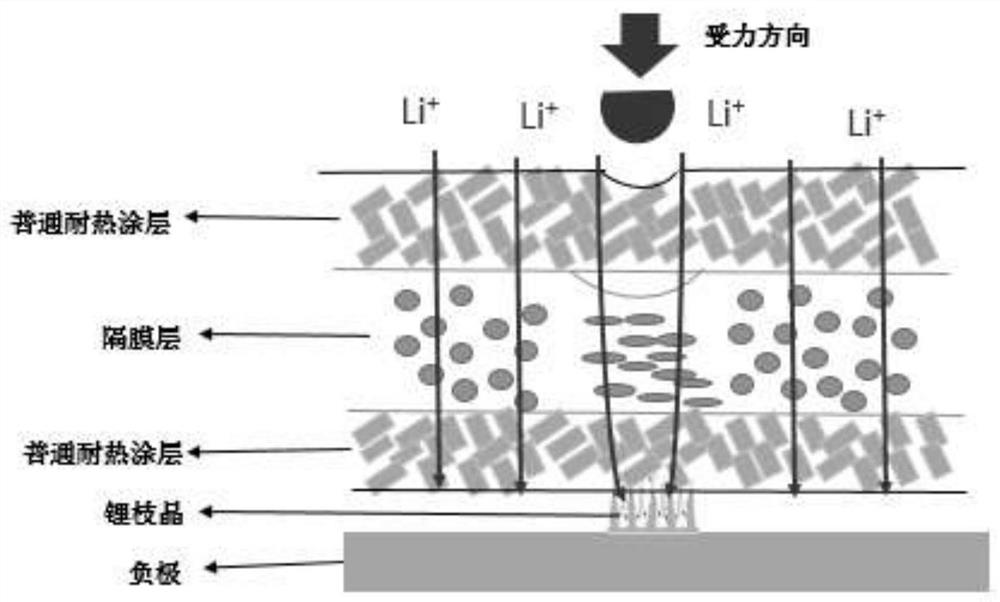

Diaphragm coating slurry capable of improving safety performance of lithium ion battery and preparation method of diaphragm coating slurry

A lithium-ion battery, safety performance technology, applied in the direction of secondary batteries, battery pack components, secondary battery repair/maintenance, etc., can solve the problems of large thickness and area density, inability to be widely used, poor heat resistance, etc., to achieve The effect of small amount of raw materials, improved processing efficiency and quality, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

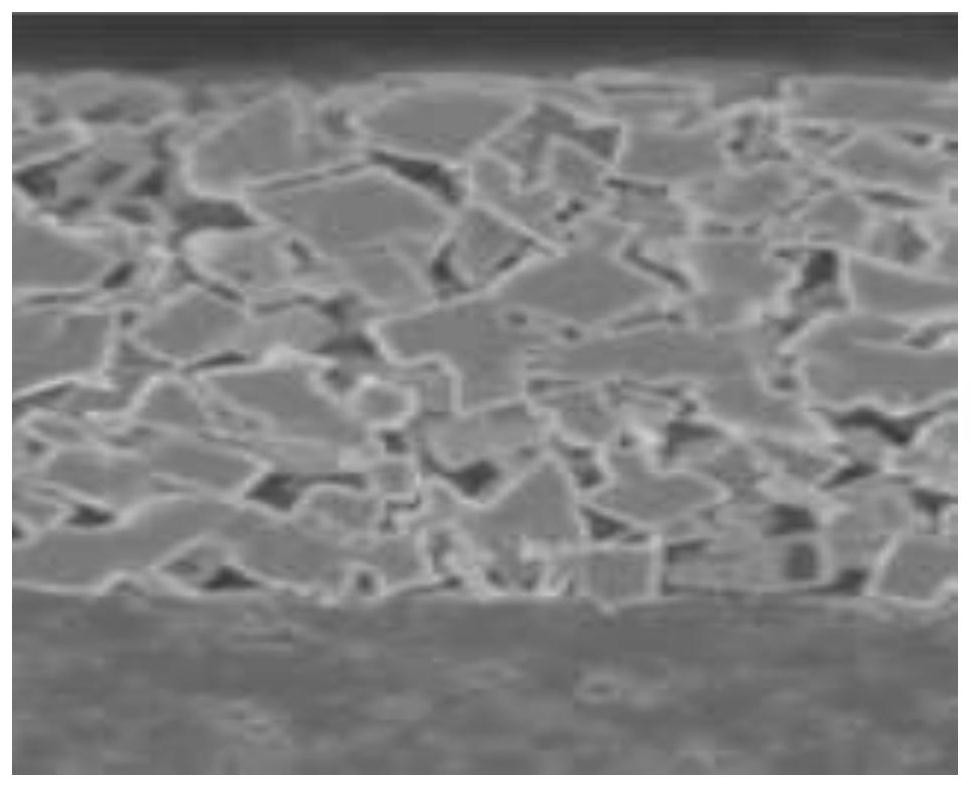

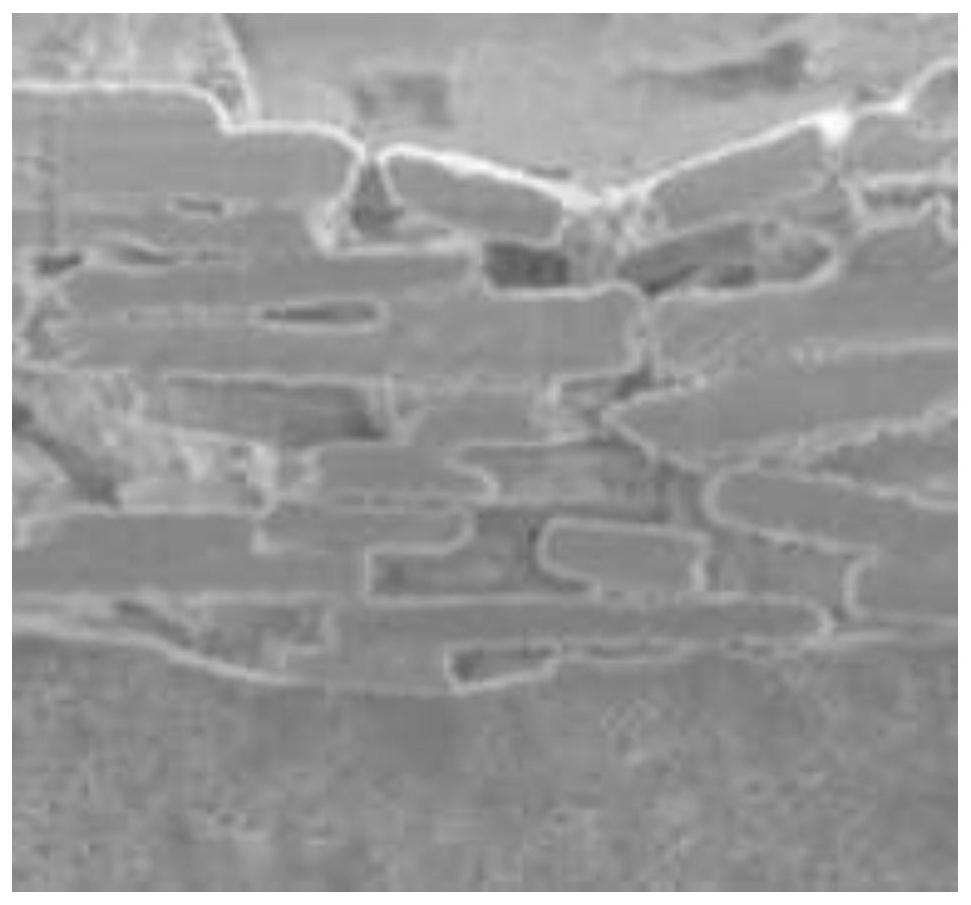

[0027] A diaphragm coating slurry capable of improving the safety performance of lithium-ion batteries, comprising the following raw materials in parts by weight: 20 parts of inorganic insulators, 0.5 parts of ammonium polyacrylate, 3 parts of binders, polyether modified silicone surfactants 0.5 parts, 76 parts of water;

[0028] Among them, the inorganic insulator is flaky aluminum oxide powder with a particle size D50 of 5-8 μm and a thickness of 0.5-1.0 μm; the binder is a modified water-based acrylic resin with a glass transition temperature of 150° C.

[0029] Preparation of Separator Coating Slurry for Improved Safety Performance of Li-ion Batteries:

[0030] S1. After mixing inorganic insulator, ammonium polyacrylate and water, ultrasonically disperse, the dispersing power is 2000W, the dispersing temperature is 25℃, and the dispersing time is 1.5h;

[0031] S2. Add the binder and polyether-modified silicone surfactant into the dispersion liquid for ultrasonic dispersi...

Embodiment 2

[0034] A separator coating slurry capable of improving the safety performance of lithium-ion batteries, comprising the following raw materials in parts by weight: 35 parts of inorganic insulators, 2 parts of polyvinylpyrrolidone, 5 parts of binders, 1 part of anionic fluorocarbon surfactants, 57 parts of water;

[0035] Among them, the inorganic insulator is flaky aluminum oxide powder with a particle size D50 of 5-8 μm and a thickness of 0.5-1.0 μm; the binder is a modified water-based acrylic resin with a glass transition temperature of 140° C.

[0036] Preparation of Separator Coating Slurry for Improved Safety Performance of Li-ion Batteries:

[0037] S1. Mix the inorganic insulator, polyvinylpyrrolidone and water and then ultrasonically disperse. The dispersing power is 2500W, the dispersing temperature is 30℃, and the dispersing time is 1h;

[0038] S2. Add the binder and anionic fluorocarbon surfactant into the dispersion liquid for ultrasonic dispersion, the dispersio...

Embodiment 3

[0041] A separator coating slurry capable of improving the safety performance of lithium-ion batteries, comprising the following raw materials in parts by weight: 30 parts of inorganic insulators, 0.2 parts of polyvinyl alcohol, 4 parts of binders, 0.1 parts of anionic fluorocarbon surfactants, 50 parts of water;

[0042] Among them, the inorganic insulator is flaky aluminum oxide powder with a particle size D50 of 5-8 μm and a thickness of 0.5-1.0 μm; the binder is a modified water-based acrylic resin with a glass transition temperature of 160° C.

[0043] Preparation of Separator Coating Slurry for Improved Safety Performance of Li-ion Batteries:

[0044] S1. After mixing inorganic insulator, polyvinyl alcohol and water, ultrasonically disperse, the dispersion power is 3000W, the dispersion temperature is 28°C, and the dispersion time is 3h;

[0045] S2. Add binder and anionic fluorocarbon surfactant to the dispersion liquid for ultrasonic dispersion, the dispersion tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Single side thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com