Method for synthesizing MOF oxygen evolution reaction catalyst by using deep eutectic solvothermal method

A technology of deep eutectic solvent and oxygen evolution reaction, which is applied in the direction of electrolysis components, electrodes, electrolysis process, etc., to reduce the difficulty of reaction, improve reaction efficiency, and reduce the effect of reaction vapor pressure and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

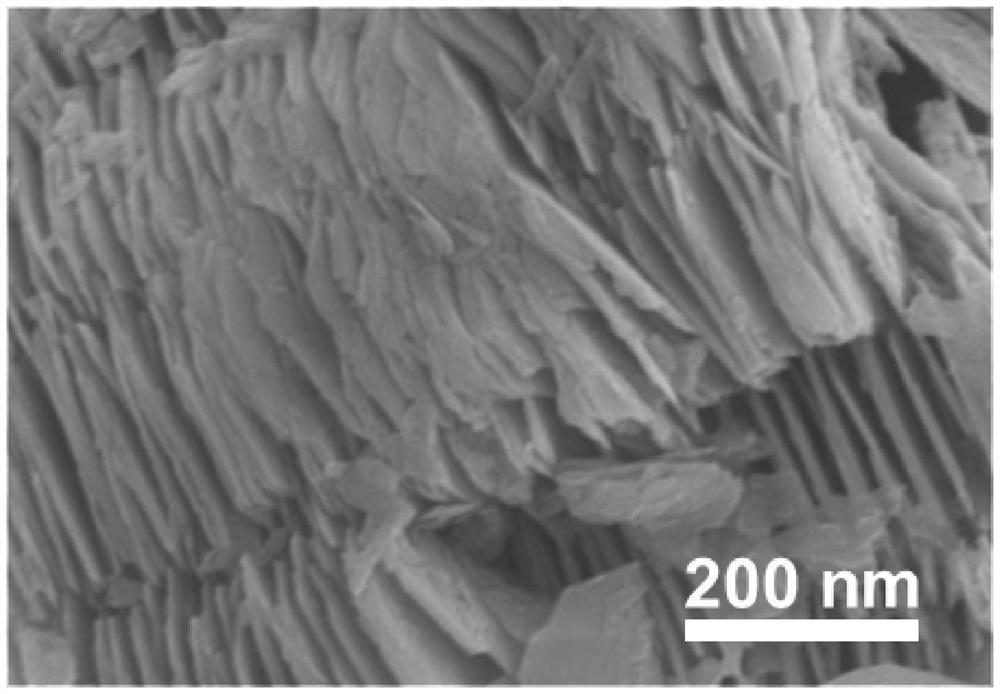

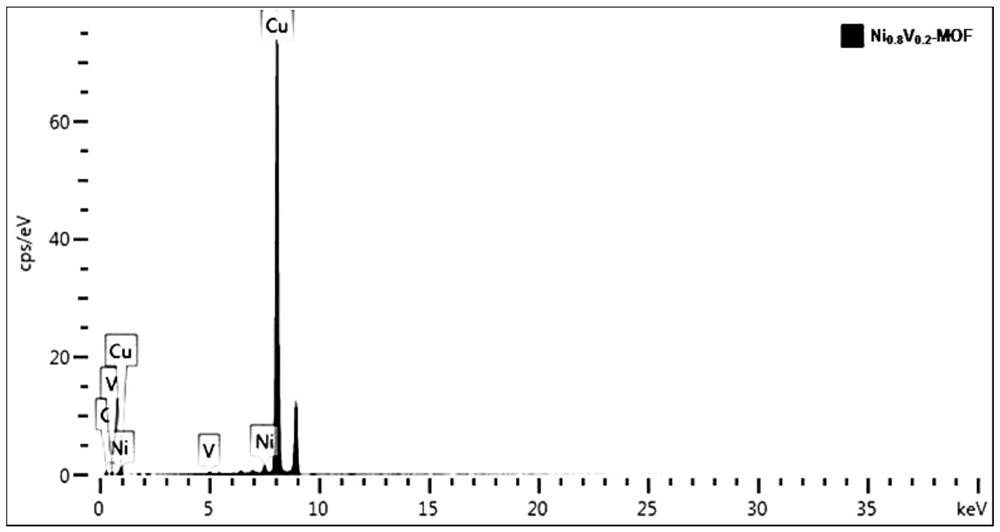

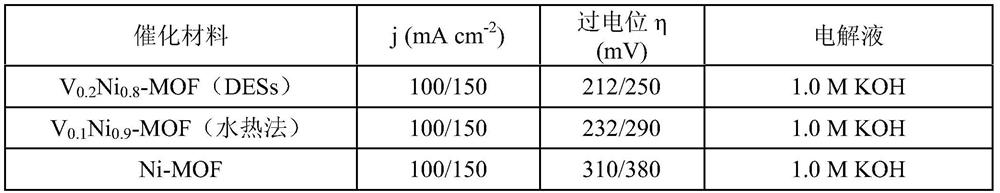

Image

Examples

Embodiment 1

[0035] (1) Add 120.2 g (2.0 mol) of ethylene glycol and 558.5 g (4.0 mol) of choline chloride into a beaker, mix and heat to 80 ° C, and make it melt into a clear transparent liquid to form a deep eutectic solvent;

[0036] (2) Add 0.5 g of nickel nitrate hexahydrate, 10.0 g of ammonium metavanadate and 8.0 g of phthalic acid to the deep eutectic solvent, and obtain the precursor after ultrasonic mixing;

[0037] (3) According to the method of step (1), configure the eutectic solution in addition, under the heating situation, add nickel nitrate hexahydrate 0.5g, ammonium metavanadate 10.0g, ammonium fluoride 0.8g and urea 10.0g in the eutectic solution g, ultrasonic dissolution; then put it into the reaction kettle, add nickel foam, so that the solution just soaks the nickel foam;

[0038] (4) Seal the reaction kettle, put it in a 150°C oven and heat it for 8 hours, take it out of the oven after the reaction is over, and let it cool naturally for 12 hours; take out the cooled ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com