A kind of mordenite with diatomite morphology and its preparation method

A pore structure, mordenite technology, applied in the direction of mordenite crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of slow diffusion of adsorbate, high cost, insignificant adsorption speed, etc., and achieve potential environmental hazards. The effect of low cost and energy consumption, efficient adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Add 1g of Jilin diatomaceous earth (the main diatom species of which is diatoms) to 5mL of furfuryl alcohol; heat to 95°C after thorough stirring and keep for 2 hours; place the obtained product under nitrogen atmosphere, The temperature was raised to 550° C., calcined for 2 hours, cooled and ground to obtain a ground solid.

[0027] 2. Add 1 g of the ground solid obtained above into 20 mL of 0.15 mol / L sodium hydroxide aqueous solution. After thorough stirring, the temperature was raised to 50°C and kept for 4 hours, then the obtained mixed solution was placed in a hydrothermal device, and the temperature was raised to 190°C and kept for 16 hours to obtain a suspension.

[0028] 3. Centrifuge the above suspension, and heat the obtained solid particles to 450° C. under air condition for 3 hours to obtain the hierarchical pore structure mordenite with diatomite morphology of this embodiment.

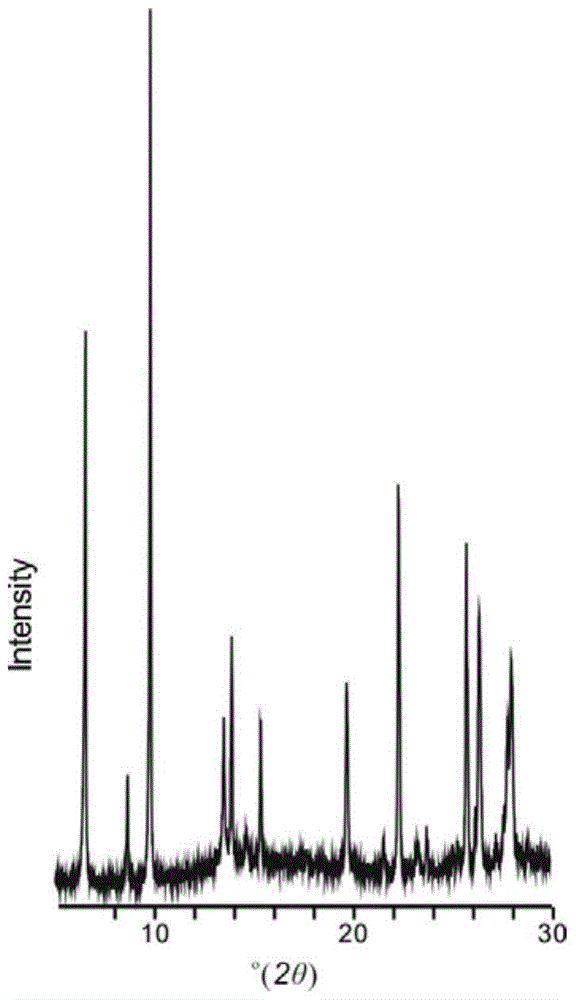

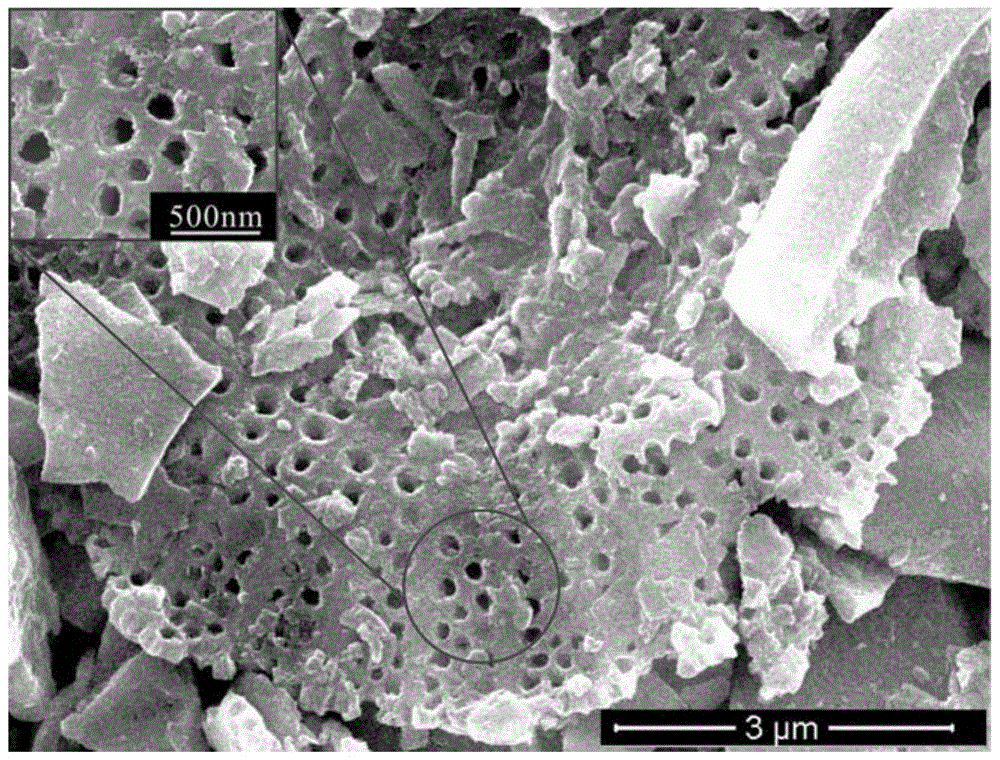

[0029] The above-mentioned hierarchical pore structure mordenite with diat...

Embodiment 2

[0032] Add 1g of Jilin diatomaceous earth (the main diatom species of which is diatoms) to 10mL of furfuryl alcohol; heat to 180°C after thorough stirring and keep for 1 hour; place the obtained product under an argon atmosphere and heat up Calcined at 700° C. for 4 hours, cooled and ground the obtained solid to obtain the ground solid. Add 1 g of the ground solid to 10 mL of 0.30 mol / L sodium hydroxide aqueous solution. After thorough stirring, the temperature was raised to 90°C and kept for 6 hours, then the obtained mixed solution was placed in a hydrothermal device, and the temperature was raised to 150°C and kept for 24 hours to obtain a suspension. The obtained suspension was subjected to centrifugation, and the obtained solid particles were heated to 600° C. under air condition and kept for 5 hours to obtain the hierarchical pore structure mordenite with diatomaceous earth morphology of this embodiment.

[0033] As an implementation application, the ability of this hie...

Embodiment 3

[0035]Add 1g of Jilin diatomaceous earth (the main diatom species of which is diatoms) to 8mL furfuryl alcohol; heat to 150°C after thorough stirring and keep for 1.5 hours; place the obtained product under a helium atmosphere and heat up Calcined at 600° C. for 3 hours, cooled and ground the obtained solid to obtain the ground solid. Add 1 g of the ground solid to 15 mL of 0.20 mol / L sodium hydroxide aqueous solution. After thorough stirring, the temperature was raised to 90°C and kept for 6 hours, then the obtained mixed solution was placed in a hydrothermal device, and the temperature was raised to 170°C and kept for 20 hours to obtain a suspension. The obtained suspension was subjected to centrifugation, and the obtained solid particles were heated to 500° C. under air condition and kept for 4 hours, so that the hierarchical pore structure mordenite with diatomite morphology of this embodiment was obtained.

[0036] As an implementation application, the ability to adsorb ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com