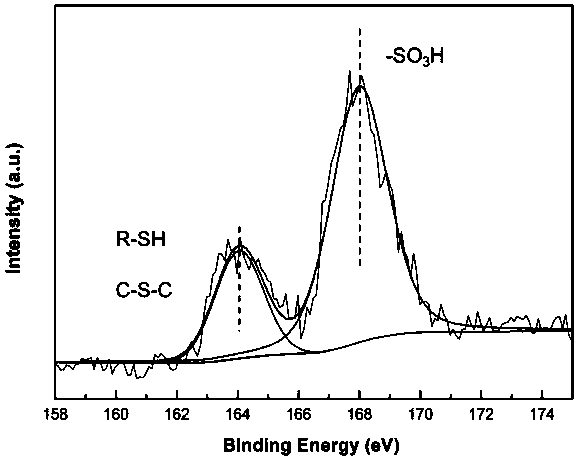

Sludge carbon-based solid acid as well as preparation method and application thereof

InactiveCN108786916ALarge specific surface areaConducive to loadFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsBiodieselSludge

The invention relates to a sludge carbon-based solid acid as well as a preparation method and application thereof. According to the sludge carbon-based solid acid disclosed by the invention, rich organic matters and special structural properties of the sludge are fully utilized, the solid acid having strong acidity is prepared by virtue of concentrated sulfuric acid sulfonation by adopting two methods and is applied to a catalytic oleic acid esterification reaction, and under the optimal conditions, the high acid value oil conversion rate can reach 95% or higher. The method disclosed by the invention is huge in amount of needed raw material resources, simple in preparation process, mild in reaction conditions, low in process cost, low in energy consumption and suitable for further large-scale production, and can scientifically and reasonably solve the problems of sludge treatment and disposal and preparation of biodiesel by utilizing high acid value oil.

Owner:SHANGHAI UNIV

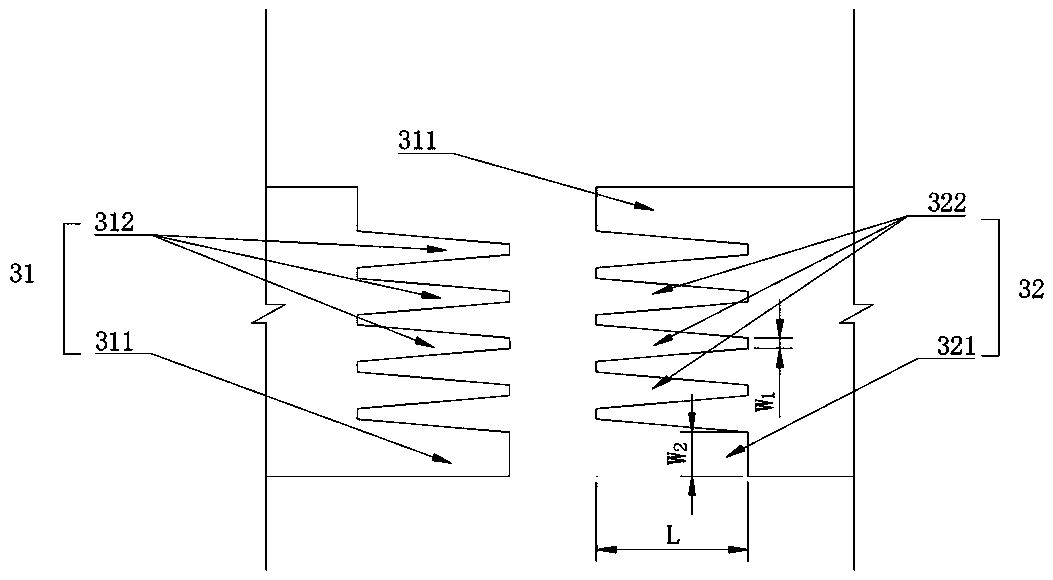

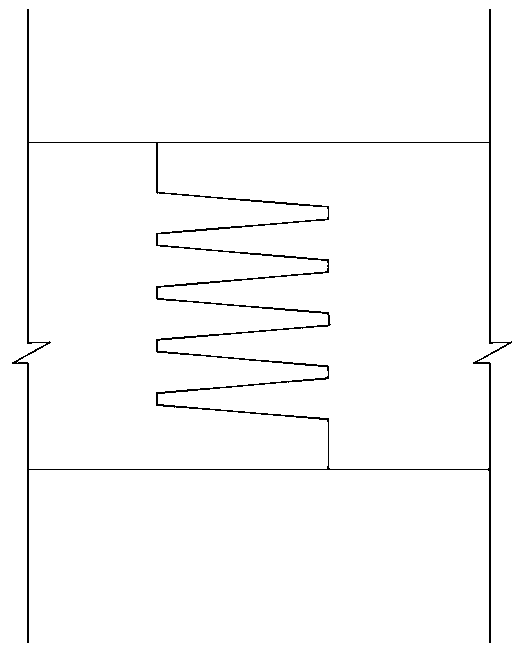

Infinite-arbitrary-length bamboo chip integrated material and manufacturing method thereof

PendingCN109808257AIncrease profitIncrease market shareCane mechanical workingLaminationButt jointEngineering

The invention discloses an infinite-arbitrary-length bamboo chip integrated material. The infinite-arbitrary-length bamboo chip integrated material is formed by a plurality of lengthened bamboo chipswhich are glued and overlaid; each lengthened bamboo chip is formed by a plurality of bamboo chip units which sequentially and continuously mesh and are connected in a butt joint mode; sharp teeth andgrooves are formed in the two ends in the length direction of the bamboo chip units, wherein the sharp tooth of each bamboo chip unit and the groove of the corresponding bamboo sheet unit are matchedto form a meshing butt-joint part, and the meshing butt-joint parts of the adjacent lengthened bamboo chips are arranged in a staggered mode; and the thickness of the bamboo chip units is 4-12 mm, and the width of the bamboo chip units is 15-50 mm. The invention further provides a manufacturing method of the bamboo chip integrated material. The manufacturing method comprises the steps of preparation of the bamboo chip units, meshing butt-joint, hot-pressing gluing and the like. The infinite-arbitrary-length bamboo chip integrated material and the manufacturing method thereof have the advantages that connectors are small, the mechanical strength is uniform, and the infinite-arbitrary-length bamboo chip integrated material is suitable for structures such as van truck bottom plates.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

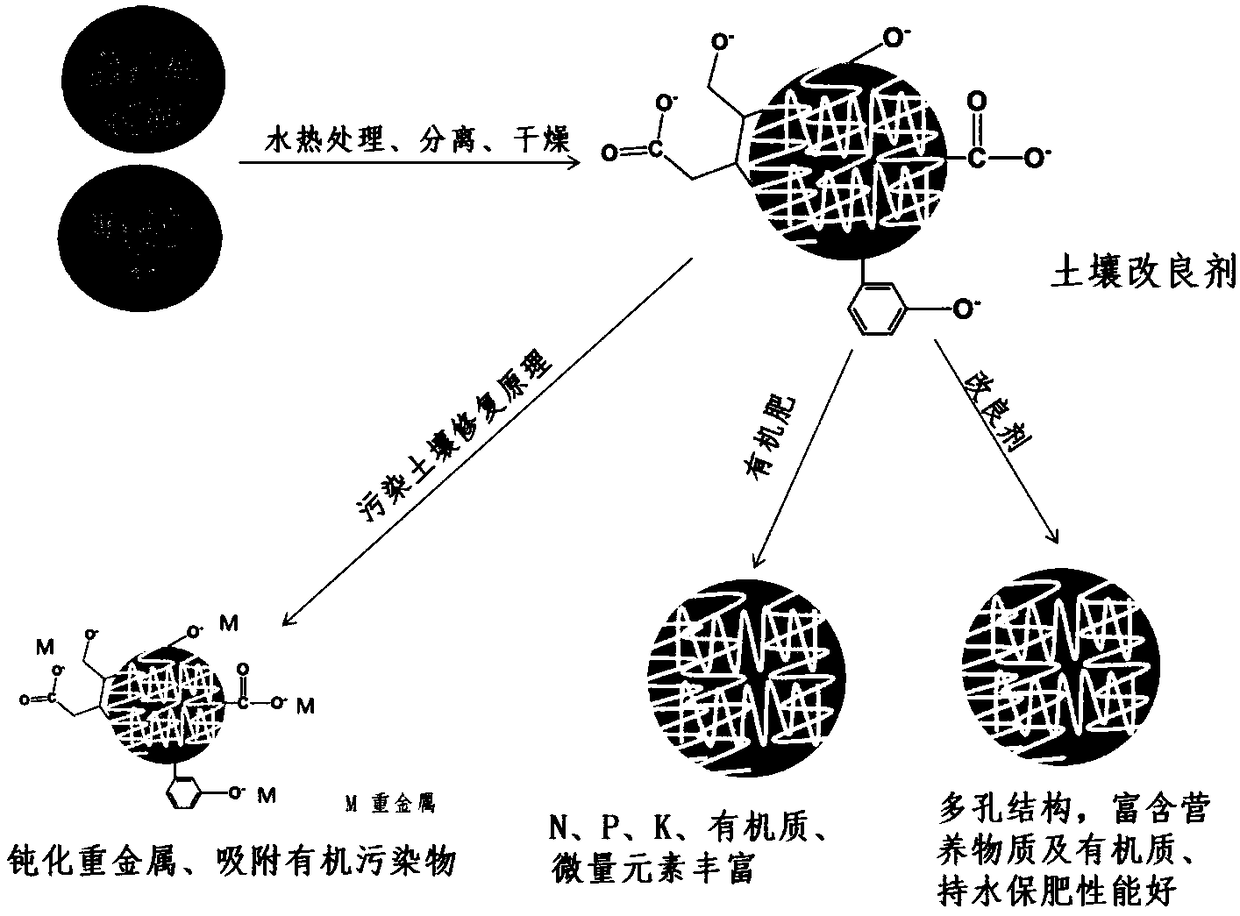

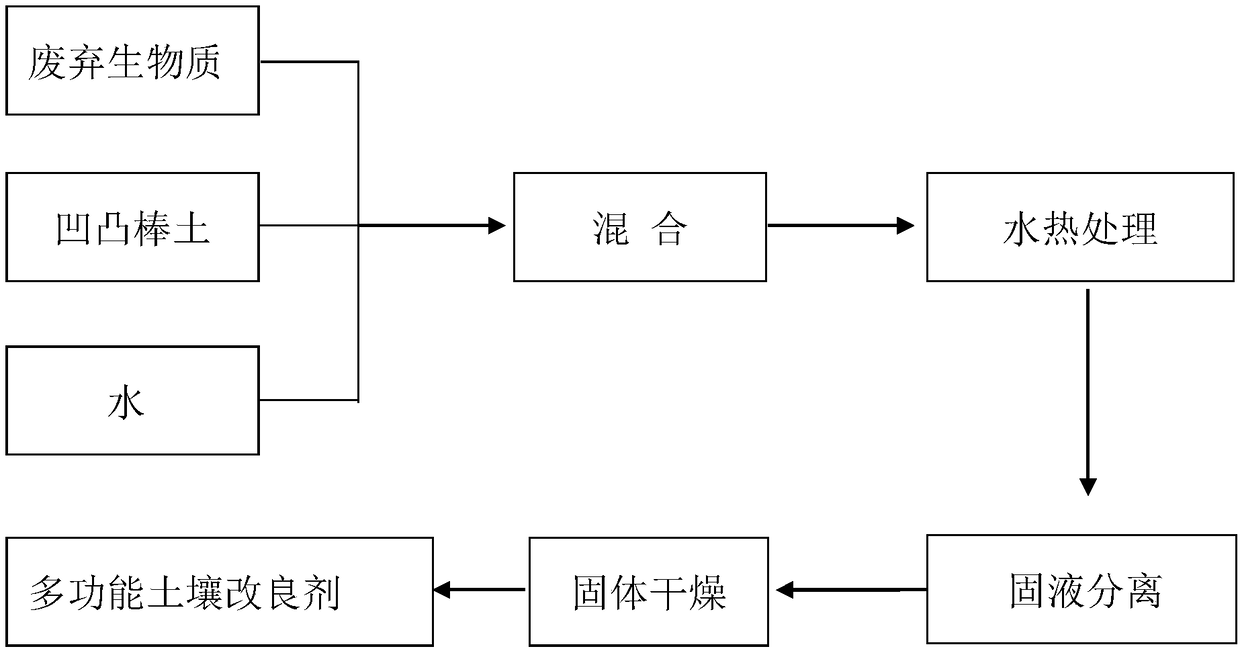

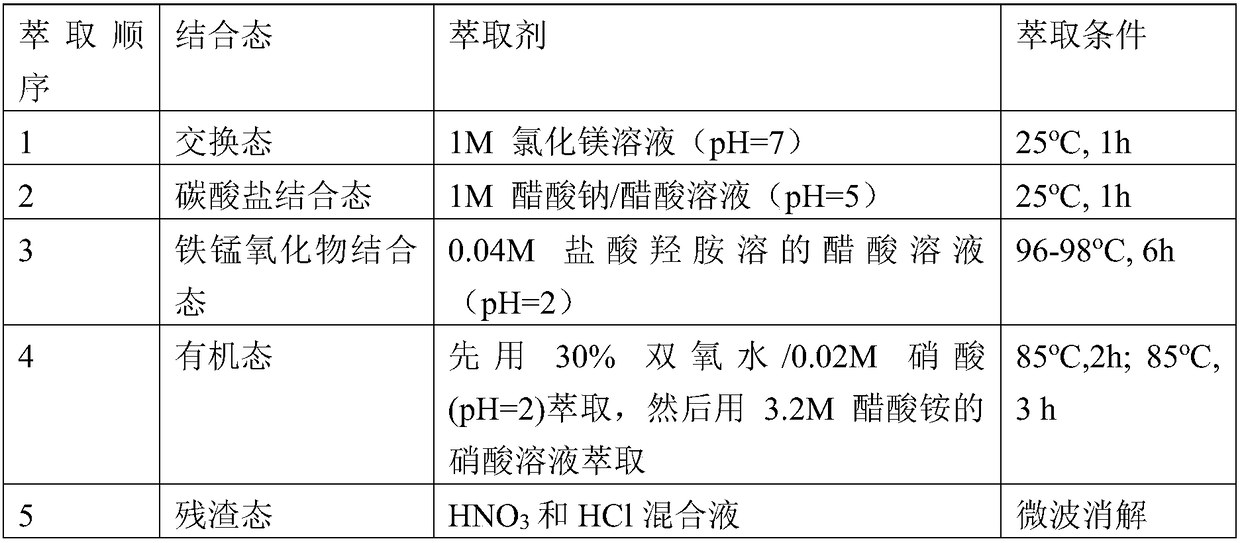

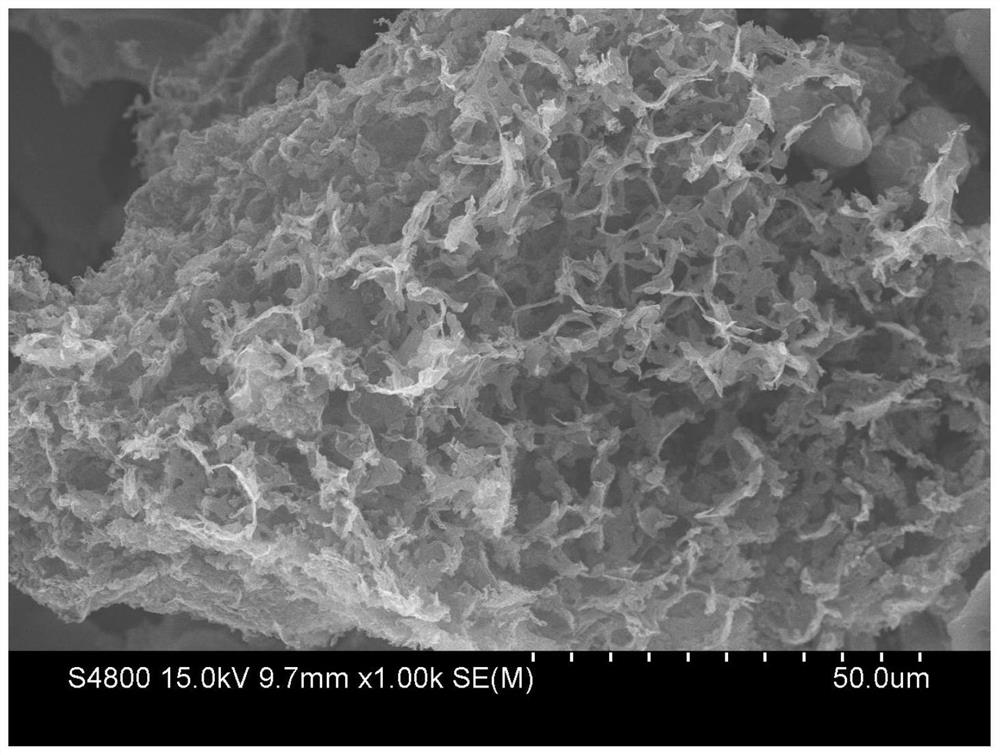

Preparation method and use of multifunctional soil improving agent

InactiveCN108752133AImprove water and fertilizer retention capacityImprove passivation effectExcrement fertilisersAgriculture gas emission reductionBiologyPollution

The high-strength utilization mode of the land in China accelerates the deterioration of a soil function, and soil pollution is very serious due to excessive application of chemical fertilizer and agricultural products. The crop yield declining and food safety incidents caused by soil degradation and soil pollution take place frequently and cause serious threats to people's health. The developmentof an eco-friendly, cheap and high-efficiency soil conditioner for improving soil fertility and reducing soil pollution is extremely urgent. The invention discloses a preparation method of a multifunctional soil improving agent. The preparation method comprises mixing waste biomass and a certain amount of attapulgite and modifying the mixture under specific conditions to obtain the multifunctional soil improving agent. The preparation method has simple processes. The multifunctional soil improving agent is renewable and eco-friendly, realizes a low cost, is rich in nutrients such as trace elements necessary for crop growth and can be used as organic fertilizer and a contaminated soil repairing agent.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Preparation method of modified coal cinder and application thereof

ActiveCN111792918AImprove sintering performanceImprove sintering strengthCeramic materials productionCeramicwareFiberBrick

The invention belongs to the technical field of buildings, and particularly relates to a preparation method of modified coal cinder and an application thereof. The composite acid solution is adopted to treat coal cinder, part of aluminum oxide, magnesium oxide and the like in the coal cinder can be dissolved in the composite acid solution, the aluminum oxide and the magnesium oxide in the composite acid solution react with zircon powder and boron powder and then are solidified and adsorbed in a pore structure of the coal cinder, the sintering performance of the coal cinder is improved, and thesintering strength of the coal cinder is improved; then surface modification liquid is adopted for modification, so that the dispersing performance of coal cinder can be improved; then the reinforcing fibers and a coupling agent are blended for modification, the reinforcing fibers are grafted into the coal slag under the action of the coupling agent, and the frost resistance and corrosion resistance of the coal slag are improved. The strength, frost resistance, dispersity, sinterability and other properties of the coal cinder subjected to acid modification, surface modification and blending modification are obviously improved, and the coal cinder can be used for preparing water-permeable shale bricks. The prepared water-permeable shale brick has good water permeability, frost resistance and corrosion resistance, and is high in strength.

Owner:GUIZHOU CONSTR SCI RES & DESIGN INST OF CSCEC

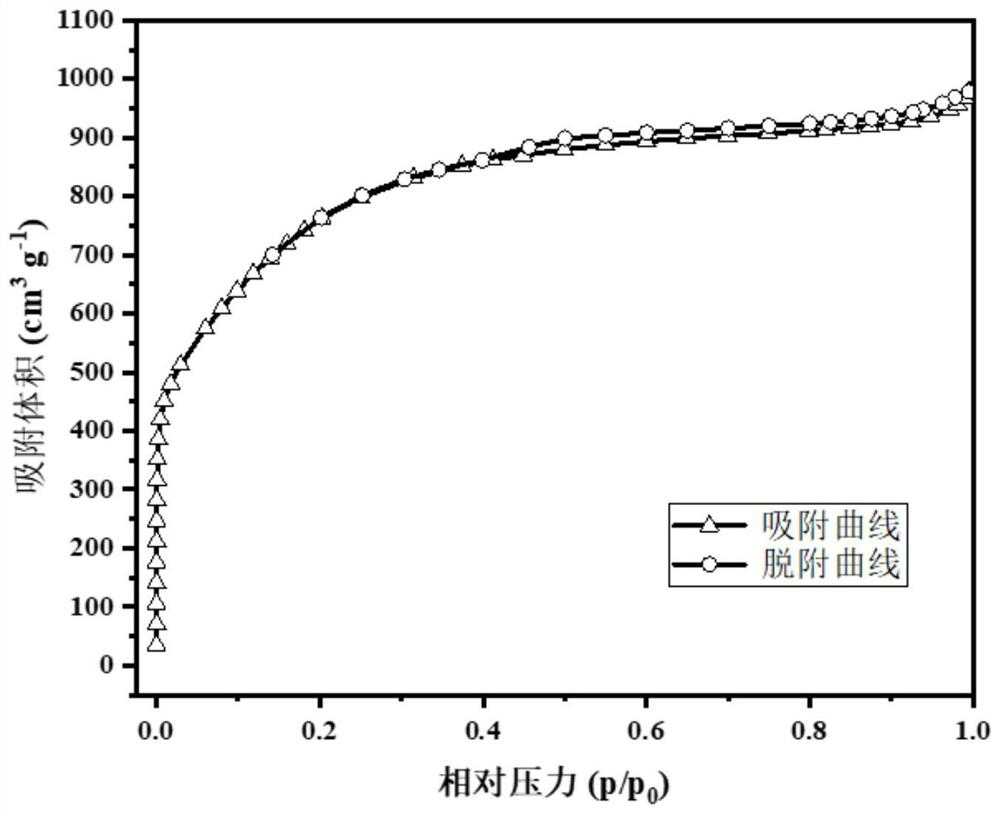

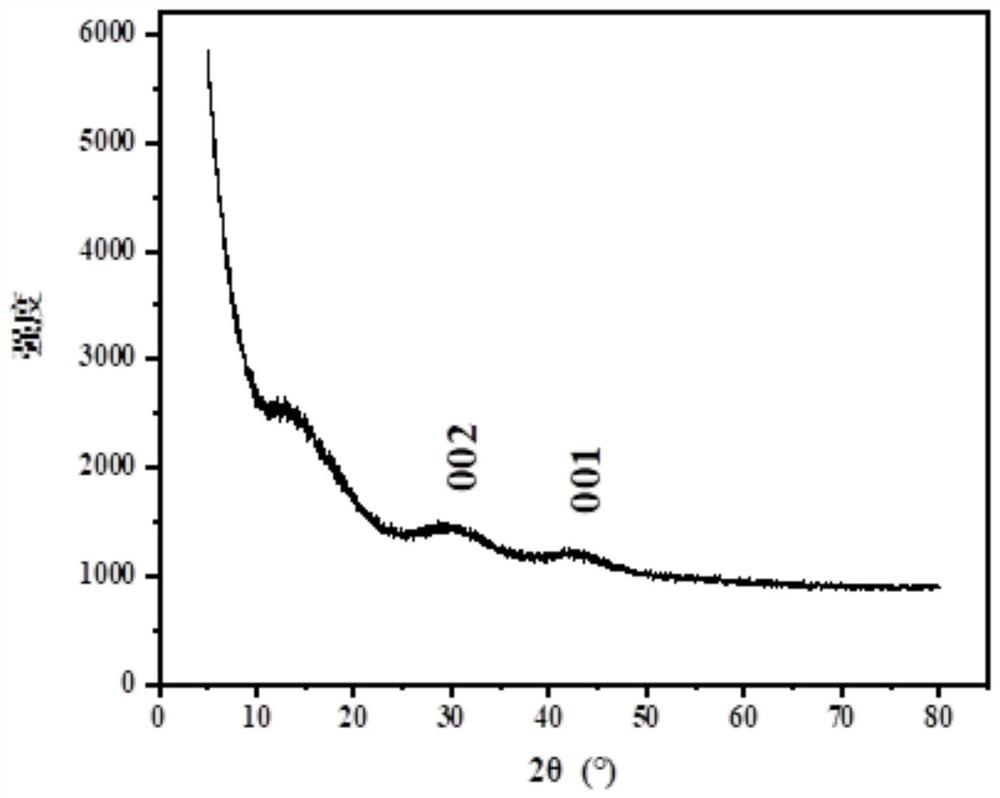

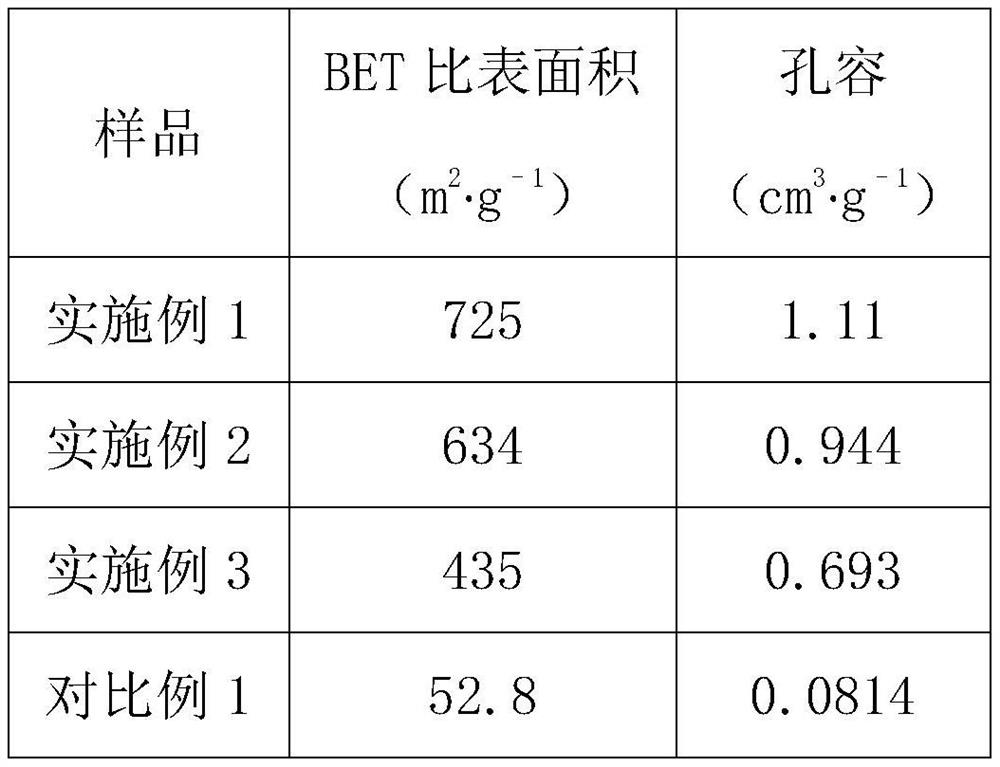

Biomass porous carbon material with high specific surface area as well as preparation method and application thereof

The invention discloses a preparation method of a biomass porous carbon material with a high specific surface area, and the method comprises the following steps: under the heating condition of inert atmosphere protection, preparing the biomass porous carbon material by taking sodium lignin sulfonate as a carbon precursor, taking anhydrous potassium carbonate as an activating agent and mixing with an N doping agent. The invention further discloses the biomass porous carbon material with the high specific surface area and application of the biomass porous carbon material to removal of chloramphenicol in a water body. Sodium lignin sulfonate which is low in cost, easy to obtain and stable in source is used as a raw material, the activating agent reacts with carbon to promote formation of pores, the N doping agent participates in the pore forming process, pore enlargement and pore structure increase in the carbon material are promoted, the specific surface area and the pore structure of the biomass porous carbon material are improved, and the adsorption quantity of pollutants is favorably improved; the preparation method is simple, high in efficiency, low in raw material cost and easy to popularize; the biomass porous carbon material disclosed by the invention has an excellent adsorption effect on chloramphenicol in a water body and is stable in adsorption performance.

Owner:CHANGAN UNIV

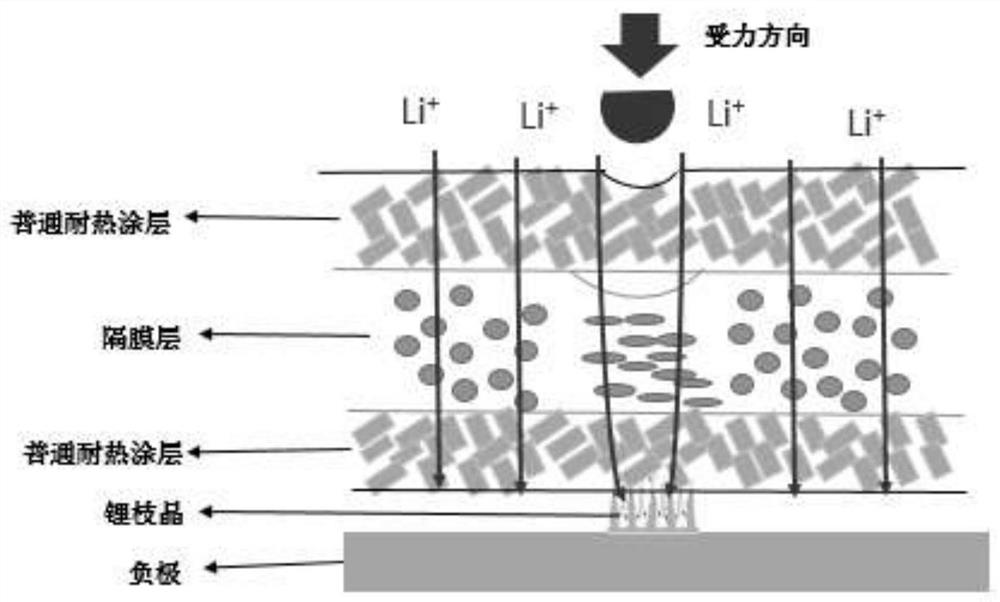

Diaphragm coating slurry capable of improving safety performance of lithium ion battery and preparation method of diaphragm coating slurry

InactiveCN111769242AGood storage stabilityImprove machinabilityCell component detailsSecondary cells servicing/maintenancePhysical chemistrySurface-active agents

The invention discloses diaphragm coating slurry capable of improving the safety performance of a lithium ion battery. The diaphragm coating slurry comprises the following raw materials in parts by weight: 20-35 parts of an inorganic insulator, 0.2-3 parts of a dispersing agent, 3-5 parts of a binder, 0.1-2 parts of a surfactant and 50-80 parts of water. The invention also discloses a preparationmethod of the diaphragm coating slurry capable of improving the safety performance of the lithium ion battery, and the lithium ion battery diaphragm prepared from the diaphragm coating slurry. The coating formed by the diaphragm coating slurry on the surface of the diaphragm can effectively maintain the pore structure in the diaphragm after impact, and ensures that the battery has more uniform lithium ion flow in the charge-discharge process, thereby enhancing the safety performance of the lithium ion battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Active carbon fibre and preparation thereof

InactiveCN101348952BLarge specific surface areaPore structure highOther chemical processesAlkali metal oxides/hydroxidesActivated carbonPolyvinyl alcohol

The invention relates to an activated carbon fiber and a preparation method thereof. The compositions in weight percentage of the activated carbon fiber are: 80 to 95 percent of fiber-forming polymer, and 20 to 5 percent of functional additive component, wherein the fiber-forming polymer can be polyacrylonitrile, modified polyacrylonitrile, polyvinyl alcohol or regenerated cellulose fiber; and the functional additive component can be a superfine absorbent of supporting metal with the average diameter of between 0.01 and 20 mu meter; and the supporting metal can be one of a silver ion, a copper ion or a zinc ion. The preparation method comprises the following steps: a base material fiber-forming polymer fiber containing the functional additive component is prepared first, wherein the base material fiber can be a polyacrylonitrile fiber, a modified polyacrylonitrile, a polyvinyl alcohol fiber or a regenerated cellulose fiber base fiber; and different physical activation treatments or / and chemical activation treatments are carried out according to different base material fibers to produce the activated carbon fiber corresponding to the base material.

Owner:TIANJIN POLYTECHNIC UNIV

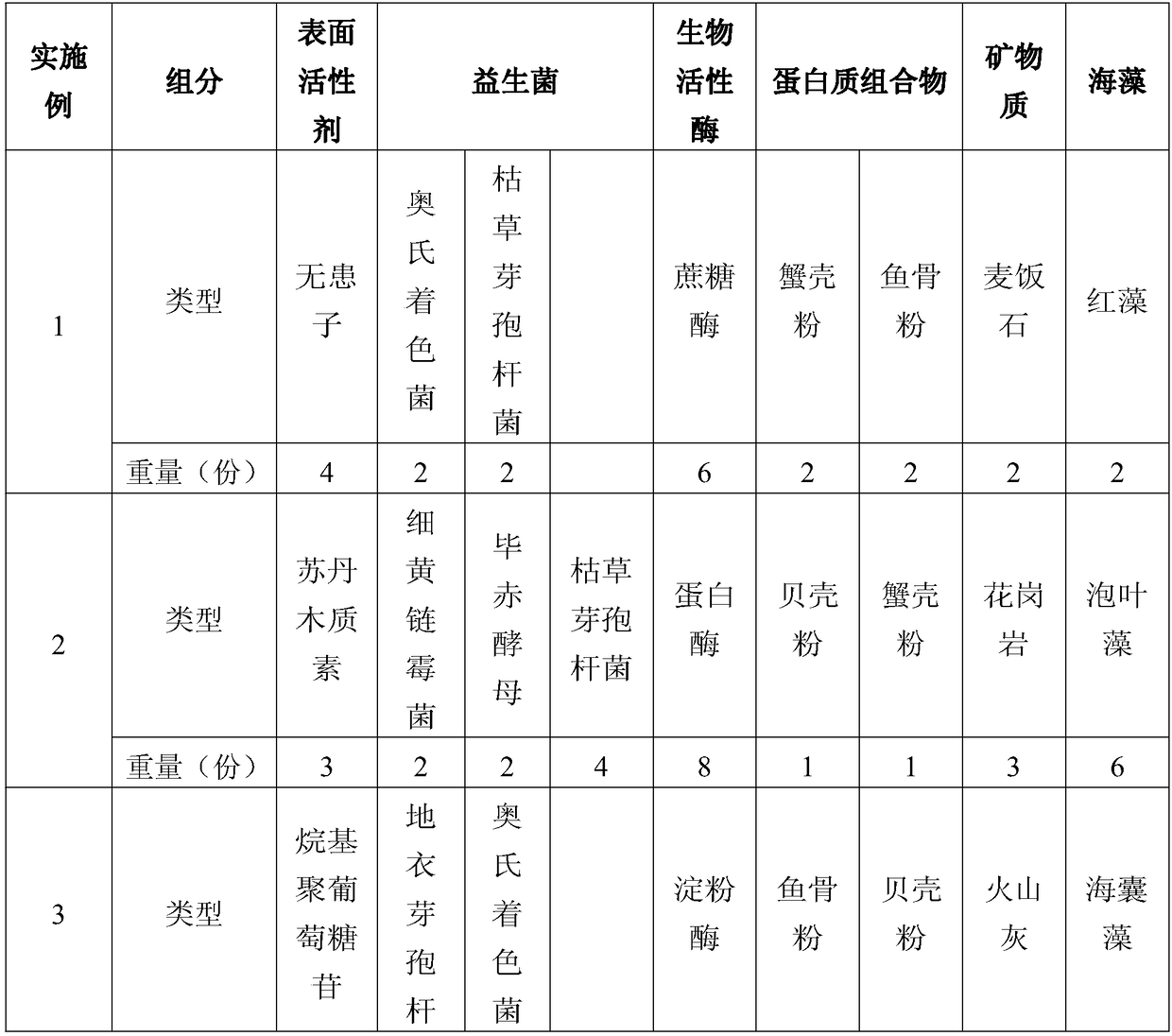

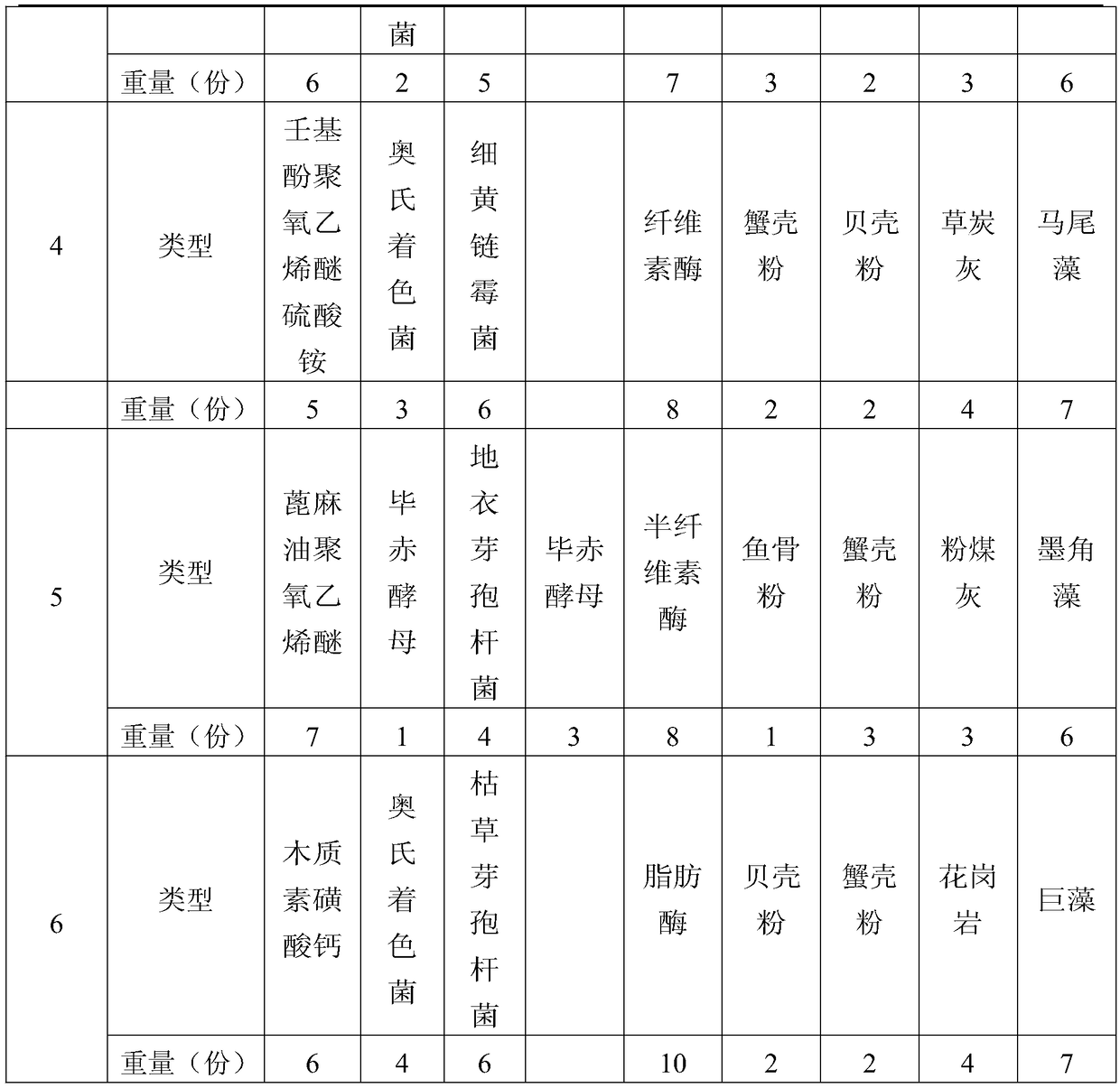

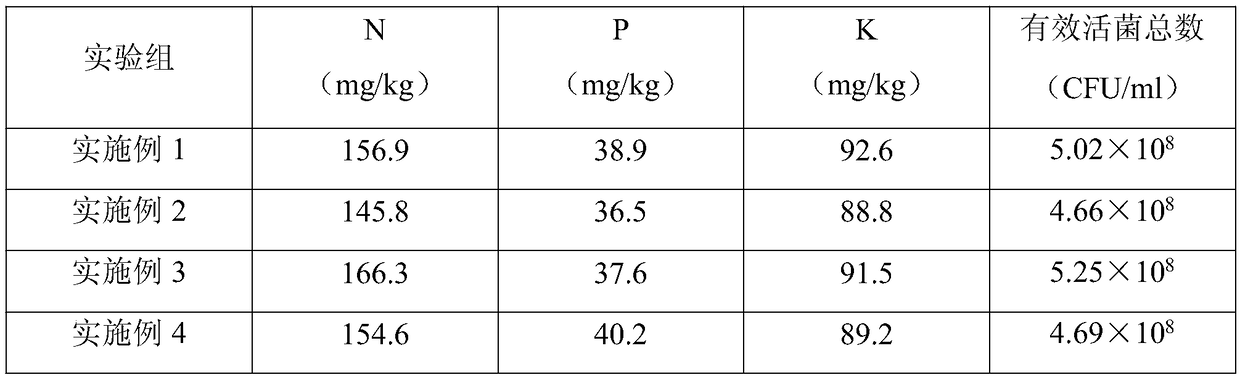

Active modified soil fertilizer and preparation method thereof

InactiveCN109369261AImprove effectivenessIncrease P and K contentCalcareous fertilisersAnimal corpse fertilisersDiseaseActive enzyme

The invention provides an active modified soil fertilizer comprising the following components by weight: 3-8 parts of surfactant, 1-4 parts of probiotics, 2-10 parts of biological active enzyme, 1-5 parts of protein composition, 2-4 parts of mineral and 2-8 parts of seaweed. The probiotics are a combination of at least two of bacillus licheniformis, bacillus subtilis, pichia pastoris, chromatium okenii and streptomyces verticillatus, and the effective viable count of each is 3*109-2.00*109 / mL. The probiotics are added to facilitate circulation of nutrients, and the mixed bacteria not only promote each other, but also promote the absorption of minerals, protein substances and the other nutrients, and can generally improve the composition of soil microflora, enhance the crop rhizospheric microbial activity, enhance the capability to dissolve phosphorus and release potassium, effectively increase the content of effective N, P and K in the soil and improve the soil fertility. At the same time, biological active enzymes and seaweed are added to further increase the content of organic matters and improve the capability to resist pests and diseases.

Owner:CHANGSHA XIAORU INFORMATION TECH CO LTD

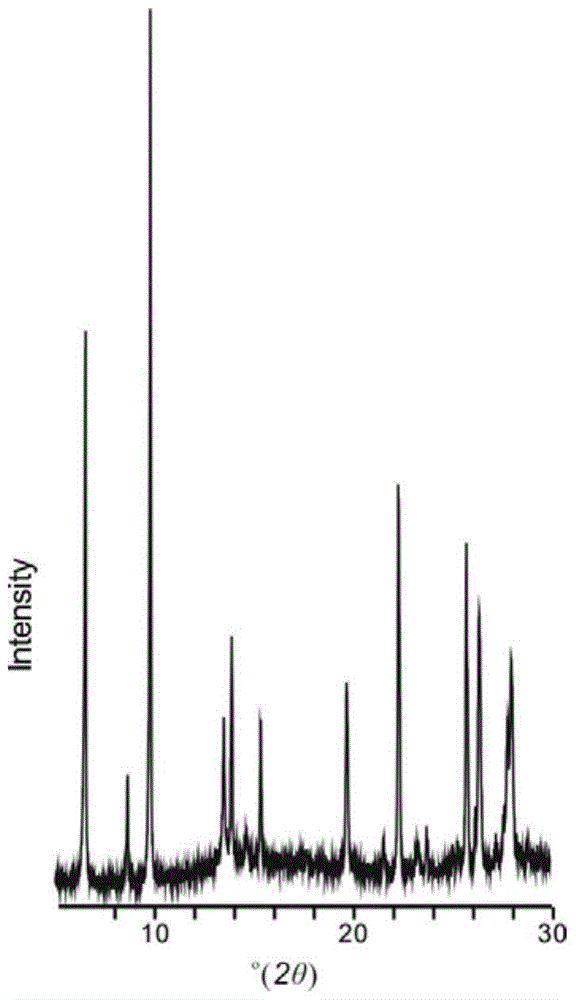

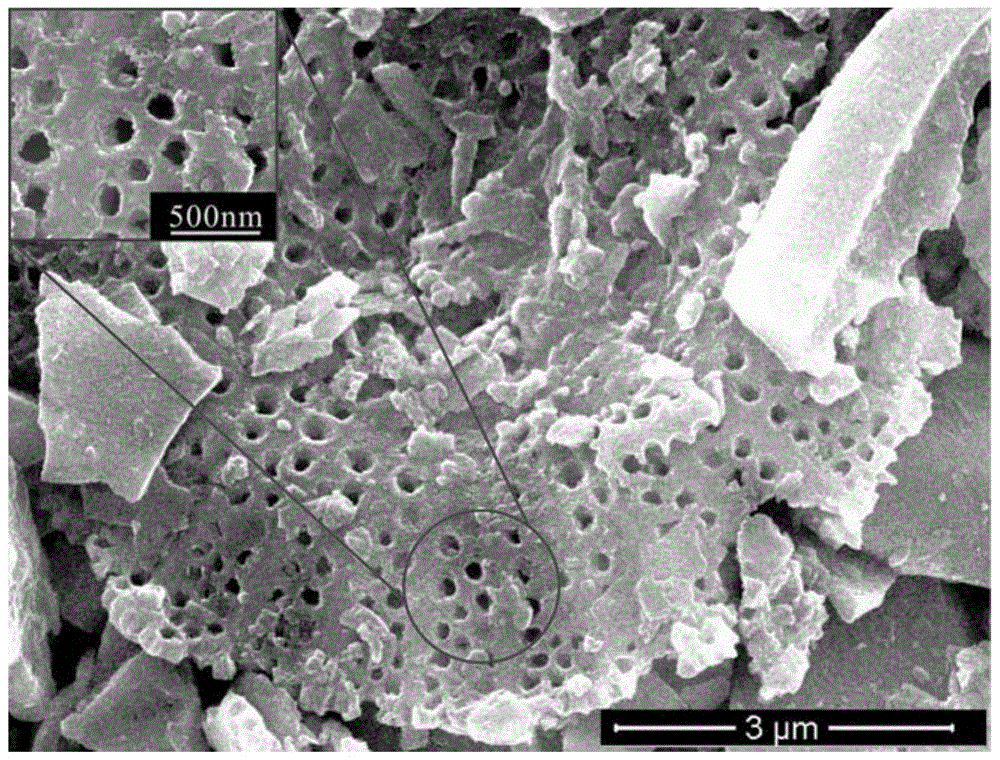

A kind of mordenite with diatomite morphology and its preparation method

ActiveCN104909384BHigh porositySimple processMordenite aluminosilicate zeolitePorous carbonMordenite

The present invention discloses mordenite having diatomite morphology and a multi-level pore channel structure, and a preparation method thereof. According to the present invention, cheap diatomite having an unique macroporous structure is adopted as a zeolite preparation template and a silicon / aluminum source, and during the preparation process, a diatomite-porous carbon intermediate is prepared, and then porous carbon is adopted as a template and diatomite is adopted as a silicon source and an aluminum source to prepare the porous mordenite having the diatomite morphology and the large / micro pores. According to the present invention, the obtained mordenite has the diatomite morphology and further has the high macroporosity so as to provide the multi-level pore channel structure, such that the efficient adsorption is provided; and compared with the mordenite processes through other template methods, the method of the present invention has characteristics of simple process and low potential environment hazard.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

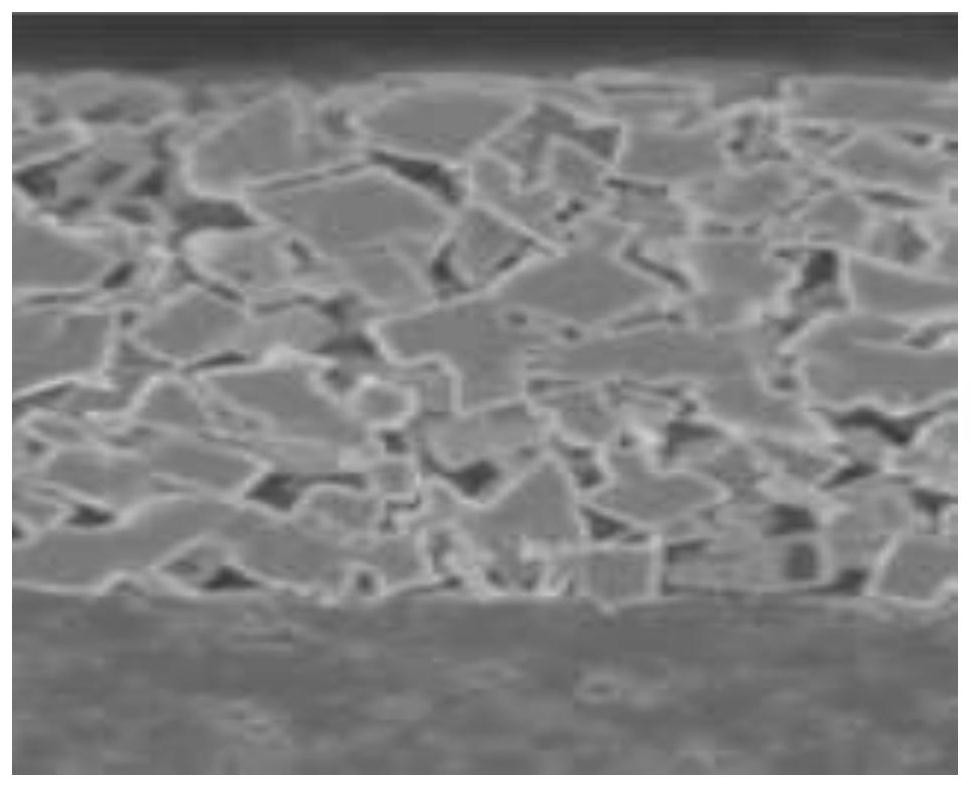

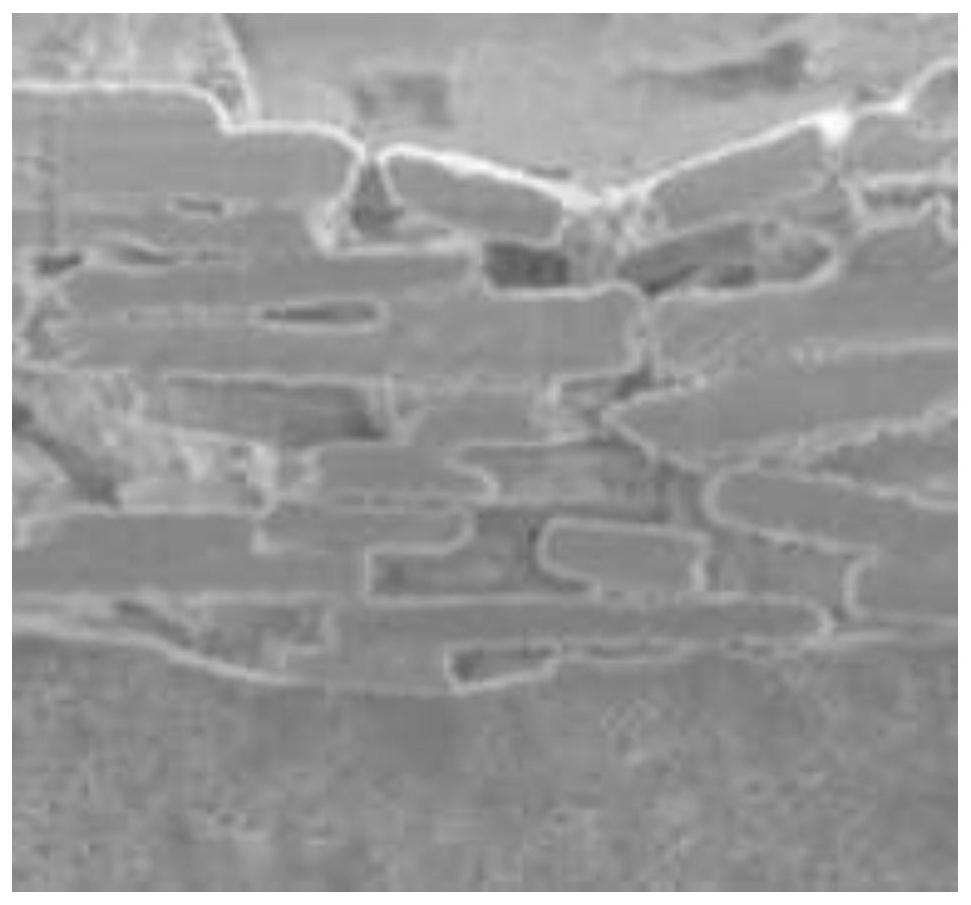

Nano carbon material composite resin hard carbon electrode material as well as preparation method and application thereof

PendingCN113161161AHigh porosityLarge specific surface areaHybrid capacitor electrodesCarbon preparation/purificationPtru catalystFreeze-drying

The invention discloses a preparation method of a nano carbon material composite resin hard carbon electrode material. The preparation method comprises the steps of preparing a phenolic aldehyde mixed solution; adding a dispersed aqueous solution of a nano carbon material into the phenolic aldehyde mixed solution to obtain a uniformly dispersed mixed solution; then adding an alkaline substance catalyst to obtain a reaction solution; heating the reaction solution at constant temperature in vacuum to obtain composite phenolic resin hydrogel; performing freeze drying on the composite phenolic resin hydrogel to obtain composite phenolic resin aerogel; crushing the composite phenolic resin aerogel, and carbonizing at low temperature to obtain composite resin carbon aerogel; performing high-temperature treatment on the composite resin carbon aerogel to obtain a composite resin hard carbon material; and uniformly mixing the composite resin hard carbon material, PTFE and ethanol to obtain the nano carbon material composite resin hard carbon electrode material. According to the invention, the phenolic resin source hard carbon is used as an active material main body, the production cost is low, and an aqueous reaction system is adopted, so that the method is environment-friendly and pollution-free.

Owner:昆山昆鹏利杰高分子材料技术有限公司

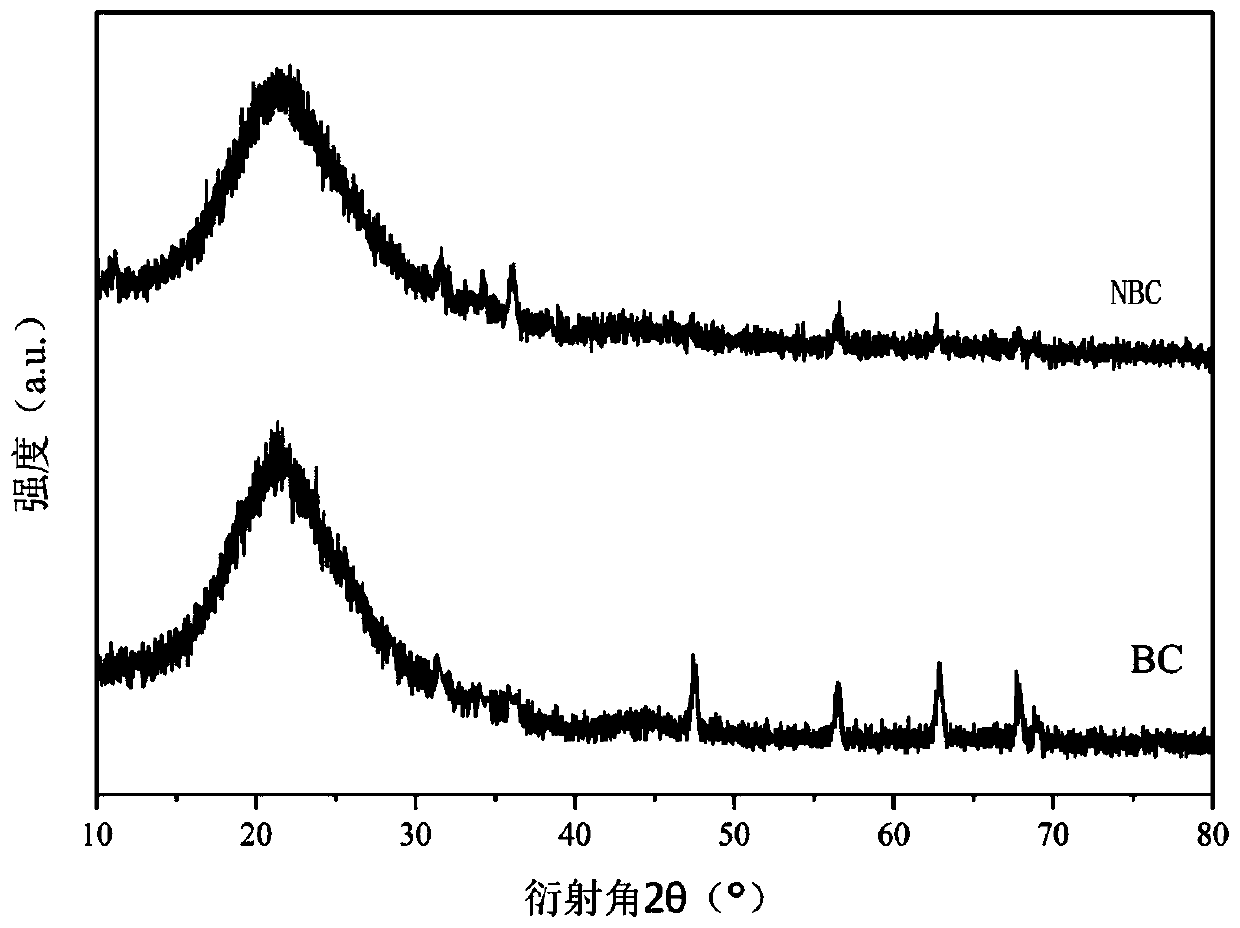

Preparation of nitrogen-doped biochar material and method for improving dark fermentation hydrogen production performance

ActiveCN111111739ASimple production processAbundant sources of materialsPhysical/chemical process catalystsFermentationDark fermentationNitrogen atmosphere

The invention provides nitrogen-doped biochar which is simple in production process and low in green cost, and the nitrogen-doped biochar is applied to the process of improving the dark fermentation hydrogen production performance for the first time. The nitrogen-doped biochar material takes corncob powder and melamine as raw materials; the high-nitrogen-doped biochar material is finally obtainedthrough high-pressure and high-temperature cooking, activator dipping, nitrogen atmosphere carbonization, washing and drying, and the bottleneck that in the prior art, the nitrogen-doped biochar material preparation process is low in nitrogen content, high in cost and complex in process, and dark fermentation hydrogen production efficiency is low is overcome.

Owner:QILU UNIV OF TECH

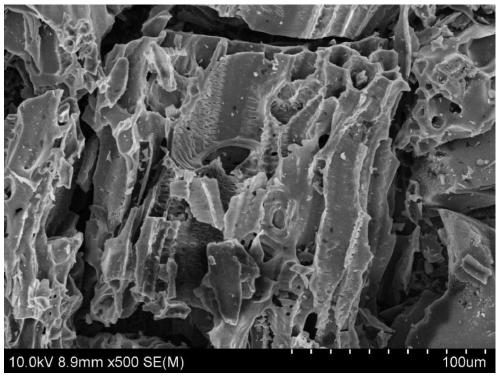

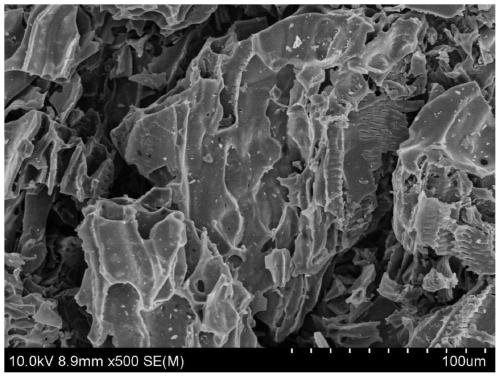

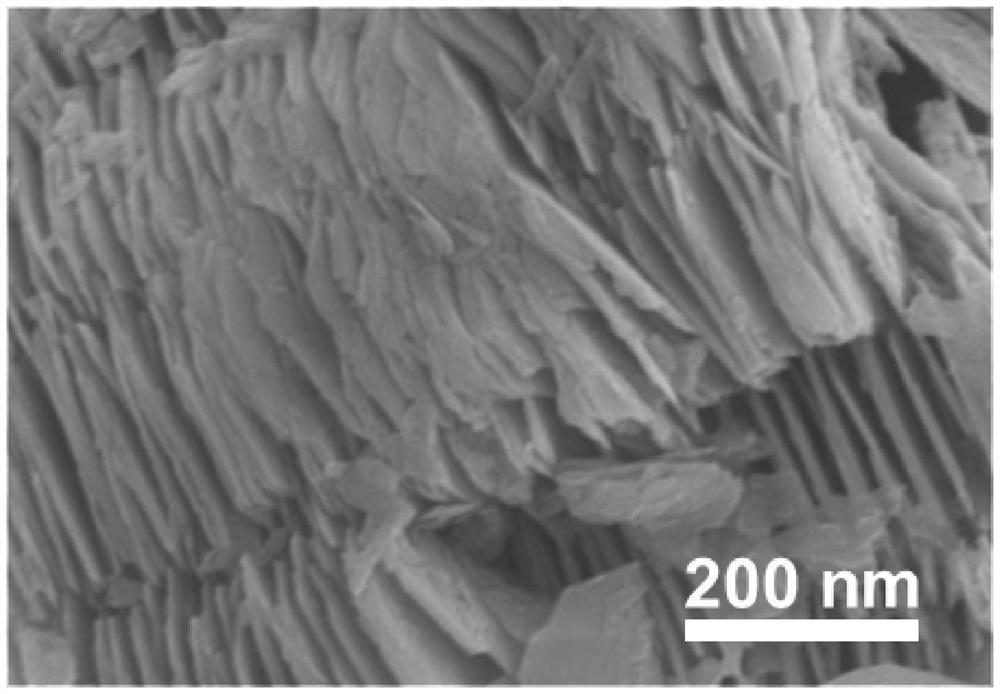

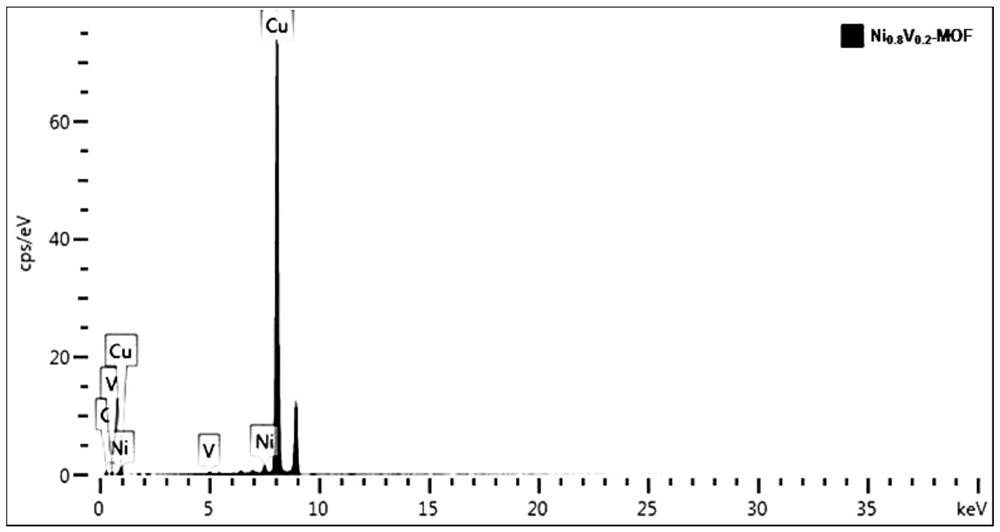

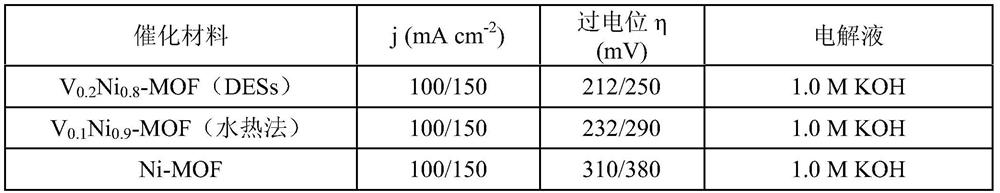

Method for synthesizing MOF oxygen evolution reaction catalyst by using deep eutectic solvothermal method

ActiveCN113215605AImprove solubilityImprove reaction efficiencyElectrodesPtru catalystOxygen evolution

The invention relates to a method for synthesizing an MOF oxygen evolution reaction catalyst by using a deep eutectic solvothermal method, and belongs to the technical field of fine chemical engineering. The method for synthesizing the MOF oxygen evolution reaction catalyst by using the deep eutectic solvent thermal method comprises the following steps: (1) preparing a deep eutectic solvent; (2) preparing a Ni < 0.8 > V < 0.2 > layered double hydroxide nano array on the foamed nickel; and (3) preparing a Ni < 0.8 > V < 0.2 >-MOF catalyst, wherein the reaction in the step (2) and the reaction in the step (3) are both carried out in the eutectic solvent. The invention adopts a simple and convenient method for preparing three-dimensional Ni0.8V0.2-MOF by using the deep eutectic solvothermal method. In the aspect of the synthesis method, the limitation of a traditional hydrothermal method is broken through, the eutectic solvent is used as a synthesis medium, the chemical pollution is reduced, and the solubility of reactants and the reaction efficiency are improved; and the reaction vapor pressure and the reaction difficulty are reduced.

Owner:山东鲁泰控股集团有限公司石墨烯高分子复合材料研发中心 +1

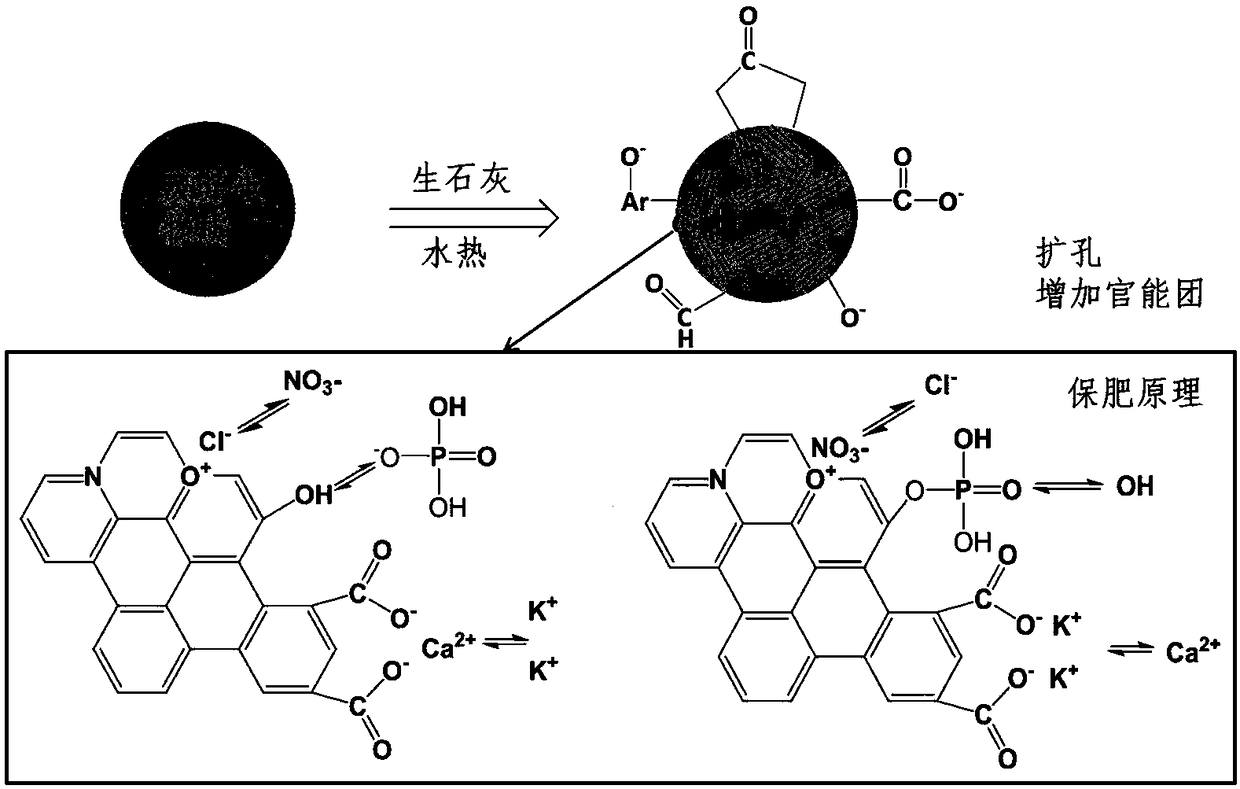

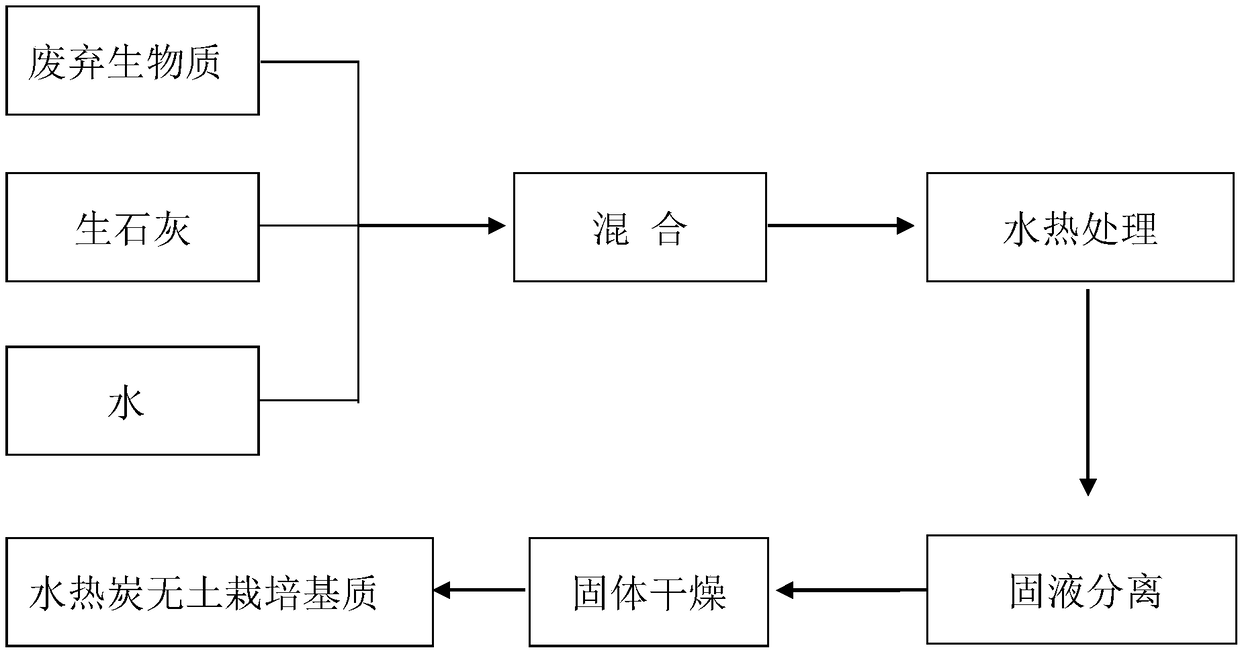

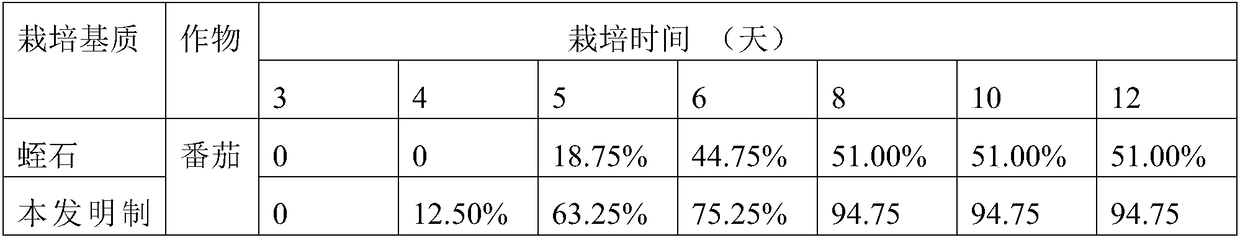

Method for preparing soilless culture substrate from waste biomass

As economy grows and food safety incidents caused by soil contamination occur frequently, demand for culture substrates required by production of pollution-free green vegetables is increased day by day. At present, a soilless culture substrate mainly uses non-renewable resources such as vermiculite and perlite, so that development of a potential renewable culture substrate is particularly important; and untimely or improper processing of a large amount of waste biomass (livestock and poultry manure, straw and the like) in China causes serious environmental pollution. The process obtains the soilless culture substrate by mixing the waste biomass and a certain amount of quicklime, performing hydrothermal treatment under specific conditions, and performing solid-liquid centrifugation. The process provided by the invention adopts the waste biomass to prepare the soilless culture substrate, the preparation process is simple, and the costs are low; and the substrate is not only rich in nutrients such as microelements necessary for crop growth, but also can improve utilization efficiency of fertilizers by crops.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Purifying agent for oilfield sewage treatment and preparation method of purifying agent

InactiveCN108993386ARich pore structureImprove thermal stabilityFatty/oily/floating substances removal devicesOther chemical processesChemical oxygen demandCobalt

The invention discloses a purifying agent for oilfield sewage treatment and a preparation method of the purifying agent, and belongs to the technical field of sewage treatment. The purifying agent isprepared from the following components in parts by weight: 22-28 parts of modified expanded graphite, 5-8 parts of cobalt nitrate hexahydrate, 12-16 parts of zinc sulfate, 5.5-9 parts of a surfactant,3-5 parts of chitosan, 2.5-5 parts of methylacryloyloxyethyl trimethyl ammonium chloride and 40-50 parts of water. According to the invention, through organic combination of all the materials, the sewage purifying agent is prepared under a synergistic effect of all the components, and the purifying agent has a large specific surface area, a large micropore volume, a developed microporous structure, high capability of adsorbing impurities such as heavy metal ions and suspended matter, and remarkable oil removal and decontamination effects. The removal rate of chemical oxygen demand (COD) is larger than or equal to 96.6%, the removal rate of suspended solids is larger than or equal to 97.2%, the oil removal rate is larger than or equal to 98%, and the removal rate of the heavy metal ions islarger than or equal to 94.7%. Purified water is clear and transparent, and requirements for purification treatment of the oilfield sewage are met.

Owner:ZHENGZHOU INST OF TECH

Method for removing micro-plastics in water based on graphene material

ActiveCN111569829AHigh electronegativityImprove adsorption capacityOther chemical processesWater contaminantsPorous grapheneWater based

The invention provides a method for removing micro-plastics in water based on a graphene material, and belongs to the technical field of environmental pollution research. The method comprises the following steps: adding a magnetic porous graphene material into a sample containing the micro-plastics, stirring and mixing for 3-6 minutes, and then attracting and removing the magnetic porous grapheneby using a magnet. The invention also provides magnetic porous graphene and a preparation method thereof. The method increases the surface hydrophobicity of the magnetic porous graphene, and can increase the electronegativity of particles; according to the method, the alkali activation effect on graphene can be enhanced, adsorption sites on non-polar organic molecules are increased, and the adsorption capacity on micro-plastics is increased so that the removal rate of the micro-plastics is increased.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Preparation process of activated carbon

InactiveCN110606483APore structure highAvoid pollutionCarbon compoundsStationary retortsActivated carbonTrace element

The invention discloses a preparation process of activated carbon, belonging to the technical field of activated carbon preparation. According to the method, coal and coal tar are mixed to prepare theactivated carbon; and the coal tar slag contains a large amount of incompletely combusted carbon and a small amount of iron, silicon and trace elements. In a process of mixing the coal tar slag withthe coal and performing activation, because the coal tar slag and the coal material have different surface and internal pore diameter structures, the pore structure of an activated carbon finished product is favorably enhanced, and the specific surface area is increased. When raw materials are dried after being formed, a hot air dryer is set at 40-65 DEG C to preheat the formed raw materials, so that the raw materials can slowly absorb heat, the internal structures of the raw materials can be uniformly and fully heated, and the phenomena that the local temperature rise of the raw materials istoo fast, the internal structures of the raw materials are damaged and the quality of activated carbon finished products is influenced when the raw materials are directly heated at high temperature after being formed are avoided.

Owner:宁夏凯铭瑞环保科技有限公司

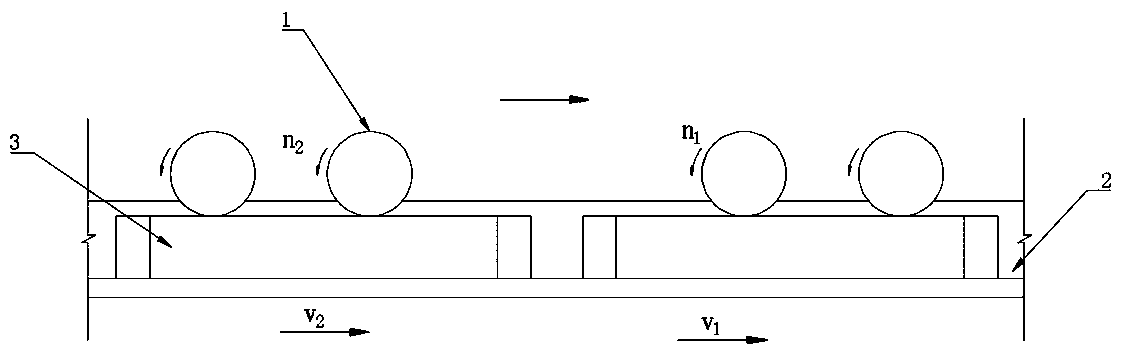

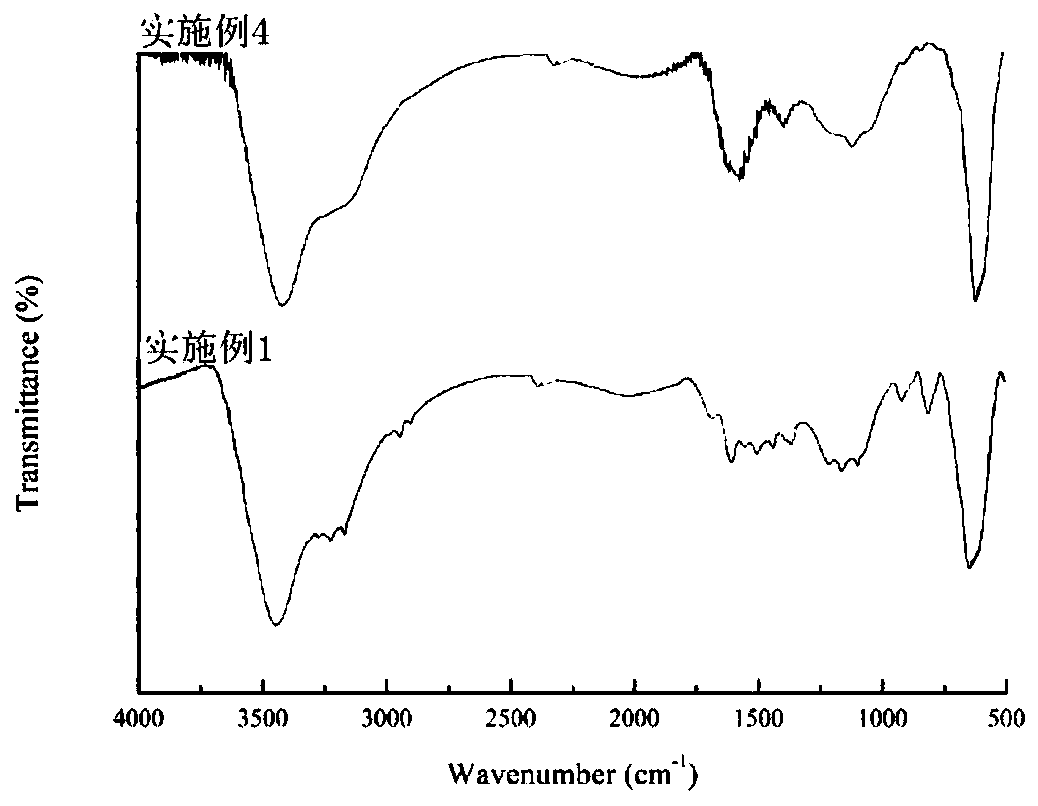

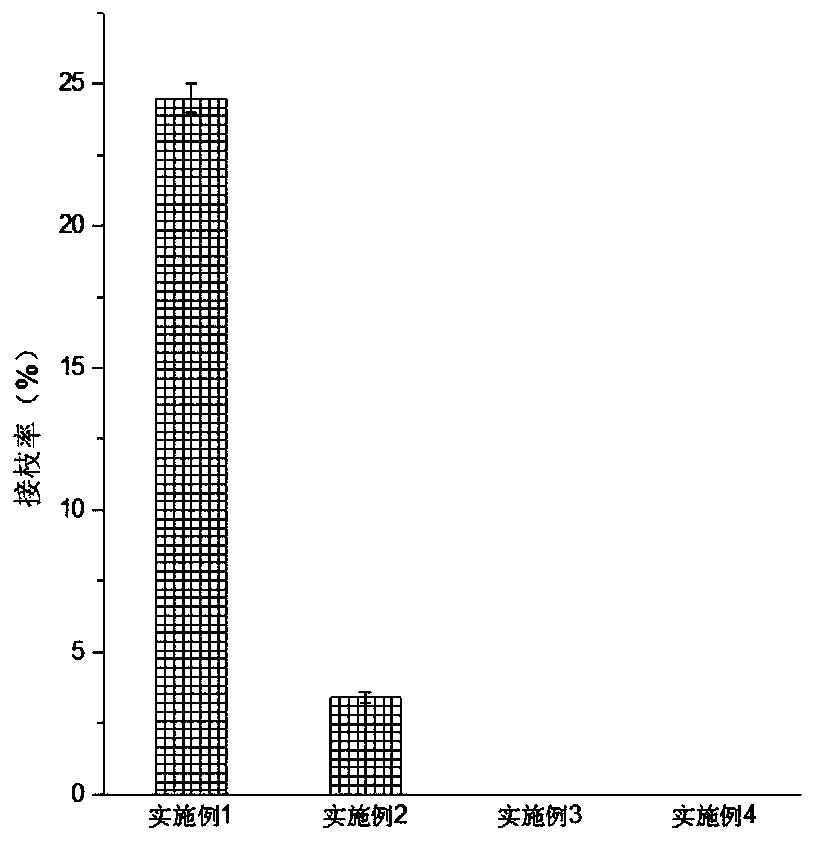

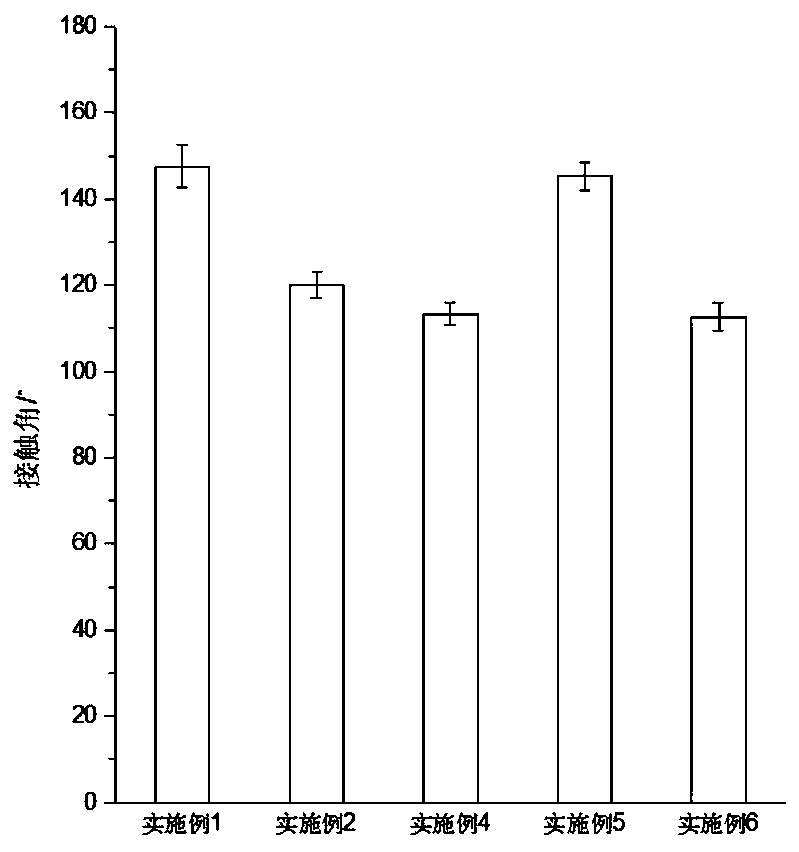

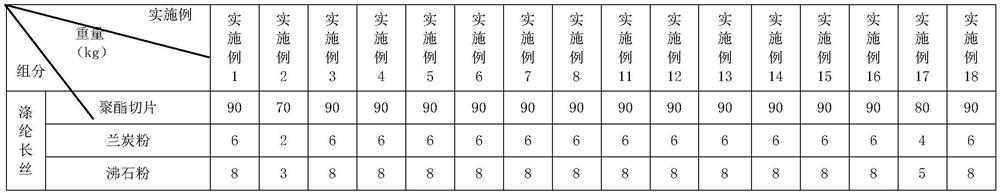

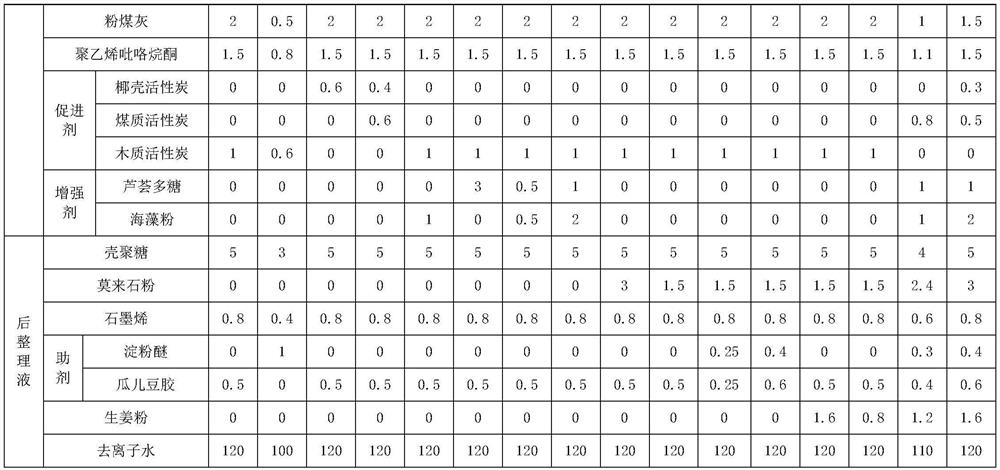

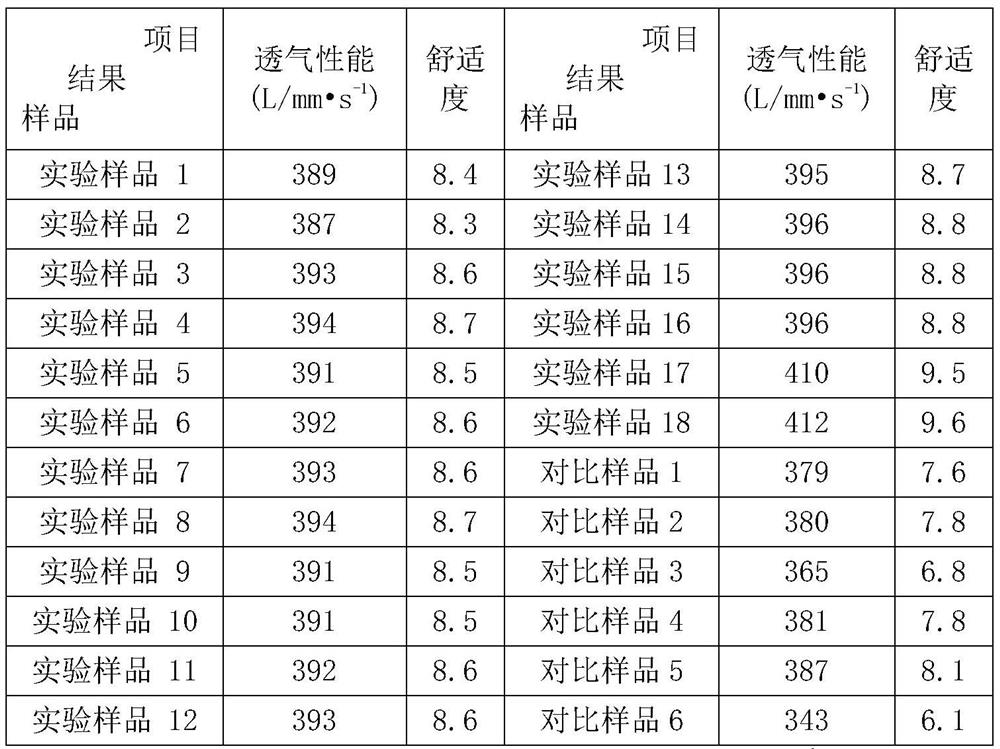

A kind of processing method of polyester filament

ActiveCN113279081BImprove breathabilityImprove adhesionBiochemical fibre treatmentFibre typesPolyesterPolymer science

Owner:杭州鑫典实业有限公司

Nanometer rare earth catalyzed ozonation method for normal temperature digestion of volatile organic matters

InactiveCN106166442AIncrease the areaPore structure highGas treatmentUsing liquid separation agentRare-earth elementCatalytic oxidation

The invention discloses a nanometer rare earth catalyzed ozonation method for normal temperature digestion of volatile organic matters. The nanometer rare earth catalyzed ozonation method comprises: (1) loading a nanometer rare earth element coating adopted as an auxiliary agent on a catalyst carrier, coating nanometer spinel adopted as the active component of the catalyst on the obtained carrier, and finally calcining the catalyst carrier loading the auxiliary agent and the active component to form a large number of micro-pores on the surface and in the internal of the catalyst carrier so as to obtain a target catalyst with pores; and (2) fixing the prepared target catalyst on the catalytic bed layer of a catalytic oxidation tower, starting an ozone generator, introducing volatile organic matters into the catalytic oxidation tower, and carrying out deep oxidation on the volatile organic matters into non-toxic and odorless substances at a room temperature of -10-40 DEG C, wherein the volatile organic matters are pre-treated and acid gas, alkali gas and other dust and particles are removed from the volatile organic matters before the volatile organic matters are introduced into the catalytic oxidation tower. According to the present invention, with the method, the VOCs can be completely oxidized at the room temperature to produce carbon dioxide and water, such that the operation is safe, and the energy consumption is low.

Owner:TIANJIN UNIV

Preparation method of artificial sandstone plate

InactiveCN110668737AImprove thermal insulationLight textureAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationCeramicwareAluminium hydroxideSodium aluminate

The invention discloses a preparation method of an artificial sandstone plate, and belongs to the technical field of preparation of building materials. The prepared artificial sandstone plate is prepared from self-made hollow raw material balls through bonding reinforcement of an organic binder and a silicon-aluminum reinforcing agent, and core-shell type organic foam particles are core-shell typeorganic foam particles with vinyl acetate resin as an inner layer, and are used for the hollow raw material balls, so that the artificial sandstone plate has good heat preservation and heat insulation performances. When carbonation decomposition of a sodium aluminate solution is carried out to prepare aluminum hydroxide, the caustic ratio of the solution is reduced, aluminum hydroxide seed crystal decomposition is inhibited, and the granularity of the aluminum hydroxide formed around is thinned to obtain high-fineness aluminum hydroxide powder, so that the contact area between the aluminum hydroxide powder and resin is increased, the interface bonding force between inorganic particles of the artificial sandstone plate and polymer resin is enhanced, and the bonding strength of organic resin in the sandstone plate is improved, thereby the sandstone plate with a low density and a high strength is obtained.

Owner:和致倍

Negative electrode material and preparation method thereof

ActiveCN110739454APore structure highSmall particle diameterNegative electrodesSecondary cellsLithiumManganese

The invention discloses a negative electrode material and a preparation method thereof. The negative electrode material comprises a three-dimensional porous framework and elemental silicon loaded on the three-dimensional porous framework; the three-dimensional porous framework is a composite framework containing metal and carbon; and the metal and the carbon in the three-dimensional porous framework both exist in an elemental form; and the metal is selected from any one or more materials from copper, iron, manganese, cobalt, tin, nickel, magnesium, titanium, aluminum and zinc. According to thenegative electrode material, the composite framework formed by the metal and carbon has excellent toughness and an ordered pore structure, and therefore, the volume effect of the silicon in the intercalation and deintercalation process of lithium ions can be buffered, the structural stability of the negative electrode material is enhanced, and the cycling stability of a negative electrode is improved; and the metal and carbon have excellent conductivity, and when the metal and carbon are compounded with the silicon, the electrochemical performance of the negative electrode material is effectively improved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com