Preparation of nitrogen-doped biochar material and method for improving dark fermentation hydrogen production performance

A technology of biochar and nitrogen doping, applied in fermentation, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low hydrogen production efficiency, complicated process, and low nitrogen content in dark fermentation, and reduce redox The effect of potential, sufficient uptake, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

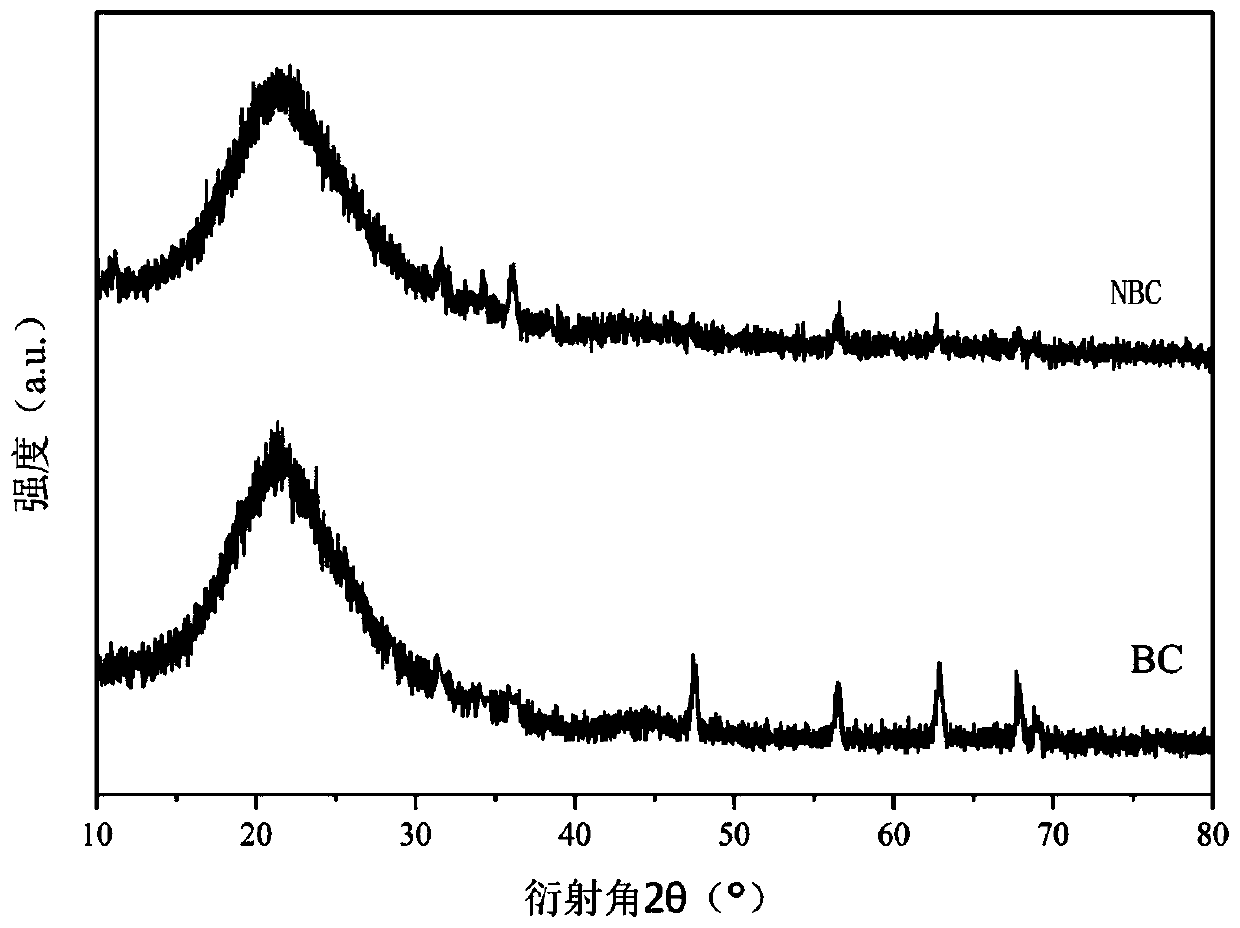

[0043] Nitrogen-doped biochar preparation:

[0044] (1) Mix 40g of corncob powder and 20g of melamine together, dissolve them in 160ml of deionized water, then cook them in a high-pressure steam sterilizer at 120°C for 2 hours, and take them out after cooling down to room temperature.

[0045] (2) Separating the turbid liquid obtained from the above steps into solid-liquid, vacuum drying at 80°C, adding 150ml of zinc chloride solution (3mol / L), soaking for 24h, drying in vacuum at 80°C for 24h, and taking out the sample.

[0046] (3) Put the sample obtained in the above steps into a tubular sintering furnace. The initial temperature of the tubular sintering furnace is 50°C, and the temperature in the furnace cavity is raised to 700°C at a rate of 10°C / min, and the holding time is 3h. After cooling to room temperature 25°C, the sample was taken out.

[0047] (4) Wash the sample obtained in the above steps with 2 mol / L hydrochloric acid, and then wash it with a certain amount o...

Embodiment 2

[0051] Nitrogen-doped biochar preparation:

[0052] (1) Mix 40g of corncob powder and 20g of melamine together, dissolve them in 160ml of deionized water, then cook them in a high-pressure steam sterilizer at 120°C for 2 hours, and take them out after cooling down to room temperature.

[0053] (2) The turbid liquid obtained in the above steps was subjected to solid-liquid separation, and after vacuum drying at 80°C, 150ml of zinc chloride solution (3mol / L) was added, soaked for 24h, dried under vacuum at 80°C for 24h, and the sample was taken out.

[0054] (3) Put the sample obtained in the above steps into a tubular sintering furnace. The initial temperature of the tubular sintering furnace is 50°C, and the temperature in the furnace cavity is raised to 800°C at a rate of 10°C / min, and the holding time is 3h. The samples were taken out after cooling to room temperature.

[0055] (4) Wash the sample obtained in the above steps with 2mol / L hydrochloric acid, and then wash it w...

Embodiment 3

[0058] Nitrogen doped carbon preparation:

[0059] (1) Mix 40g of corncob powder and 20g of melamine together, dissolve in 160ml of deionized water, then cook in a high-pressure steam sterilizer at 120°C for 2 hours, and take it out after cooling down to room temperature.

[0060] (2) The turbid liquid obtained in the above steps was subjected to solid-liquid separation, and after vacuum drying at 80°C, 150ml of zinc chloride solution (3mol / L) was added, soaked for 24h, dried under vacuum at 80°C for 24h, and the sample was taken out.

[0061] (3) Put the sample obtained in the above steps into a tubular sintering furnace. The initial temperature of the tubular sintering furnace is 50°C, and the temperature in the furnace cavity is raised to 800°C at a rate of 10°C / min, and the holding time is 2h. The samples were taken out after cooling to room temperature.

[0062] (4) Wash the sample obtained in the above steps with 2mol / L hydrochloric acid, and then wash it with a certain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com