Iron-based catalyst for preparing low-carbon alkane as well as preparation method and using method of iron-based catalyst for preparing low-carbon alkane

A technology of iron-based catalysts and low-carbon olefins, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, etc., can solve low-carbon olefins low selectivity, strength, Poor thermal stability, low conversion rate of CO, etc., to achieve the effect of improving selectivity, good thermal stability, and reducing internal diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

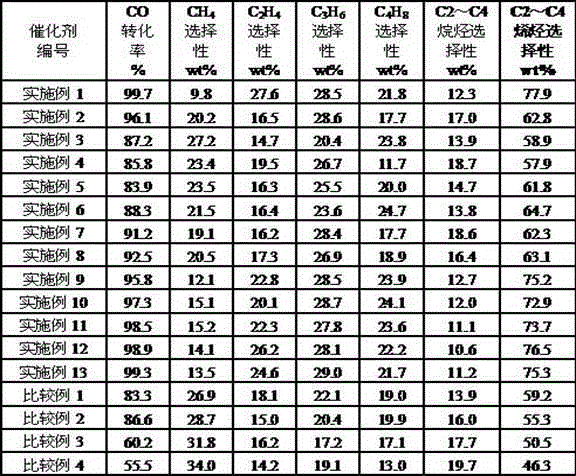

Embodiment 1

[0028] Weigh 55.0 grams of iron oxide (Fe 2 o 3 ), 5.0 grams of cobaltous oxide (CoO), 17.0 grams of molybdenum oxide (MoO 3 ), 10.0 grams of magnesium oxide (MgO), 10.0 grams of tin oxide (SnO 2 ) and 3.0 g of scandium oxide (Sc 2 o 3 ) Six kinds of raw materials and 3 grams of scallop powder with a weight percentage of 3% by weight of the total amount of raw materials were mixed in a ball mill for 2 hours; The kneaded material is kneaded until soft; the kneaded material is sent into the extruder, made into a strip with a diameter of 5mm, and cut into a column with a length of 20mm. After natural drying, it is sent to the drying equipment , dried at 120°C for 8 hours for later use; put the dried precursor into a high-temperature furnace, calcined at 1200°C for 4.0 hours, and after cooling, crush and sieve into 60-80 meshes to obtain the required synthesis gas for low-carbon production Iron-based catalysts for olefins. The prepared catalyst comprises the following compon...

Embodiment 2

[0031] Weigh 78.0 grams of iron oxide (Fe 2 o 3 ), 0.7 grams of cobaltous oxide (CoO), 6.5 grams of molybdenum oxide (MoO 3 ), 3.2 grams of magnesium oxide (MgO), 3.2 grams of tin oxide (SnO 2 ) and 8.4 g of scandium oxide (Sc 2 o 3 ) Six kinds of raw materials and 3 grams of scallop powder with a weight percentage of 3% by weight of the total amount of raw materials were mixed in a ball mill for 2 hours; The kneaded material is kneaded until soft; the kneaded material is sent into the extruder, made into a strip with a diameter of 5mm, and cut into a column with a length of 20mm. After natural drying, it is sent to the drying equipment , dried at 120°C for 8 hours for later use; send the dried precursor into a high-temperature furnace, calcined at 1000°C for 4.0 hours, and after cooling, crush and sieve into 60-80 meshes to obtain the required synthesis gas for low-carbon production Iron-based catalysts for olefins. The prepared catalyst comprises the following componen...

Embodiment 3

[0034] Weigh 30.0 grams of iron oxide (Fe 2 o 3 ), 20.0 grams of cobaltous oxide (CoO), 37.0 grams of molybdenum oxide (MoO 3 ), 4.0 grams of magnesium oxide (MgO), 4.0 grams of tin oxide (SnO 2 ) and 5.0 g of scandium oxide (Sc 2 o 3 ) Six kinds of raw materials and 3 grams of scallop powder with a weight percentage of 3% by weight of the total amount of raw materials were mixed in a ball mill for 2 hours; The kneaded material is kneaded until soft; the kneaded material is sent into the extruder, made into a strip with a diameter of 5mm, and cut into a column with a length of 20mm. After natural drying, it is sent to the drying equipment , dried at 120°C for 8 hours for later use; put the dried precursor into a high-temperature furnace, calcined at 1400°C for 4.0 hours, and after cooling, crush and sieve into 60-80 meshes to obtain the required synthesis gas to produce low-carbon Iron-based catalysts for olefins. The prepared catalyst comprises the following components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com